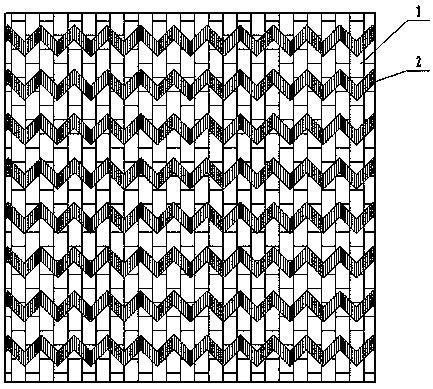

Crossed wavy fabric with comparatively good tearing strength

A wave pattern and fabric technology, applied in the field of fabrics and textile fabrics, can solve the problems of no three-dimensional effect, poor cold-proof effect, and inability to satisfy, and achieve the effect of enhancing the three-dimensional feeling and hand feeling, reasonable structure and good tearing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The object of the present invention is achieved in the following way: a cross-wavy fabric with better tear strength includes a fabric body 1, the outer surface of the fabric body 1 is provided with a number of protrusions 2, and the protrusions 2 are wavy, The protrusions 2 are connected to the fabric body 1 as a whole, and the protrusions 2 are inclined at an angle of 90 degrees to the fabric body 1 and arranged in parallel.

[0014] The fabric body 1 is woven from warp and weft threads, jute fibers are used for the warp threads, and polyvinyl chloride fibers are used for the weft threads, wherein the jute fiber has a diameter of 21.76 μm and a fineness of 253 dtex, and the polyvinyl chloride fiber has a diameter of 45.71 μm and a fineness of 573 dtex , the warp density is 23.8 threads / cm, and the weft density is 54.8 threads / cm.

[0015] The inner surface of the fabric body is provided with a lining fabric layer, the lining fabric layer is a composite fabric, which in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com