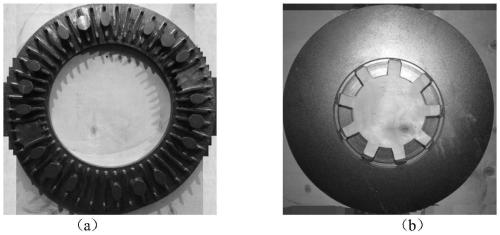

A Casting Process of Rare Earth Alloy Brake Disc Castings for High Speed Railway Passenger Cars

A rare earth alloy, high-speed railway technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of brake disc fatigue damage, etc., to achieve the effect of fine inclusions, uniform structure, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In this embodiment, trial production of high-speed railway passenger car brake disc castings, the material rare earth low alloy steel 30CrMoRE, its specific composition is as follows: C 0.25wt%, Si 0.48wt%, Mn 1.03wt%, Cr 0.87wt%, Ni 1.26wt% , Mo0.51wt%, V 0.04wt%, Nb 0.08wt%, RE 0.05wt%, O 10ppm, N 30ppm, P 0.005wt%, S0.004wt%, the balance is Fe. The weight of the casting rough is respectively: 110kg for the wheel, 143kg for the shaft, 15s for the filling time, and 1560-1570℃ for the pouring temperature.

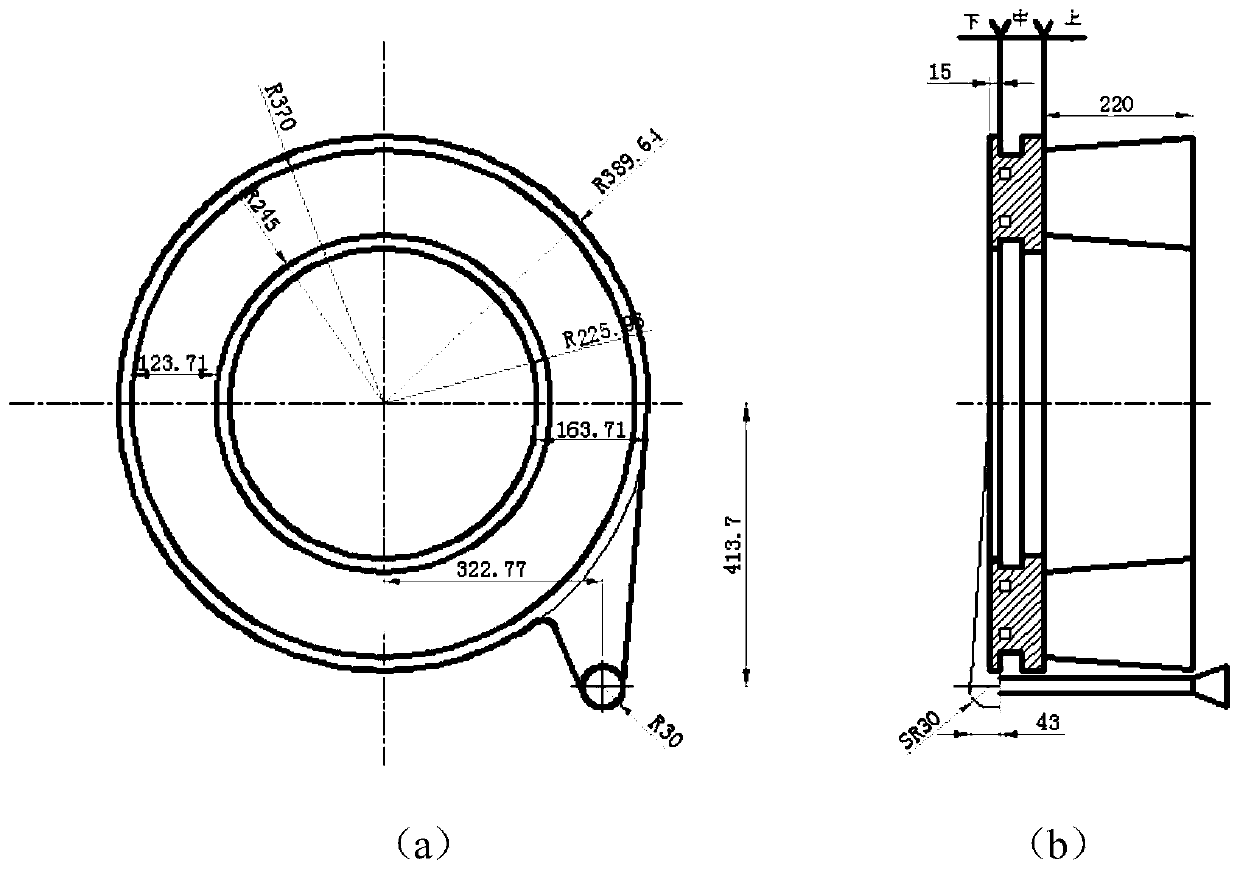

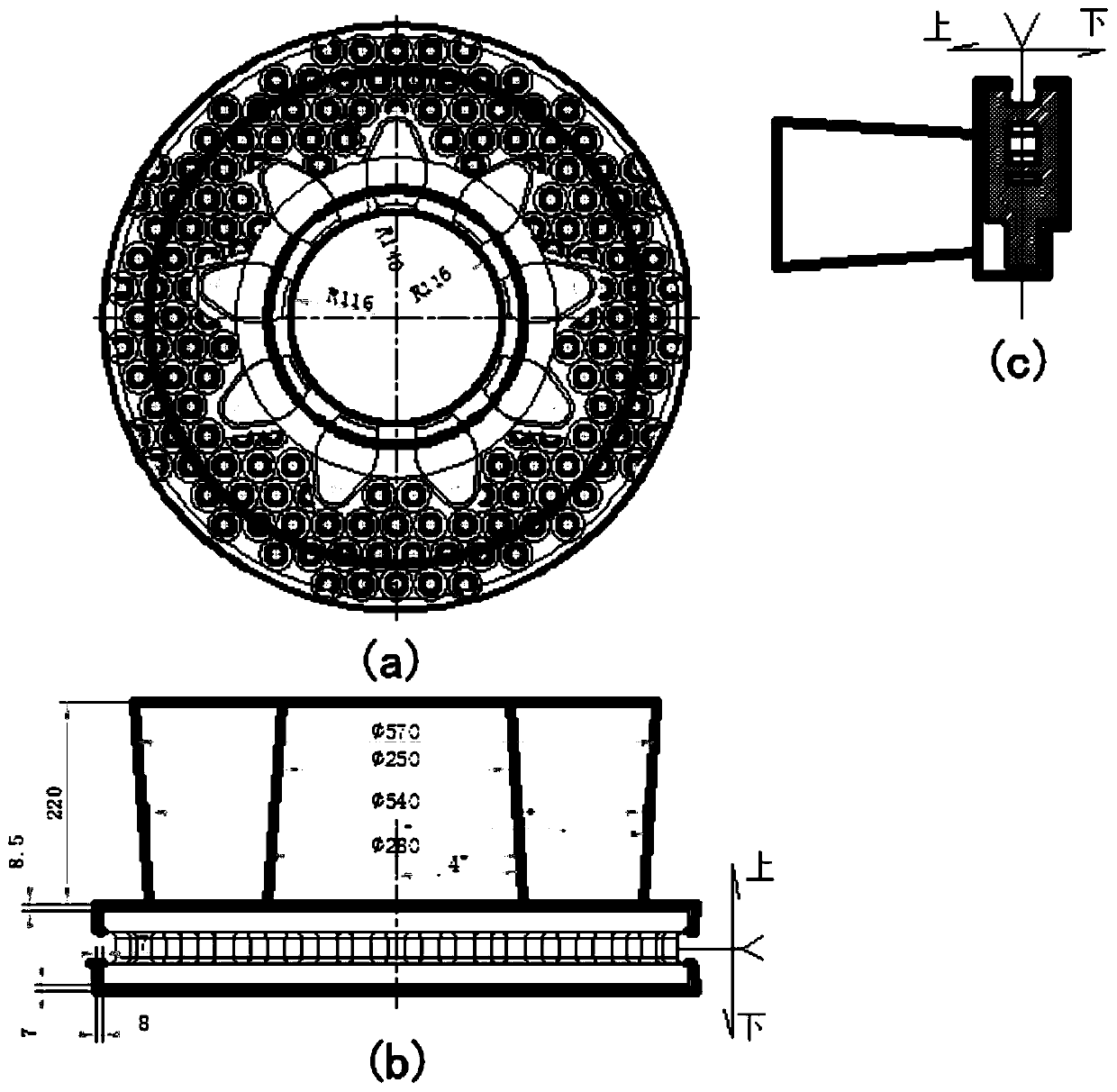

[0036] Such as Figure 1-Figure 3Shown, the railway passenger car bogie brake disk smelting process scheme of the present invention is as follows:

[0037] 1) Strictly control the ingredients, start with the ingredients, use high-quality scrap steel, metal chromium, low-phosphorus ferromanganese and ferromolybdenum for ingredients, and prepare according to the total amount of molten steel 15 tons. Electric arc furnace smelting, strict control of phosphorus content,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com