A manufacturing method of shaft products with thick and large section qt500-14

A technology for product manufacturing and large cross-section, applied in the field of metallurgy, can solve the problems of large differences in the structure of castings, limited effect of cold iron, complicated operation steps, etc., and achieve the effects of small differences, simple operation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

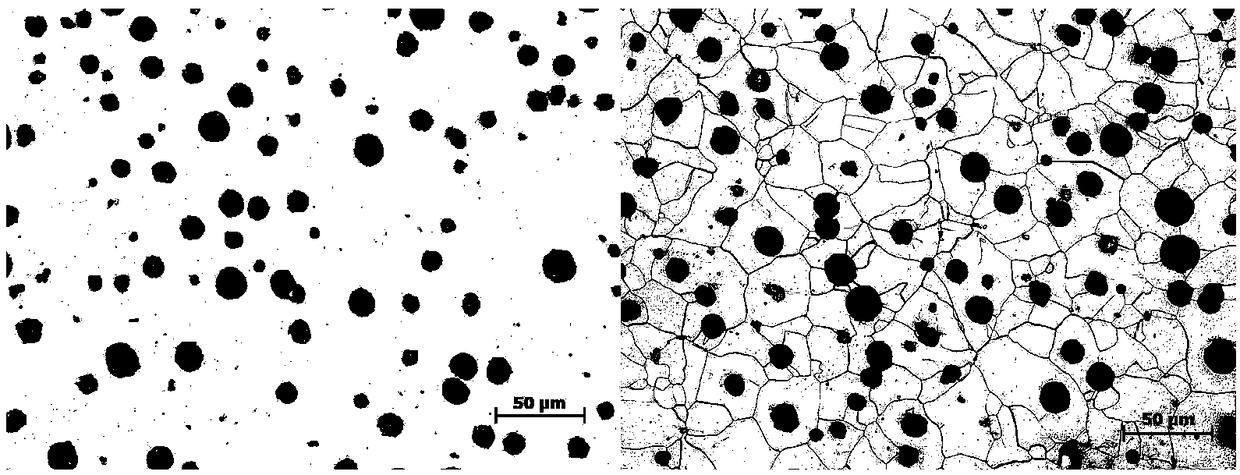

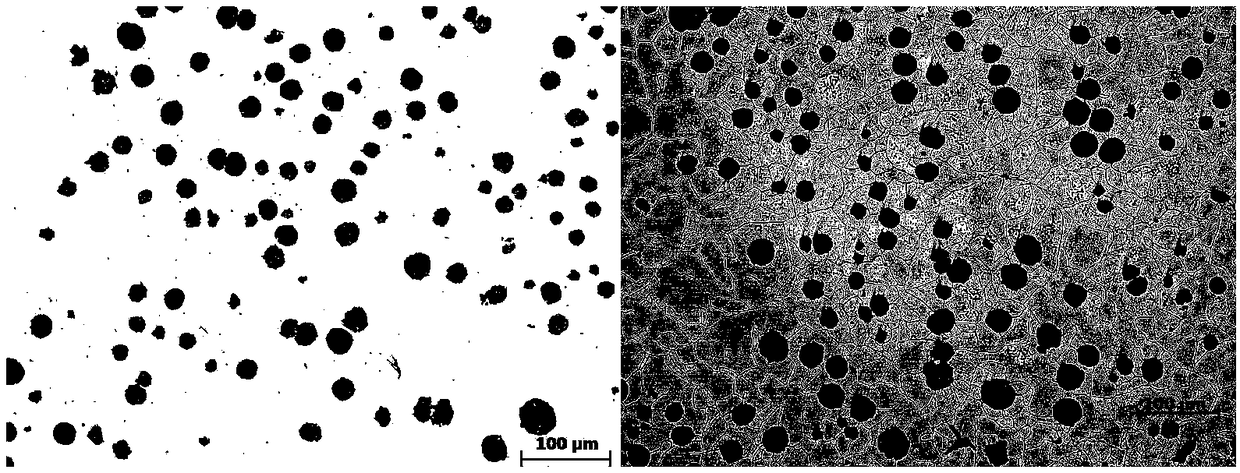

Image

Examples

specific Embodiment 1

[0018] A method for manufacturing shaft products with thick and large section QT500-14, comprising the following steps:

[0019] Step (1), bottom box preparation: place the sand box flat on the mold, and the edge of the sand box is in direct contact with the flat plate to ensure that the flatness of the flat plate is ≤3mm, and then start to put sand, and the mold is released after the resin sand is cured for ≥2 hours;

[0020] Step (2), preparation of the cover box: place the sand box flat on the mold, then start to put sand, and release the mold after the resin sand solidifies for ≥ 2 hours;

[0021] Step (3), sand core preparation: place the mandrel, put the sand to solidify for ≥ 1 hour, and then release the mold;

[0022] Step (4), coating: preheat the metal mold to 50°C, evenly paint the inner cavity of the metal mold, the thickness of the coating is >0.5mm, and dry it, and prepare and paint the rest of the sand molds;

[0023] Step (5), assembly: adjust the level of the...

specific Embodiment 2

[0026] A method for manufacturing shaft products with thick and large section QT500-14, comprising the following steps:

[0027] Step (1), bottom box preparation: place the sand box flat on the mold, and the edge of the sand box is in direct contact with the flat plate to ensure that the flatness of the flat plate is ≤3mm, and then start to put sand, and the mold is released after the resin sand is cured for ≥2 hours;

[0028] Step (2), preparation of the cover box: place the sand box flat on the mold, then start to put sand, and release the mold after the resin sand solidifies for ≥ 2 hours;

[0029] Step (3), sand core preparation: place the mandrel, put the sand to solidify for ≥ 1 hour, and then release the mold;

[0030] Step (4), coating: the metal mold is preheated to 100°C, and the paint is evenly painted on the inner cavity of the metal mold, the thickness of the paint is > 0.5mm, and dried, and the rest of the sand molds are prepared and painted;

[0031] Step (5), ...

specific Embodiment 3

[0034] A method for manufacturing shaft products with thick and large section QT500-14, comprising the following steps:

[0035] Step (1), bottom box preparation: place the sand box flat on the mold, and the edge of the sand box is in direct contact with the flat plate to ensure that the flatness of the flat plate is ≤3mm, and then start to put sand, and the mold is released after the resin sand is cured for ≥2 hours;

[0036] Step (2), preparation of the cover box: place the sand box flat on the mold, then start to put sand, and release the mold after the resin sand solidifies for ≥ 2 hours;

[0037] Step (3), sand core preparation: place the mandrel, put the sand to solidify for ≥ 1 hour, and then release the mold;

[0038] Step (4), coating: the metal mold is preheated to 80°C, and the paint is evenly painted on the inner cavity of the metal mold, the thickness of the paint is >0.5mm, and dried, and the rest of the sand molds are prepared and painted;

[0039] Step (5), as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com