Manufacturing method of 2.8 MW wind power hub

A manufacturing method and hub technology, applied in the field of metallurgy, can solve problems such as loose structure and graphite distortion of thick and large cross-section wind power hubs, and achieve the effects of low cost, balanced casting structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

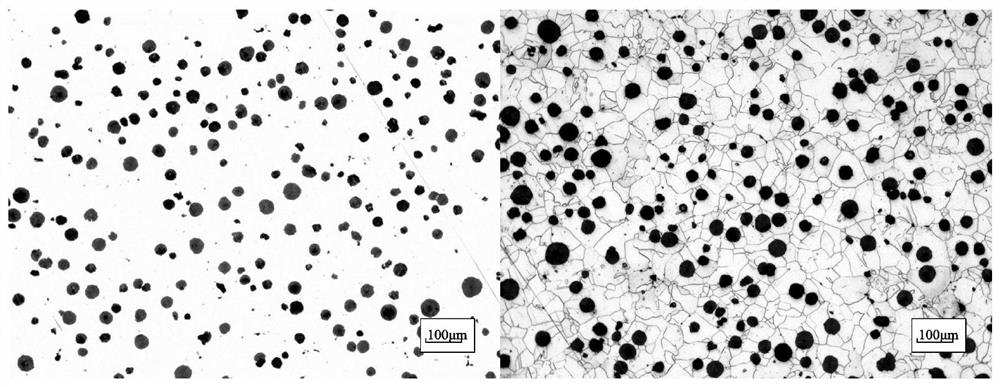

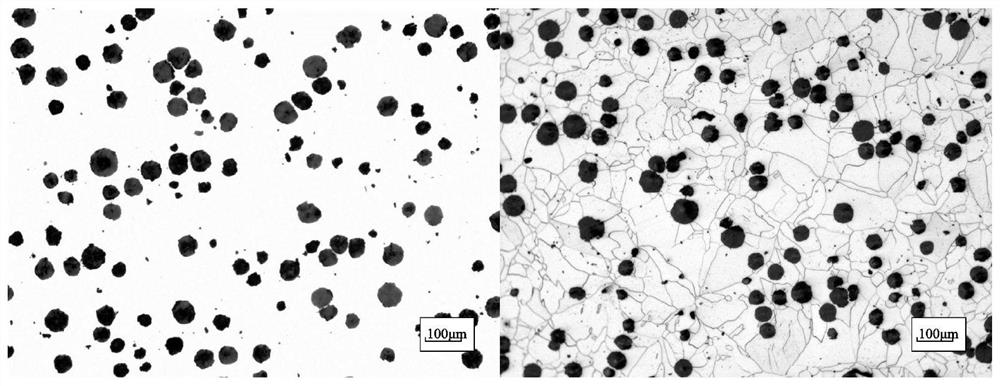

Image

Examples

specific Embodiment 1

[0019] A method for manufacturing a 2.8MW wind power hub, comprising the steps of:

[0020] Step (1), shaking and tamping when putting the sand, the actual measurement of the sand mold tensile strength after the resin sand solidifies is 1.3MPa;

[0021] Step (1), place the cold iron on the boss of the casting, the thickness of the boss is 60-90mm, the actual thickness of the cold iron is 60mm, the straight gate is φ80, and the actual air outlet is 6 φ50 air outlets;

[0022] Step (3), using high-purity pig iron and scrap steel, controlling the sum of trace impurity elements to be less than 0.15%;

[0023] Step (4), spheroidizing inoculation: add 0.90% spheroidizing agent and 0.35% covering inoculant in turn to the spheroidizing bag, add 35ppm Sb during spheroidizing; stand still for 6 minutes after spheroidizing and then slag. After spheroidizing, C in molten iron: 3.72%, Si: 2.09%, Mn: 0.15%, P: 0.020%, S: 0.008%, Mg: 0.037%;

[0024] Step (5), control the pouring temperatu...

specific Embodiment 2

[0026] A method for manufacturing a 2.8MW wind power hub, comprising the steps of:

[0027] Step (1), shaking and tamping when putting the sand, the actual measurement of the sand mold tensile strength after the resin sand solidifies is 1.2MPa;

[0028] Step (1), place the cold iron on the boss of the casting, the thickness of the boss is 60-80mm, the actual thickness of the cold iron is 60mm, the sprue uses a φ80 straight gate, and the actual air outlet places 5 φ50 air outlets;

[0029] Step (3), using high-purity pig iron and scrap steel, controlling the sum of trace impurity elements to be less than 0.15%;

[0030] Step (4), spheroidizing inoculation: add 0.85% spheroidizing agent and 0.45% covering inoculant in turn to the spheroidizing bag, add 40ppm Sb during spheroidizing; stand still for 8 minutes after spheroidizing and then slag. After spheroidizing treatment, C in molten iron: 3.69%, Si: 2.10%, Mn: 0.13%, P: 0.021%, S: 0.009%, Mg: 0.039%;

[0031] Step (5), contr...

specific Embodiment 3

[0033] A method for manufacturing a 2.8MW wind power hub, comprising the steps of:

[0034] Step (1), shaking and tamping when putting the sand, the actual measurement of the sand mold tensile strength after the resin sand solidifies is 1.4MPa;

[0035] Step (1), place the cold iron on the boss of the casting, the thickness of the boss is 60-80mm, the actual thickness of the cold iron is 60mm, the sprue uses a φ80 straight gate, and the actual air outlet places 5 φ50 air outlets;

[0036] Step (3), using high-purity pig iron and scrap steel, controlling the sum of trace impurity elements to be less than 0.15%;

[0037] Step (4), spheroidizing inoculation: add 0.90% spheroidizing agent and 0.40% covering inoculant in turn to the spheroidizing bag, add 45ppm Sb during spheroidizing; stand still for 8 minutes after spheroidizing and then slag. After spheroidizing, C: 3.75%, Si: 2.05%, Mn: 0.14%, P: 0.022%, S: 0.010%, Mg: 0.040%;

[0038] Step (5), control the pouring temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com