Vanadium-titanium-containing ductile cast iron material and thermal treatment process

A technology of nodular iron, vanadium and titanium, applied in the field of casting processing, to achieve the effect of reducing the austenitization temperature, eliminating potential safety hazards, and uniform as-cast structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

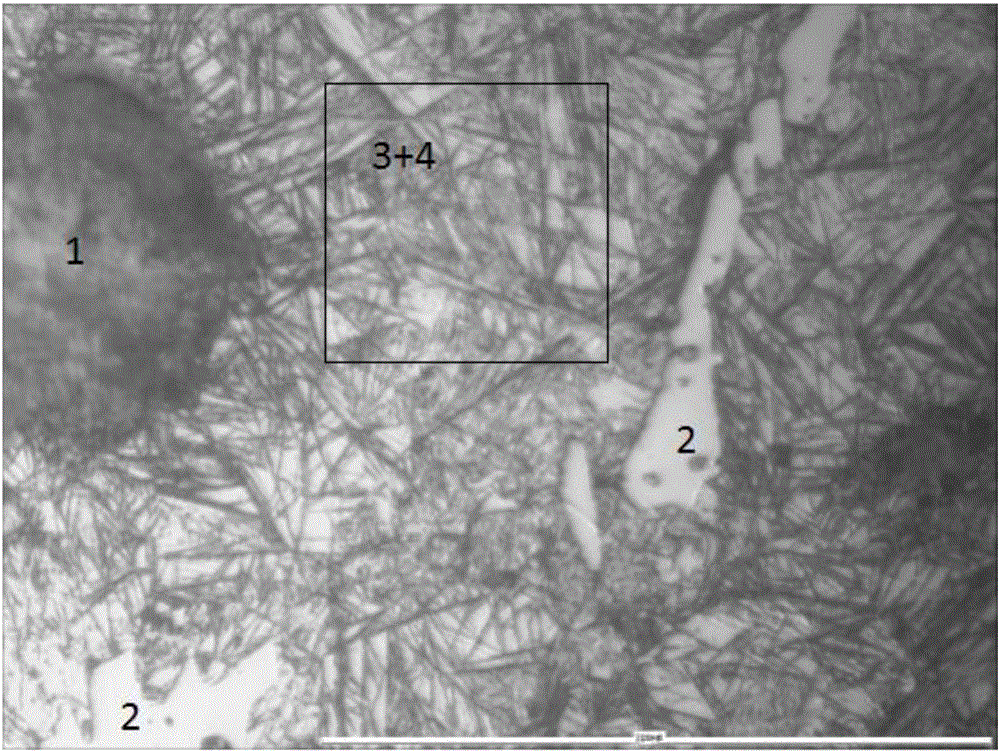

Image

Examples

Embodiment 1

[0035] A vanadium-containing titanium ductile iron material, by mass percentage, includes the following components: C3.20%, Si2.30%, Mn0.96%, Cr0.20%, Cu0.60%, Mo0.80%, V0 .54%, Ti0.3%, Nb0.01%, Mg0.03%, rare earth element 0.02%, and the rest is Fe.

[0036] The production state of the vanadium-containing titanium ductile iron material is a process of quenching and low-temperature tempering, which includes the following steps:

[0037] 1) According to the above ratio, castings are made by smelting molten iron, spheroidizing, and casting;

[0038] 2) Austenitize the casting for heat preservation, the specific operation is: heat the casting obtained in step 1) at a temperature of 830°C, and the heat preservation time is calculated as D×2min / mm, where D is the maximum thickness of the casting, and the unit is mm;

[0039] 3) cooling the austenitized and heat-preserved casting in step 2) in a quenching medium, the quenching medium is an aqueous NaCl solution with a mass concentr...

Embodiment 2

[0042] A vanadium-containing titanium ductile iron material, by mass percentage, includes the following components:

[0043] C3.90%, Si2.93%, Mn2.80%, Cr0.90%, Cu0.90%, Mo1.20%, V0.68%, Ti0.78%, Nb0.09%, P0.045%, S0.028%, Mg0.05%, rare earth element 0.03%, and the rest is Fe.

[0044] The process is as follows:

[0045] 1) According to the above ratio, the casting is made by melting molten iron, spheroidizing, and casting.

[0046]2) Austenitize the casting for heat preservation, the specific operation is: heat the casting obtained in step 1) at a temperature of 880°C, and the heat preservation time is calculated as D×2min / mm, where D is the maximum thickness of the casting, and the unit is mm.

[0047] 3) cooling the casting of step 2) austenitized heat preservation in a quenching medium, the quenching medium is an aqueous NaCl solution with a mass concentration of 10%, and the cooling time is calculated by D×sec / 3mm, wherein D is the maximum Thickness dimension, the unit...

Embodiment 3

[0050] A vanadium-containing titanium ductile iron material, by mass percentage, includes the following components:

[0051] C3.60%, Si2.5%, Mn1.56%, Cr0.50%, Cu0.70%, Mo1.00%, V0.60%, Ti0.50%, Nb0.05%, P0.02%, S0.01%, Mg0.04%, rare earth element 0.025%, and the rest is Fe.

[0052] The process is as follows:

[0053] 1) According to the above ratio, castings are made by smelting molten iron, spheroidizing, and casting;

[0054] 2) Austenitize the casting for heat preservation, the specific operation is: heat the casting obtained in step 1) at a temperature of 850°C, and the heat preservation time is calculated as D×2min / mm, where D is the maximum thickness of the casting, and the unit is mm;

[0055] 3) Cool the castings austenitized and kept in step 2) in a quenching medium, the quenching medium is an aqueous NaCl solution with a mass concentration of 12%, and the cooling time is calculated by D×sec / 3mm, where D is the maximum Thickness dimension, the unit is mm; sec is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com