Septum used in battery

A battery and separator technology, which is applied in the field of battery separators, can solve the problems of battery separators such as reduced voids, reduced tear strength, reduced liquid absorption or liquid retention, and achieves excellent quality uniformity and tear resistance. excellent cracking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0061] A core-sheath composite fiber (cross-sectional area ratio (β / α) = 70 / 30, melting peak area ratio (A / B ) = 0.60, fineness 0.8dtex, fiber length 5mm) 100 parts by mass were dissociated and dispersed in the water of the pulper, and stirred slowly with a stirrer to prepare a uniform slurry for papermaking. The papermaking slurry is made using the wet papermaking method using a cylinder paper machine, and is dried by a Yankee dryer with a hot plate pressing method set at 135°C and a hot air hood installed side by side. The sheath portion of the core-sheath composite fiber was thermally melt-bonded to produce a nonwoven fabric having a width of 500 mm. Alkyl phosphate ester salt (manufactured by Takamatsu Yushi Chemical Co., Ltd., trade name: Elenait AB-100) as a surfactant is impregnated and coated at a concentration of 0.50% by mass, dried, and corona treated. The super calender adjusts the thickness to 120 μm to obtain a battery separator.

Embodiment 2~17)

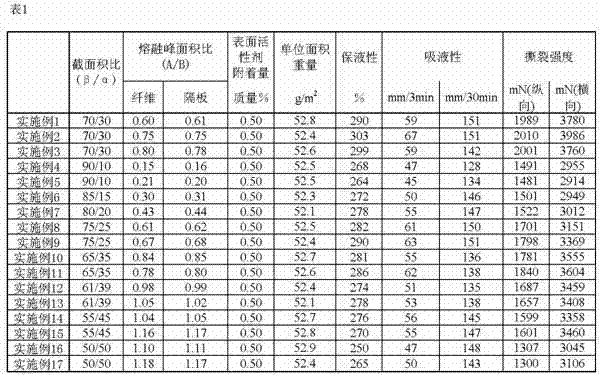

[0063] In addition to using the core-sheath composite fiber (fineness 0.8dtex, fiber length 5mm) having the cross-sectional area ratio (β / α) and melting peak area ratio (A / B) described in Table 1, polypropylene was used as the core component (melting point: 165° C.) and a core-sheath composite fiber in which the sheath component was polyethylene (melting point: 135° C.), a battery separator was obtained in the same manner as in Example 1.

Embodiment 18)

[0065] A core-sheath composite fiber (cross-sectional area ratio (β / α) = 70 / 30, melting peak area ratio (A / B ) = 0.78, fineness 0.8dtex, fiber length 5mm) 100 parts by mass were dissociated and dispersed in the water of the pulper, and stirred slowly with a stirrer to prepare a uniform slurry for papermaking. The papermaking slurry is made using the wet papermaking method using a cylinder paper machine, and is dried by a Yankee dryer with a hot plate pressing method set at 135°C and a hot air hood installed side by side. The sheath portion of the core-sheath composite fiber was thermally melt-bonded to produce a nonwoven fabric having a width of 500 mm. Alkyl phosphate ester salt (manufactured by Takamatsu Yushi Chemical Co., Ltd., trade name: エレナイト AB-100) as a surfactant is impregnated and coated at a concentration of 0.05% by mass, dried, and corona treated. The super calender adjusts the thickness to 120 μm to obtain a battery separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com