Vertical type centrifugal casting device of thin-wall alloy steel

A centrifugal casting machine and alloy steel technology, applied in the field of casting devices for thin-walled alloy steel castings, can solve the problems of difficulty in meeting casting production requirements, high consumption of materials and power, high production costs, etc., and achieve novel structure, Simple structure and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

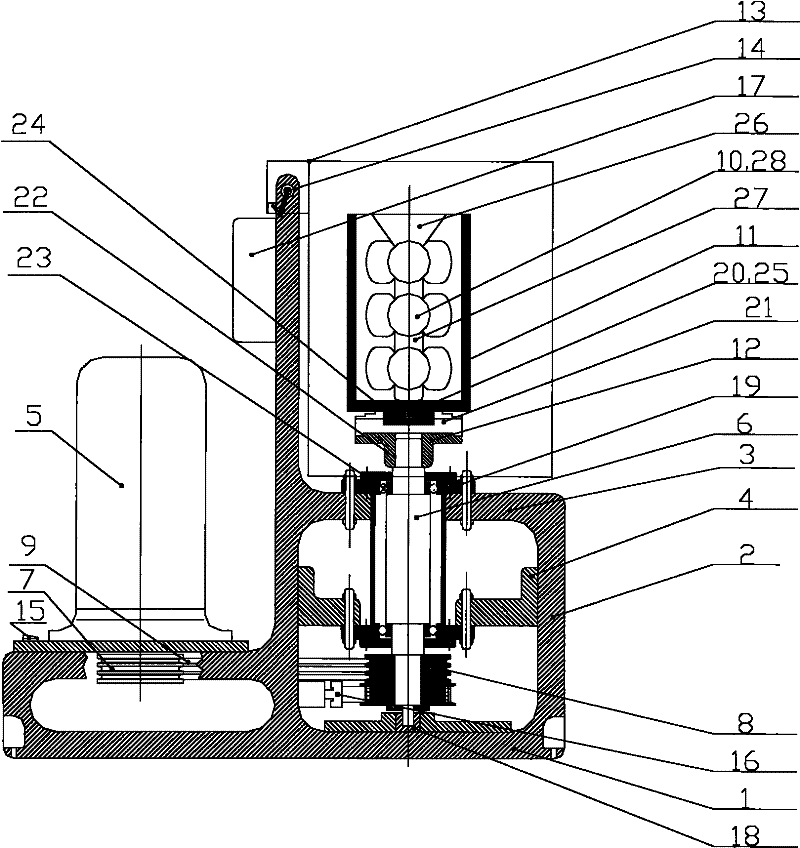

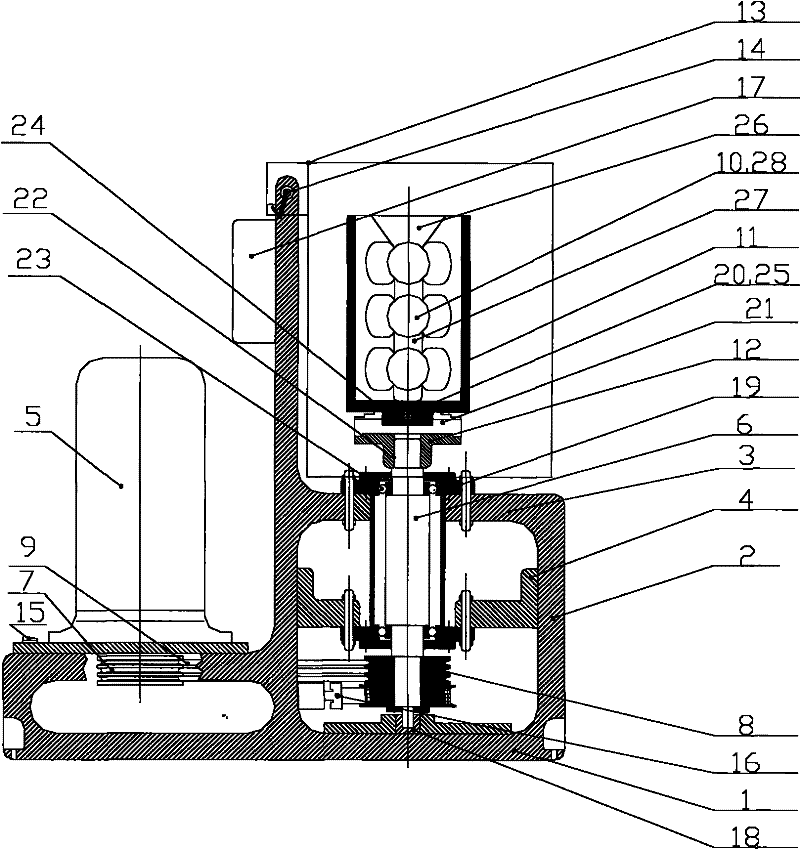

[0013] From figure 1 It can be seen from the figure that the vertical thin-wall alloy steel centrifugal casting machine is composed of a frame, a motor 5, a main shaft 6, a chuck 12, movable jaws 21, a drum 11, and a mold 10. The frame is composed of a machine base 1, a column 2, a worktable 3 and a fixed plate 4 connected. Motor 5 axially is fixedly installed on the left side of support 1, and belt pulley 7 is established on the motor shaft, and pedal 15 is also established on support 1 to be connected with electromagnetic brake 16 for braking. The right side of the frame is provided with a worktable 3, an enclosure 13 is arranged above the worktable 3, a fixed plate 4 is arranged between the worktable 3 and the machine base 1, and a passageway for the series-mounted main shaft 6 is provided with the worktable 3 and the fixed plate 4. Hole, machine base 1 establishes groove 18, and the center of three is on the same straight line, through hole establishes bearing seat 19, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com