Novel battery

A new type of battery technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve the problems of low specific energy, heavy pollution, short life, etc., and achieve the effect of solving the dendrite problem and prolonging the cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take 10kg of manganese dioxide (Tianjin Guangcheng Chemical Reagent Co., Ltd., AR grade, the same below), polyaniline (Shijiazhuang Ji’an Yada New Material Co., Ltd., conductive state, the same below) 4kg, colloidal graphite (Qingdao Tianheda) Graphite Co., Ltd., S-2, the same below) 1kg, after being ground for 12 hours by ball milling, it was taken out. Add 4kg of electrolyte to mix and stir to obtain a viscous slurry. Take the above slurry, at 2.7t / cm 2 Under pressure, it was pressed into a cylindrical shape with a diameter of 12 mm. Take another zinc skin cylinder, put it into the cut diaphragm, press and fix it, then put the above-mentioned manganese dioxide / polyaniline / carbon cylinder material into the cylinder, and the carbon rod machine will nail the carbon rod of the positive electrode current collector. Then inject the electrolyte until it is fully wetted, then add glass fiber paper to seal the top, and then seal it with a rubber gasket.

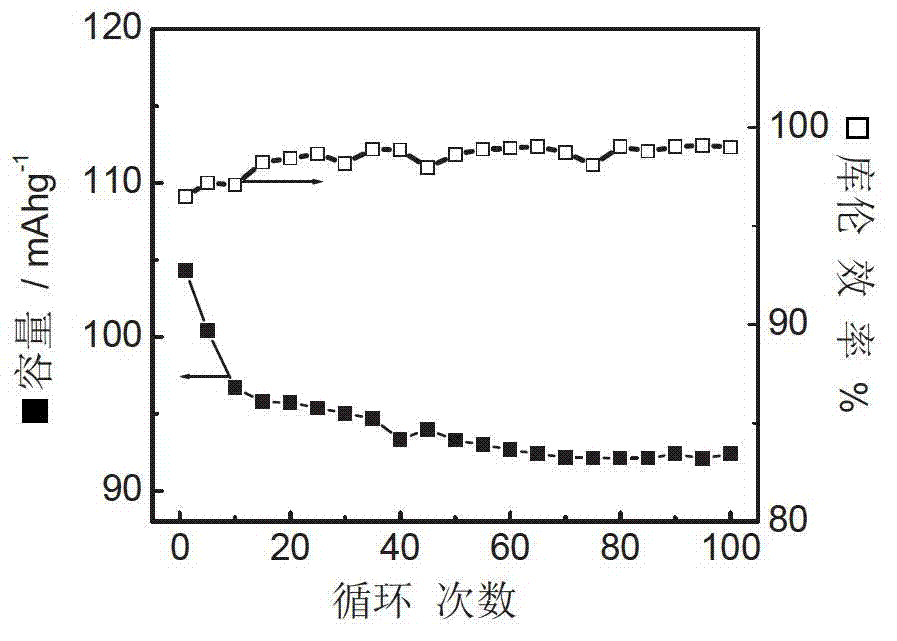

[0042] After stand...

Embodiment 2

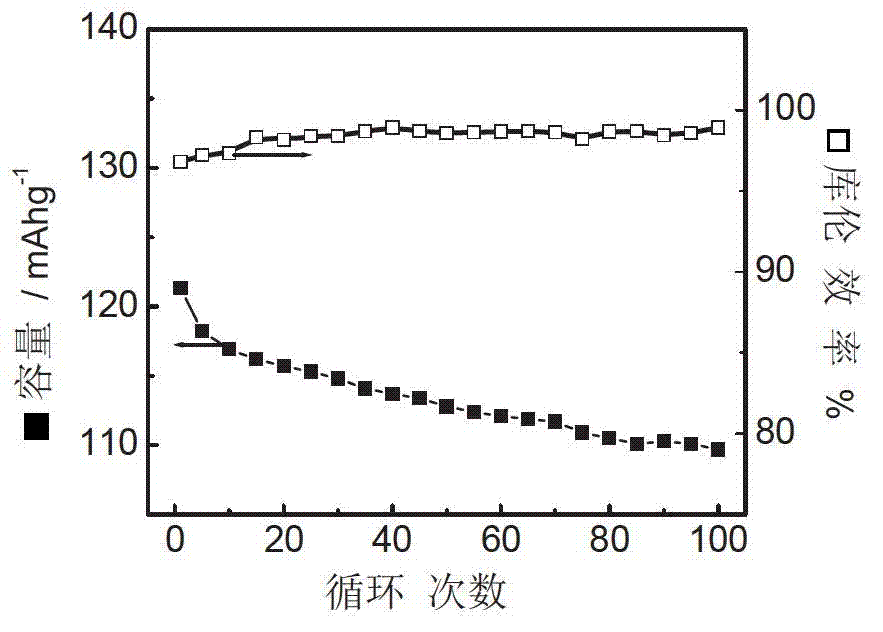

[0044] Take 34.7kg of deionized water, add 10kg of polyaniline, stir and disperse evenly, add 100ml of sulfuric acid (Shenzhen Likexian Technology Co., Ltd., AR grade), and then add manganese sulfate monohydrate (Hebei Hengji Manganese Industry Co., Ltd., AR grade) ) 19.4kg, stir until all dissolved. Take another 25.3 kg of deionized water, add 26.3 kg of ammonium persulfate, and stir until dissolved. After mixing the above two solutions evenly, raise the temperature to 80°C while stirring, react at constant temperature for 24 hours, then cool to room temperature naturally, filter with suction, wash with deionized water until the solution is neutral, and dry it in vacuum for 24 hours. What is obtained is a manganese dioxide / polyaniline composite material with good uniformity. Take 14 kg of the above-mentioned composite material, add 1 kg of colloidal graphite, stir and disperse evenly, then add 4 kg of electrolyte, and stir for 50 min to obtain a viscous manganese dioxide / pol...

Embodiment 3

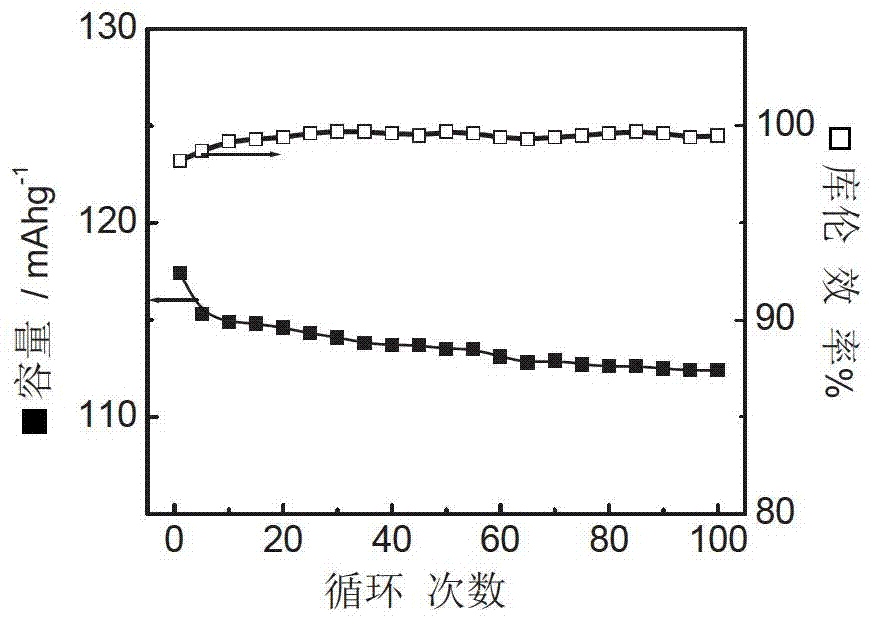

[0047] Take 40kg of deionized water, add 3.9kg of concentrated hydrochloric acid (Qingzhou Hongtong Chemical Co., Ltd., AR grade), cool down to 5°C, add 1.8kg of aniline while stirring, stir and cool down until the aniline is completely dissolved and the temperature drops to 5°C; take another 5kg of deionized water, add 0.5kg of concentrated hydrochloric acid, and then add 4.4kg of ammonium persulfate (Wujiang Yonghe Fine Chemical Co., Ltd., AR grade), stir until the ammonium persulfate is completely dissolved, and cool down to 10°C; Mix the above two solutions quickly and evenly. When the solution changes color 5 minutes later, add 7kg of manganese dioxide, stir quickly, control the reaction temperature at about 10°C, and react for 30 minutes; filter, wash with deionized water until the solution pH is greater than 5, and vacuum dry Just 24 hours, at this time, a manganese dioxide / polyaniline composite material with good uniformity is obtained. Take 4.9 kg of the above composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com