Patents

Literature

156results about How to "Excellent liquid retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

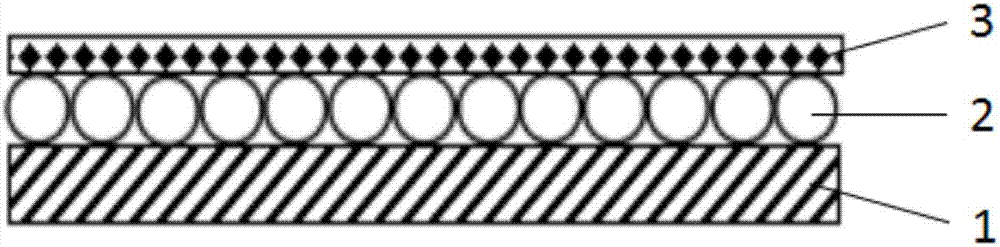

Lithium ion battery composite diaphragm and preparation method and application thereof

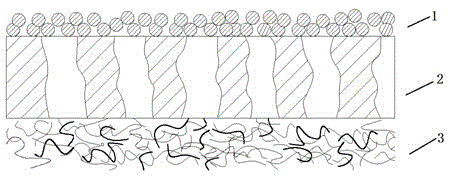

InactiveCN104157811AGood air permeabilityImprove securitySecondary cellsCell component detailsLithium electrodePolymer

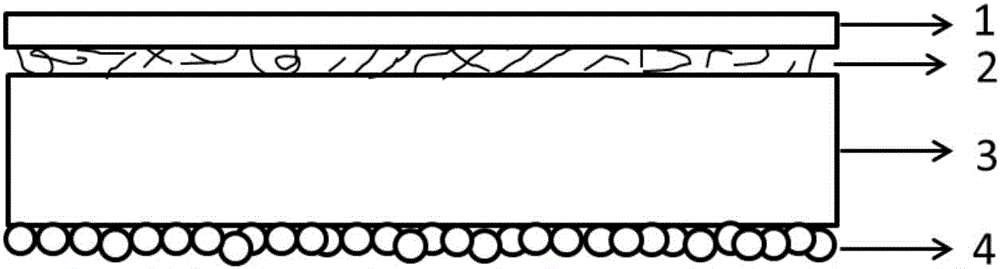

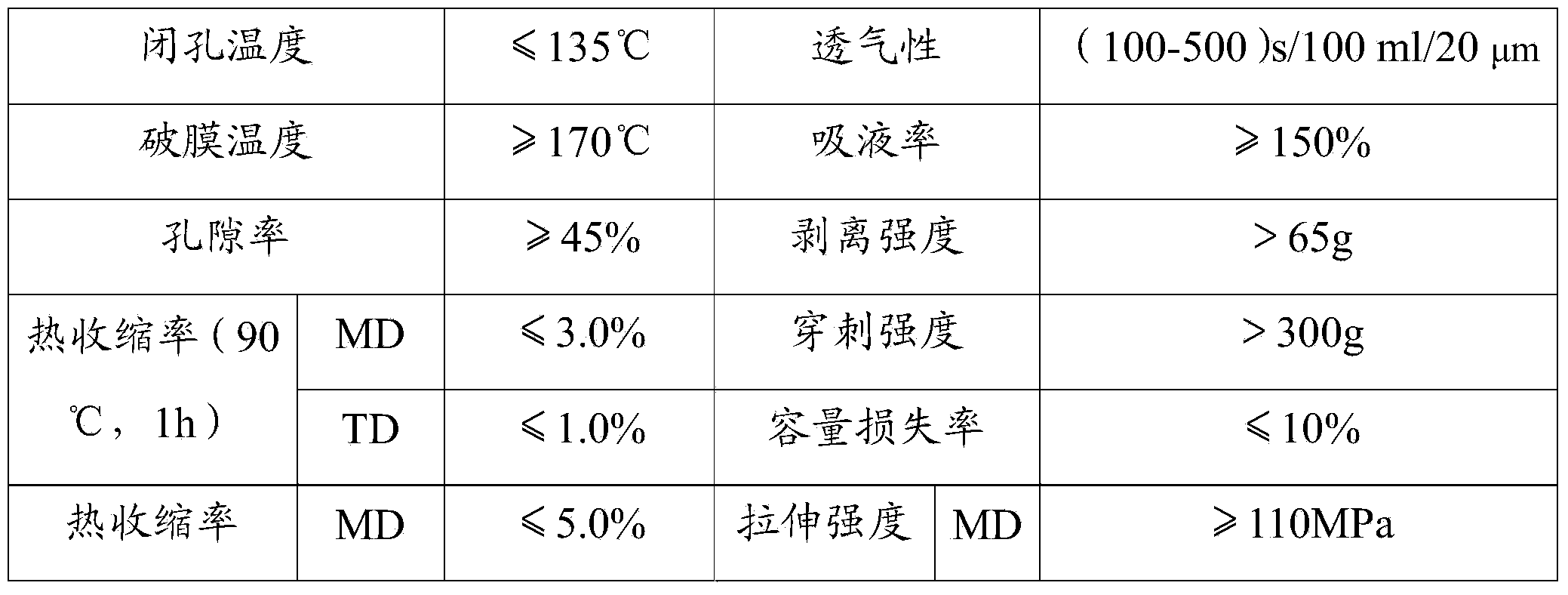

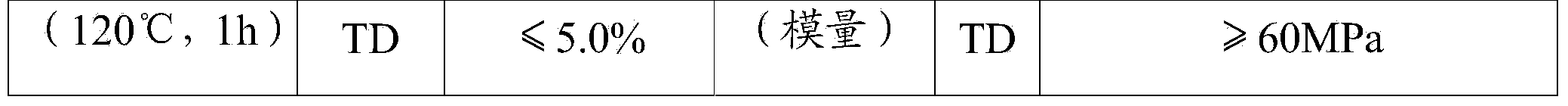

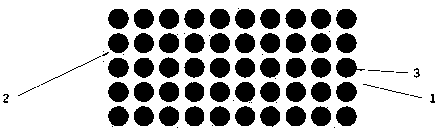

The invention discloses a lithium ion battery composite diaphragm and a preparation method and an application thereof, belonging to the technical field of lithium ion batteries. The composite diaphragm comprises a polyolefin microporous membrane, a polymer microsphere based coating on one side surface of the polyolefin microporous membrane, and an inorganic ceramic-based coating on the other side surface of the polyolefin microporous membrane. The lithium ion battery composite diaphragm has good air permeability, liquid retaining capability and high-temperature resistance and can remarkably improve the security and the circulation property of the battery. The melting point or softening point of the polymer microsphere-based coating in the composite diaphragm is 90-140 DEG C, and when the temperature of the battery is increased, the polymer microsphere based coating is molten or swelled within a short time, then the apertures of the polyolefin microporous membrane are blocked rapidly, the thermal turn-off effect of the diaphragm is achieved, a lithium ion conveying channel is cut off, and short circuit inside the battery is prevented; meanwhile as ceramic grains inside the inorganic ceramic-based coating have the high-temperature resistance property, the polyolefin microporous membrane is effectively prevented from shrinkage, and the situation that positive and negative films directly come into contact to cause short circuit of the battery.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

Novel ceramic coating polyolefin composite film and preparation method thereof

ActiveCN103811702AReduced service lifeExtended service lifeSecondary cellsCell component detailsSolventPolyolefin

The invention relates to a novel ceramic coating polyolefin composite film which comprises a polyolefin substrate with micro pores, wherein one side or both sides of the polyolefin substrate is / are compounded with ceramic coating(s); the ceramic coating comprises porous ceramic particles, an inorganic filler and an adhesive. The invention also relates to a method for preparing the novel ceramic coating polyolefin composite film. The method comprises the following steps: a, dissolving the adhesive in a solvent, thereby preparing an adhesive solution; b, adding the porous ceramic particles and the functional inorganic filler into the adhesion solution prepared in the step a, and performing dispersing treatment, thereby preparing coating slurry; and c, coating one or two surfaces of the polyolefin substrate with the coating slurry prepared in the step b, and drying and curing to prepare the product. The novel functional composite film has high liquid absorption and retention performance, has the functions of reducing harmful gases inside a battery, improving the performance of the battery and prolonging the service life of the battery, and has the safety characteristics of low closed pore temperature, high melting temperature and low hot-shrinkage rate.

Owner:河南惠强新能源材料科技股份有限公司

Lithium-ion battery separator subjected to composite coating treatment and preparation method thereof

ActiveCN106252565ATight bondIncrease volumetric energy densityFireproof paintsCell component detailsLithium-ion batteryAramid

The invention discloses a lithium-ion battery separator subjected to composite coating treatment and a preparation method thereof. The lithium-ion battery separator comprises a basement membrane, a polymer coating coated at one side of the basement membrane, and an inorganic particle coating coated at the other side of the basement membrane; the polymer coating is composed of an aramid coating coated on the basement membrane and a polyvinylidene fluoride coating coated on the aramid coating, and the thickness of the polymer coating is 0.3 to 5 [mu] m; and the inorganic particle coating is composed of inorganic particles of different particle sizes and a binding agent, and the thickness of the inorganic particle coating is s 0.5 to 5 [mu] m. The lithium-ion battery separator provided by the invention has the characteristics of being excellent in mechanical property and heat resistant property, having good wettability and solution preserving property to electrolyte, and excellent in cycle performance and high in safety performance.

Owner:深圳市鼎泰祥新能源科技有限公司

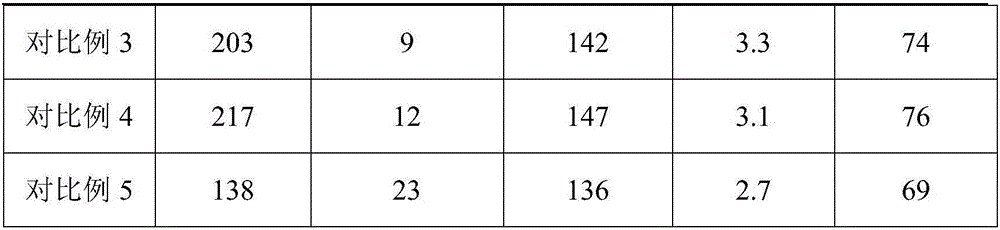

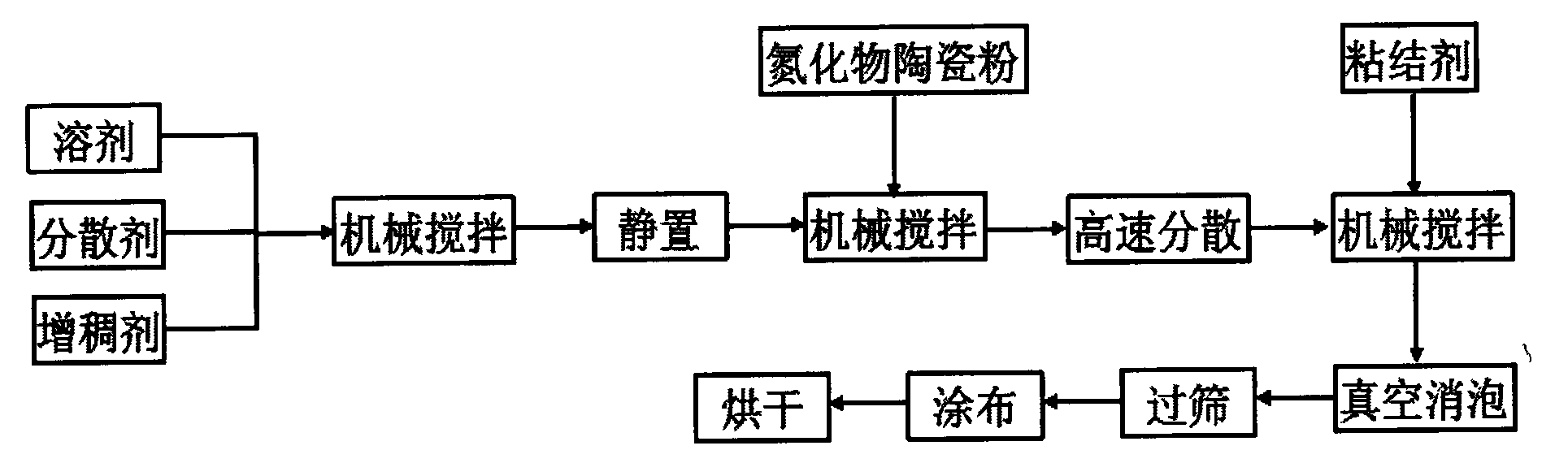

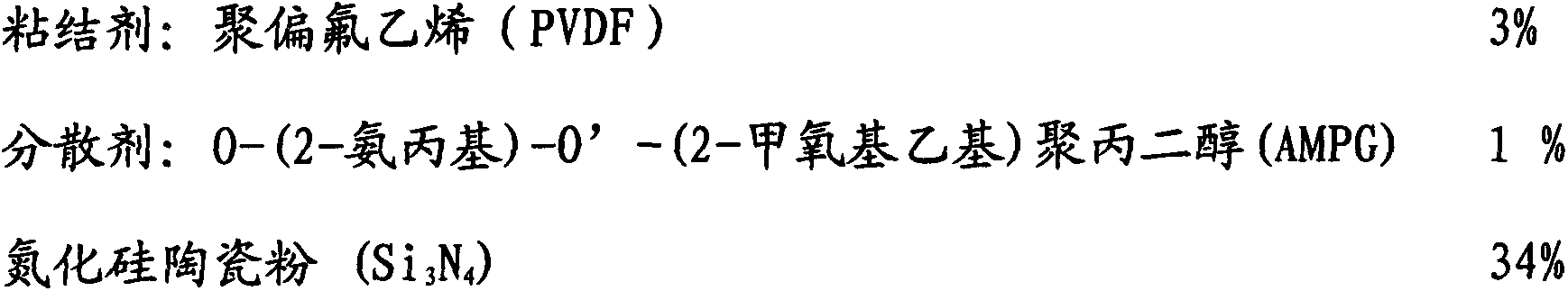

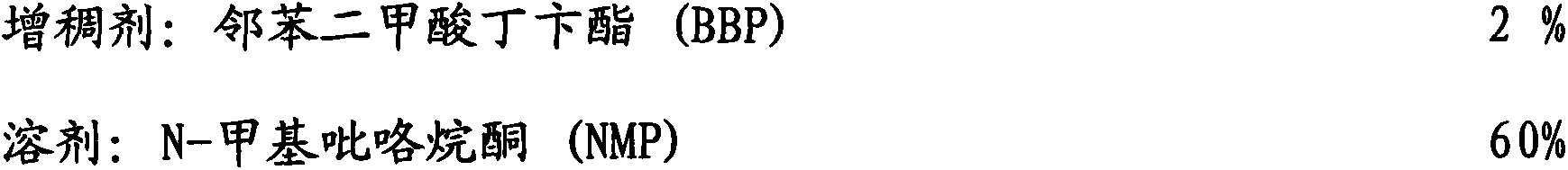

Method for preparing nitride ceramic coating applied to lithium ion battery

InactiveCN103647034AImproves liquid absorption and retentionImproved hydrofluoric acid resistance and thermal shock resistanceNon-aqueous electrolyte accumulator electrodesCell component detailsSolventCeramic particle

The invention discloses a nitride ceramic coating applied to a lithium ion battery. The nitride ceramic coating consists of the following components in parts by weight: 2-10 parts of adhesive, 10-40 parts of nitride ceramic particles, 0.5-3 parts of thickening agent, 0.05-2 percent of dispersing agent and the balance of solvent. The nitride ceramic coating is prepared by the following steps: (1) preparing slurry, namely uniformly mixing and stirring the solvent, the dispersing agent and the thickening agent, standing, defoaming, adding the nitride ceramic particles, uniformly dispersing and forming slurry A; (2) dispersing at high speed, namely dispersing the slurry A at high speed, then adding the additive, uniformly stirring, performing vacuum defoaming, and screening to form slurry B; (3) coating, namely coating the slurry B on an edge of the anode and / or the surface of the cathode and / or a diaphragm in the lithium ion battery, and drying at the temperature of 60-120 DEG C. According to the nitride ceramic coating, the liquid absorption capacity and liquid retaining capacity of the diaphragm or the pole piece can be effectively improved, the hydrofluoric acid resistance and thermal shock resistance of the pole piece or the diaphragm are improved, and a better heat barrier effect is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

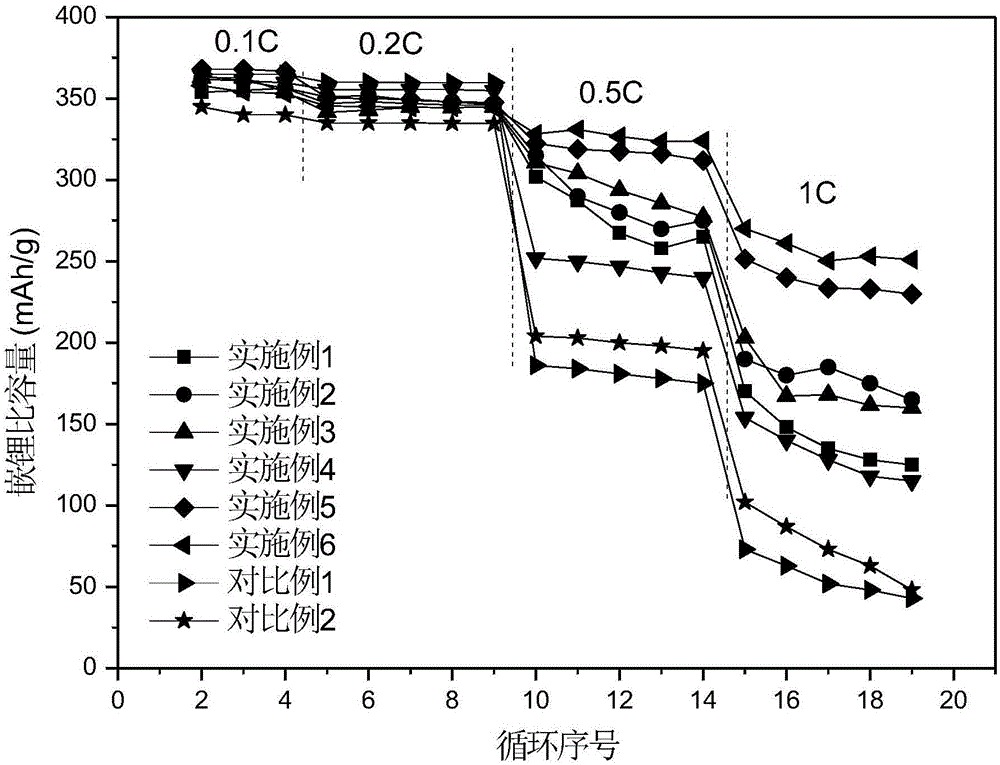

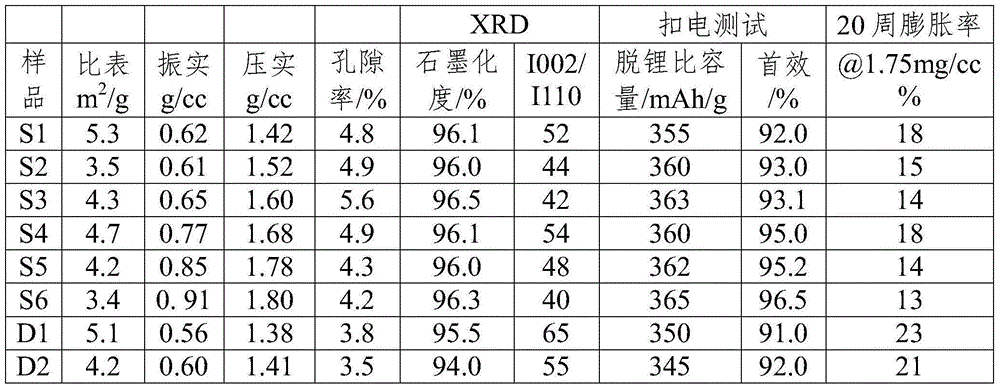

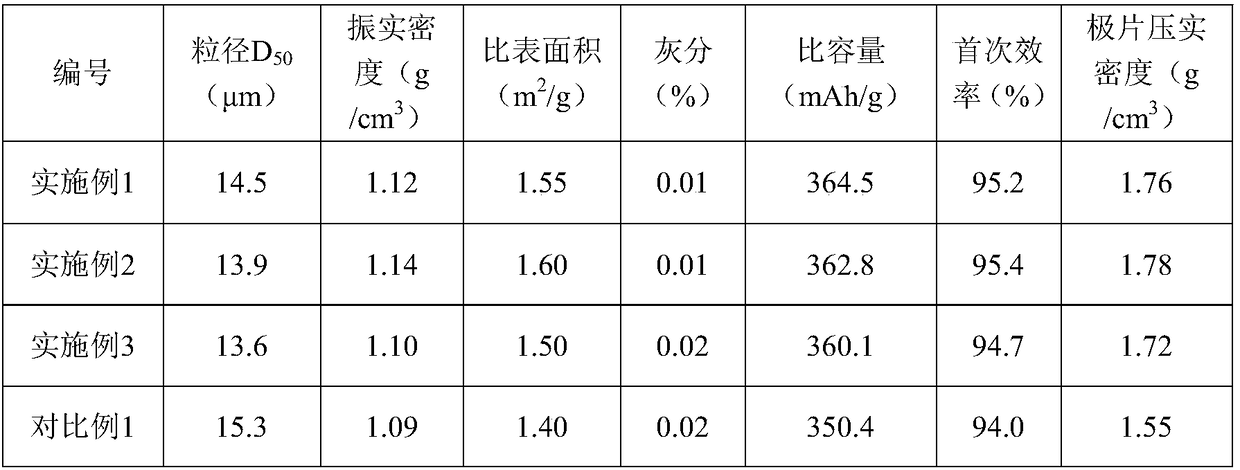

Artificial graphite negative electrode material for lithium ion battery and preparation method thereof

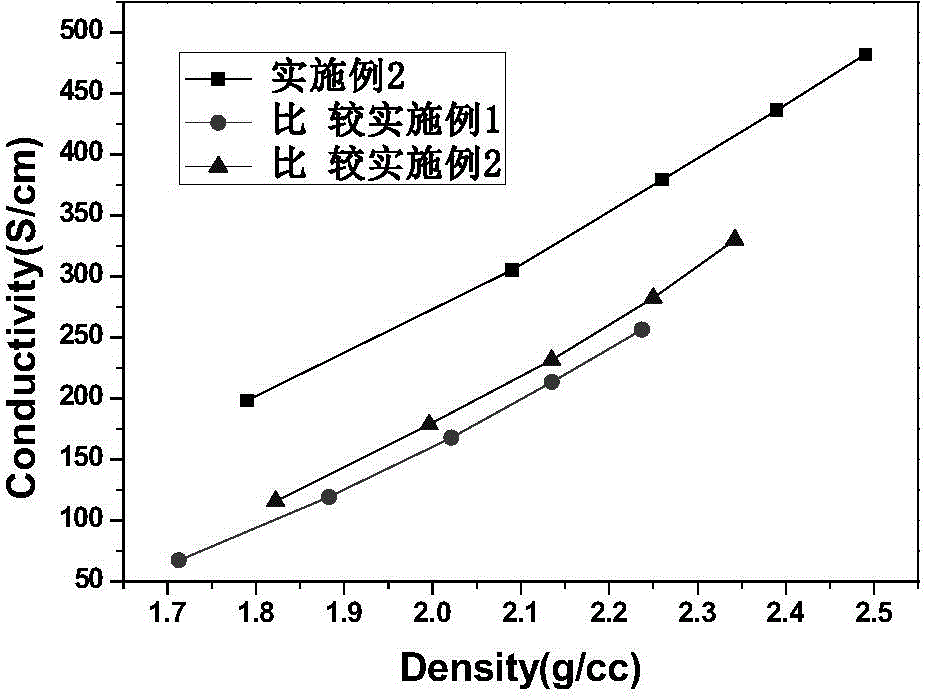

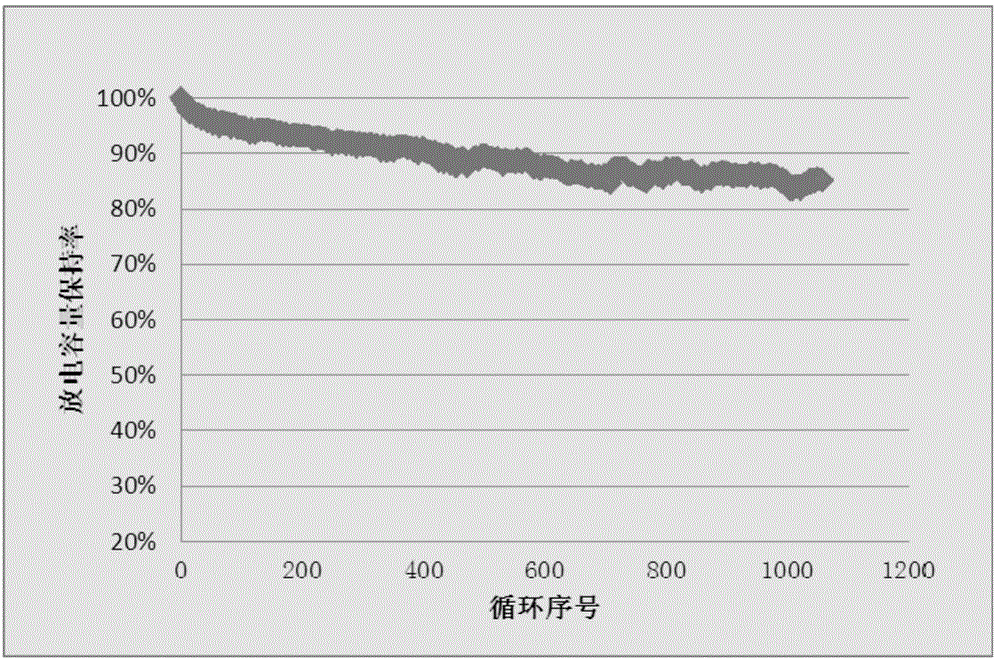

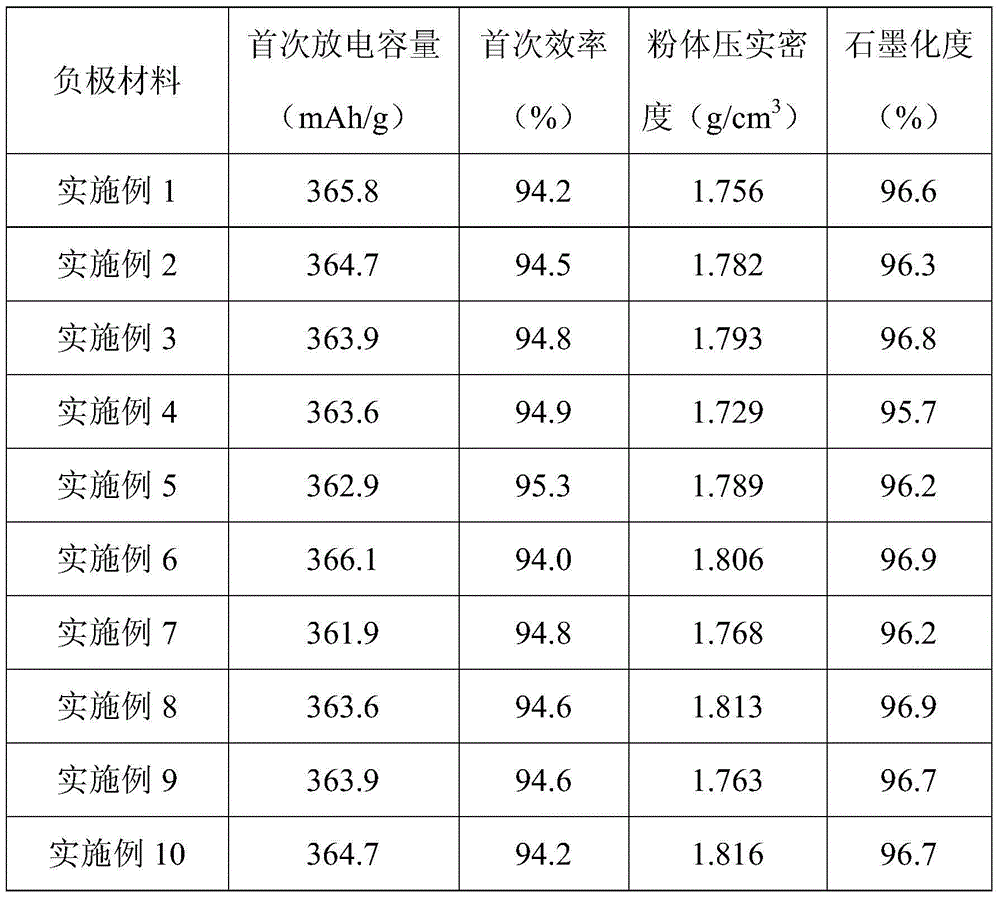

ActiveCN104085883AImprove cycle lifeImprove the degree of graphitizationCell electrodesSecondary cellsCompression moldingAluminium-ion battery

The invention discloses an artificial graphite negative electrode material for a lithium ion battery and a preparation method thereof. The preparation method for the artificial graphite negative electrode material comprises the following steps: preparing powder, adding a binder and / or a crystal nucleus-induced growth additive, kneading, carrying out compression molding, thermally roasting, carrying out nodulizing shaping and / or fusing, carrying out ultrahigh-temperature graphitization, screening, removing magnetism and screening. The preparation method disclosed by the invention is simple to operate, easy to control, lower in production cost and suitable for industrial production. The prepared artificial graphite negative electrode material has high graphitization degree, high compactness, high capacity, high coulombic efficiency, high conductivity and high multiplying power, and can be used for the lithium ion battery.

Owner:贝特瑞(江苏)新材料科技有限公司

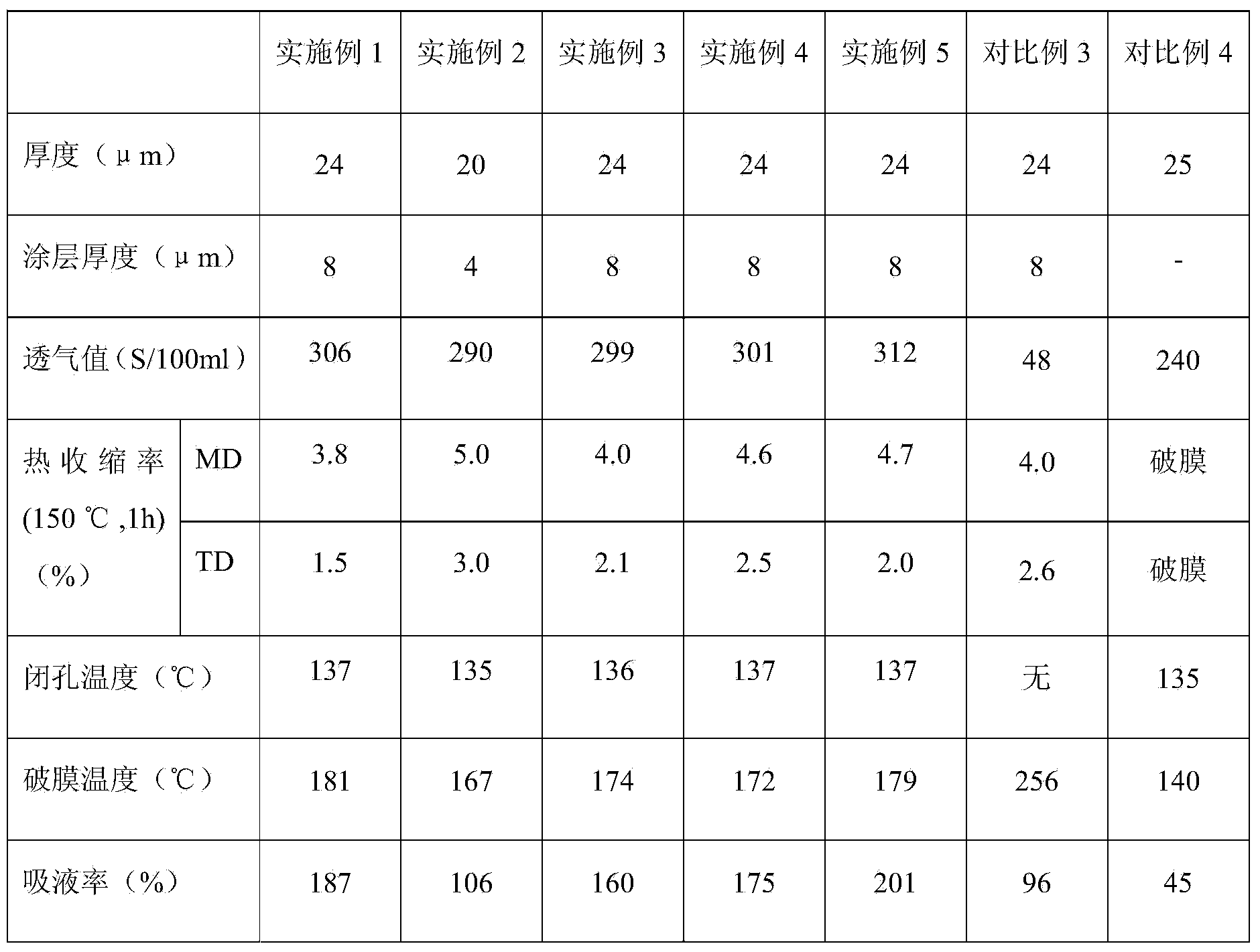

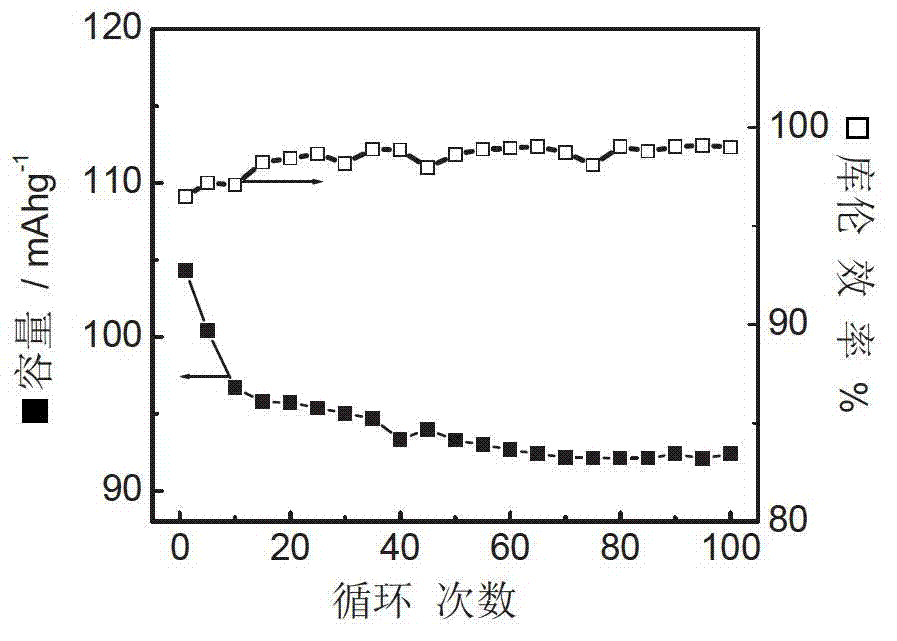

Composite coating lithium-ion battery separator and preparation method thereof

ActiveCN105552284AImprove thermal performanceImprove mechanical propertiesCell component detailsWater basedPole piece

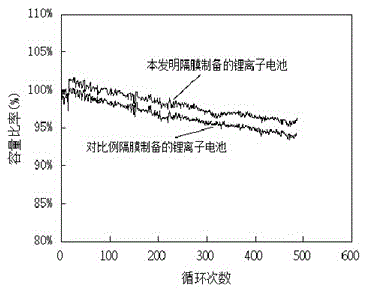

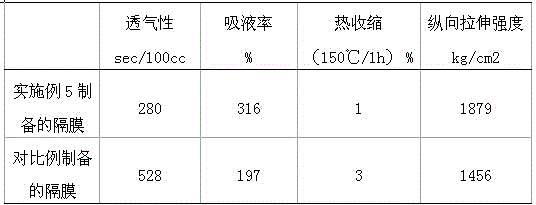

The invention relates to a composite coating lithium-ion battery separator. The composite coating lithium-ion battery separator is composed of a base film, an aramid fiber coating coated on one side of the base film and a PVDF coating coated on the other side of the base film; the aramid fiber coating is obtained by an aramid fiber sizing agent after coating, soaking and drying, and the thickness of the coating is 0.5-4 microns; the PVDF coating is obtained by a water-based PVDF sizing agent after coating and drying, and the thickness of the coating is 0.1-2 microns. The invention also provides a preparation method of the separator. According to the composite coating lithium-ion battery separator and the preparation method thereof, the separator has the characteristics that the aramid fiber coating is good in thermal performance and mechanical performance and the PVDF coating has good wettability and liquid retention property for electrolytes, can effectively adhere batteries and pole pieces and is little in environmental pollution, and is beneficial for preparing lithium-ion batteries with longer cycle life and higher safety. Tests indicate that the separator has good air permeability, liquid absorption rate, thermal contraction and tensile strength, so that the cycle life of the batteries can be obviously prolonged by using the lithium-ion batteries prepared by the separator.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

Lithium ion battery electrode slice, electric core and its making method

ActiveCN101150182AImprove high temperature melting strengthLow melt fluidity at high temperatureElectrode carriers/collectorsSecondary cellsCross-linkPolyolefin

This invention discloses pole plates of Li ionic cells, in which, a micro-porous film is set on the pole plate with PVDF as the matrix and chemical gel formed by chimical cross-link is set in the micro-porous film.This invention also discloses a Li-ionic cell core with said pole plates and a preparation method including: the PVDF film forming chemical gel inside by irradiation and cross-link has the heat contraction rate of nearly zero under 100-220deg.C, which can prevent electronic short circuit of positive and negative pole plates caused by over contraction of intensified switchable Polyolefin micro-hole septums under high temperature when being coated on the pole plates.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

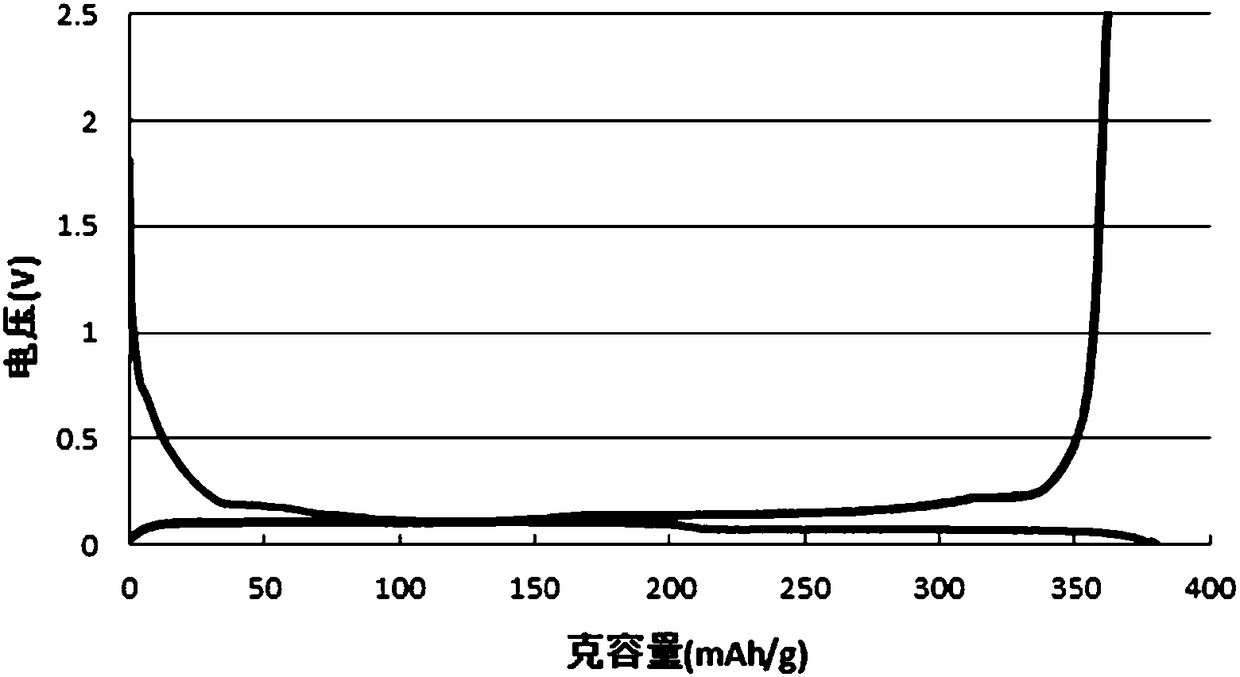

Preparation method of composite graphite, composite graphite and lithium ion battery

InactiveCN105098184ALow costHomogeneous catalytic effectCell electrodesSecondary cellsLithium electrodeGraphite

The invention provides a preparation method of composite graphite to overcome the problems that the composite graphite prepared by the method in the prior art is low in energy density, poor in high-rate charge and discharge properties and high in expansion rate in the charging and discharging processes. The preparation method comprises the following steps: (S1) providing ultrafine carbon powder, wherein the ultrafine carbon powder comprises green coke and / or mesophase carbon green microspheres; (S2) mixing the ultrafine carbon powder with a binder to obtain a mixture A, mixing the mixture A with a catalyst to obtain a mixture B, and then carrying out combined treatment on the mixture B to obtain a precursor; (S3) carrying out graphitizing treatment on the precursor to obtain a semi-finished product; and (S4) crushing, spheroidizing, wrapping and sieving the semi-finished product to obtain the composite graphite. Meanwhile, the invention further discloses the composite graphite prepared by the method and a lithium ion battery. The composite graphite provided by the invention is high in energy density, good in liquid absorption and retention properties, good in isotropic property, good in high-rate charge and discharge properties and low expansion rate in the charging and discharging processes.

Owner:BTR NEW MATERIAL GRP CO LTD

Polyolefin multilayer micro porous diaphragm for lithium ion battery and preparation method of polyolefin multilayer micro porous diaphragm

ActiveCN103531735AWith ion acceleration functionExcellent Adhesive FunctionCell component detailsPolyolefinHigh diaphragm

The invention relates to a polyolefin multilayer micro porous diaphragm for a lithium ion battery and a preparation method of the polyolefin multilayer micro porous diaphragm. The polyolefin multilayer micro porous diaphragm comprises a polyethylene micro porous layer, wherein an ion acceleration layer is arranged on each of the upper surface and the lower surface of the polyethylene micro porous layer, and a polypropylene micro porous layer is arranged on the outer surface of each ion acceleration layer. According to the polyolefin multilayer micro porous diaphragm, due to the adoption of a five-layer structure, a low hole closing temperature and a high diaphragm breaking temperature of the diaphragm can be provided, thus a safety window of the diaphragm is increased and the good safety performance is provided; and meanwhile, the ion acceleration layers provide low resistance, high electron conduction rate and good solution absorption performance and solution maintaining performance of the diaphragm, thus the charge-discharge power and the cycle service life of the lithium ion battery can be improved; and the ion acceleration layers have micro porous net-shaped structures and have excellent lyophilic performance and adhering performance, the ion transmission performance of the diaphragm is improved when all layers of the multilayer micro porous diaphragm are well compounded, and good gas permeability is kept.

Owner:河南惠强新能源材料科技股份有限公司

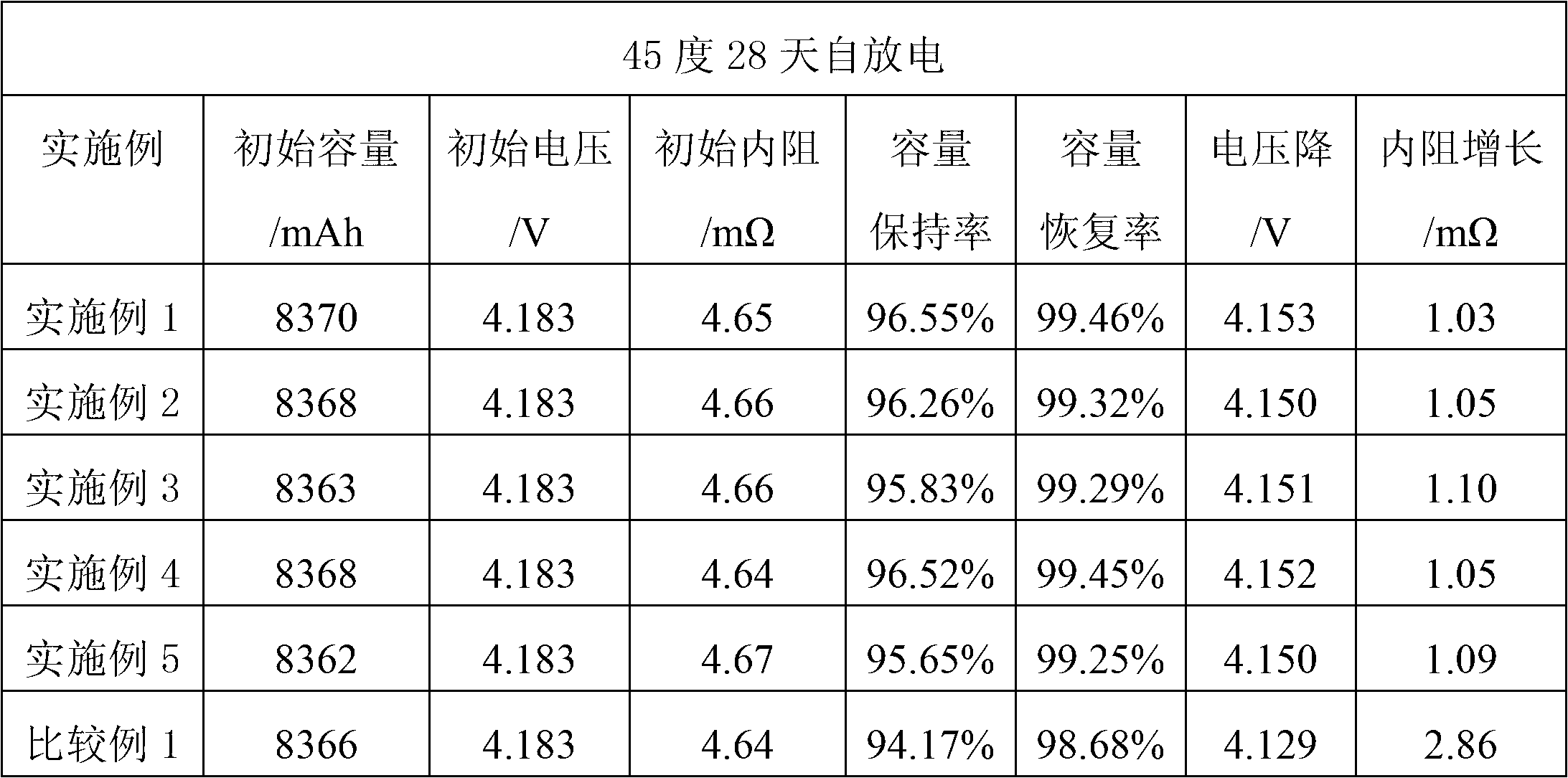

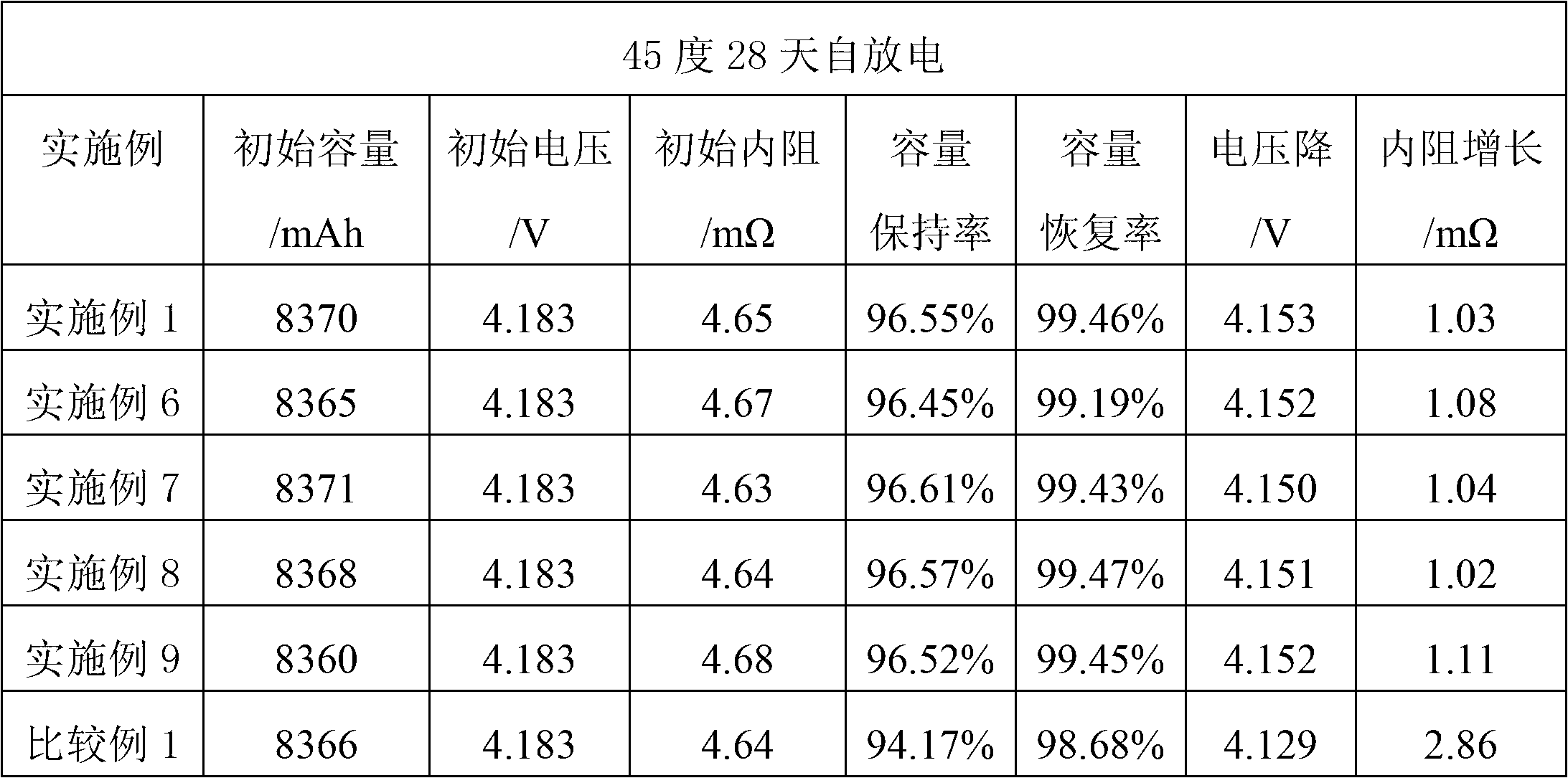

Low-temperature type lithium ion battery with high voltage and high volume energy density

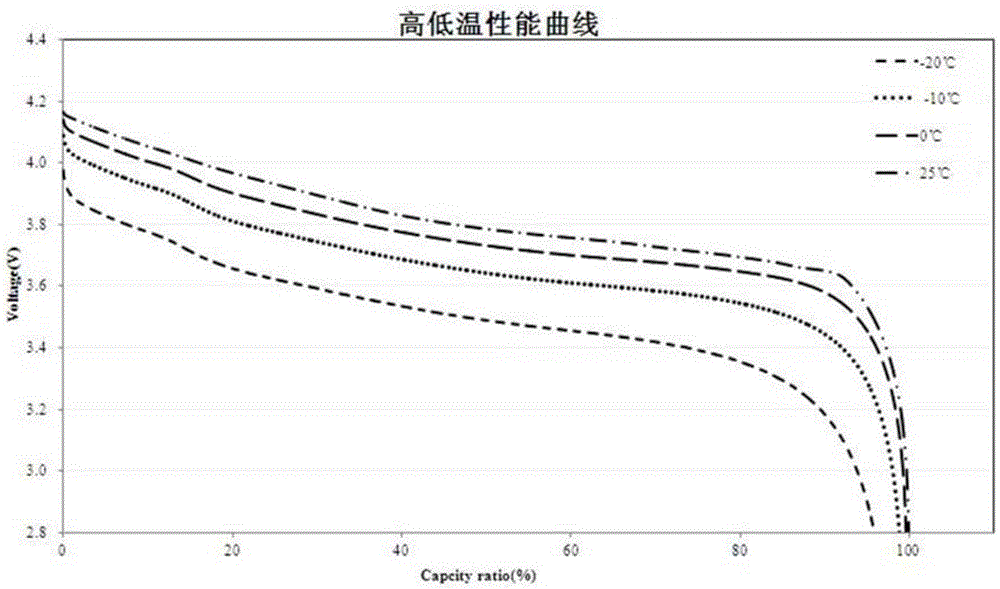

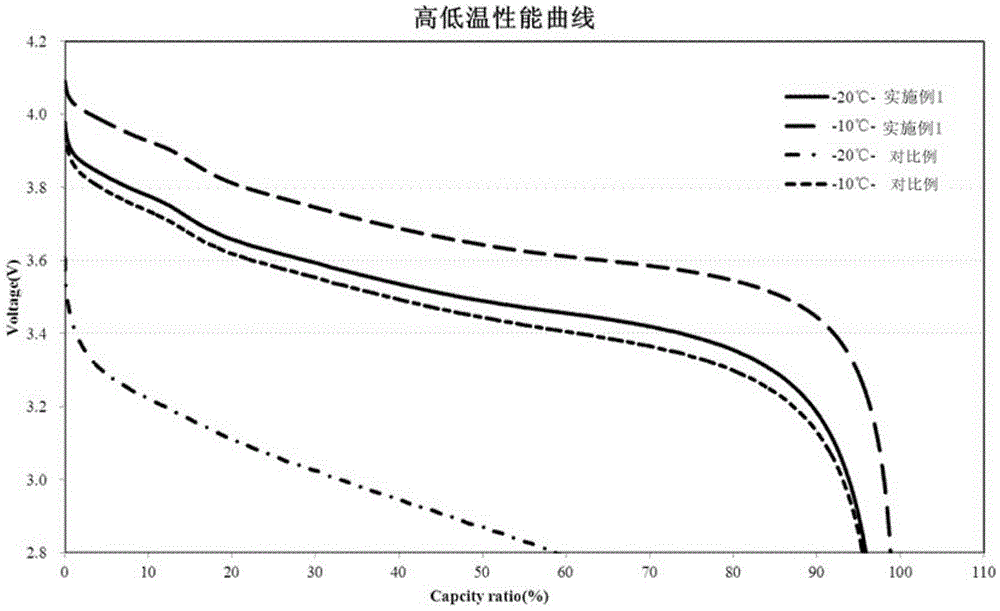

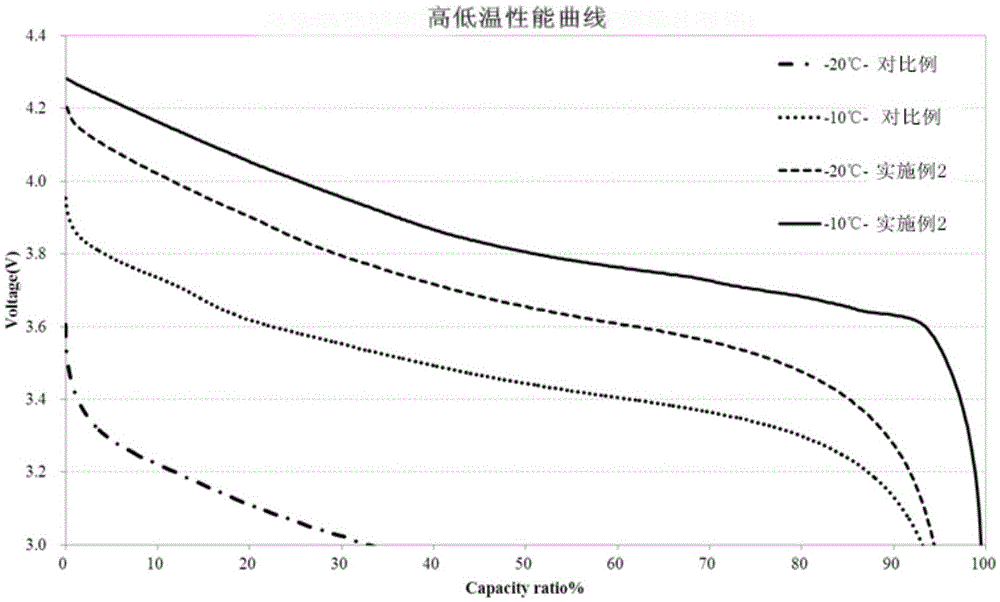

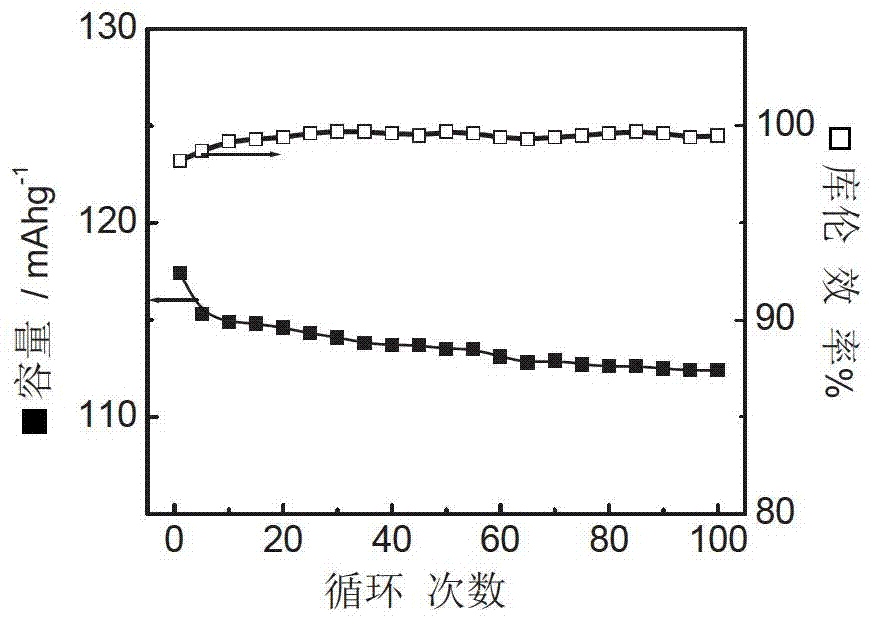

InactiveCN105470519AExcellent liquid retentionReduce bloatCell electrodesFinal product manufacturePolyvinylidene fluoridePolyolefin

The invention provides a low-temperature type lithium ion battery with high voltage and high volume energy density. The low-temperature type lithium ion battery comprises a cathode, an anode, an isolating membrane and an electrolyte solution, wherein the isolating membrane is formed by coating polyvinylidene fluoride-hexafluoropropylene copolymer coatings on both sides of a polyolefin isolating membrane substrate. According to the low-temperature type lithium ion battery with high voltage and high volume energy density provided by the invention, the polyvinylidene fluoride-hexafluoropropylene copolymer coated on the surfaces of the isolating membrane can polymerize with polyvinylidene fluoride in positive and negative pole pieces, so that the cathode and the anode are tightly attached with the isolating membrane together, the expansion of the cathode and the anode is reduced, the inner volume of the battery is further reduced, and the energy density is improved; moreover, the polyvinylidene fluoride on the surfaces of the isolating membrane has good electrolyte retention, and is matched with the low-temperature type lithium ion electrolyte solution and good cathode and anode space conducting network, so that lithium ions can be relatively high in diffusion and disembedding speed between the electrolyte solution and the cathode and the anode under low temperature, and the discharging capacity of greater than or equal to 90% at -20 DEG C can be realized.

Owner:TIANJIN ENERGIES

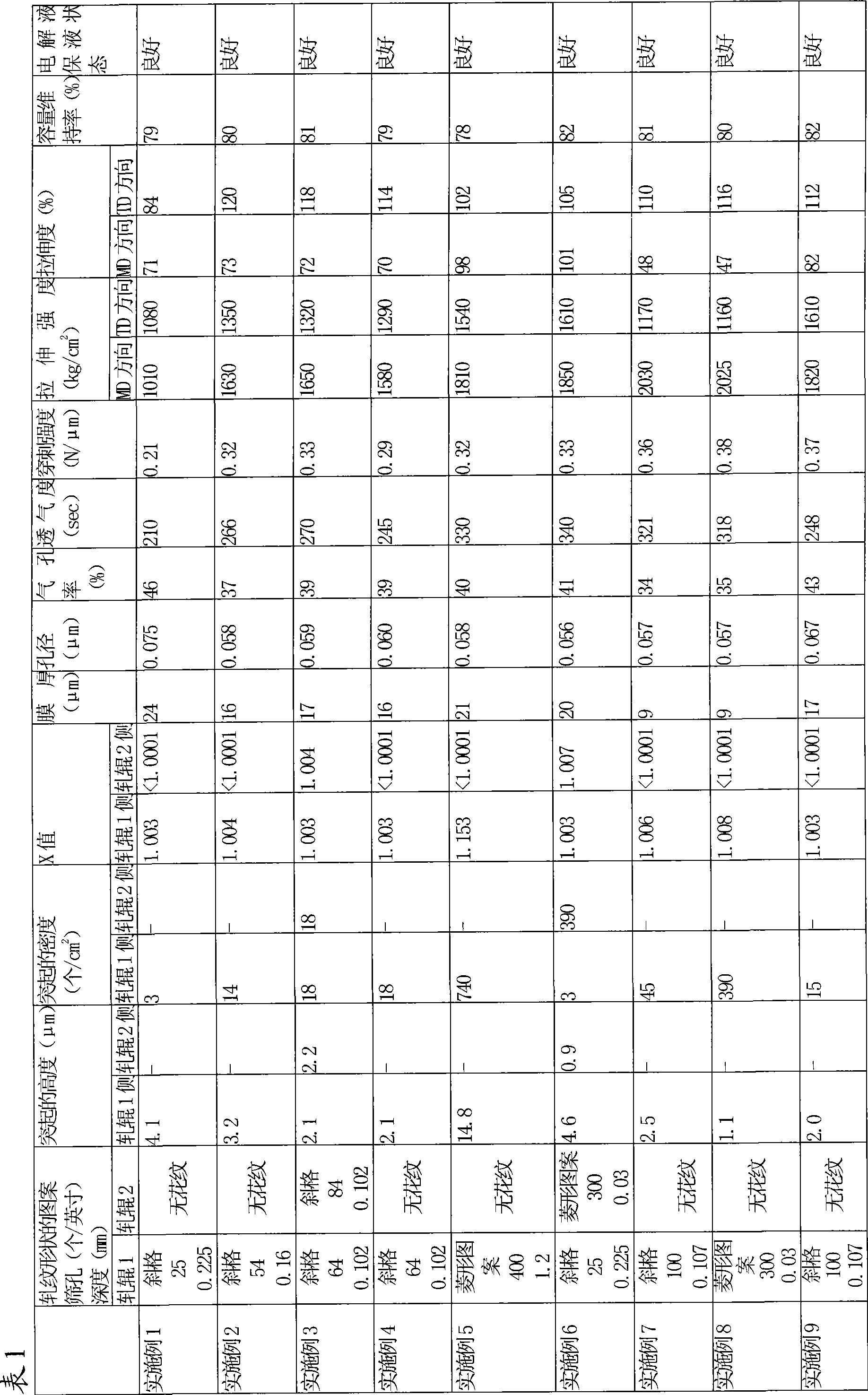

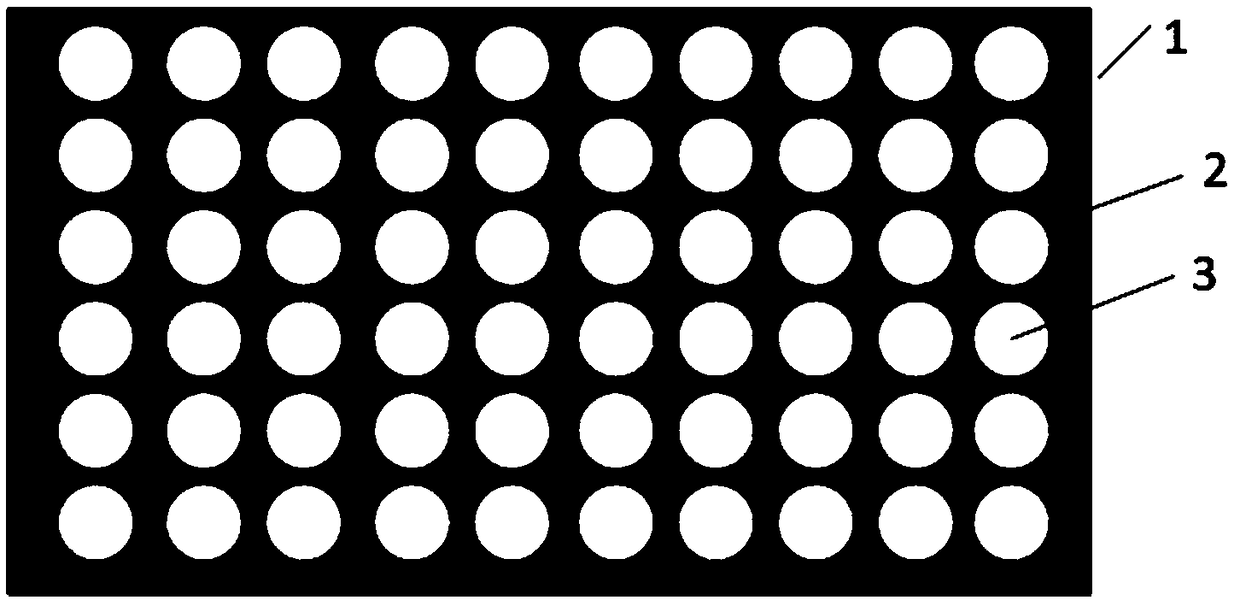

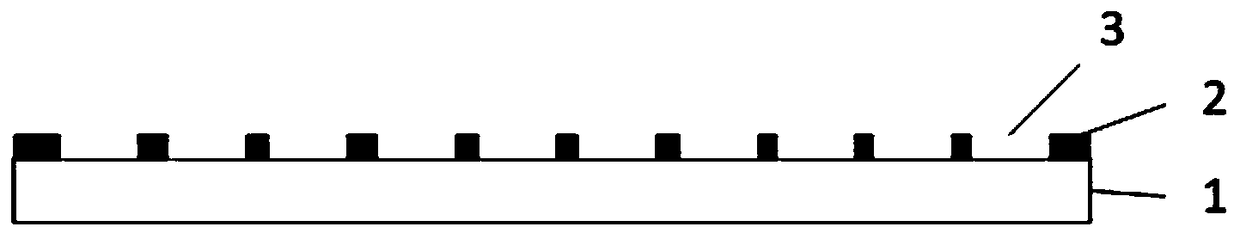

Polyolefin microporous membrane

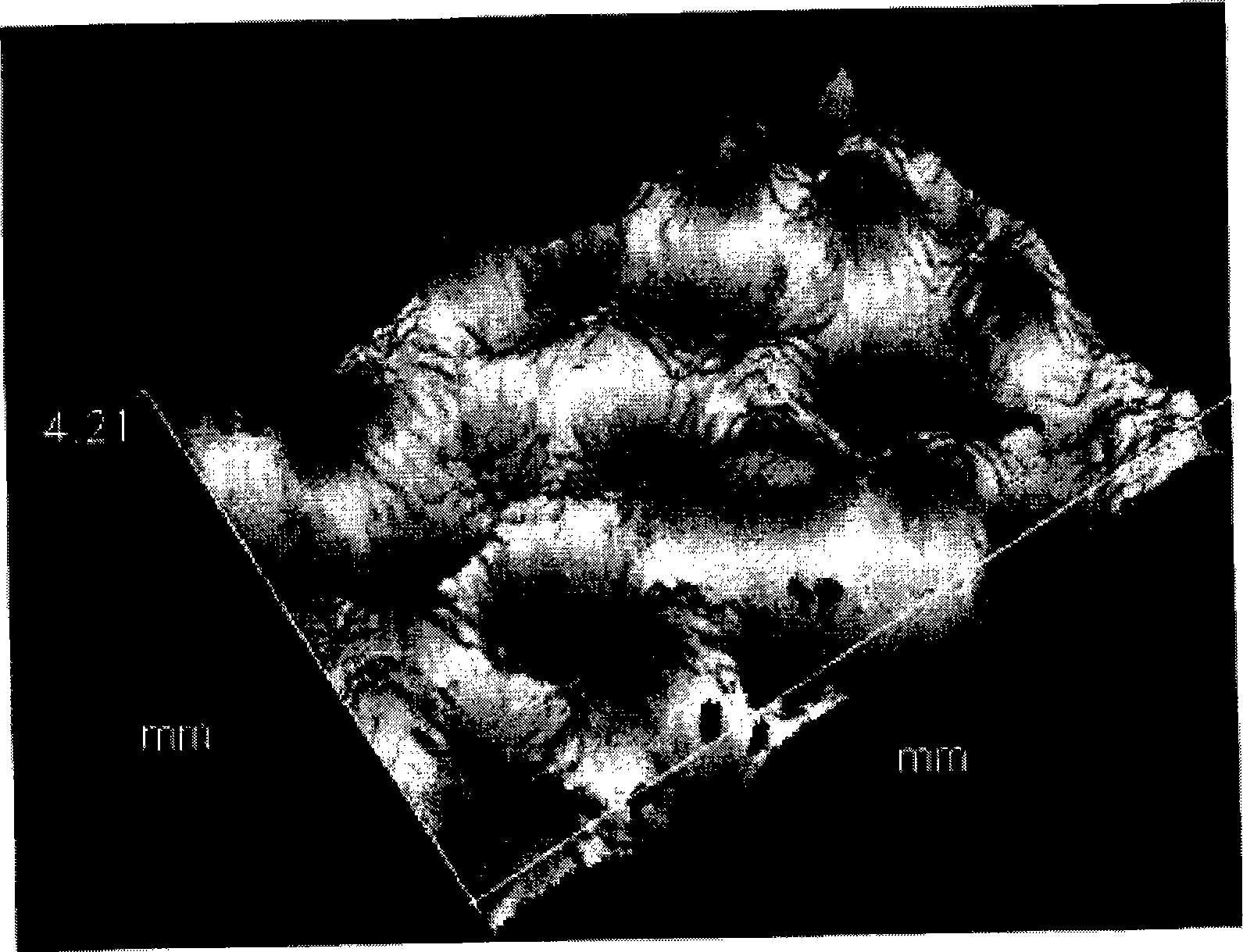

ActiveCN101535386AAvoid compressionAvoid destructionSolid electrolytesCell seperators/membranes/diaphragms/spacersPolyolefinPolymer science

A polyolefin microporous membrane, which has a thickness of 1-100[mu]m, a pore diameter of 0.01-1[mu]m and a protrusion having a height of 0.5-30[mu]m arranged by embossing at least on one surface, is provided. A method for manufacturing the membrane and a battery separator made of the membrane are also provided.

Owner:ASAHI KASEI KK

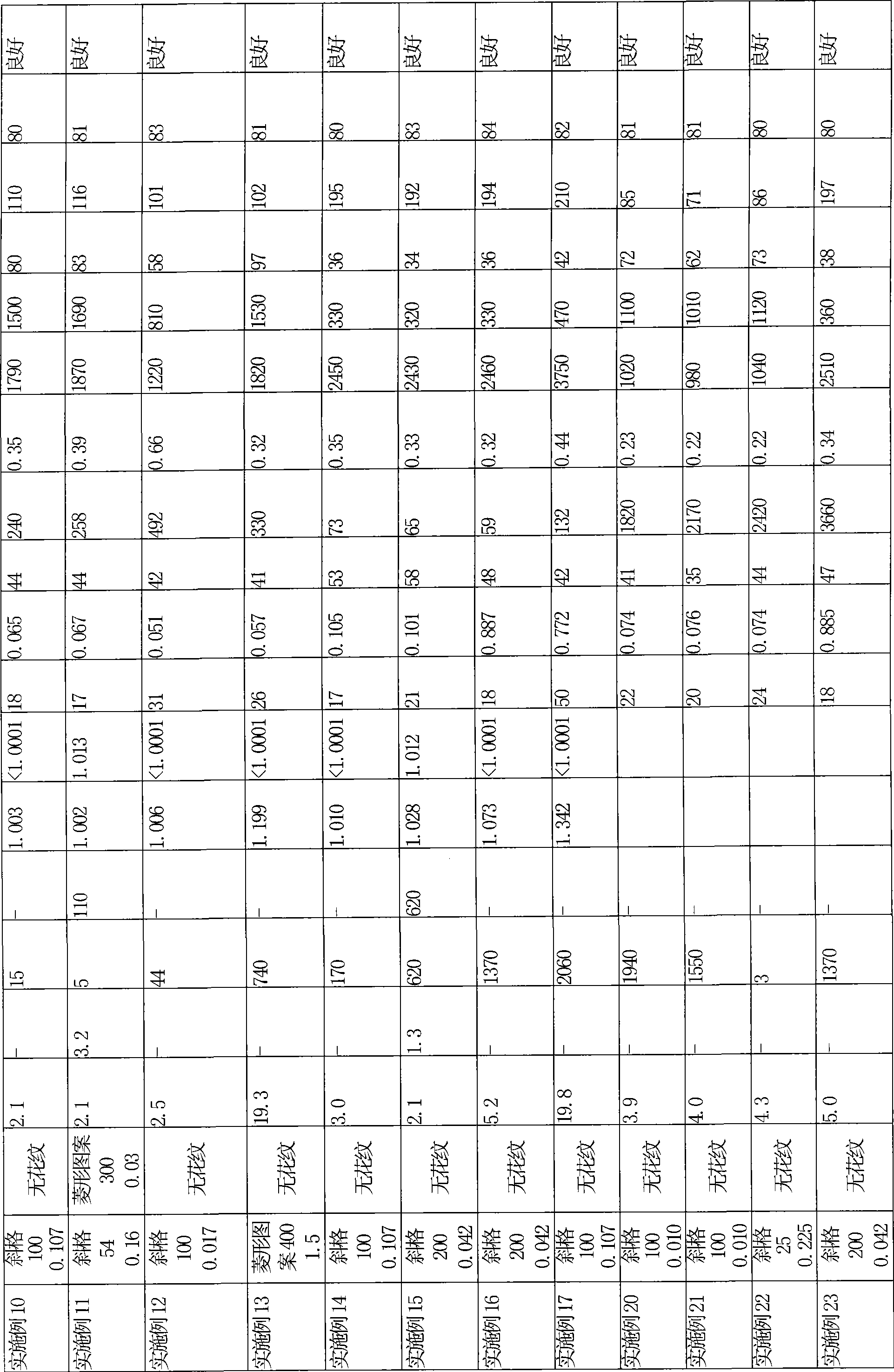

High-temperature resistant micropore thin film material and application thereof

ActiveCN102522514AImprove liquid absorption performanceExcellent liquid retentionCell component detailsPorosityAdhesive

The invention relates to a high-temperature resistant micropore thin film material prepared from inorganic fiber, synthetic fiber, natural organic fiber, nano-grade inorganic powder and an adhesive. The thin film material is a non-woven fabric material prepared through one-step molding with a wet papermaking technology combined with a coating technology. The material has a 3-dimensional network structure and porosity higher than 90%. The high-temperature resistant micropore thin film material has an outstanding high-temperature resistance. Under a temperature of 260 DEG C, excellent dimension and structure stabilities of the material are maintained for a long time. The material has excellent liquid absorbency, excellent liquid retaining capacity, and 3-dimensional stereo pores with good uniformity. An average pore size is 0.02-2.5mum. The high-temperature resistant micropore thin film material can be used as lithium ion power battery separation films, super-capacitor separation films, or filtrating materials.

Owner:莱州联友金浩新型材料有限公司

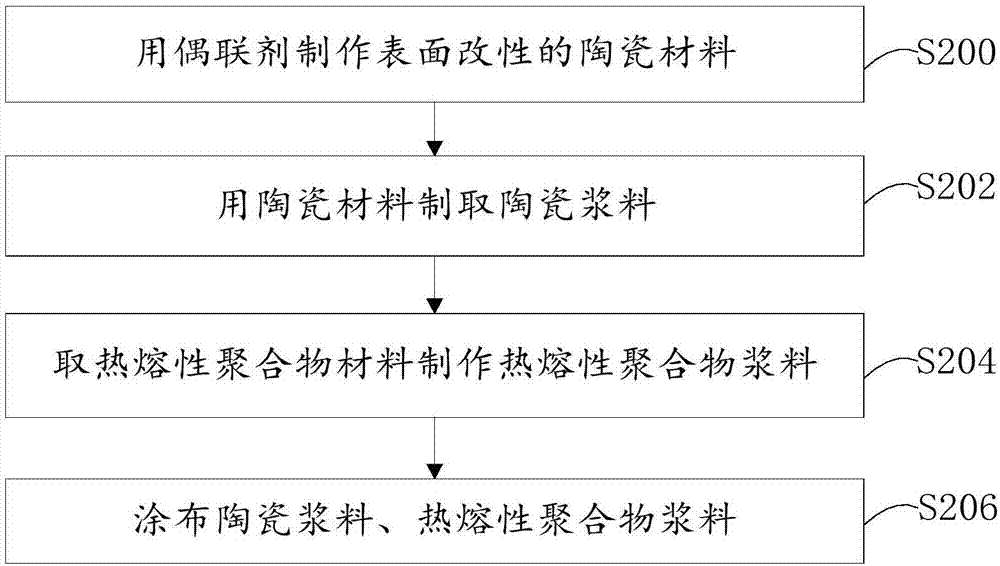

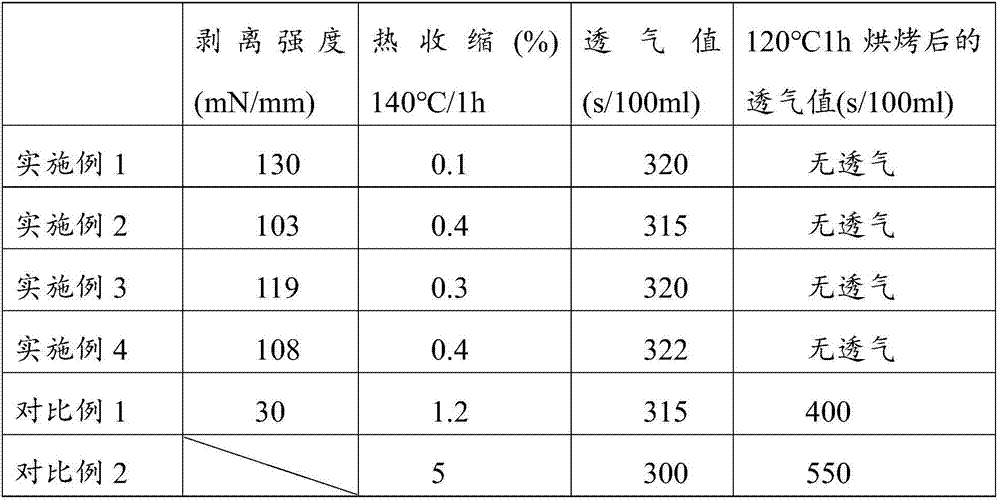

Diaphragm of lithium battery and preparation method thereof

InactiveCN106887559AGood high temperature resistancePrevent heat shrinkageCell seperators/membranes/diaphragms/spacersCeramic coatingCeramic particle

The invention provides a diaphragm of a lithium battery and a preparation method thereof. The diaphragm of the lithium battery comprises a base diaphragm, a ceramic coating and a hot melted polymer coating. The ceramic coating and the hot melted polymer coating are located on the same side of the base diaphragm, and the ceramic coating comprises a ceramic particle material and a first adhesive; the hot melted polymer coating comprises hot melted polymer material particles and a second adhesive. The problem of thermal closing and thermal contraction of the diaphragm is solved.

Owner:XUCHENG FUJIAN SCI & TECH

Novel battery

ActiveCN102856557AUniform growthLong cycle lifeCell electrodesSecondary cellsCarbon compositesRechargeable cell

The invention relates to a novel battery, which solves technical problems of a conventional chargeable battery, including high cost, low specific energy, short service life and serious pollution. The novel battery comprises a battery anode, a battery cathode, an electrolyte and a diaphragm. The battery anode is made of manganese dioxide / polyaniline / carbon composite materials. The electrolyte is weakly acidic. The novel battery can be widely applied to the field of batteries.

Owner:HARBIN INST OF TECH AT WEIHAI

Lithium ion battery electrode slice, preparation method thereof and purpose thereof

InactiveCN103066296AEasy to prepareIncrease productivityNon-aqueous electrolyte accumulator electrodesPolyvinylidene fluorideMaleic anhydride

The invention discloses a lithium ion battery electrode slice which comprises binder I. The binder I is made from any one of or a mixture of at least two of maleic anhydride grafted polyvinylidene fluoride, polymethyl methacrylate and polyethylene oxide. The electrode slice can be a positive electrode slice or a negative electrode slice. The invention further discloses a preparation method of the positive electrode slice. The preparation method includes the following steps: (1), binder II is added into dissolvent, and mixed to be dissolved in the dissolvent, and then the binder I is added into the dissolvent to prepare and obtain binder mother solution; (2), conductive agent and positive electrode active material are added into the binder mother solution to prepare and obtain sizing agent, and then coating and drying are performed to prepare and obtain the lithium ion battery positive electrode slice. The preparation process is simple, the production efficiency is high, the lithium ion battery positive electrode slice is compatible with existing equipment for battery preparation, industrial and large batch production can be achieved, and the prepared lithium ion battery positive electrode slice is good in machinability and liquid retainability.

Owner:HYB BATTERY

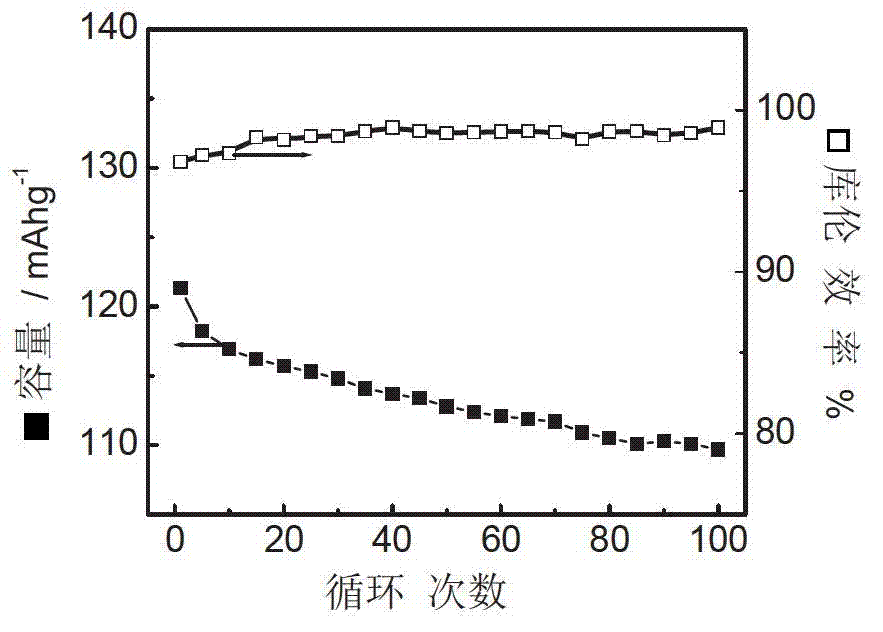

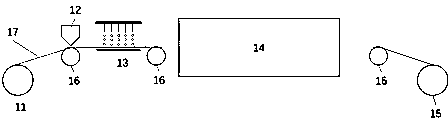

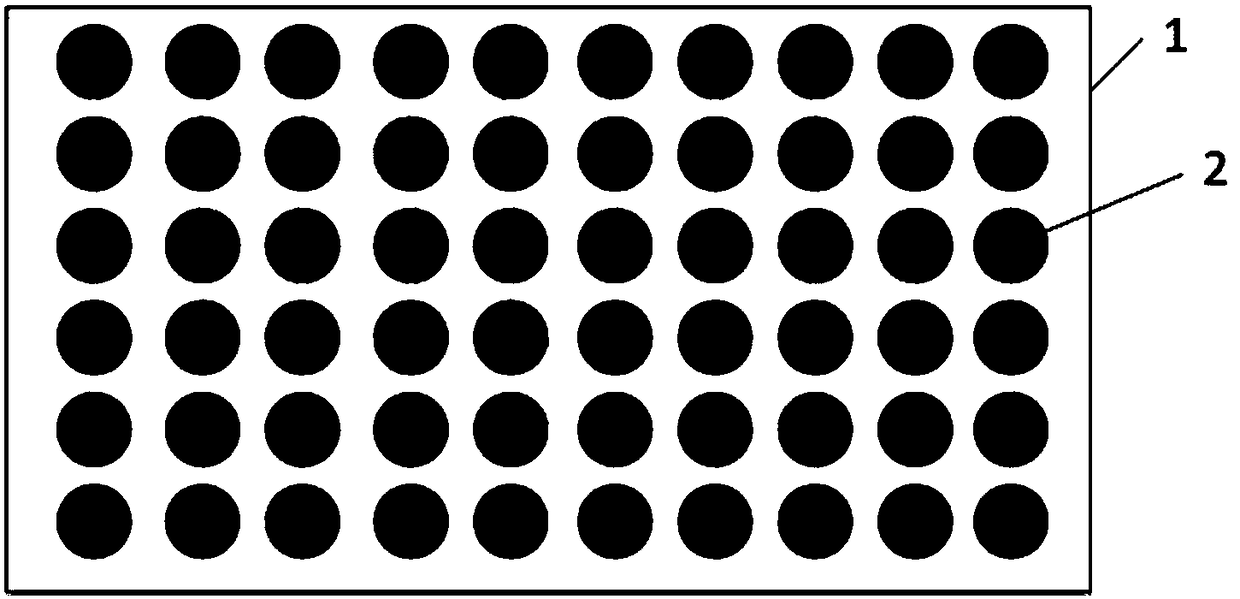

Polymer slurry, composite diaphragm and preparation method thereof

ActiveCN109994695AUniform sizeAvoid easy cloggingSecondary cellsCell component detailsPolymer scienceCeramic coating

The invention relates to the technical field of lithium ion battery diaphragm preparation and discloses polymer slurry, a composite diaphragm and a preparation method thereof. The polymer slurry includes, by weight, 10-30 parts of the polymer, 0.05-1.0 parts of the thickener, 5.1-26.5 parts of the wetting agent, 1.0-5.0 parts of the binder, 0.1-1.0 parts of the dispersant and 80-120 parts of the water. The composite diaphragm includes a base film, and a ceramic coating and a polymer dot coating coated on both sides of the base film, wherein the polymer dot coating is obtained by coating the above polymer slurry in a high pressure jet mode. The composite diaphragm has good thermal stability, strong adhesion stress and good permeability, when the composite diaphragm is applied to a lithium ion battery, performance of the lithium ion battery is improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

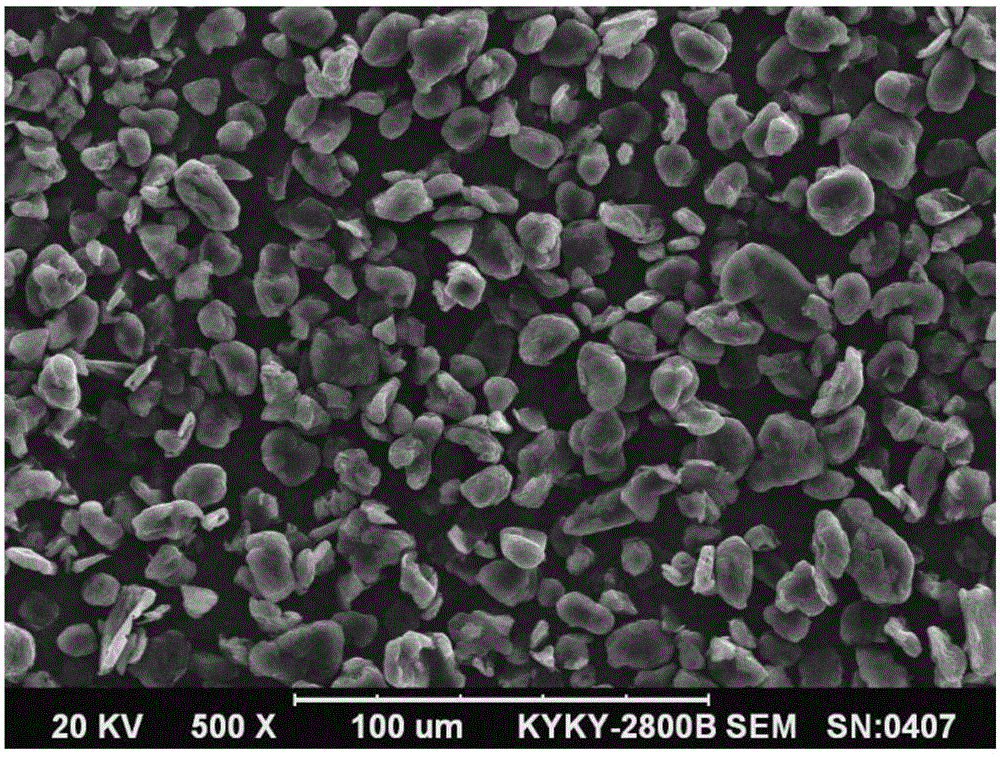

High-capacity and high-compaction artificial graphite negative electrode material, preparation method thereof and lithium ion battery

InactiveCN108550850AIncrease compaction densitySolve the problem of easy overvoltageCell electrodesSecondary cellsMixed materialsGraphite

The invention relates to a high-capacity and high-compaction artificial graphite negative electrode material, a preparation method thereof and a lithium ion battery. The preparation method comprises the steps of selecting at least two of pitch coke, petroleum coke and needle coke as graphite raw materials, and uniformly mixing with a coating agent to obtain a mixed material; and performing graphitization on the mixed material at 3,000-3,300 DEG C under a protection atmosphere to obtain the high-capacity and high-compaction artificial graphite negative electrode material. According to the preparation method of the high-capacity and high-compaction artificial graphite negative electrode material, the problem that the material is easy to press excessively due to inappropriate selection of theraw material cokes is solved by selection and matching of raw material cokes with different hardness, and the prepared graphite negative electrode material has appropriate hardness and rebound rate.A pole plate prepared from the artificial graphite negative electrode material is high in compaction density, an electrolyte is rapidly immersed, and the electrochemical performance of the lithium ionbattery is prolonged.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

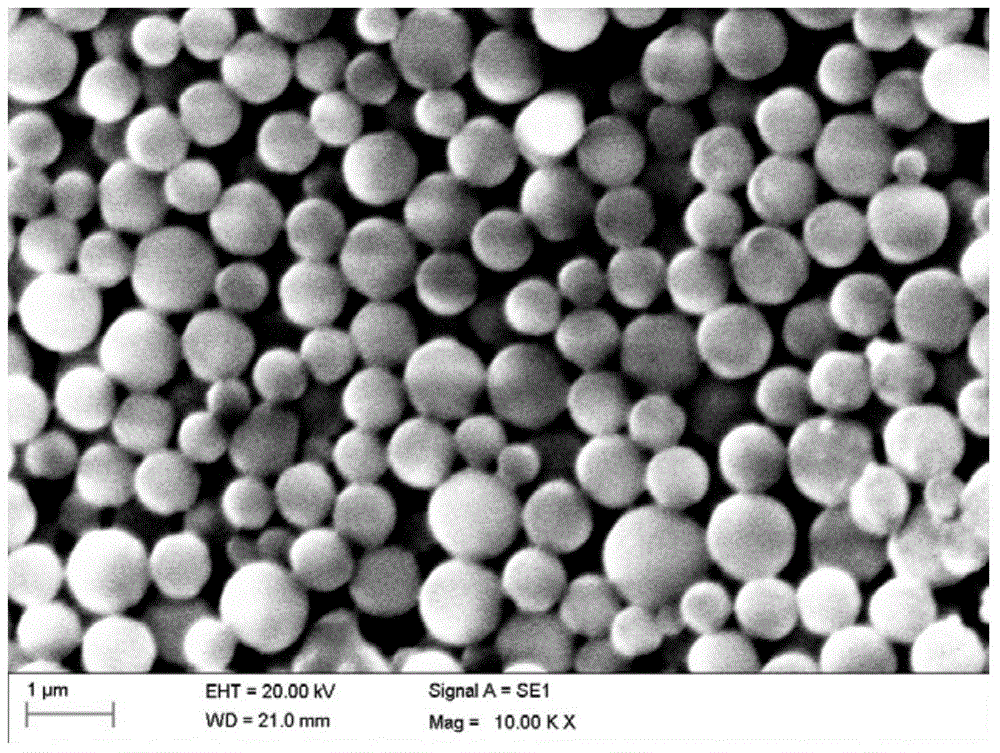

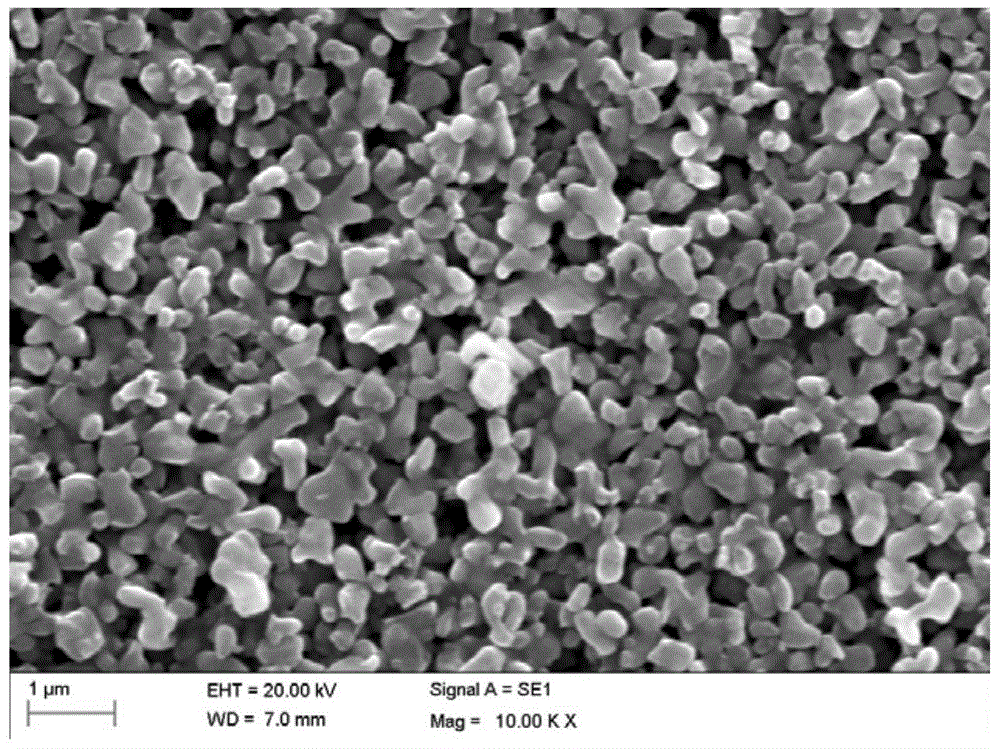

Ionic polymer film material and preparation method thereof, and lithium secondary battery

ActiveCN102702657ANo pollution in the processSimple production processSecondary cellsCell component detailsElectrical batteryPolymer thin films

The invention relates to an ionic polymer film material and a preparation method thereof, and a lithium secondary battery, belonging to the technical field of manufacturing of lithium batteries. The invention provides an ionic polymer film material consisting of polymer colloid particles with sulfonate groups on surfaces. A reactive sulfonate surfactant is taken as an emulsifier for synthesizing an acrylate polymer colloid emulsion with sulfonate groups on the surface, and a film is formed by performing curtain coating film forming on the emulsion. The film is formed by colloid particles, and is a pore-free dense film with a colloid particle structure; and when the battery is overheated, a diaphragm is free from remarkable thermal shrinkage. Moreover, a through ion conducting path is formed among colloid particles after a polymer film absorbs an electrolyte, and the ionic polymer film material can keep a colloid particle structure after absorbing an electrolyte solution or solvent; and through dense deposition of colloid particle sphere structures, the sinuosity of the ion conducting path is increased, and the electronic insulating performance of a poly-anion electrolyte film is enhanced.

Owner:SICHUAN INDIGO TECH CO LTD

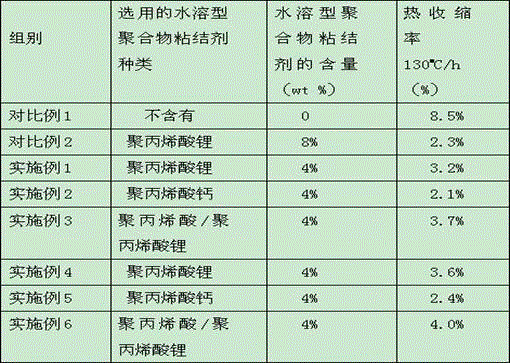

Inorganic/organic compound functional porous isolating membrane and preparation method as well as lithium ion battery adopting inorganic/organic compound functional porous isolating membrane

ActiveCN105789523AGood dispersionImproved high temperature thermal stabilitySecondary cellsCell component detailsPorous substrateOrganic compound

The invention provides an inorganic / organic compound functional porous isolating membrane. The inorganic / organic compound functional porous isolating membrane comprises a porous substrate and an inorganic functional coating which is adhered to at least one surface of the porous substrate, wherein the inorganic functional coating is prepared from inorganic ceramic particles, a water-soluble macromolecular thickening agent, a water emulsion type polymer binding agent and a water soluble type polymer binding agent; the water emulsion type polymer binding agent is a macromolecular polymer with the surface tensile force of 40dyne / cm to 50dyne / cm, and a water drip contact angle of water emulsion type polymer binding agent dry glue is 100 degrees to 130 degrees; the water emulsion type polymer binding agent is a polar macromolecular polymer with the glass transition temperature of 100 DEG C to 150 DEG C. Therefore, the inorganic / organic compound functional porous isolating membrane has the advantages that the heat stability of the isolating membrane can be effectively improved, and the moisture content of the inorganic coating can also be reduced, so that the safety performance of a battery and the stability of long-period cycle are improved.

Owner:深圳市旭然电子有限公司

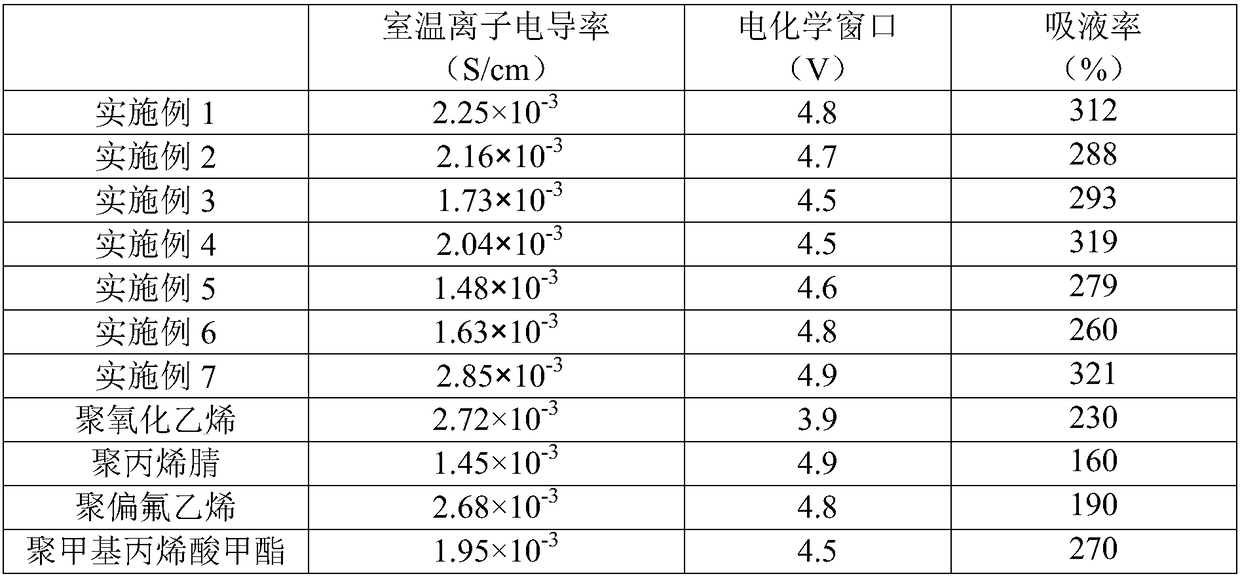

Preparation method of composite polymer electrolyte membrane and lithium ion battery

ActiveCN108400380AImprove electrochemical stabilityImprove mechanical propertiesSolid electrolytesFinal product manufactureEvaporationSolvent

The invention discloses a preparation method of a composite polymer electrolyte membrane and a lithium ion battery. The preparation method of the electrolyte membrane comprises the following steps: mixing a carbonate functionalized vinyl monomer and a polyether structural monomer with a solvent under stirring in an inert gas atmosphere, then adding an initiator, reacting in the inert gas atmosphere, and drying and purifying to obtain a carbonate functionalized vinyl copolymer; adding the obtained carbonate functionalized vinyl copolymer and inorganic filler into the solvent, and mixing under stirring to obtain a uniform mixed solution; and uniformly coating the mixed solution on a mold, and performing vacuum drying and evaporation on the solvent to obtain a composite polymer electrolyte membrane. The electrolyte membrane disclosed by the invention has higher liquid retention rate, higher lithium ion conductivity, more superior mechanical property, high machining performance, higher electrochemical stability and better application prospect.

Owner:ZHUHAI COSMX BATTERY CO LTD

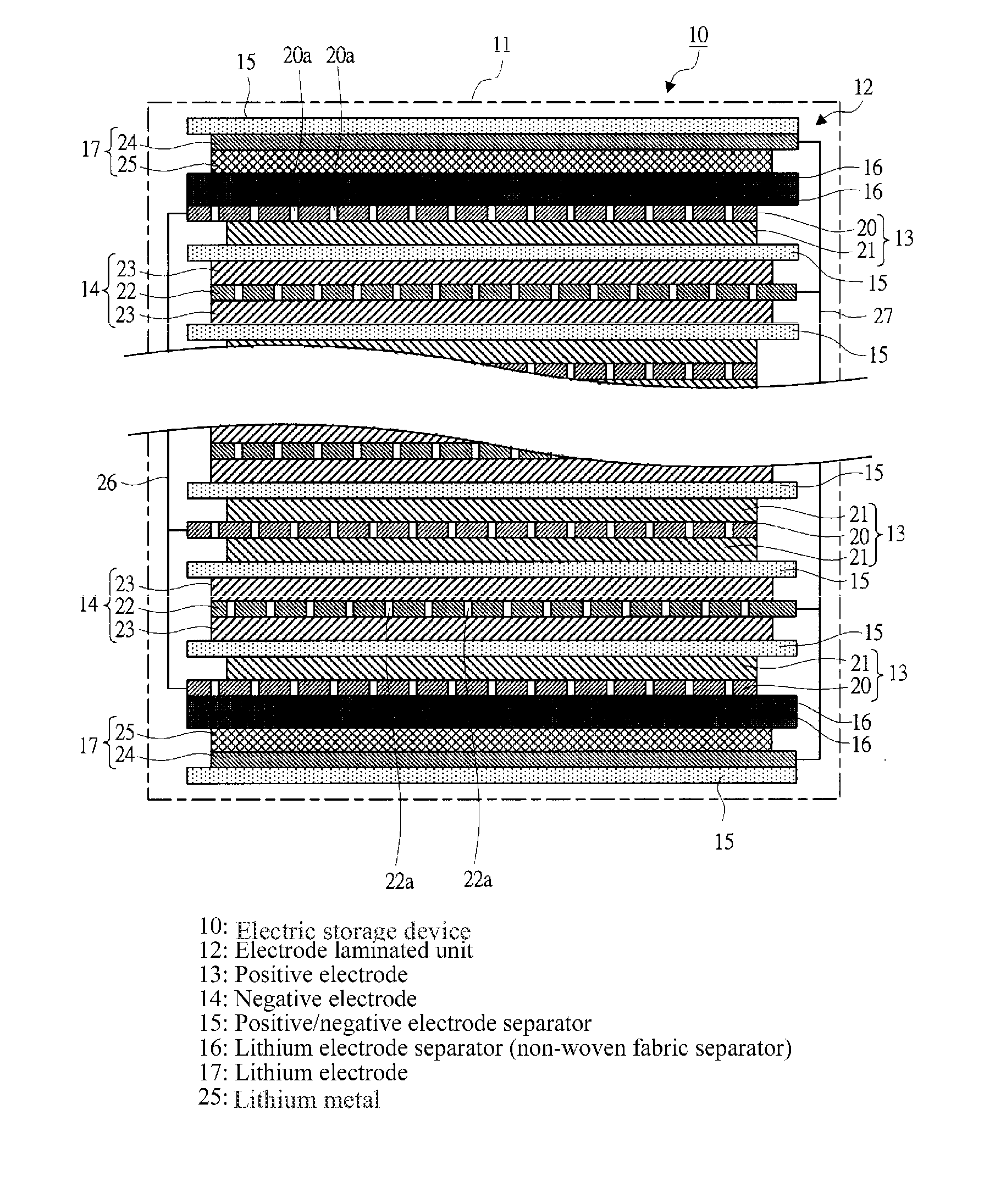

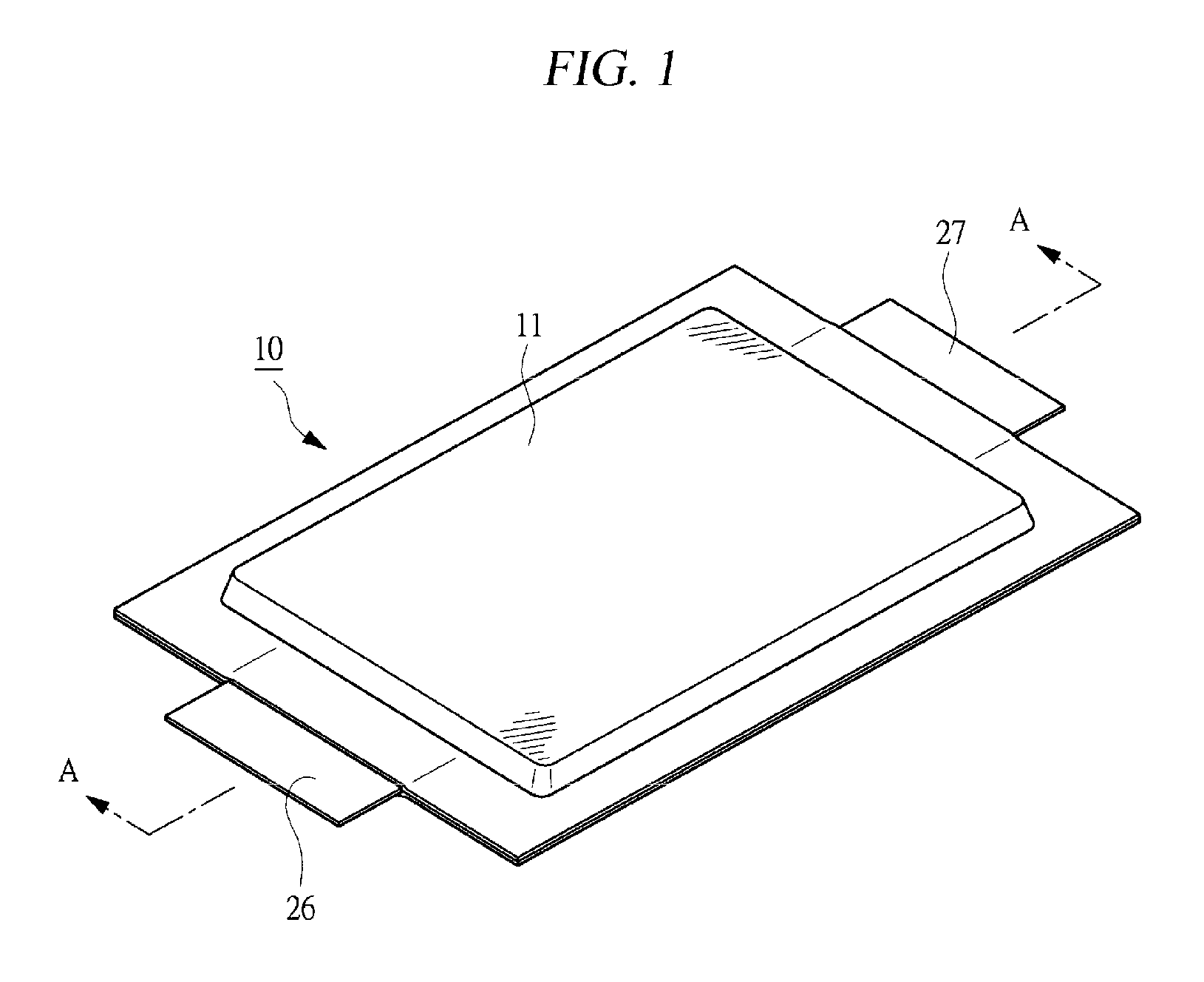

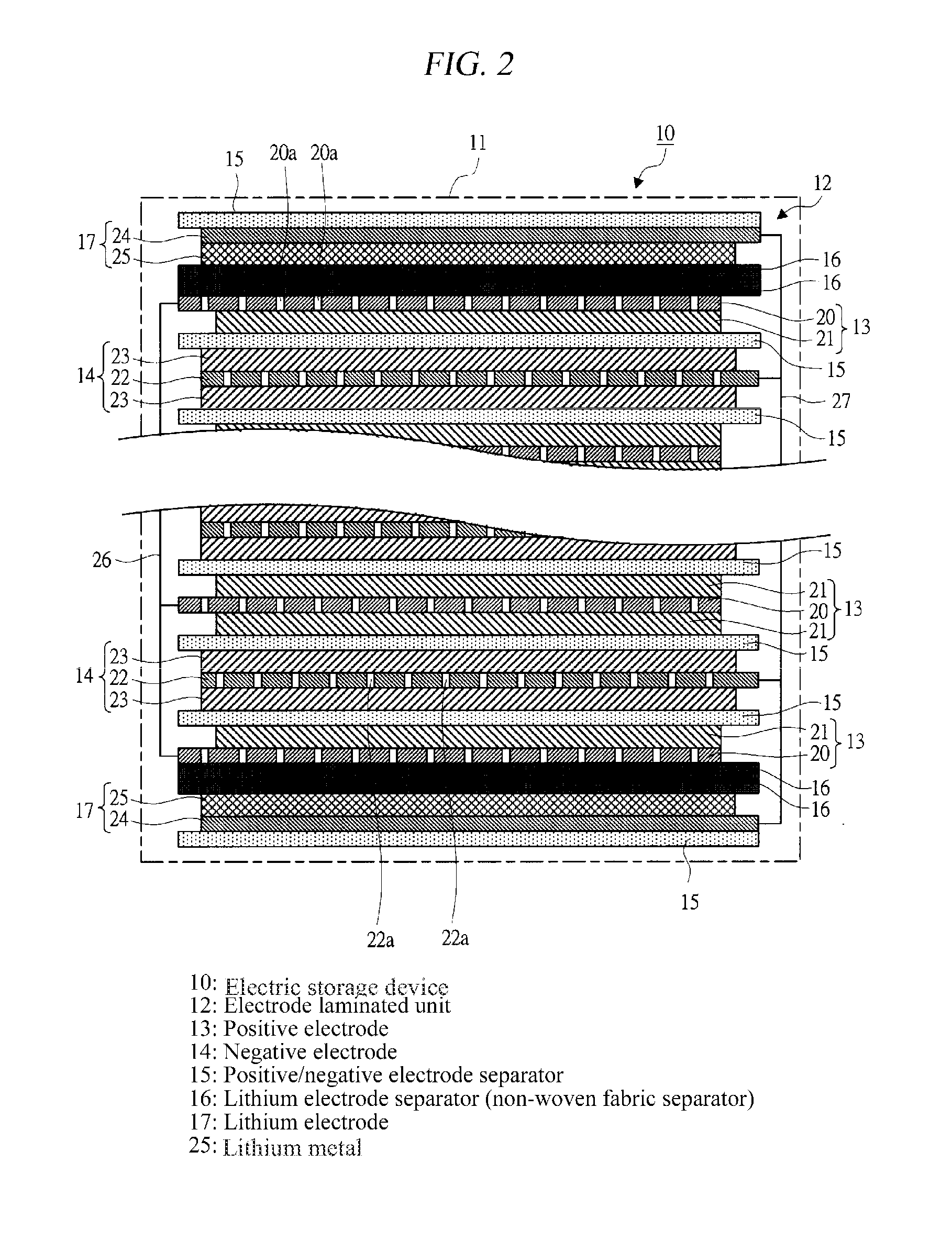

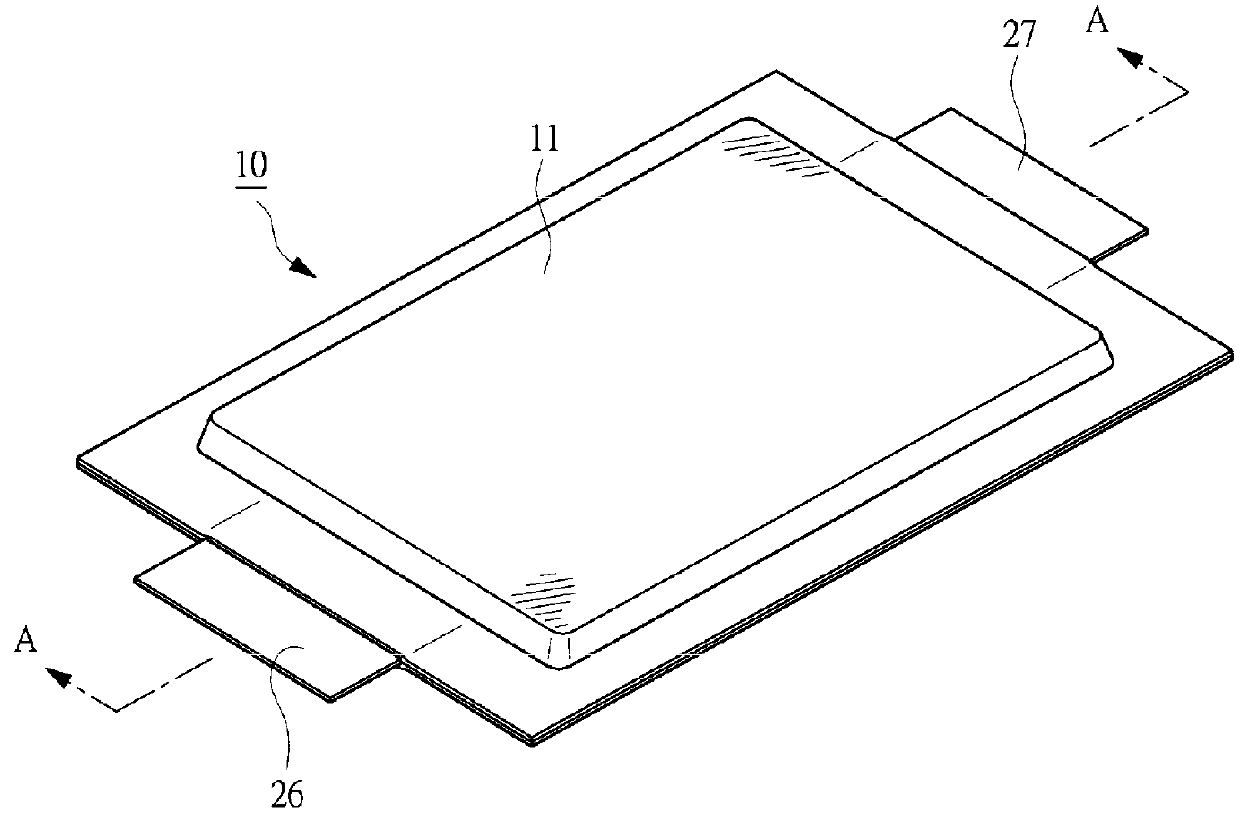

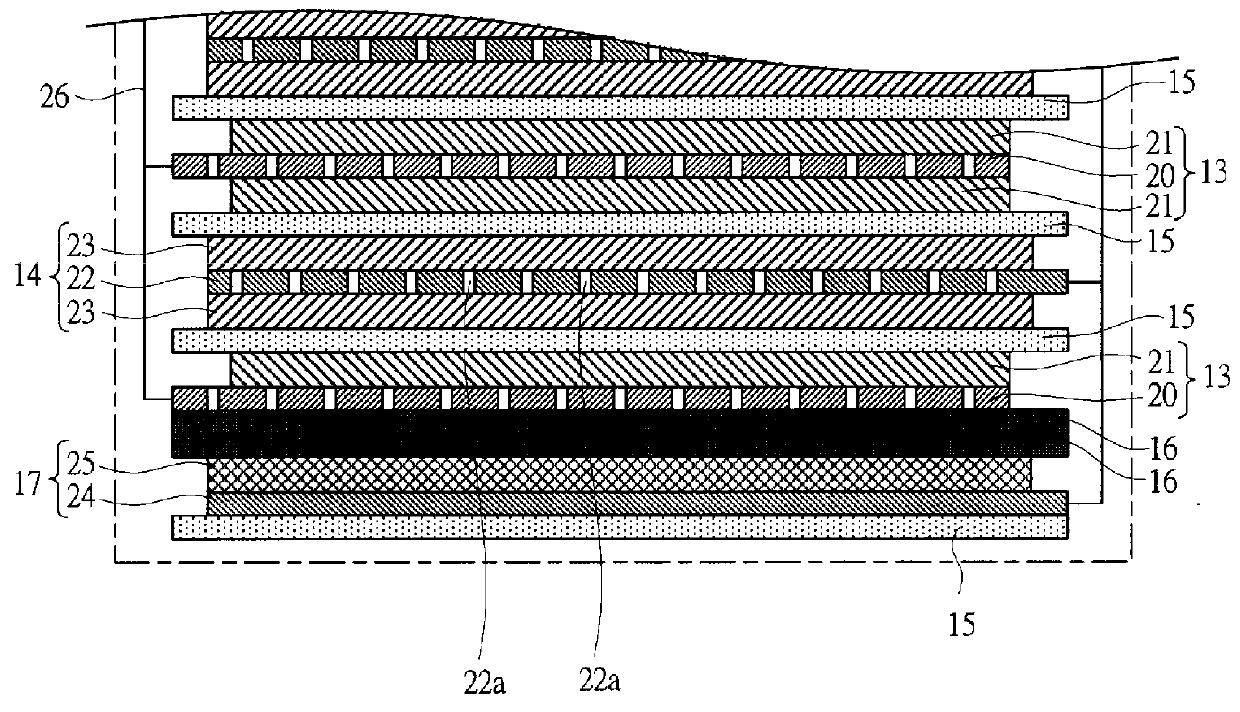

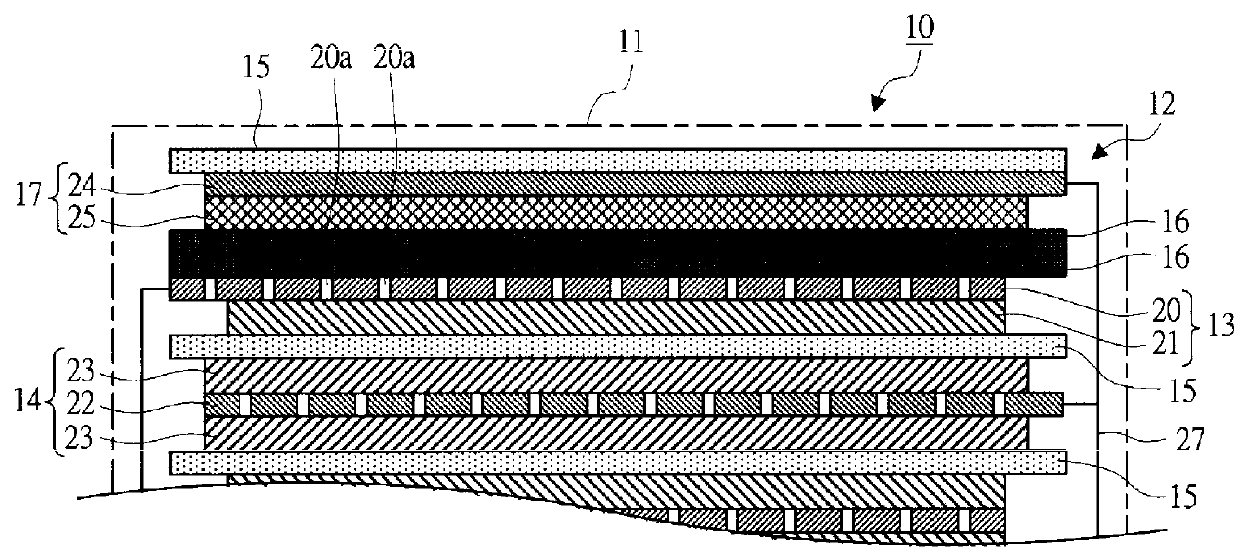

Electric storage device

ActiveUS20110236763A1Excellent liquid retentionProcess stabilityHybrid capacitor separatorsHybrid capacitor electrodesLithium metalEngineering

In an electric storage device, lithium electrodes are disposed on respective outermost portions of an electrode laminated unit in which a positive electrode and a negative electrode are laminated alternately via positive / negative electrode separators. The lithium electrode includes lithium metal serving as a lithium ion supply source, and a lithium electrode separator (a non-woven fabric separator) constituted by a non-woven fabric that satisfies the following conditions: (a) an average fiber diameter of 0.1 μm to 10 μm; and (b) a thickness of 5 μm to 500 μm is provided. By forming the lithium electrode separator that contacts the lithium electrode including the lithium ion supply source from a non-woven fabric in this manner, a dramatic improvement can be achieved in the cycle characteristic of the electric storage device.

Owner:SUBARU CORP

Electric storage device

ActiveUS9231238B2Excellent liquid retentionProcess stabilityHybrid capacitor separatorsHybrid capacitor electrodesElectricityLithium metal

In an electric storage device, lithium electrodes are disposed on respective outermost portions of an electrode laminated unit in which a positive electrode and a negative electrode are laminated alternately via positive / negative electrode separators. The lithium electrode includes lithium metal serving as a lithium ion supply source, and a lithium electrode separator (a non-woven fabric separator) constituted by a non-woven fabric that satisfies the following conditions: (a) an average fiber diameter of 0.1 μm to 10 μm; and (b) a thickness of 5 μm to 500 μm is provided. By forming the lithium electrode separator that contacts the lithium electrode including the lithium ion supply source from a non-woven fabric in this manner, a dramatic improvement can be achieved in the cycle characteristic of the electric storage device.

Owner:SUBARU CORP

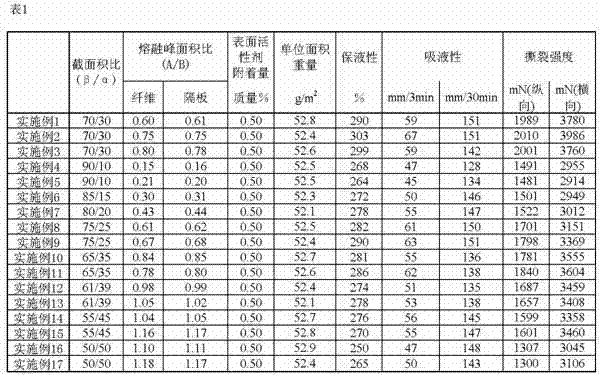

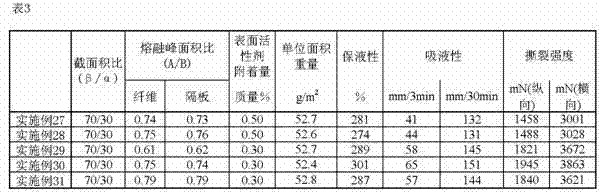

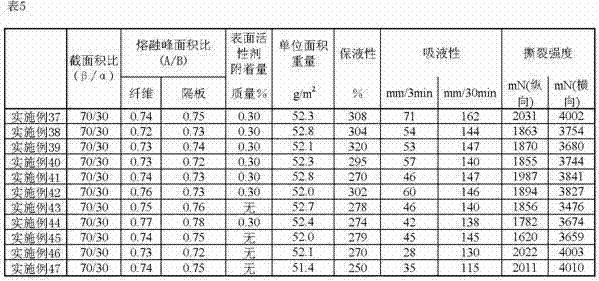

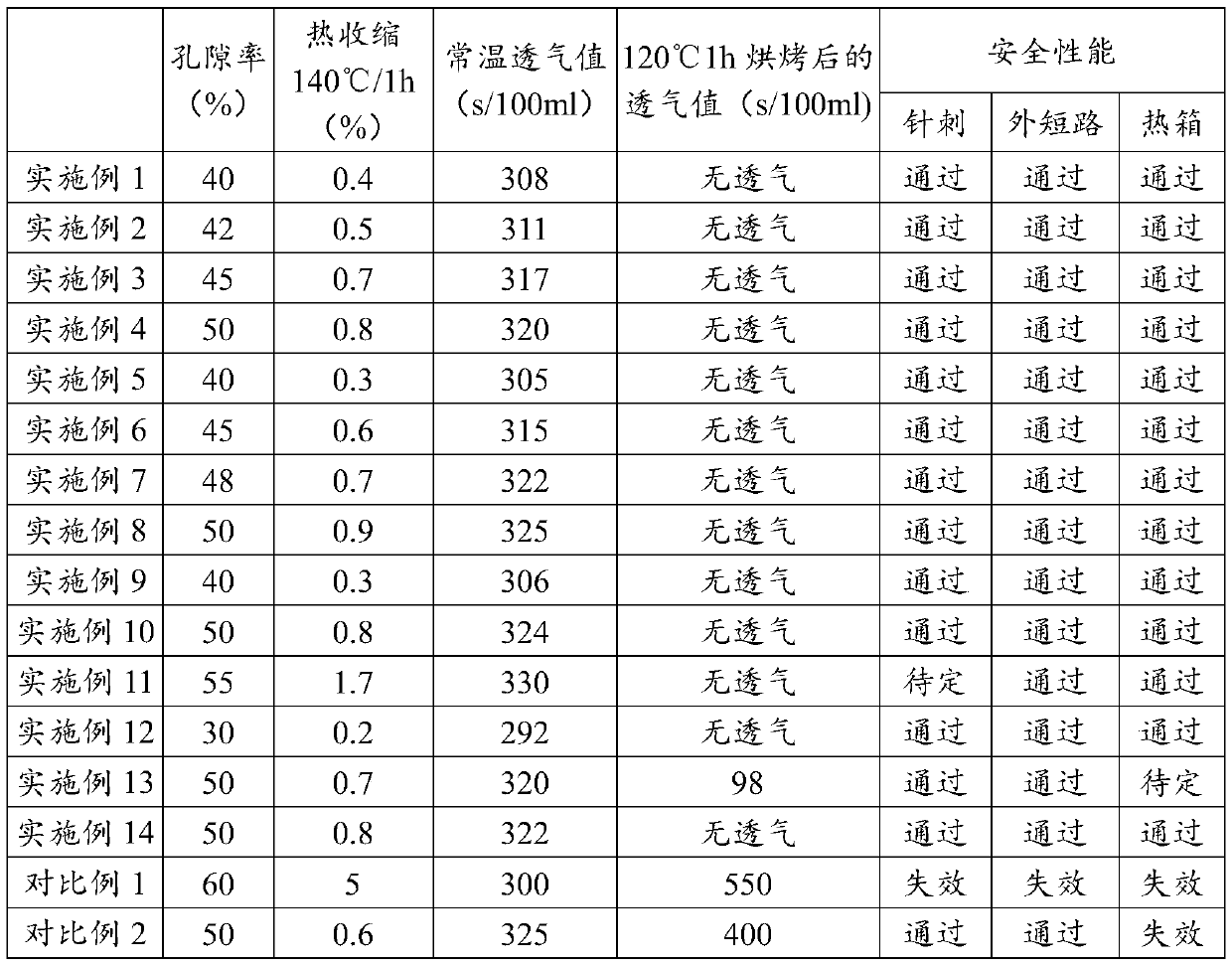

Septum used in battery

ActiveCN102903878AExcellent uniformity of qualityGood tear strengthCell component detailsPolypropylenePeak area

The invention provides a septum used in a battery which is suitable to be used in nickel-cadmium battery, nickel-zinc battery, nickel-hydrogen battery, and other alkaline rechargeable batteries. The septum has excellent tear strength, and using a surfactant makes for reducing short circuit incidence rate. The septum is made of non-woven fabric which is processed by hydrophilization. The septum used in the battery is formed by a core-sheath type complex fibernon-woven fabric, with polypropylene as composition of a core and polyethylene as composition of a sheath. The septum is characterized in that a ratio ([beta / alpha]) of a sectional area ([beta]) of polypropylene and a sectional area ([alpha])ofpolyethylene is larger than 50 / 50 and is lower than 90 / 10. In a DSC curve obtained by differential scanning thermal analysis of the septum used in the battery, a ratio (A / B) of fusing peak area (A) from the polyethylene on a low-melting-point side and fusing peak area (B) from the polypropylene on a high-melting-point side is larger than 0.15 and lower than 1.20.

Owner:MITSUBISHI PAPER MILLS LTD

Battery diaphragm and preparation method thereof, and lithium ion battery containing diaphragm

InactiveCN109841785AImprove performanceImprove insulation performanceCell component detailsSecondary cells servicing/maintenanceFiberGlass fiber

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a battery diaphragm. The battery diaphragm includes a diaphragm base layer and a hot-melt polymer layer arranged on at least one surface of the diaphragm base layer. The diaphragm base layer includes at least one of glass fibers and ceramic fibers, and first adhesive. The hot-melt polymer layer includes a hot-melt polymer and second adhesive. Compared with the prior art, the diaphragm has better thermal stability, higher mechanical strength and stronger liquid retention and absorption capacity. In addition, the invention provides a preparation method of the battery diaphragm and a lithium ion battery containing the diaphragm.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

Preparation method of material for abdominal wall defect intraperitoneal repair, and obtained material thereof

InactiveCN104826168AGood mechanical propertiesGood biocompatibilityProsthesisPolypropylene meshBiocompatibility Testing

The present invention discloses a preparation method of a material for abdominal wall defect intraperitoneal repair, and the obtained material thereof. The preparation method comprises: 1, preparing a quaternized bacterial cellulose solution; 2, carrying out polydopamine modification on a polypropylene mesh sheet; and 3, coating the quaternized bacterial cellulose solution on the obtained polypropylene mesh sheet. The present invention further provides the material used for the abdominal wall defect intraperitoneal repair and obtained through the process. The obtained material of the present invention has characteristics of good mechanical property, good biocompatibility, good adhesion resistance and good antibacterial property.

Owner:王辉 +4

Diaphragm coat composition, slurry and preparation method thereof, diaphragm and lithium ion battery

InactiveCN109065812AImprove breathabilityImprove performanceSecondary cellsCell component detailsPolymer scienceAdhesive

A lithium ion battery separator coat composition, slurry and preparation method thereof, separator and lithium ion battery are disclosed. The membrane coating composition comprises, in parts by weight, 8-30 part of polymer, 3-10 part of dispersant, 0.2-1.0 part of wetting agent, 2-6 part of adhesive and 0.05-0.5 part of defoamer. The slurry comprises a diaphragm coating composition and a solvent;A dispersant and a wetting agent are dissolved in a solvent and added with a polymer, and after stirring, a binder and a defoaming agent are sequentially added and stirred to obtain the product. The diaphragm provided by the present invention includes a base film and a polymer coating coated on one or both sides of the base film, the polymer coating being formed by drying the slurry coated on oneor both sides of the base film. A membrane coat composition, a slurry and a preparation method thereof can be used to prepare a high permeability coat membrane without changing existing coating equipment, and when apply to a lithium ion battery, that performance of the battery can be improved.

Owner:RUYUAN DONGYANG LIGHT FLUORINE RESIN CO LTD

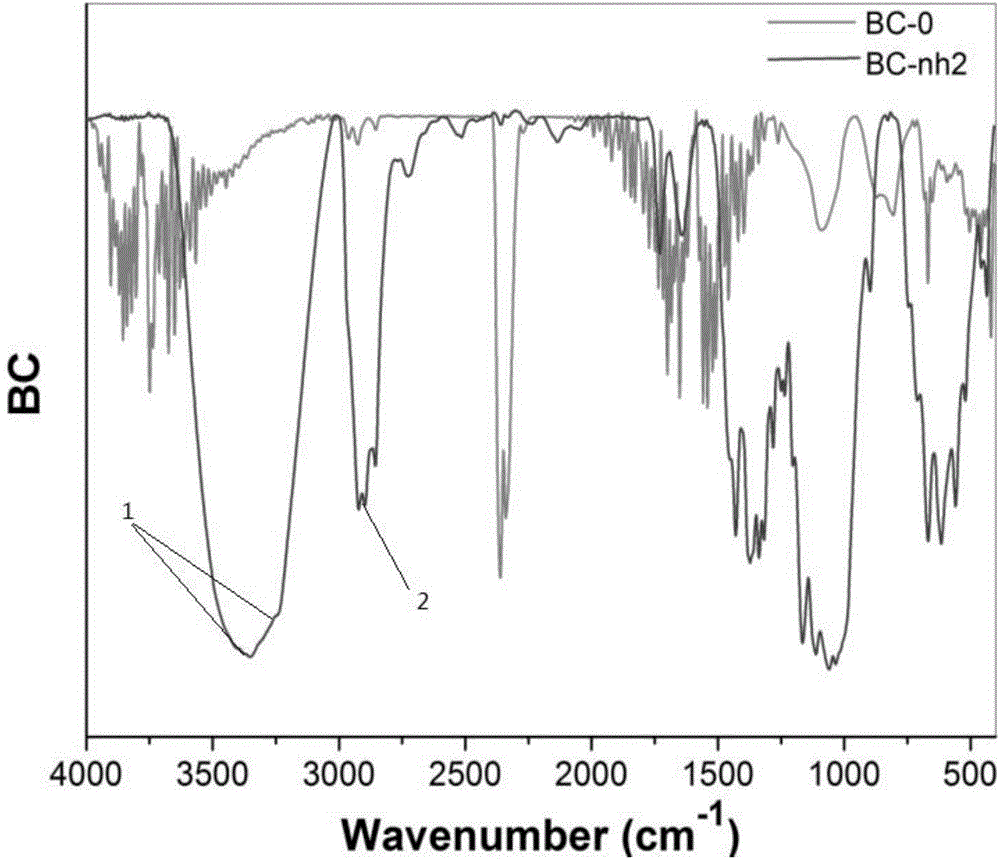

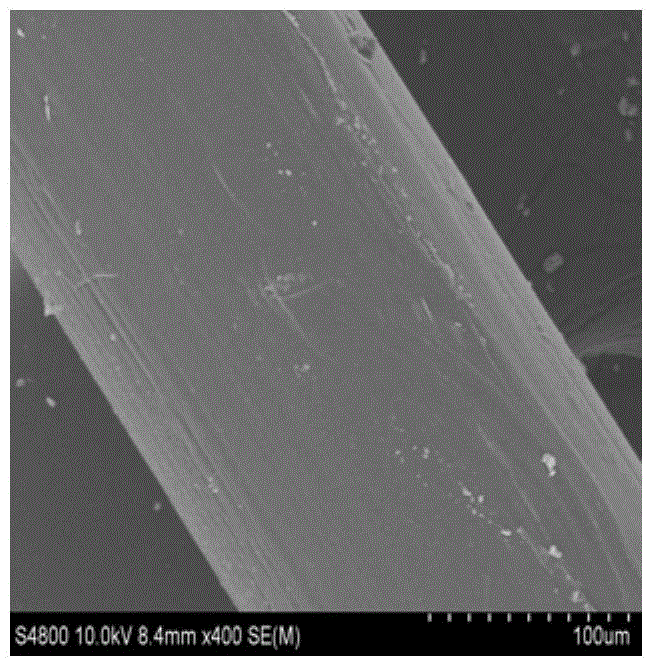

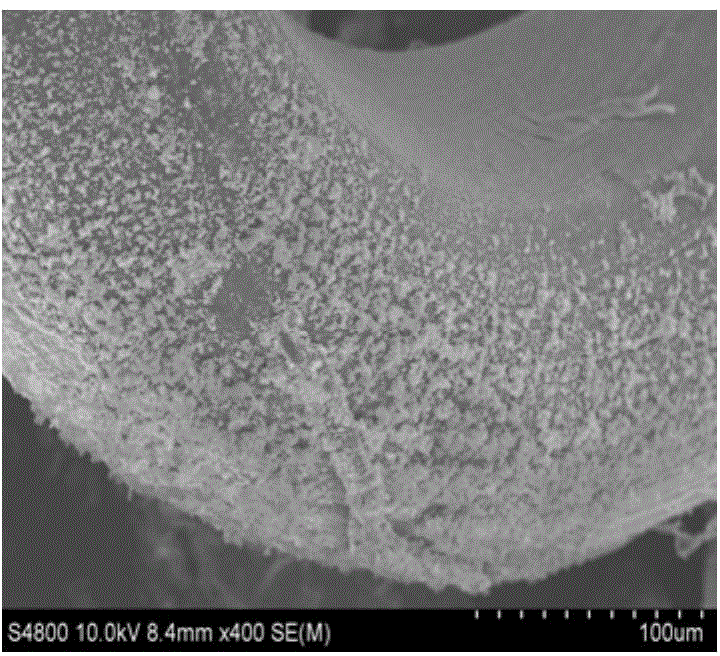

Bacterial cellulose/fabric laminated composite material and preparation method thereof

ActiveCN103938447AEasy to operateEasy to usePhysical treatmentFibre typesOxygen plasmaUltraviolet lights

The invention discloses a bacterial cellulose / fabric laminated composite material and a preparation method thereof. The preparation method comprises the following steps: (1) inoculating acetobacter xylinum into a fluid medium for enlarged cultivation; (2) appropriately cutting a fabric and treating with low-temperature oxygen plasmas or aqueous alkali, or through ultraviolet light surface grafting; and sterilizing and then drying the fabric; (3) arranging the medium containing floccules into a culture dish, spreading the treated fabric on bacterium solution, adding the medium containing floccules into the fabric, and arranging in a biochemical incubator until the laminated composite material is formed; and (4) soaking the composite material with deionized water at normal temperature, soaking the composite material with sodium hydroxide solution for two days, and soaking the composite material with deionized water until the composite material is neutral. The composite material is formed at a time, the appetency of the single fabric and the texture is improved, and the water retainability and the transdermal absorption ratio of the fabric are improved; meanwhile, the operation is convenient and simple and the using efficacy is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

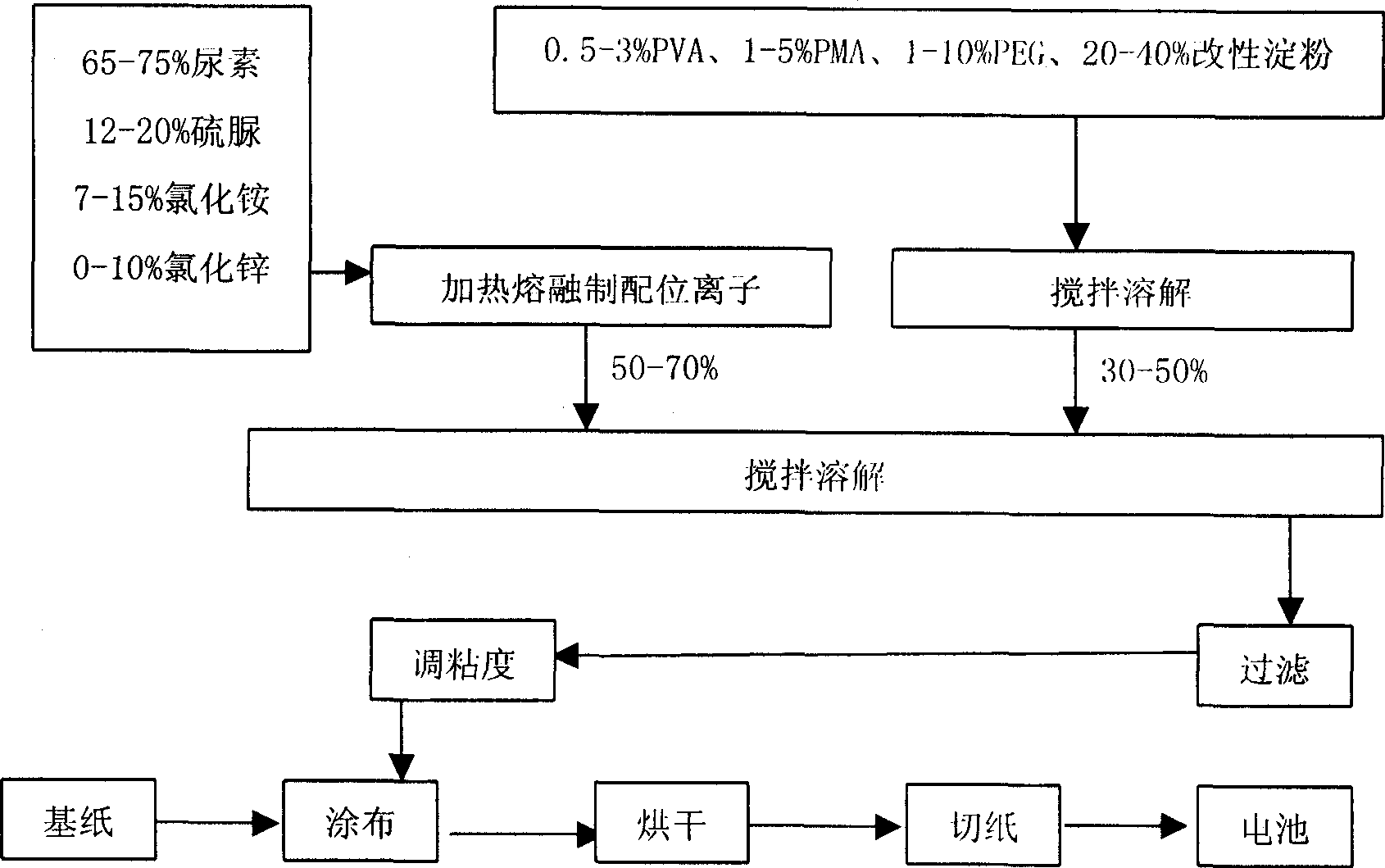

Non-mercury pulp layered paper of zinc-manganese battery containing high-polymer solid electrolyte

InactiveCN1673455ALower internal resistanceIncrease short circuit currentNon-fibrous pulp additionCell seperators/membranes/diaphragms/spacersInternal resistanceThiourea

The present invention relates to one kind of slurry paper for no-mercury Zn-Mn cell with polymer electrolyte. The slurry paper includes base paper and slurry, and the slurry consists of one kind of polymer gel prepared with coordination ion liquid and organic mercury-replacing buffer liquid. The coordination ion liquid is prepared with urea, thiourea, zinc chloride and ammonium chloride; and the polymer gel is prepared with coordination ion liquid, PVA, PAM, PEG and crosslinking starch in certain proportion. The no-mercury Zn-Mn cell with polymer electrolyte can decrease the internal resistance of cell, improve dynamic discharge performance of cell, prolong the maintenance time and avoid environmental pollution caused by mercury.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

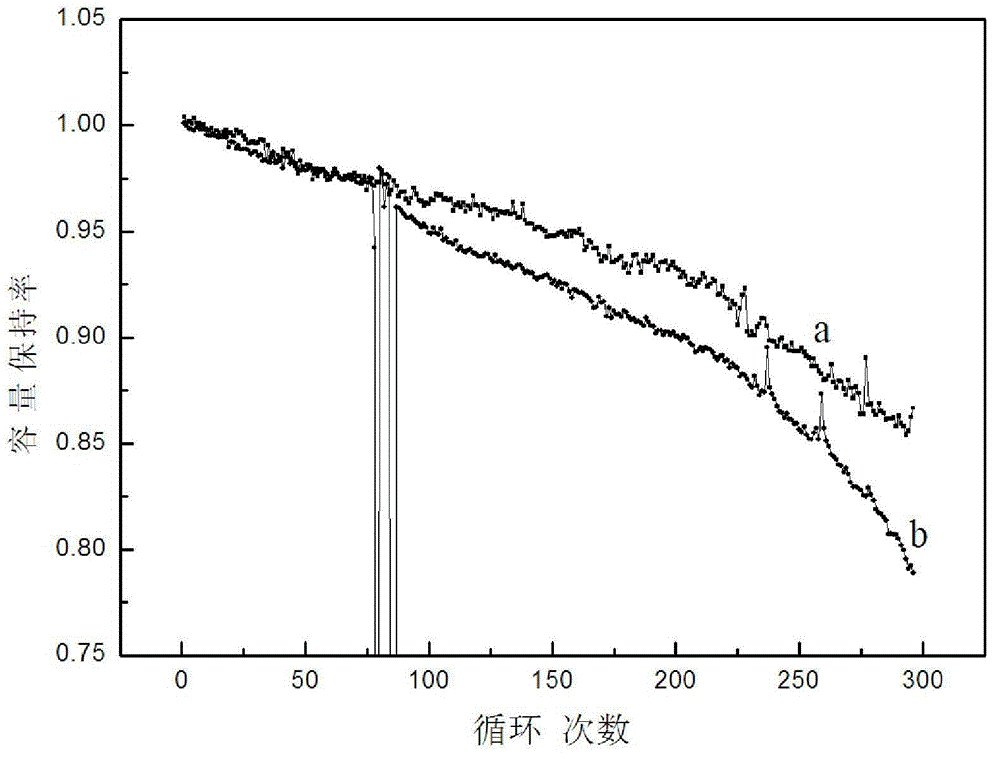

Secondary lithium ion battery and preparation method thereof

InactiveCN102709595APrevent escapePrevent electrodepositionCell electrodesFinal product manufactureLithium-ion batteryInorganic materials

The invention relates to a secondary lithium ion battery and a preparation method thereof. The secondary lithium ion battery comprises an anode, a cathode, a diaphragm and a non-water electrolyte, wherein the surface of the cathode is coated with a mixture containing an anode exchange mateiral and an inorganic material, the anode exchange material is aluminosilicate or phosphoaluminate containing anions of lithium, sodium and ammonium, the inorganic material is Al2O3 or SiO2, and in addition, the mass ratio of the anode exchange material to the inorganic material is (1:50)-(10:1). Compared with the traditional lithium ion battery, the lithium ion battery disclosed by the invention is obviously promoted in safety performance and cycle performance, and is long service life and suitable for large-scale industrial production.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

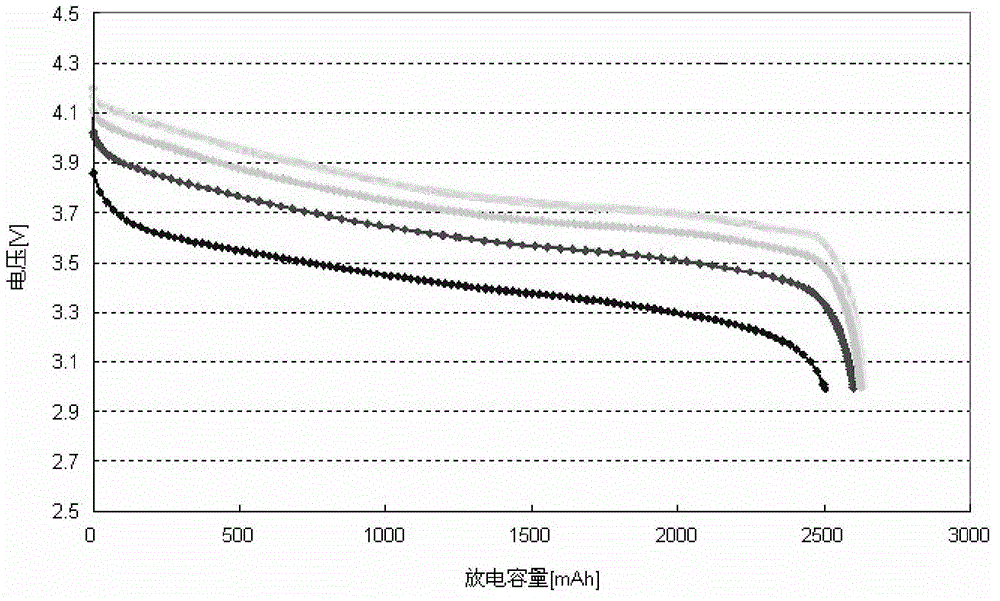

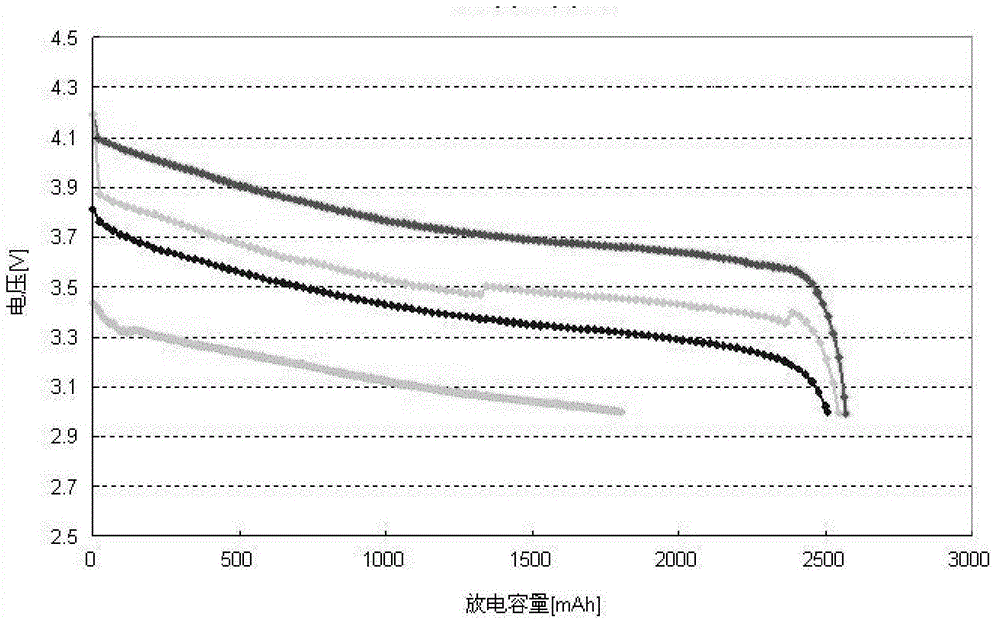

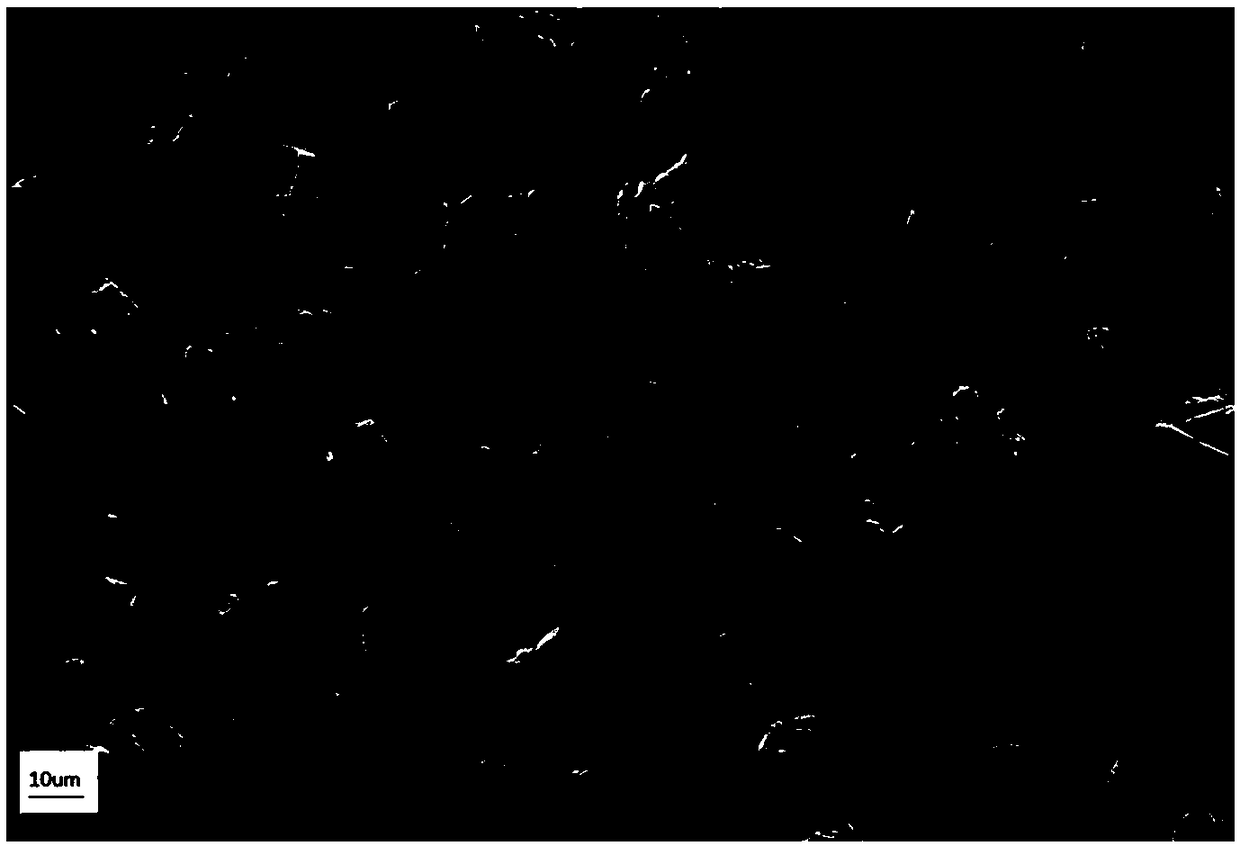

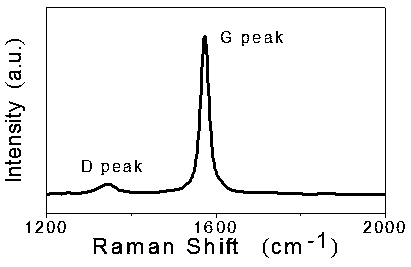

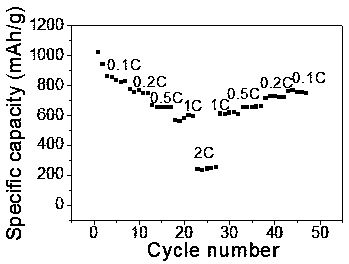

Small-size graphene positive electrode material for lithium-sulfur battery, lithium-sulfur battery prepared by small-size graphene positive electrode material and preparation method

ActiveCN107611395AImproved magnification performanceImprove wettabilityCell electrodesFinal product manufactureElectrolysisLithium sulfur

The invention discloses a small-size graphene positive electrode material for a lithium-sulfur battery, the lithium-sulfur battery prepared by the small-size graphene positive electrode material and apreparation method and belongs to the field of battery materials. The preparation method comprises the steps of preparing small-size graphene through electrolyzing microcrystalline graphite powder; compounding the small-size graphene or surface-modified small-size graphene, such as the small-size graphene-modified by sodium carboxymethyl cellulose, sulfate, silicate, metal ions, a metal oxide, anon-metallic element or a high polymer material and sulfur at the mass ratio of 2:(1-9) to prepare the positive electrode material for the lithium-sulfur battery; and then preparing the lithium-sulfurbattery by adopting metal lithium as a negative electrode. The prepared lithium-sulfur battery is a real sense of graphene lithium-sulfur battery, the graphene is only used as an additive in the other lithium-sulfur batteries, and the prepared lithium-sulfur battery is fundamentally different from the other lithium-sulfur batteries. The positive electrode material for the lithium-sulfur battery is high in specific capacity, good in cycle performance, high in security, high in conductivity and low in cost, and has a very broad market prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com