Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

A rare earth and steel technology, applied in the field of alloy steel, can solve the problems of secondary oxidation and burning, achieve the effects of refining grains, reducing dislocation density, and improving shape and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Glossary explanation: degree of superheat, the temperature difference between the molten steel temperature and its melting point.

[0046] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention. The percentages not specified in the present invention are all percentages by weight.

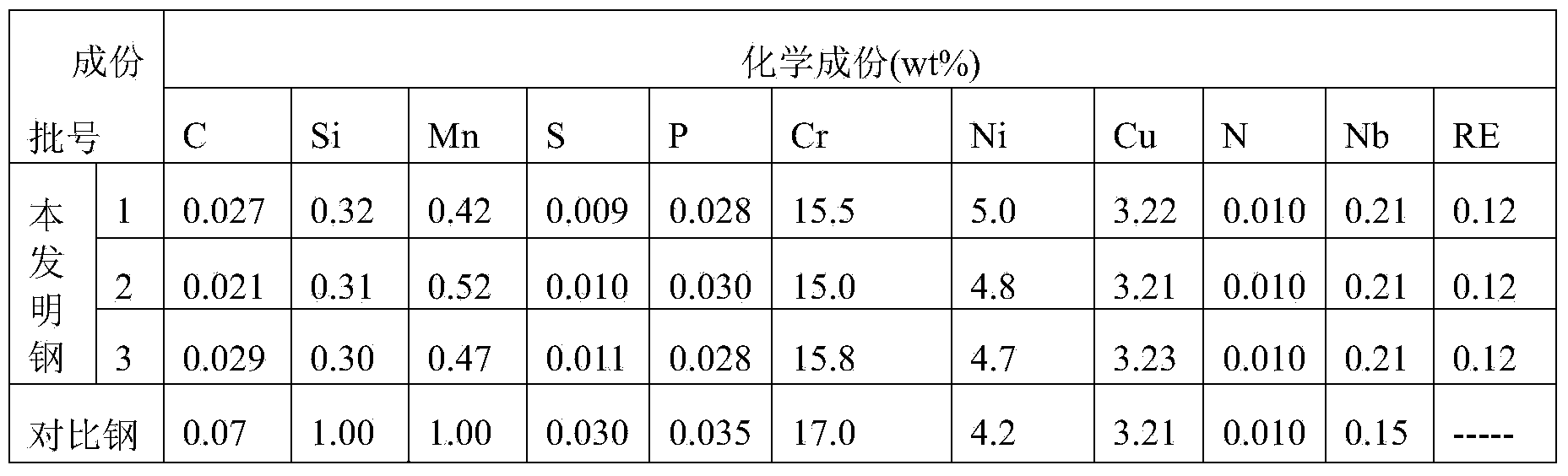

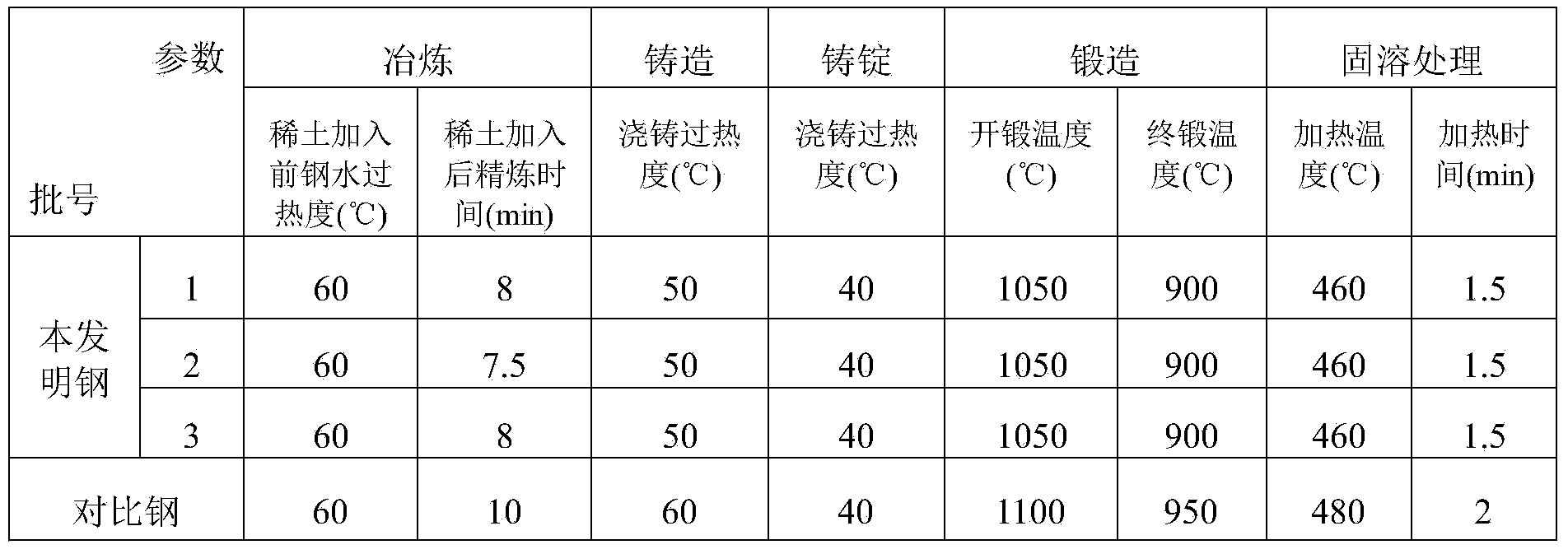

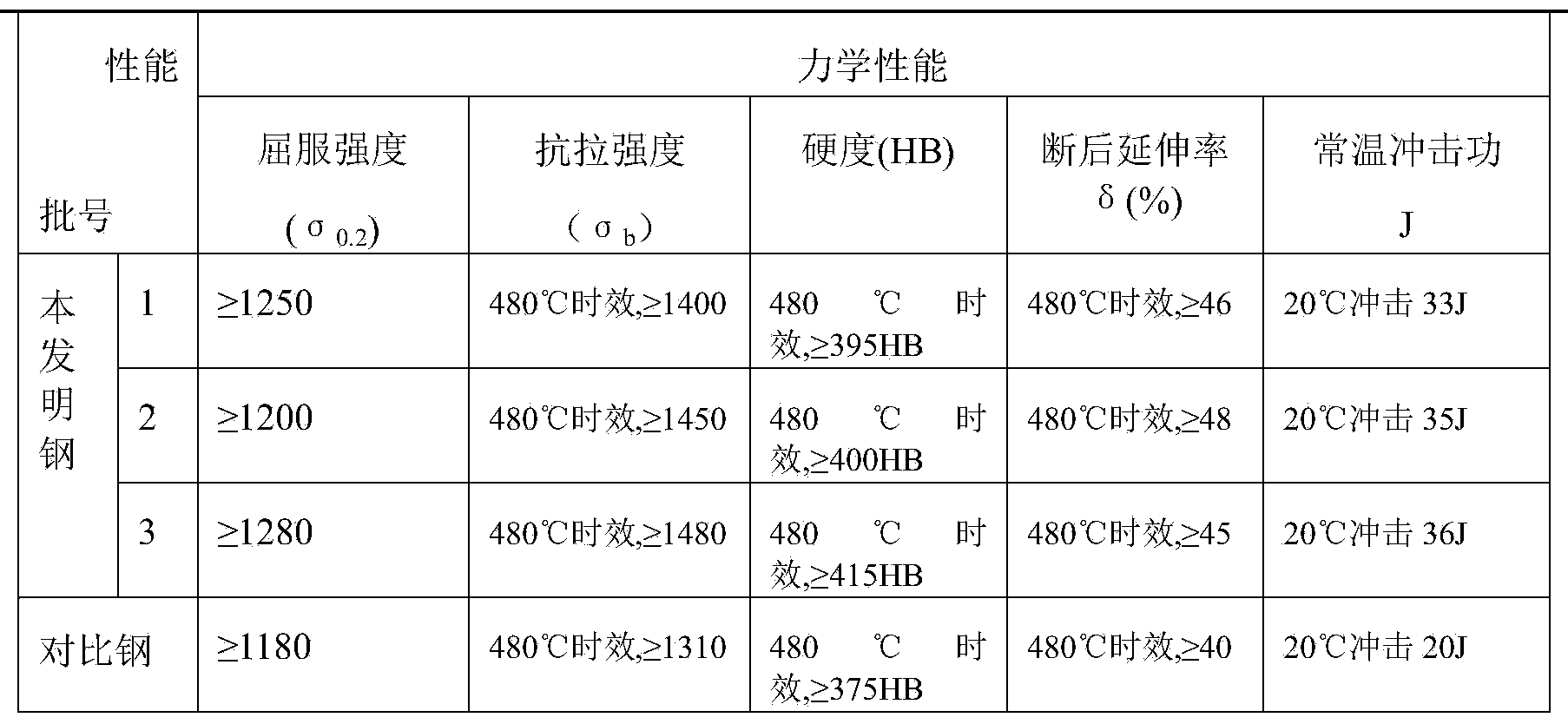

[0047] According to the chemical composition of a kind of rare earth type 0Cr17Ni4Cu4Nb martensitic precipitation hardening stainless steel according to the present invention, 3 furnaces of the steel of the present invention were smelted on a non-vacuum induction furnace, and the chemical composition (wt%) of the 3 furnaces of steel is as shown in Table 1 . Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com