Patents

Literature

259results about How to "Increase liquid absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

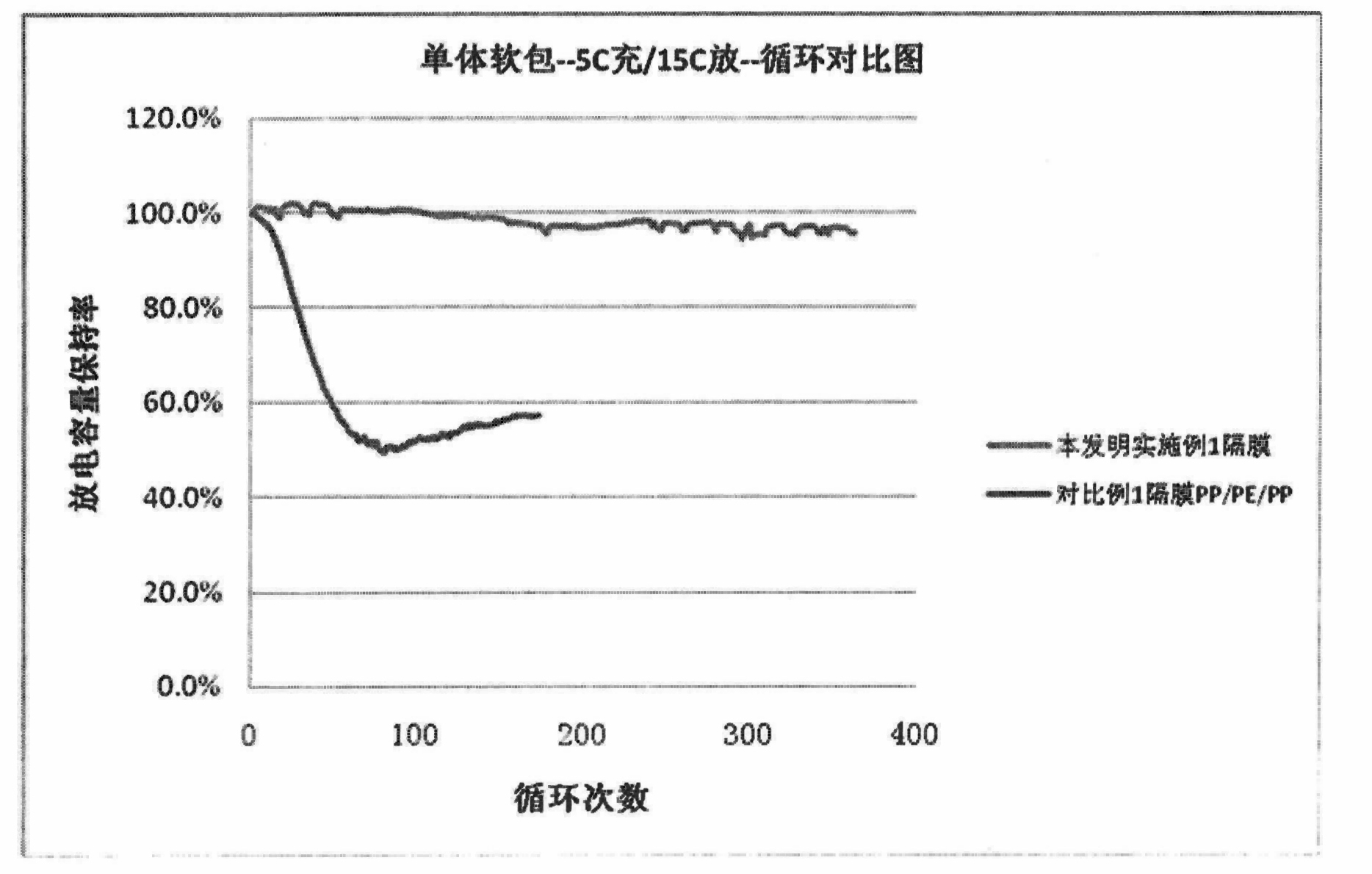

Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

ActiveCN102035043AImprove rate discharge performanceImprove cycle performanceFinal product manufactureSynthetic resin layered productsPolymer electrolytesPolymer science

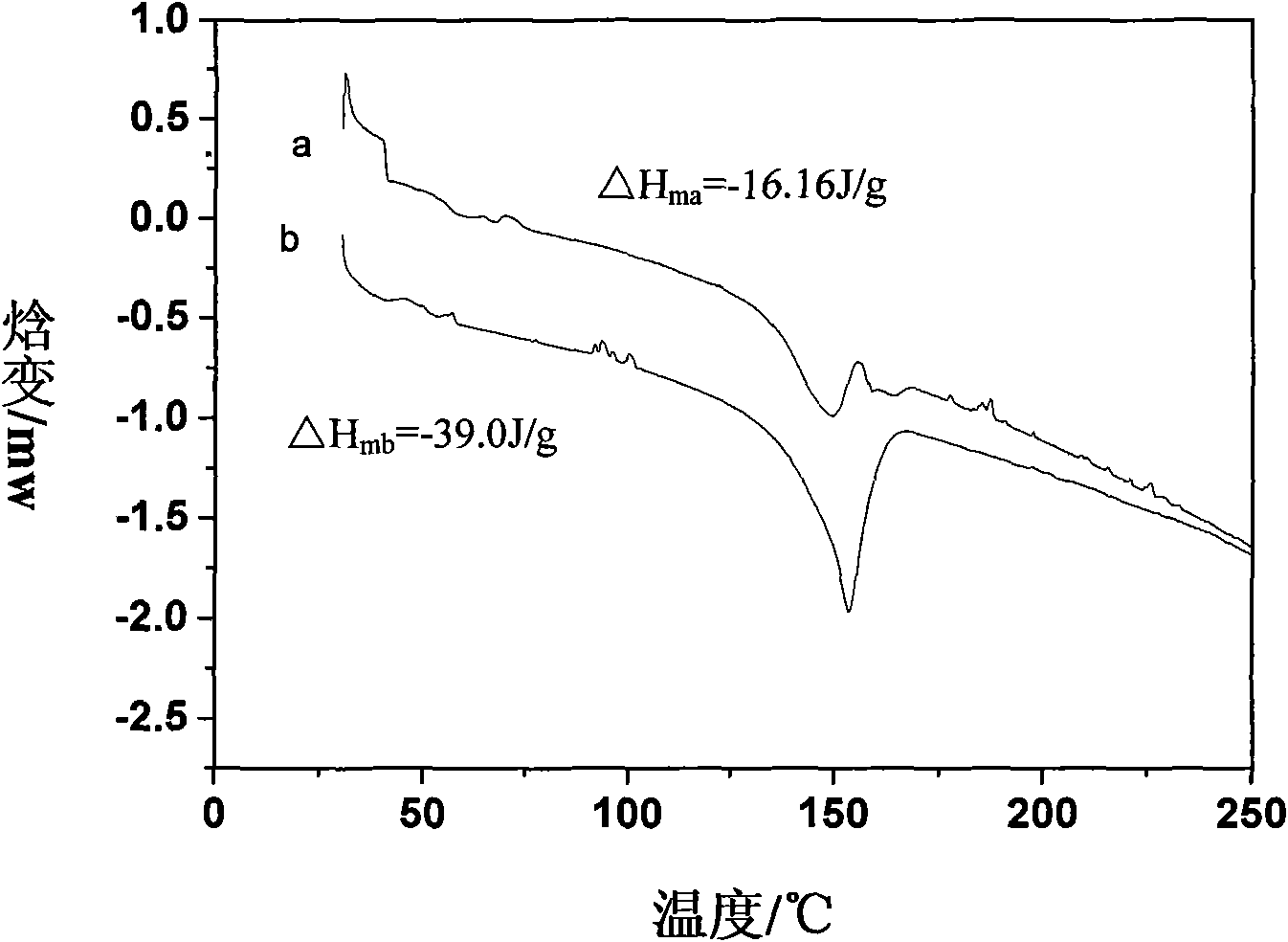

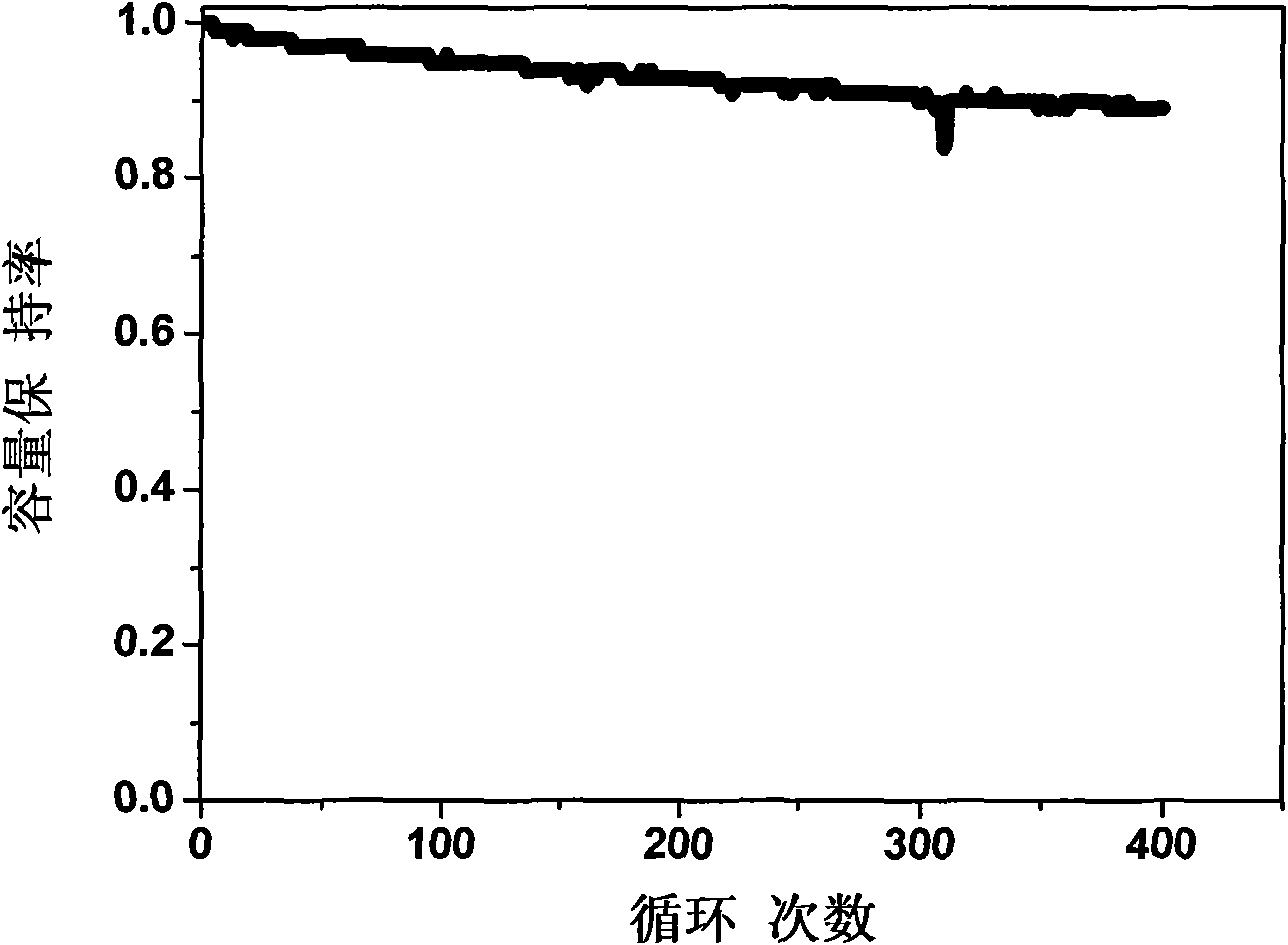

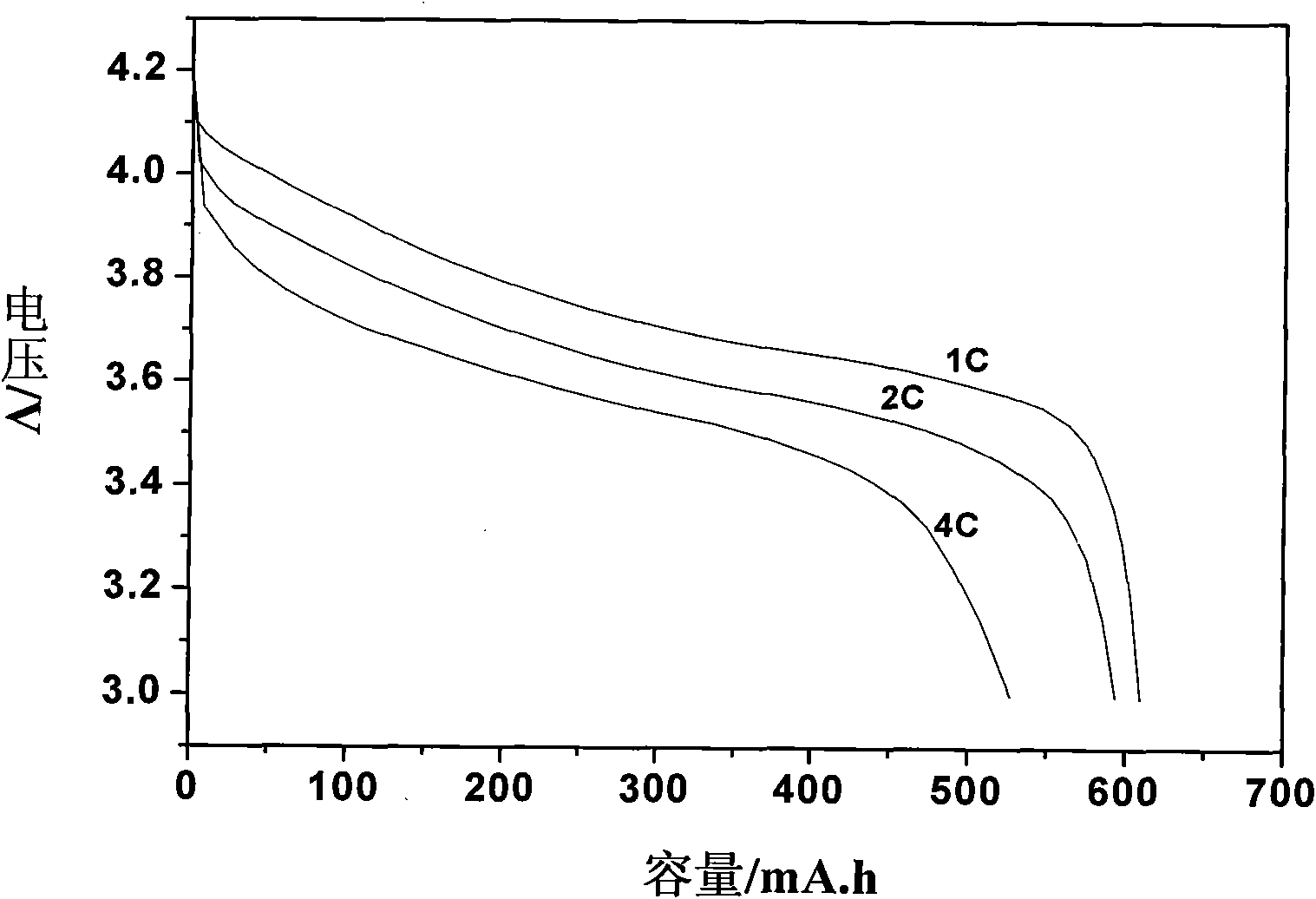

The invention provides a polymer porous membrane, a preparation method of the polymer porous membrane, a polymer electrolyte, a polymer battery and a preparation method of the polymer battery. A carbon material is dispersed in the polymer porous membrane, so that the degree of crystallization of a polymer which constitutes the polymer porous membrane is lowered and the liquid absorption of the polymer porous membrane is increased; the liquid absorption rate, liquid holding capability and ionic conductivity of the polymer porous membrane are increased; interface impedance is reduced, battery magnification discharging performance and the circulating performance of the battery are enhanced; simultaneously, the battery prepared by the method has excellent high temperature circulation and storage performance and low expansion ratio at a high temperature and further meets the development requirement of the polymer battery. Simultaneously, the preparation method is simple and is easy to implement and the prepared battery has high performance.

Owner:SHANGHAI BYD

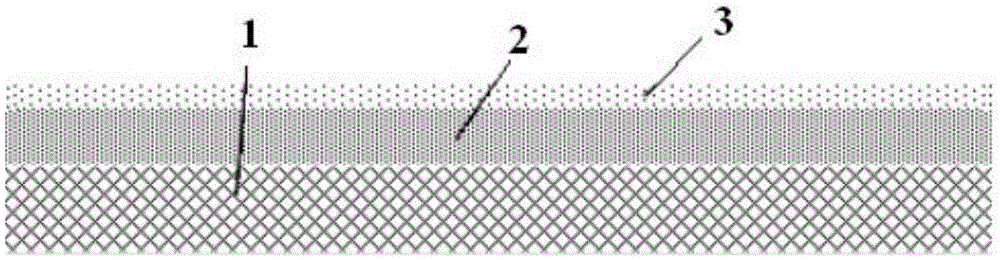

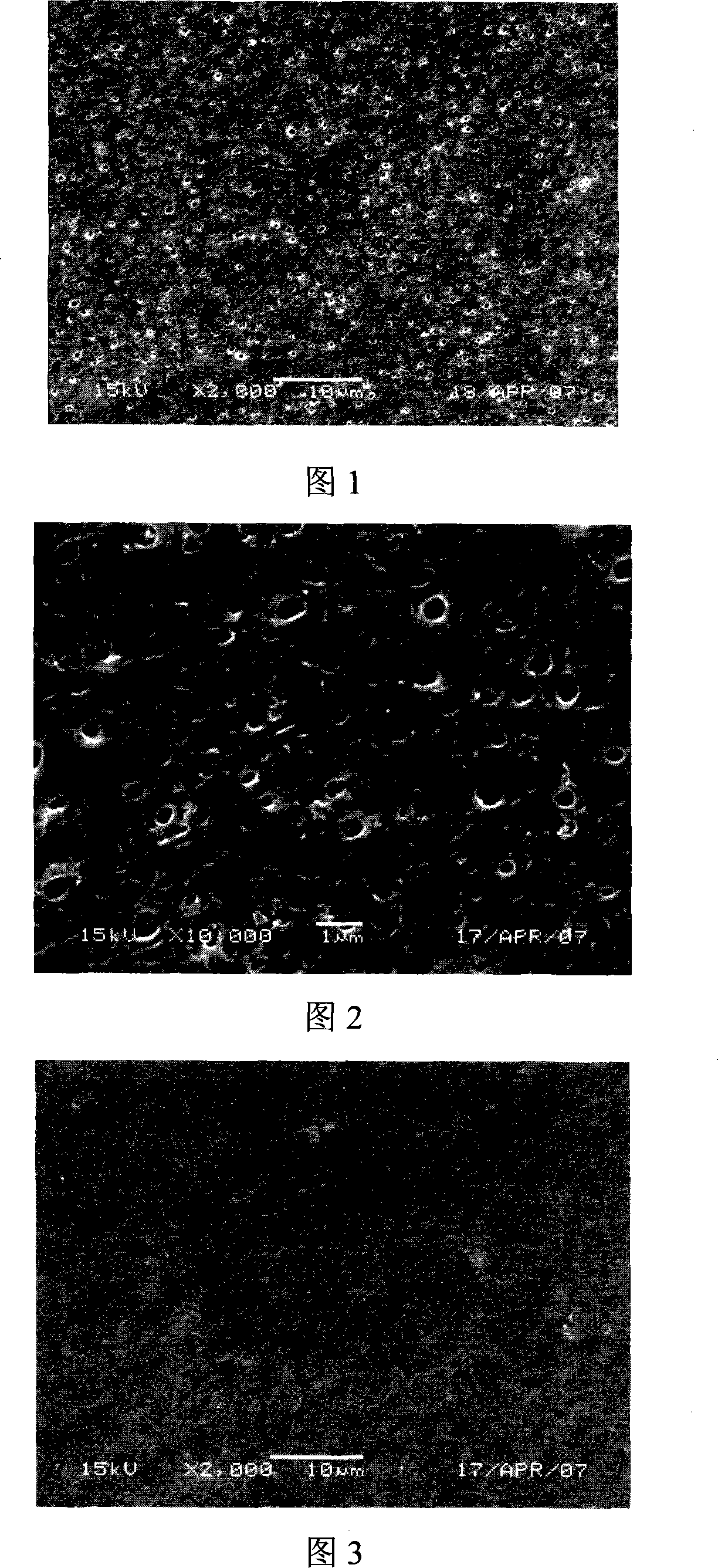

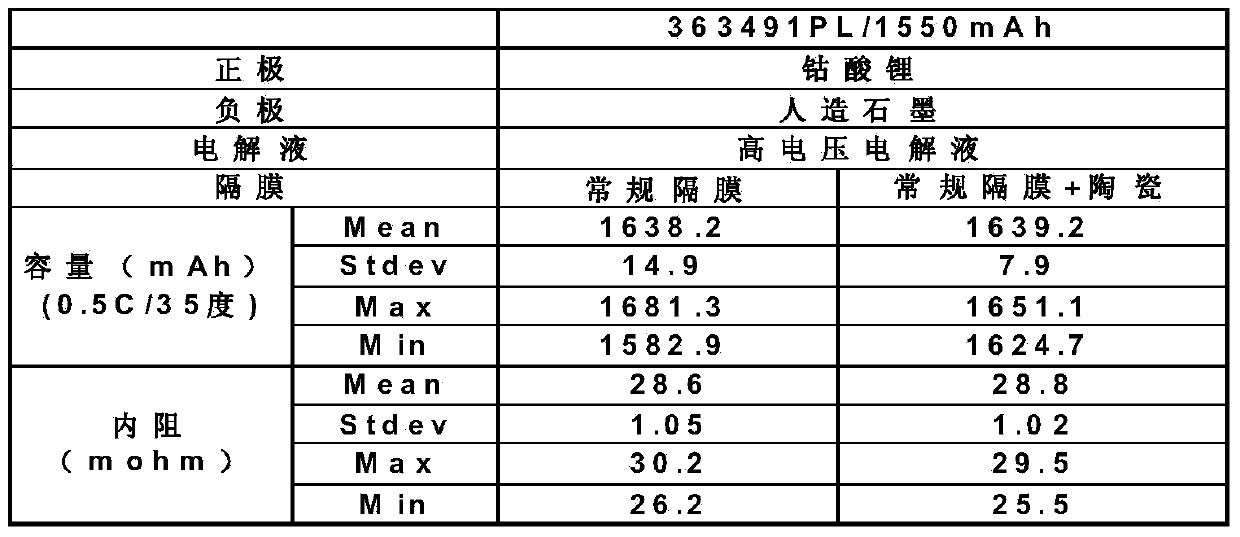

Polymer lithium ion battery and diaphragm thereof

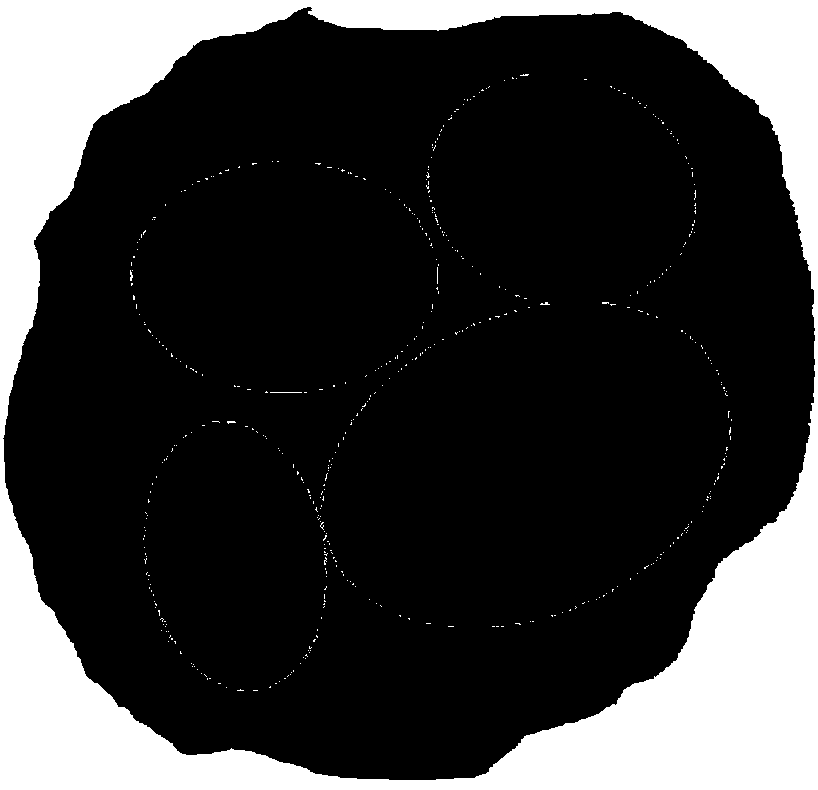

ActiveCN102610773AImprove thermal stabilityImprove mechanical propertiesSecondary cellsCell component detailsCyclic processSwelling capacity

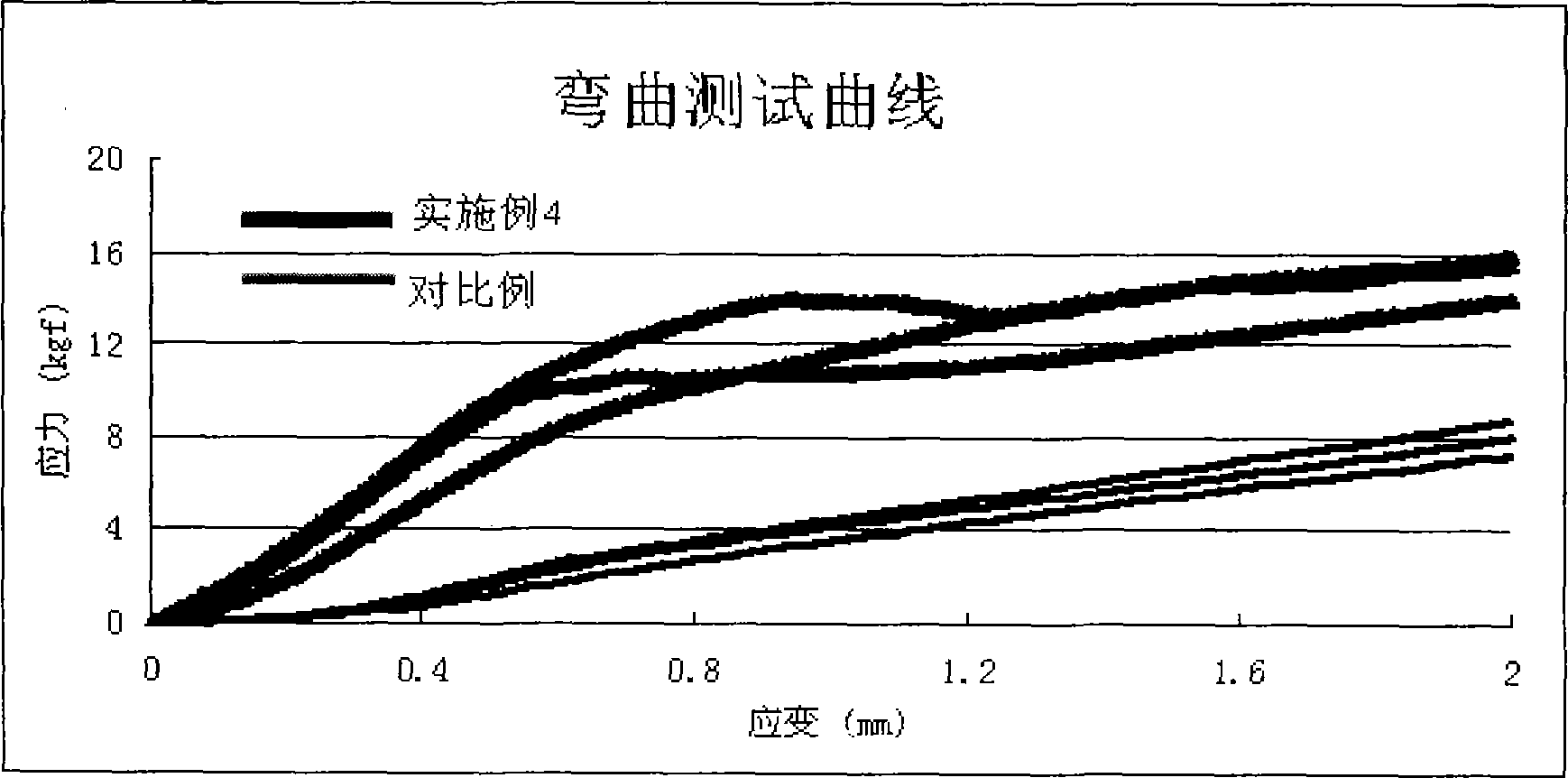

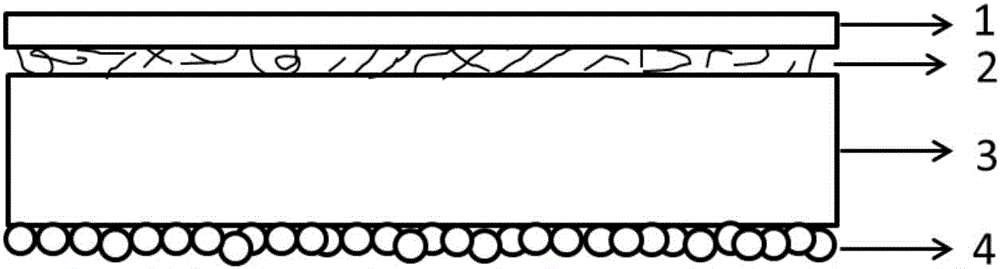

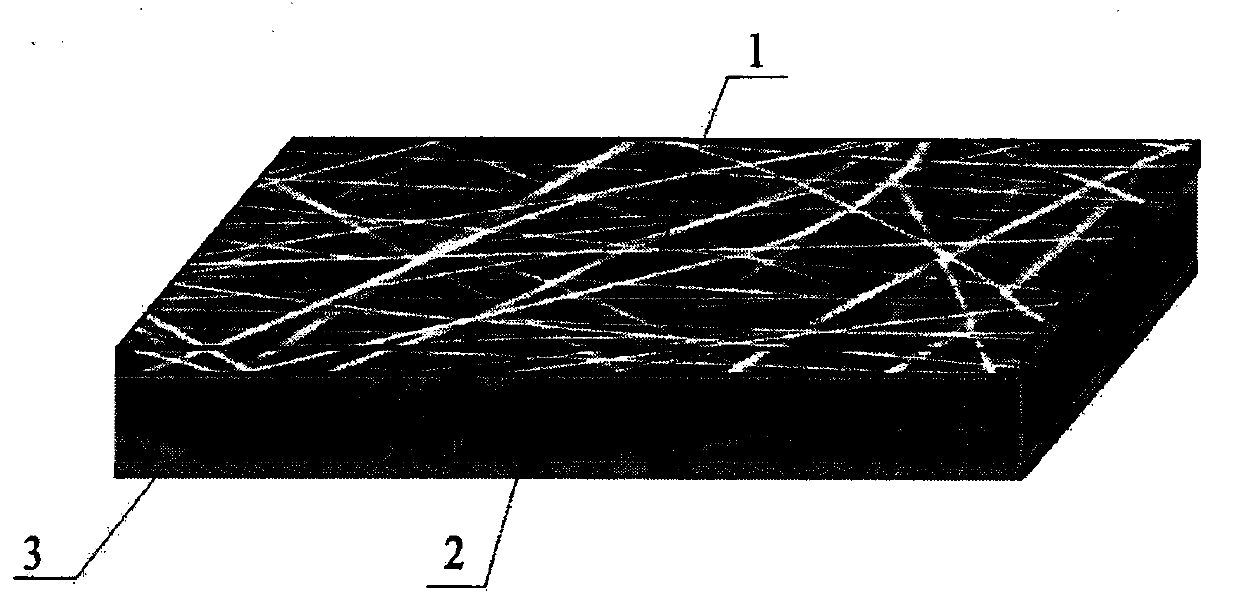

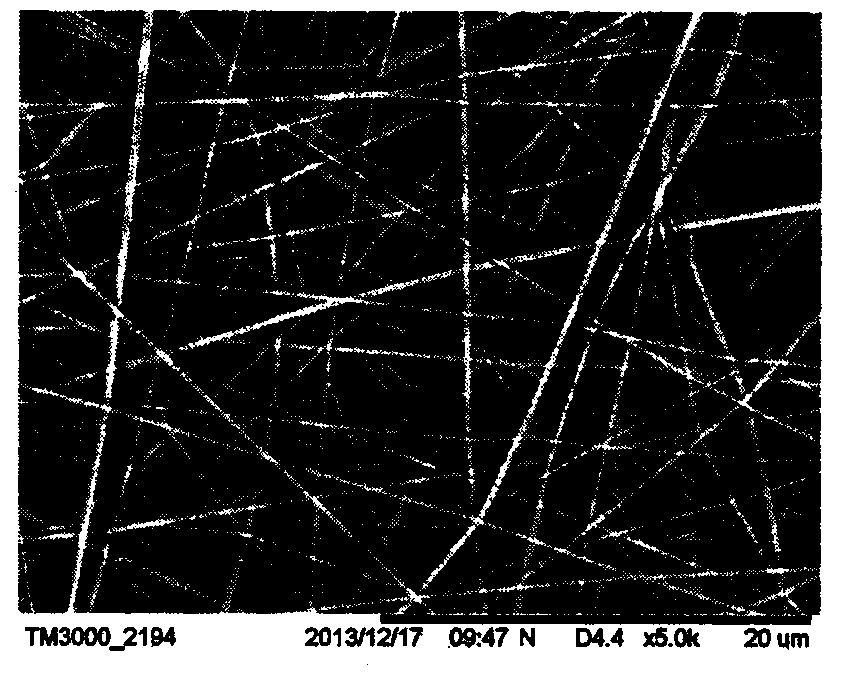

The invention belongs to the technical field of polymer lithium ion batteries, in particular to a diaphragm for the polymer lithium ion battery. The diaphragm comprises a multihole base material, wherein an inorganic substance coating layer and an organic substance coating layer are coated on at least one surface of the multihole base material; and the organic substance coating layer is in island-type and / or linear distribution and coated on the surface of the multihole base material and / or the inorganic substance coating layer. Compared with the prior art, due to the inorganic substance coating layer, the diaphragm can keep relatively high heat stability and mechanical performance, so that the lithium ion battery has high safety performance; the organic substance coating layer has high imbibition swelling capacity, and an interface has high stability, so that the manufactured lithium ion battery has perfect mechanical performance; due to the distribution characteristic of the organic substance coating layer, spaces are provided for charging and discharging processes of a pole piece and a circulation process; and the problem of deformation of the polymer lithium ion battery is well solved. Furthermore, the invention also discloses a polymer lithium ion batter with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

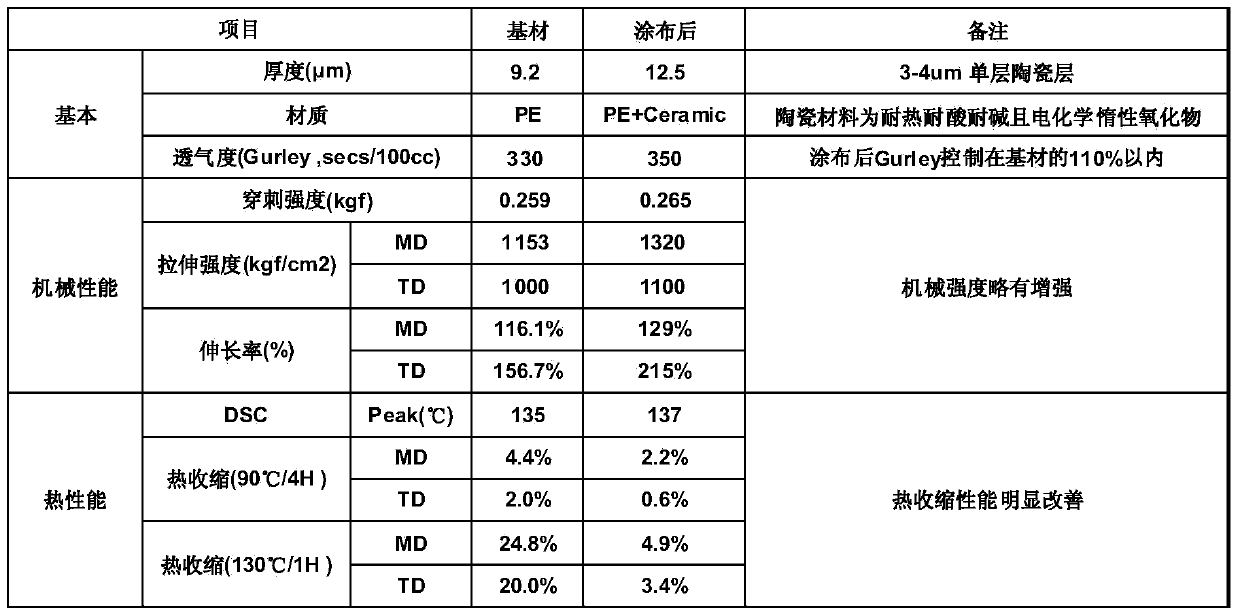

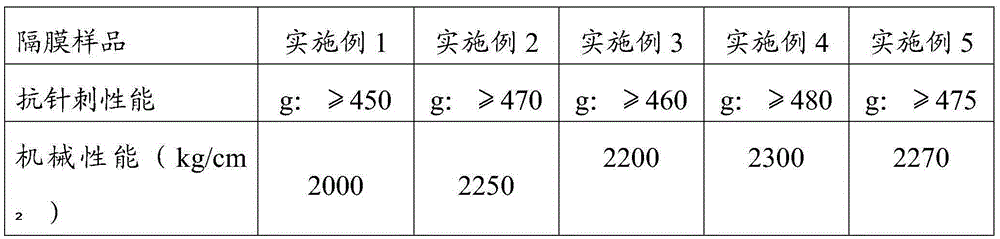

Lithium-ion battery separator subjected to composite coating treatment and preparation method thereof

ActiveCN106252565ATight bondIncrease volumetric energy densityFireproof paintsCell component detailsLithium-ion batteryAramid

The invention discloses a lithium-ion battery separator subjected to composite coating treatment and a preparation method thereof. The lithium-ion battery separator comprises a basement membrane, a polymer coating coated at one side of the basement membrane, and an inorganic particle coating coated at the other side of the basement membrane; the polymer coating is composed of an aramid coating coated on the basement membrane and a polyvinylidene fluoride coating coated on the aramid coating, and the thickness of the polymer coating is 0.3 to 5 [mu] m; and the inorganic particle coating is composed of inorganic particles of different particle sizes and a binding agent, and the thickness of the inorganic particle coating is s 0.5 to 5 [mu] m. The lithium-ion battery separator provided by the invention has the characteristics of being excellent in mechanical property and heat resistant property, having good wettability and solution preserving property to electrolyte, and excellent in cycle performance and high in safety performance.

Owner:深圳市鼎泰祥新能源科技有限公司

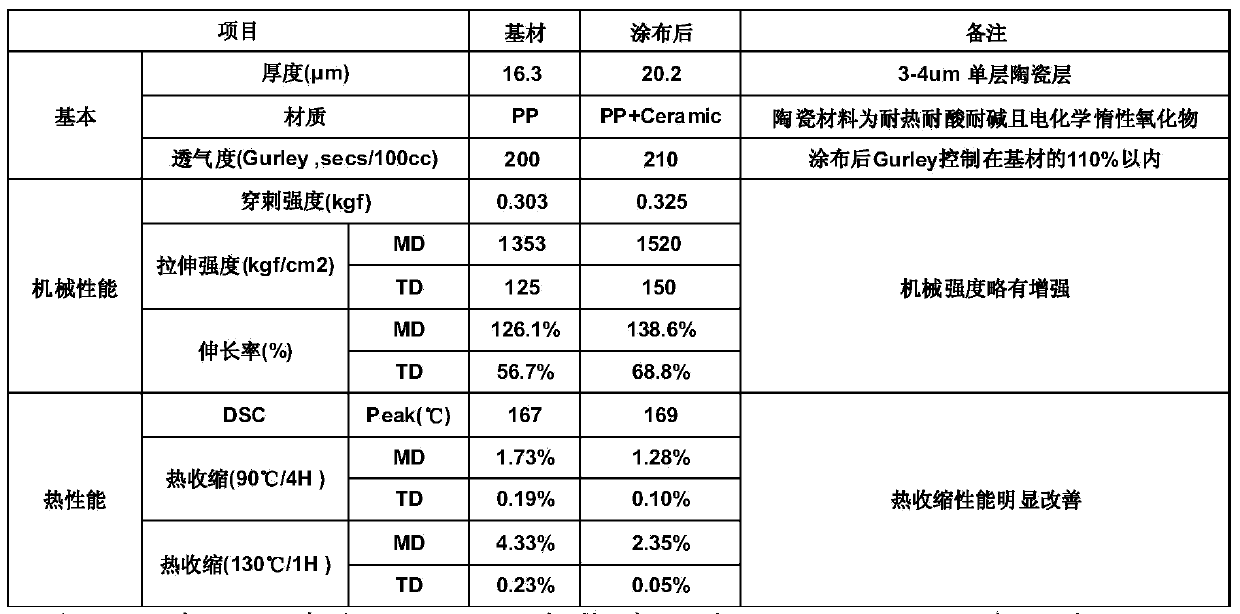

Composite coating lithium-ion battery separator and preparation method thereof

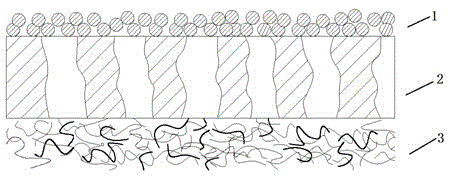

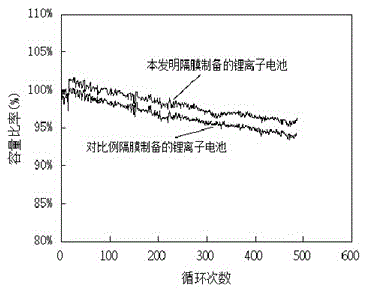

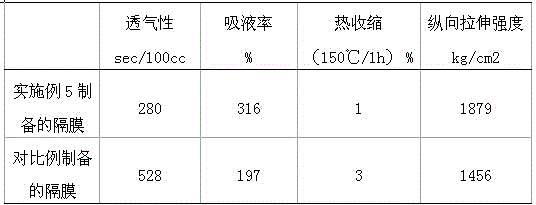

ActiveCN105552284AImprove thermal performanceImprove mechanical propertiesCell component detailsWater basedPole piece

The invention relates to a composite coating lithium-ion battery separator. The composite coating lithium-ion battery separator is composed of a base film, an aramid fiber coating coated on one side of the base film and a PVDF coating coated on the other side of the base film; the aramid fiber coating is obtained by an aramid fiber sizing agent after coating, soaking and drying, and the thickness of the coating is 0.5-4 microns; the PVDF coating is obtained by a water-based PVDF sizing agent after coating and drying, and the thickness of the coating is 0.1-2 microns. The invention also provides a preparation method of the separator. According to the composite coating lithium-ion battery separator and the preparation method thereof, the separator has the characteristics that the aramid fiber coating is good in thermal performance and mechanical performance and the PVDF coating has good wettability and liquid retention property for electrolytes, can effectively adhere batteries and pole pieces and is little in environmental pollution, and is beneficial for preparing lithium-ion batteries with longer cycle life and higher safety. Tests indicate that the separator has good air permeability, liquid absorption rate, thermal contraction and tensile strength, so that the cycle life of the batteries can be obviously prolonged by using the lithium-ion batteries prepared by the separator.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

Antibacterial wound dressing and preparation method thereof

InactiveCN104189942AIncrease surface areaFully absorbedAbsorbent padsNon-woven fabricsFiberSide effect

The invention provides an antibacterial wound dressing and a preparation method thereof. The antibacterial compound type wound dressing is characterized by comprising a chitosan-based medicine carrying compound antibacterial ultrafine fibrous membrane, a calcium alginate fiber non-woven fabric and a supporting protective layer which are sequentially arranged from top to bottom. The medicine carrying ultrafine fibrous membrane obtained by adopting an electrostatic spinning method has the advantages that the surface area of a medicament can be effectively increased, medicines can be slowly and sustainably released by virtue of high porosity and uniform pore diameter of ultrafine fibers, so that the medicines can be fully absorbed by a human body, medication is not need to be carried out frequently, the effect of the medicines can be maintained, and toxic and side effects of the medicines are reduced.

Owner:DONGHUA UNIV

Composite diaphragm for lithium ion battery for lithium-sulfur battery and preparation method and application of composite diaphragm for lithium ion battery

InactiveCN106356488AFacilitates fast transfersImproved thermal stability and safety performanceCell component detailsElectrochemical energy storageLithium electrode

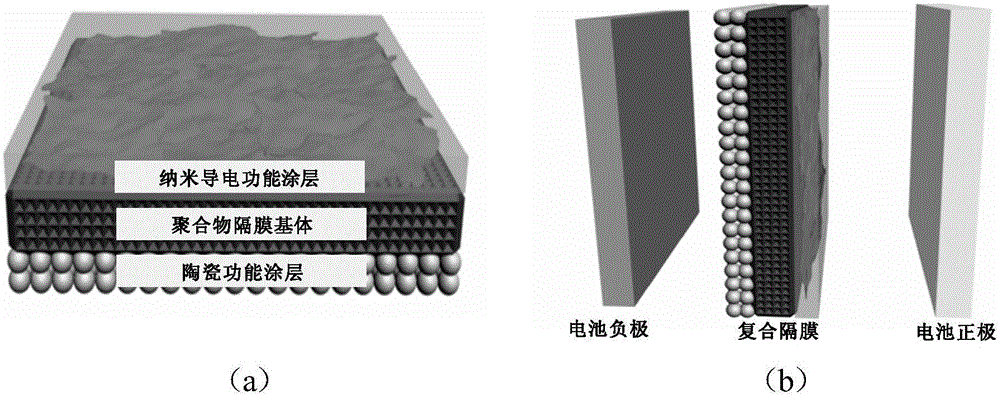

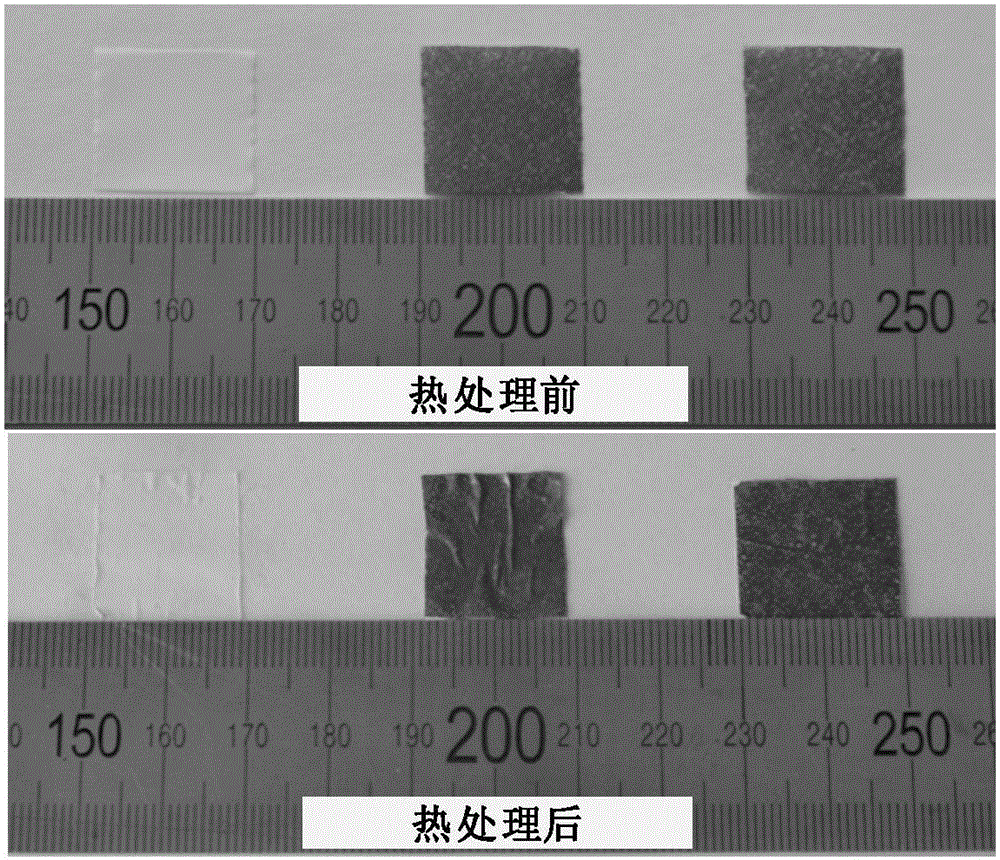

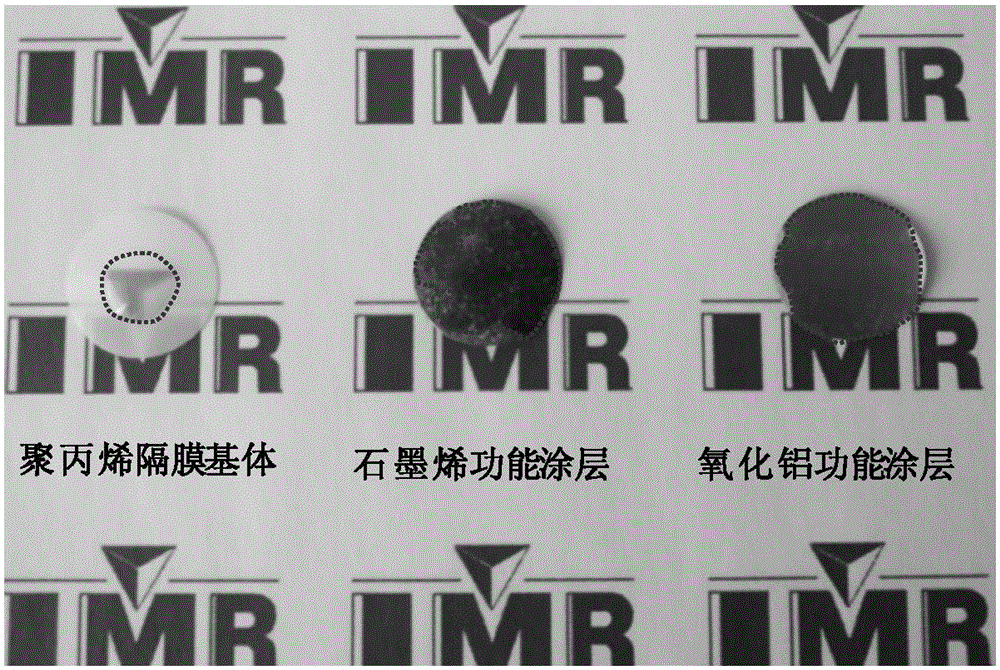

The invention discloses a composite diaphragm for lithium ion battery for a lithium-sulfur battery and a preparation method and application of the composite diaphragm for lithium ion battery, and belongs to the technical field of electrochemical energy storage. The composite diaphragm of the battery is a three-layer composite diaphragm prepared by respectively coating two sides of a polymer base body with a nano conductive functional coating layer and a ceramic functional coating layer. The nano conductive functional coating layer can accelerate quick transmission of electrons and ions in the battery, and the ceramic functional coating layer can improve the heat stability and the safety of the battery at high temperature, so that the battery prepared based on the composite diaphragm is excellent in electrochemical performance and heat stability. The method is simple in process and liable for industrialization; the prepared composite diaphragm can be widely applied to various lithium ion batteries and lithium-sulfur batteries.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electrolyte film and porous substrate and preparation thereof, lithium ion secondary battery

InactiveCN101388441AHave mechanical strengthGood flexibilitySecondary cellsCell component detailsPorous substratePolymer electrolytes

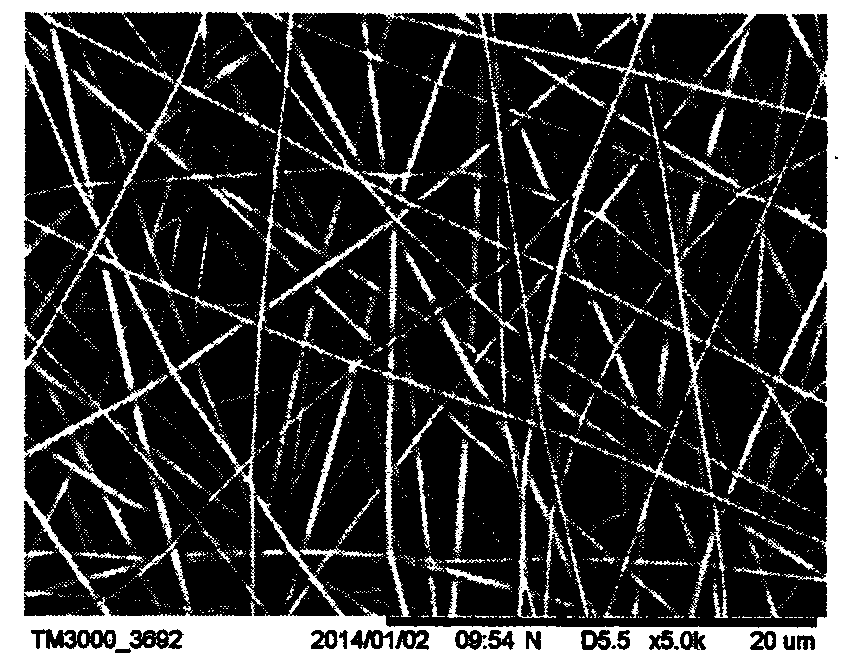

The invention relates to a gel-type polymer electrolyte film for a lithium ion secondary battery and a process for preparation, and a lithium ion secondary battery which contains the electrolyte film. The gel-type polymer electrolyte film for the lithium ion secondary battery can be obtained through the following method: preparing polyvinylidene fluoride nonwoven through the electrostatic spinning method, making the surface of the polyvinylidene fluoride nonwoven activate through radiating electron beams for the obtained the polyvinylidene fluoride nonwoven in air, contacting a methyl methacrylate monomer and the polyvinylidene fluoride nonwoven after the surface activation, thereby obtaining the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate. Furthermore, the lithium ion battery electrolyte film can be obtained through making the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate absorbs a certain amount of electrolytic solution. The invention develops the respective advantages in the lithium ion battery owing to using the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate, compared with singly using polyvinylidene fluoride or polymethyl methacryate or the both simple composite, and eliminates the disadvantages caused by singly using one material or several materials. The electrolyte film has high ion electrical conductivity under ambient temperature after absorbing the electrolytic solution, and can manifest excellent heavy-current discharge performance and circulation stability after being assembled in the batteries.

Owner:PANASONIC CORP +1

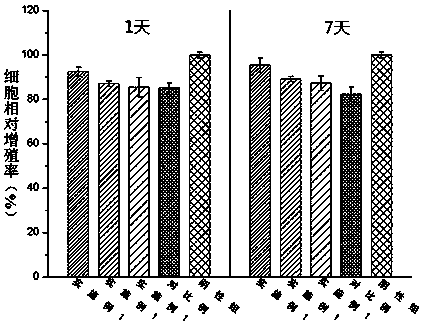

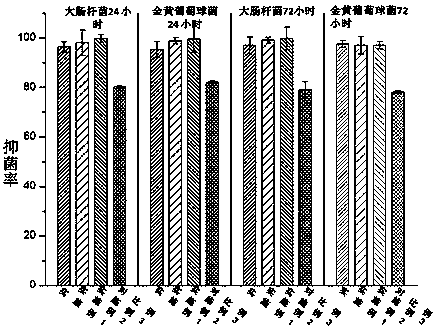

Synthetic method of anti-compression and anti-bacterial super absorbent polymer for physiology

The invention relates to a super absorbent polymer for physiology, in particular to an anti-compression and anti-bacterial super absorbent polymer still with high water absorbency under compression and with natural anti-bacterial property. The super absorbent polymer adopts the following technical scheme: taking polyvinyl alcohol with the polymer long chain rich in hydroxy as the interpenetrating polymer network (IPN), carboxymethyl chitosan with bioactivity and natural antibacterial property as the graft polymer and acrylate as the main comonomer, being combined with a cross-linking agent with molecular chains different in length, adopting the three-stage complex initiation system and realizing interpenetrating of polyvinyl alcohol and grafting of carboxymethyl chitosan by way of aqueous solution radical copolymerization to prepare the super absorbent resins with regular granularity, uniform crosslinking and less residual monomers. The invention develops multi-component composite surface treatment solution to carry out surface treatment on the super absorbent resins, thus further reducing the residual monomers, forming gradient crosslinking on the surfaces of the super absorbent resins and finally preparing the anti-compression and anti-bacterial super absorbent polymer for physiology. The super absorbent polymer is white without yellow spots, has regular granularity, inadherent surface, good liquidity, high absorption rate and absorption, excellent filtration property and less residual monomers and is against compression and tolerant to salt and free of gel plugging.

Owner:NANTONG KEYI CHEM

Non-woven fabric based multi-layer composite diaphragm for lithium ion battery and preparation method of multi-layer composite diaphragm

ActiveCN105470435AImprove high temperature closed cell performanceHigh tensile strengthCell component detailsEmulsionInorganic particle

The invention discloses a non-woven fabric based multi-layer composite diaphragm for a lithium ion battery and a preparation method of the multi-layer composite diaphragm. The non-woven fabric based multi-layer composite diaphragm comprises a non-woven fabric base material, an intermediate thermoplastic material coating and an outer-layer ceramic coating. The preparation method comprises the following steps of (1) mixing and uniformly stirring thermoplastic material particles, a binding agent and a solvent to form a mixed emulsion 1, and mixing and uniformly stirring inorganic particles, the binding agent and the solvent to form a mixed emulsion 2; and (2) uniformly applying the mixed emulsion 1 on one surface of the non-woven fabric base material, drying the mixed emulsion 1 to form the thermoplastic material coating, applying the mixed emulsion 2 on the thermoplastic material coating, drying the mixed emulsion 2 to form a ceramic coating, and rolling the ceramic coating to prepare a three-layer composite diaphragm. The three-layer composite diaphragm prepared according to the method has high-temperature obturator performance, favorable liquid absorption capability and mechanical property.

Owner:TIANNENG SAFT ENERGY JOINT CO

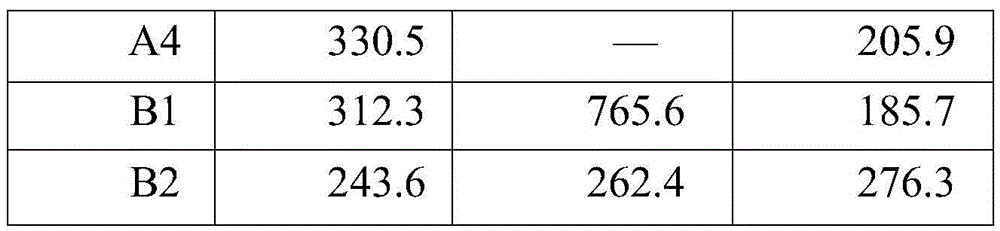

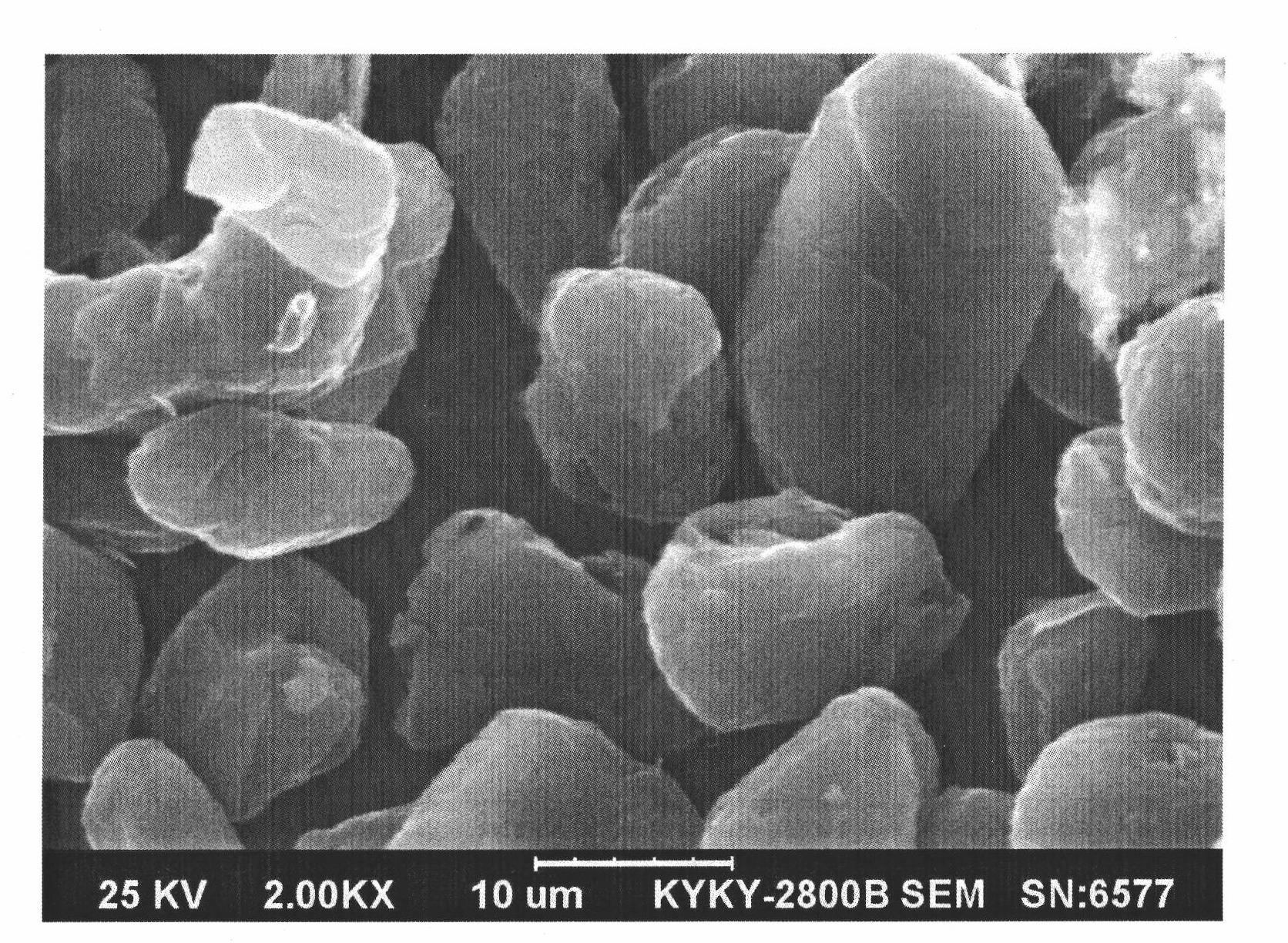

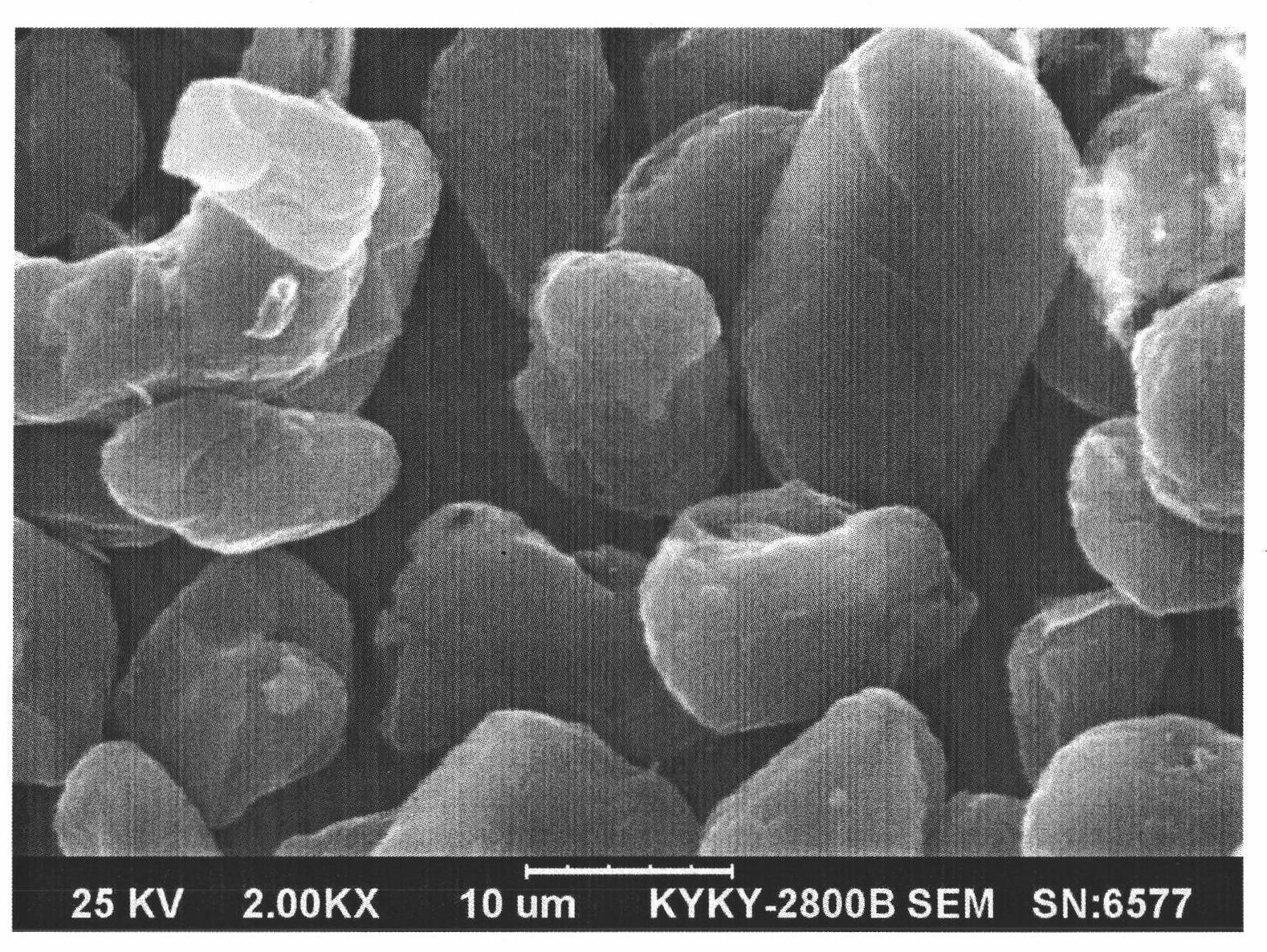

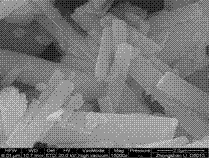

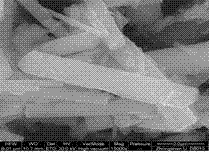

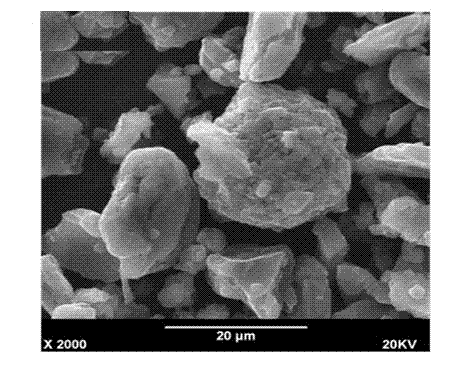

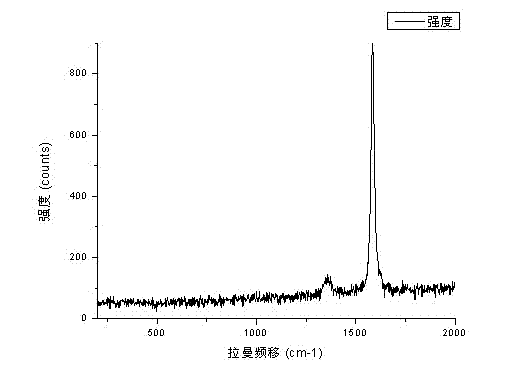

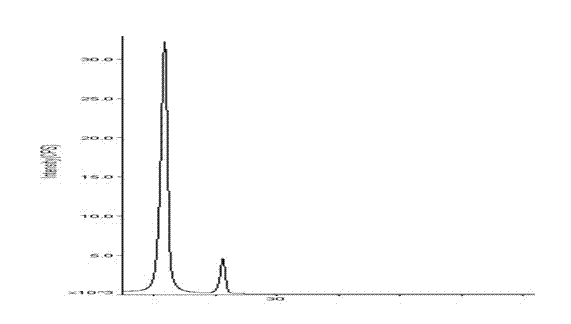

Cathode material for lithium-ion power battery and preparation method thereof

InactiveCN102148355AIncrease capacityExcellent rate performanceNon-aqueous electrolyte accumulator electrodesPower batteryGranularity

The invention discloses a cathode material for a lithium-ion power battery and a preparation method thereof. A graphite matrix used by the cathode material is spherical-like artificial graphite which has a spherical shape and has a length-width ratio of 1.0-3.0; the granularity D50 before the matrix material is coated is 9 to 11 mu m; a layer of ungraphitised carbon material is coated on the surface of the matrix to form a nucleus-shell structure; the coating amount is 2 to 8 percent of the mass of the matrix; the granularity D50 of the coated cathode material granules is 10 to 12 mu m; the specific surface area is 2 to 4m<2> / g; the tap density of powder is 0.9 to 1.1g / cm<3>; and the carbon content is over 99.95 percent. The invention has the advantages that: the cathode material for the lithium-ion power battery has the characteristics of high capacity, excellent rate performance and excellent liquid absorption property, and the preparation method is simple, easy to control, low in production cost and suitable for industrial production.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

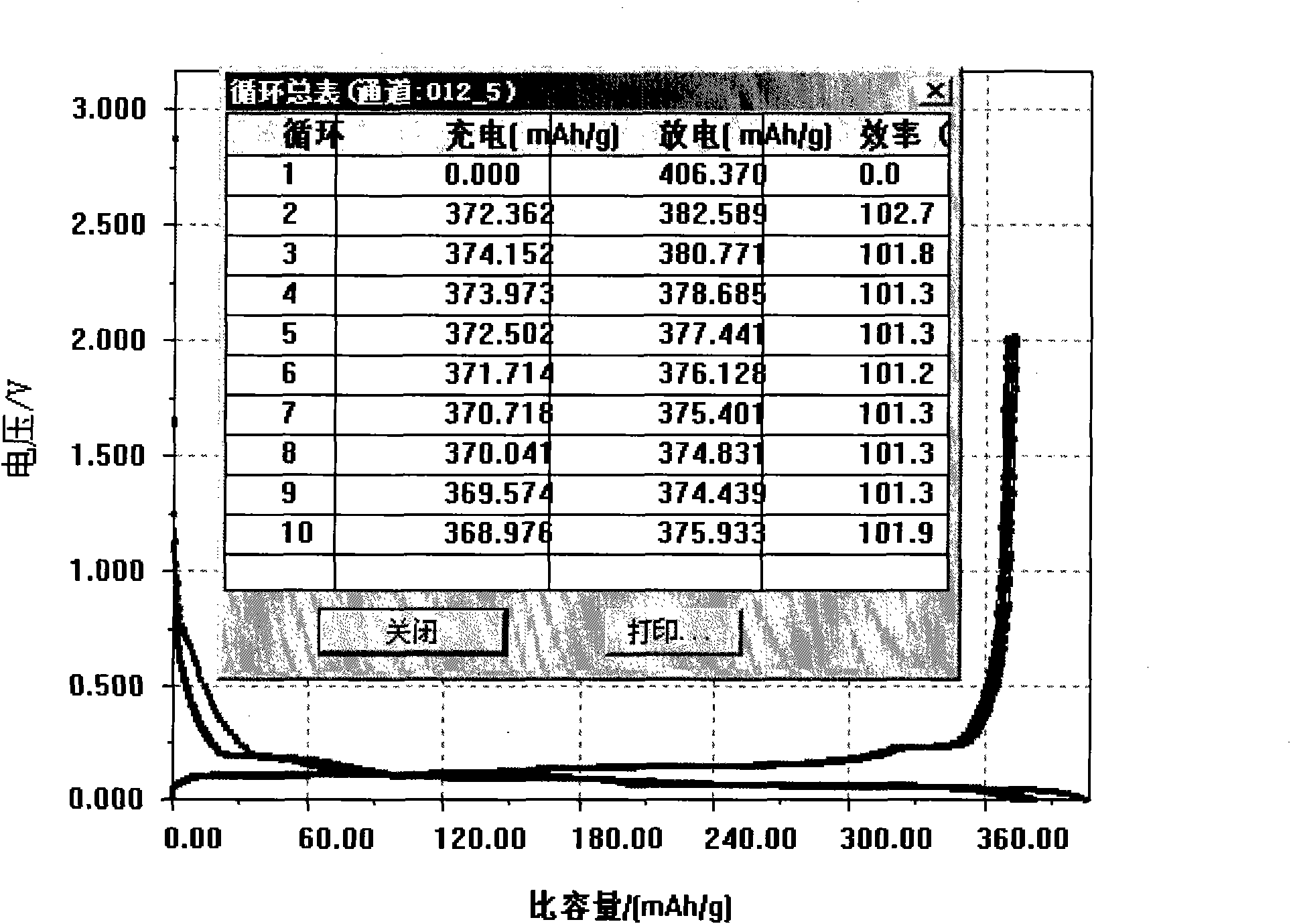

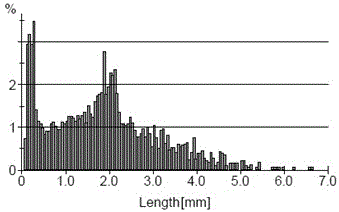

Anode material for lithium ion power battery and preparation method thereof

The invention discloses an anode material for a lithium ion power battery and a preparation method thereof, which aims to solve the technical problem of reducing the cost. The anode material for the lithium ion power battery of the invention takes spherical-like graphite, spheroid graphite with the major-minor axis ratio of 1.0-3.5, blocky graphite and / or flake graphite as a substrate, and non-graphite carbon material is coated outside the substrate to form composite particles. The preparation method comprises the following steps: mixing the precursors of the graphite and the non-graphite carbon material in liquid phase to obtain a suspensoid mixture; mixing and coating to obtain precursors of composite particles; and carbonizing to obtain the anode material for the lithium ion power battery. Compared with the prior art, the anode material for the lithium ion power battery of the invention has the characteristics of high capacity, high efficiency, excellent low-temperature performance, excellent magnification performance, superior absorption performance, simple preparation method and easy control, greatly reduces the cost of the lithium ion power battery, and is suitable for industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

Antibacterial and high absorptive composite material of polymer, and preparation method

An antibacterial high-hydroscopicity polymer composition is composed of high-hydroscopicity polymer with cross-linked structure (75-100 Wt. Portions) and inorganic antibacterial agent (1-10). It is prepared through dispersing the inorganic antibacterial agent in monomer solution, adding trigger and cross-linking agent, and in-situ polymerizing.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

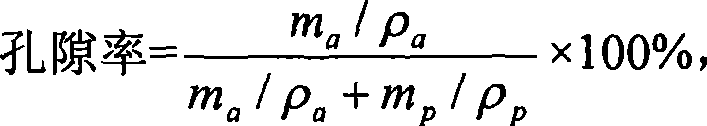

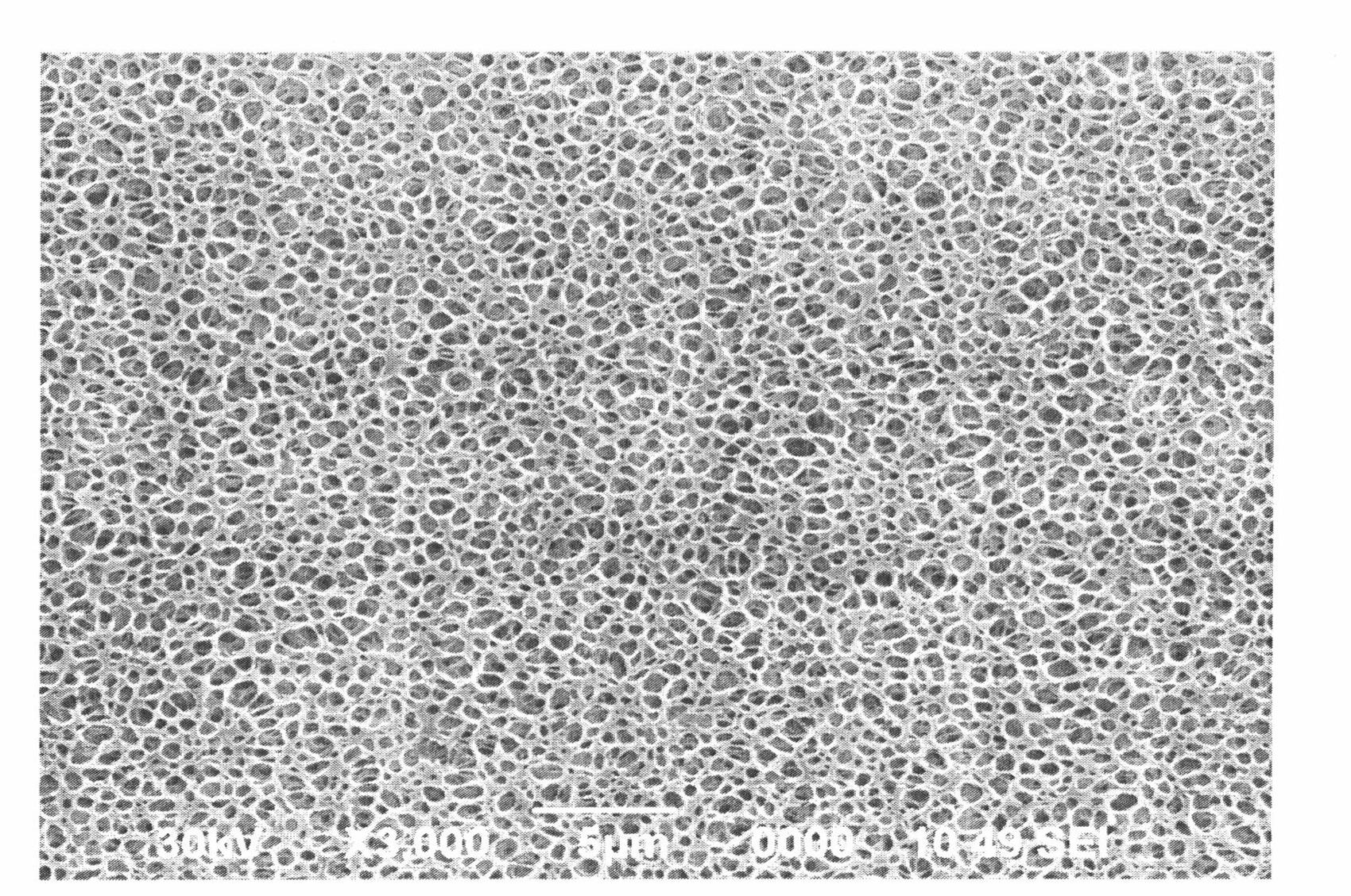

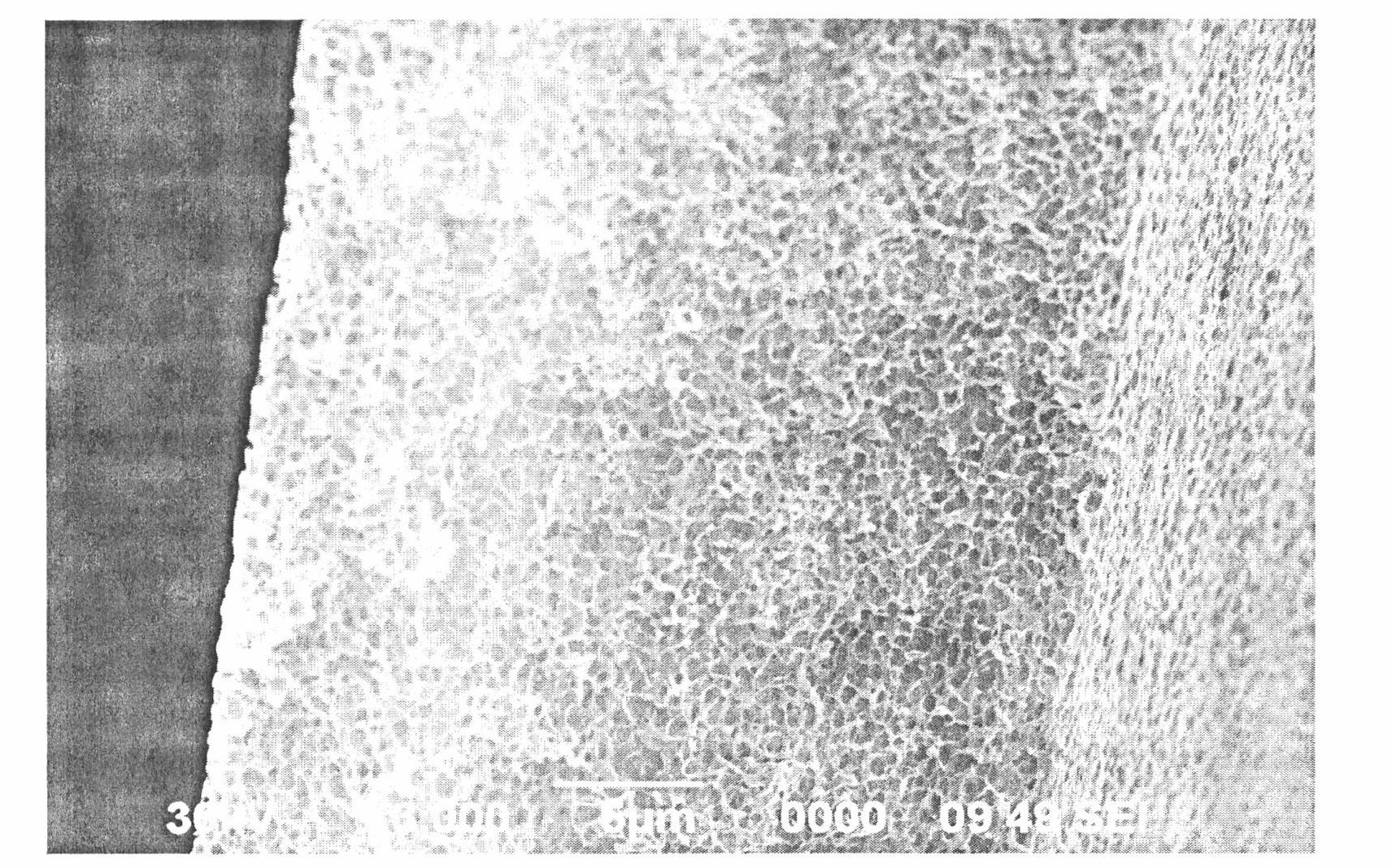

Porous membrane and preparation method thereof

InactiveCN102464803AReduce usagePrecise temperature controlSemi-permeable membranesCell seperators/membranes/diaphragms/spacersElectrical batteryPhysical chemistry

The invention provides a preparation method of a porous membrane, comprising the following steps: mixing and dispersing a polymer and solvent to prepare slurry; enabling the slurry to flow out of a narrow break joint to form a membrane in a gel tank; introducing the membrane to an extraction tank to carry out solvent replacement to form the porous membrane; and drying the porous membrane. The preparation method is simple in process, precise in control, low in cost and high process safety. The porous membrane prepared by using the preparation method can be widely applied to primary batteries, secondary batteries, electrochemical containers and the like.

Owner:MICROVAST POWER SYST CO LTD

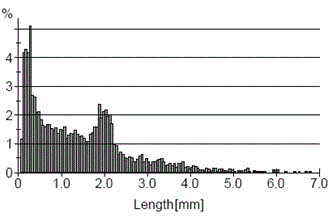

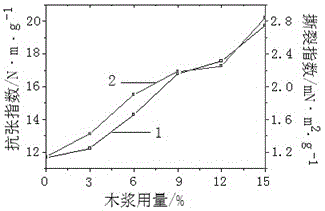

Reconstituted tobacco paper base and method for improving quality of reconstituted tobacco paper base by adding wood pulp fiber

The invention provides a reconstituted tobacco paper base and a method for improving quality of the reconstituted tobacco paper base by adding wood pulp fiber. The method for improving quality of the reconstituted tobacco paper base by adding wood pulp fiber includes steps of impregnating for extracting tobacco stem and tobacco powder, grinding, pulping, sheeting, pressing and drying. Wood pulp fiber accounting for 3-15% of tobacco material pulp by weight percent is added into the tobacco material pulp in the sheeting step. Researches show that tensile index, tear index and permeability of the reconstituted tobacco paper base with the added wood pulp fiber are improved evidently, overall absorbent property of the reconstituted tobacco paper base is improved, contents of tar, CO and total particulate matter in the sheeted paper base are lowered evidently, tar reduction and harm reduction for reconstituted tobacco are better played, sensory evaluation of cigarettes made by applying the sheeted paper base to cigarette production is improved comprehensively, and technical support for improving the quality of the reconstituted tobacco is provided.

Owner:CHINA TOBACCO GUANGDONG IND +1

Novel nano-crystalline cellulose modified lithium ion battery diaphragm and preparation method thereof

ActiveCN105720224AGood mechanical propertiesImprove hydrophilicitySecondary cellsCell component detailsPolymer substrateLithium electrode

The invention discloses a novel nano-crystalline cellulose modified lithium ion battery diaphragm and a preparation method thereof, and aiming to provide a novel nano-crystalline cellulose modified lithium ion battery diaphragm which has relatively high hydrophily, liquid absorption rate, liquid retention rate, mechanical property and environmental friendliness and a preparation method thereof. The novel nano-crystalline cellulose modified lithium ion battery diaphragm comprises cellulose nanofiber-lithium and a polymer substrate and is prepared according to the steps of film scraping liquid configuration, defoaming, film scarping and coagulating bath. The cellulose nanofiber-lithium improved lithium ion battery diaphragm prepared according to the method is favorably maintained with a natural cellulose I crystal structure, a composite membrane is endowed with relatively high mechanical performance, and the hydrophily and the stability of the composite membrane are improved; and the method has the advantages of very high industrial production capability and wide application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

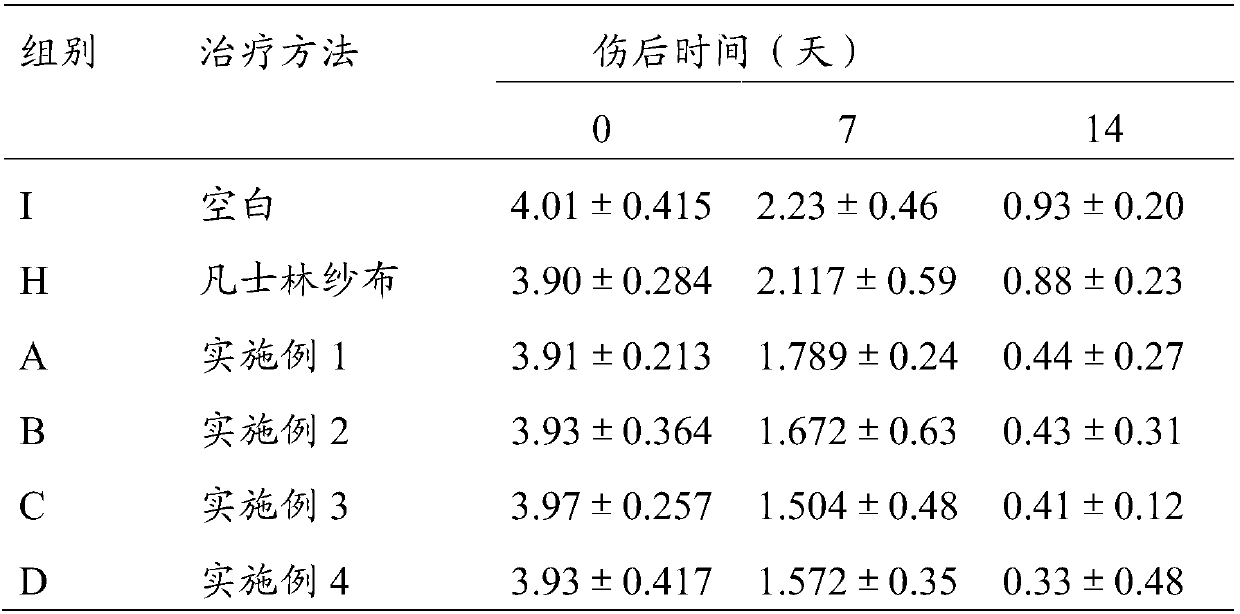

Antibacterial hydrocolloid dressing and preparation method thereof

ActiveCN104225663AStrong antibacterialAvoid Potential Biosafety RisksAbsorbent padsBandagesElastomerAntioxidant

The invention provides antibacterial hydrocolloid dressing and a preparation method thereof, and belongs to the technical field of medical dressing. The preparation method of the antibacterial hydrocolloid dressing is as follows: firstly, elastomers, tackifying resin, a plasticizer and an antioxidant are added into an internal mixer and mixed to prepare a hot-melt pressure-sensitive adhesive; hydrocolloid particles, polyvinyl alcohol, chitosan derivative and an antibacterial agent are added into the hot-melt pressure-sensitive adhesive and mixed; and the mixture is placed in a press vulcanizer for treatment, a waterproof polyurethane backing is coated with the treated mixture, release paper is covered, and a finished product is prepared after irradiation sterilization. The anti-bacterial hydrocolloid dressing prepared with the method has good antibacterial performance and has no safety risk; and the polyvinyl alcohol ingredient added in the preparation process is crosslinked during irradiation to form physical gel, the integrity of the dressing is effectively maintained, and the corrosion resistance of the dressing is improved.

Owner:HENAN HUIBO MEDICAL CO LTD

Isolating membrane and lithium ion secondary battery

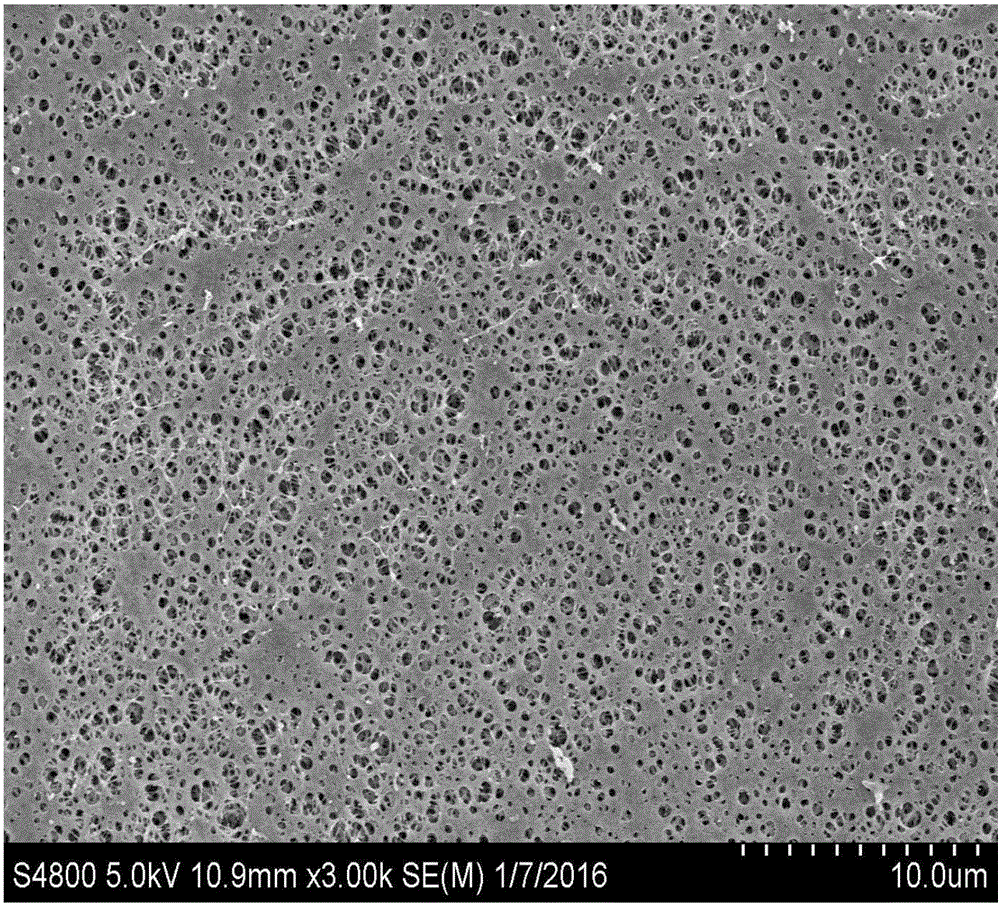

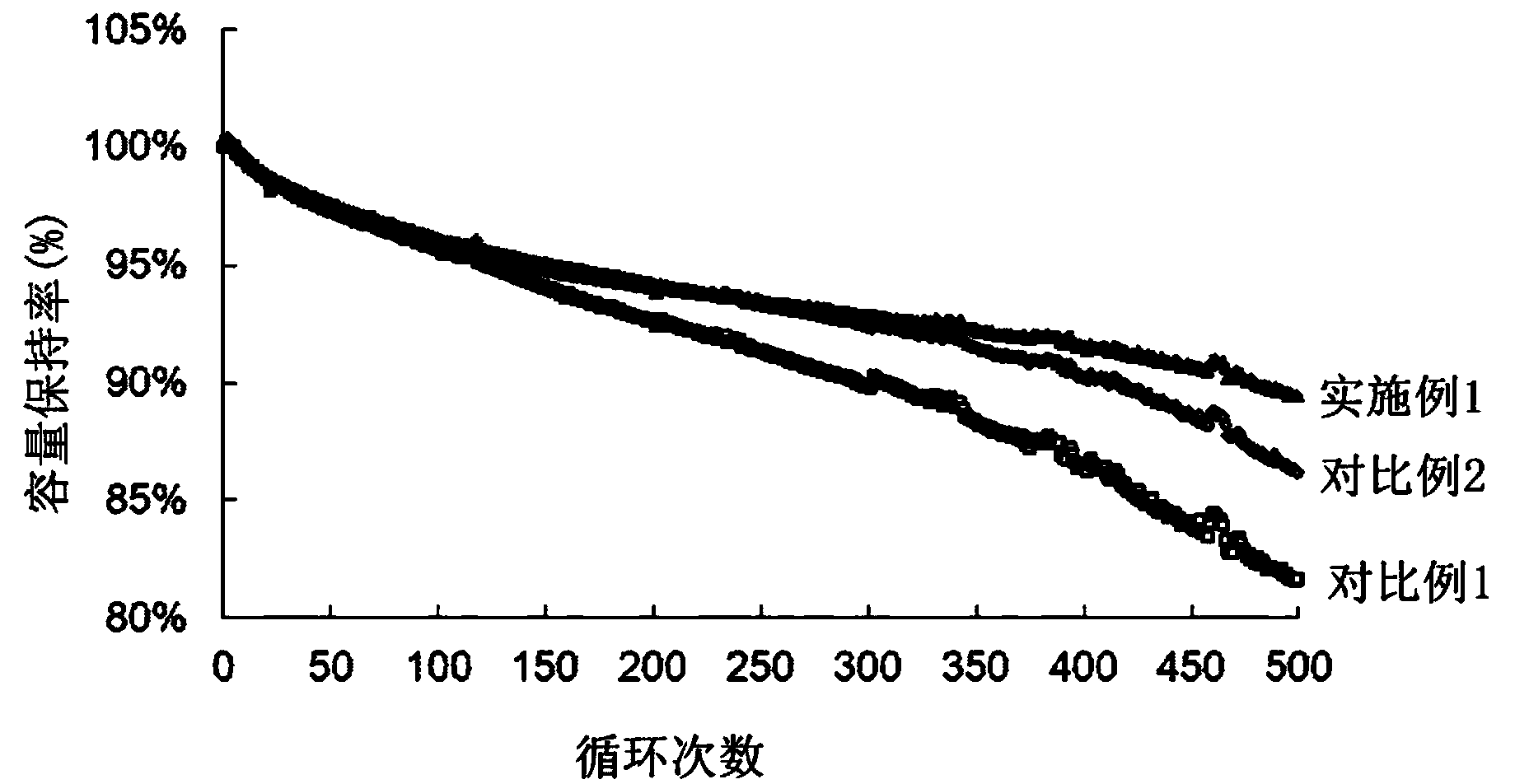

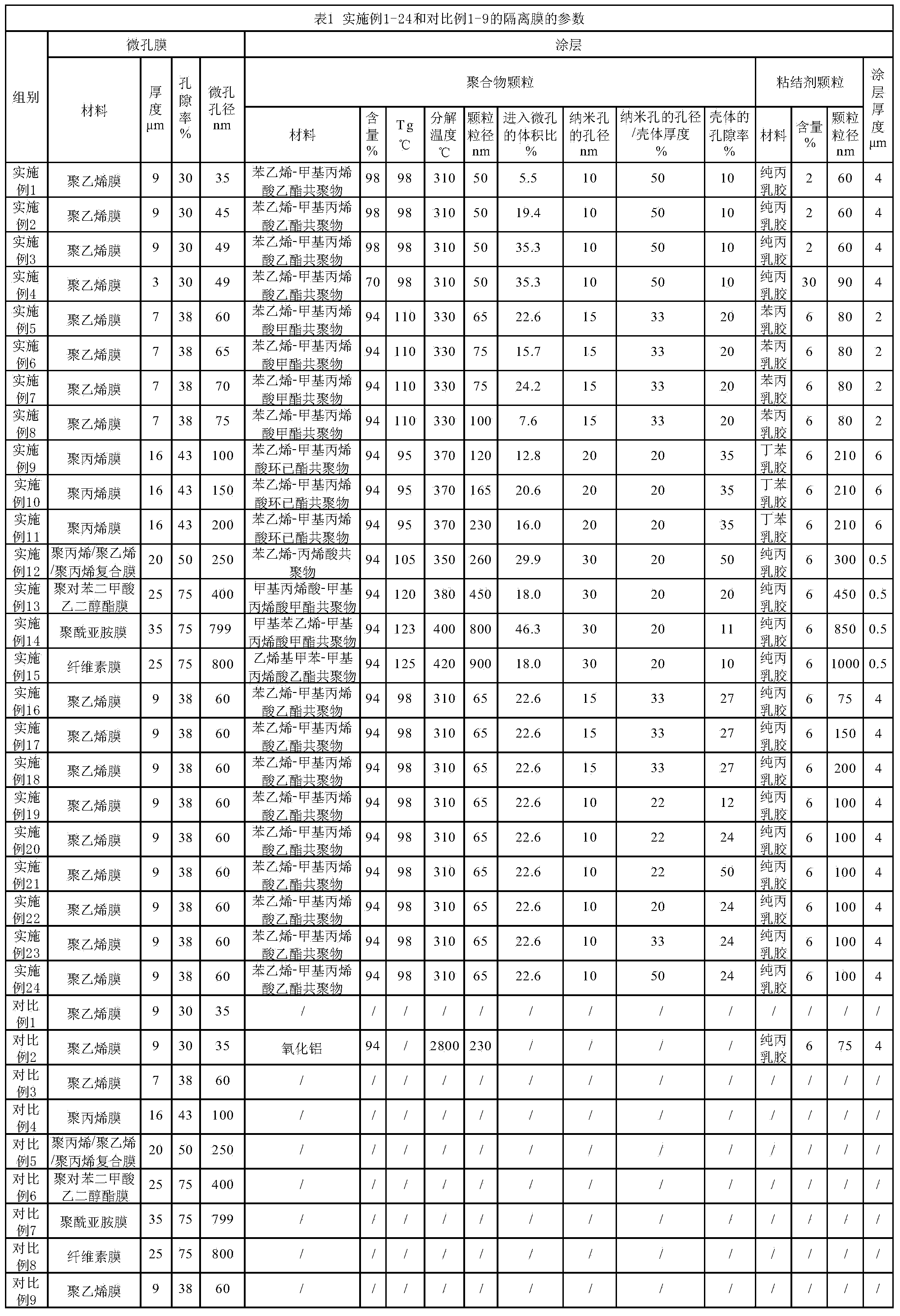

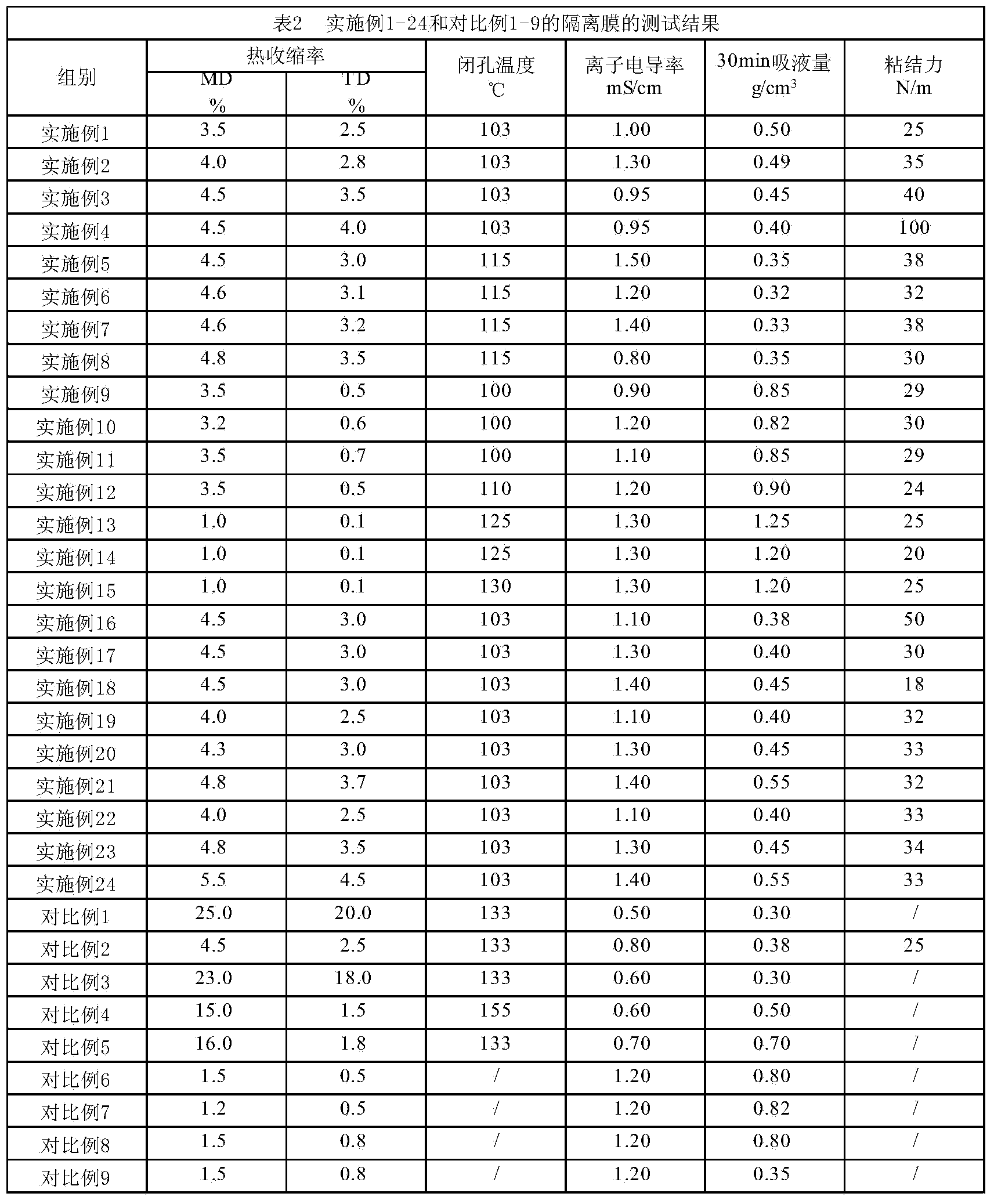

ActiveCN103956448AIncrease liquid absorptionImprove ionic conductivityCell seperators/membranes/diaphragms/spacersLi-accumulatorsLithiumHigh absorption

The invention provides an isolating membrane and a lithium ion secondary battery. The isolating membrane comprises a microporous membrane with micropores and a coating arranged on the surface of the microporous membrane, wherein the coating comprises polymer particles and binder particles, the polymer particles are of empty shell structures, each empty shell structure comprises a shell and a cavity formed inside the shell, nanopores communicated with the cavity are distributed on the outer surface of the shell, and the diameters of the polymer particles are more than the bore diameter of the micropore of the microporous membrane; the diameters of the binder particles are more than the bore diameter of the micropore of the microporous membrane; the lithium ion secondary battery comprises a positive electrode piece, a negative electrode piece, the isolating membrane interlaid between the positive electrode piece and the negative electrode piece, and electrolyte. The isolating membrane has high absorption amount, high ionic electrical conductivity and low heat shrinkage, and the lithium ion secondary battery has good-normal temperature cycle performance, low-temperature discharge performance, rate capability and safety performance.

Owner:DONGGUAN AMPEREX TECH

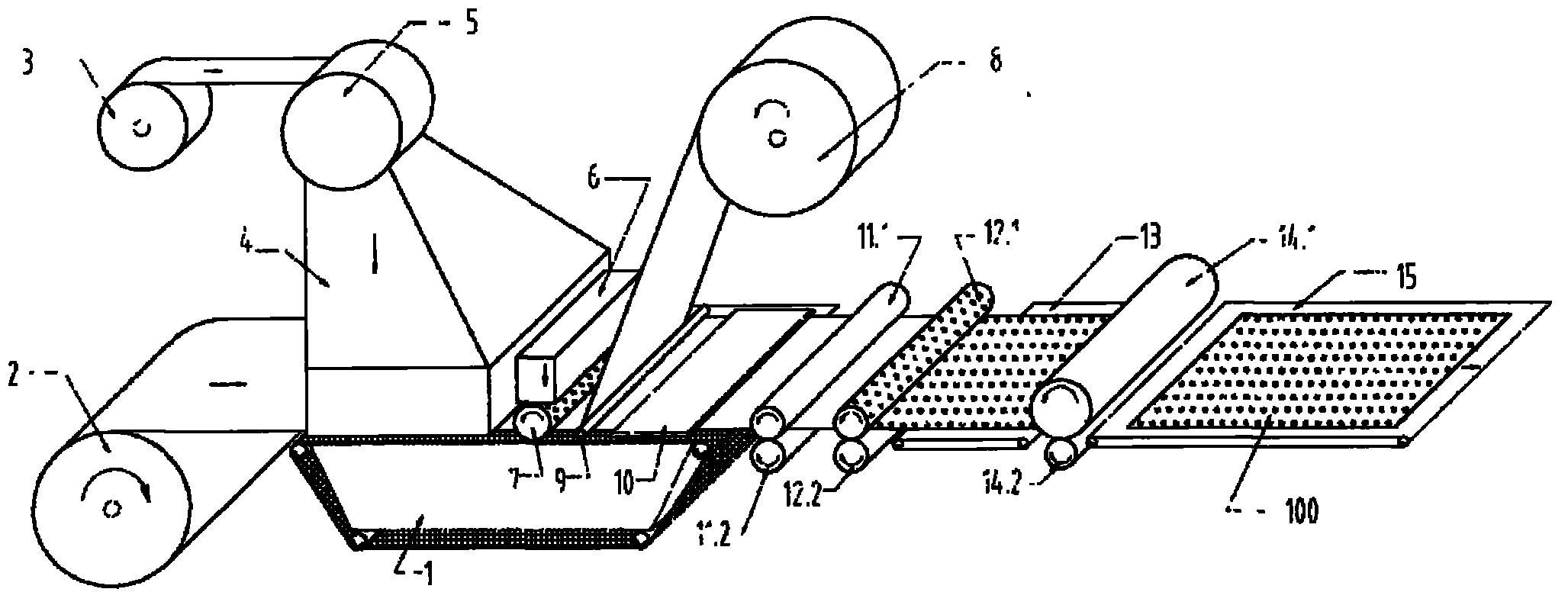

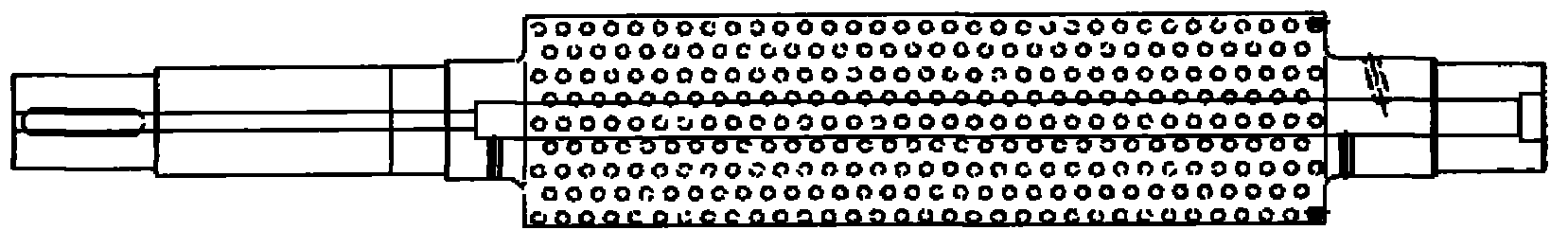

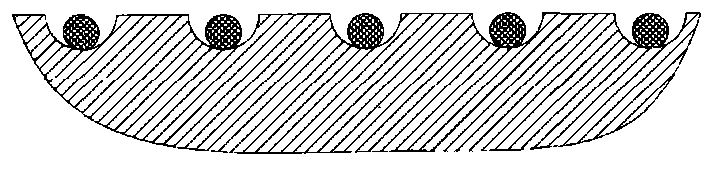

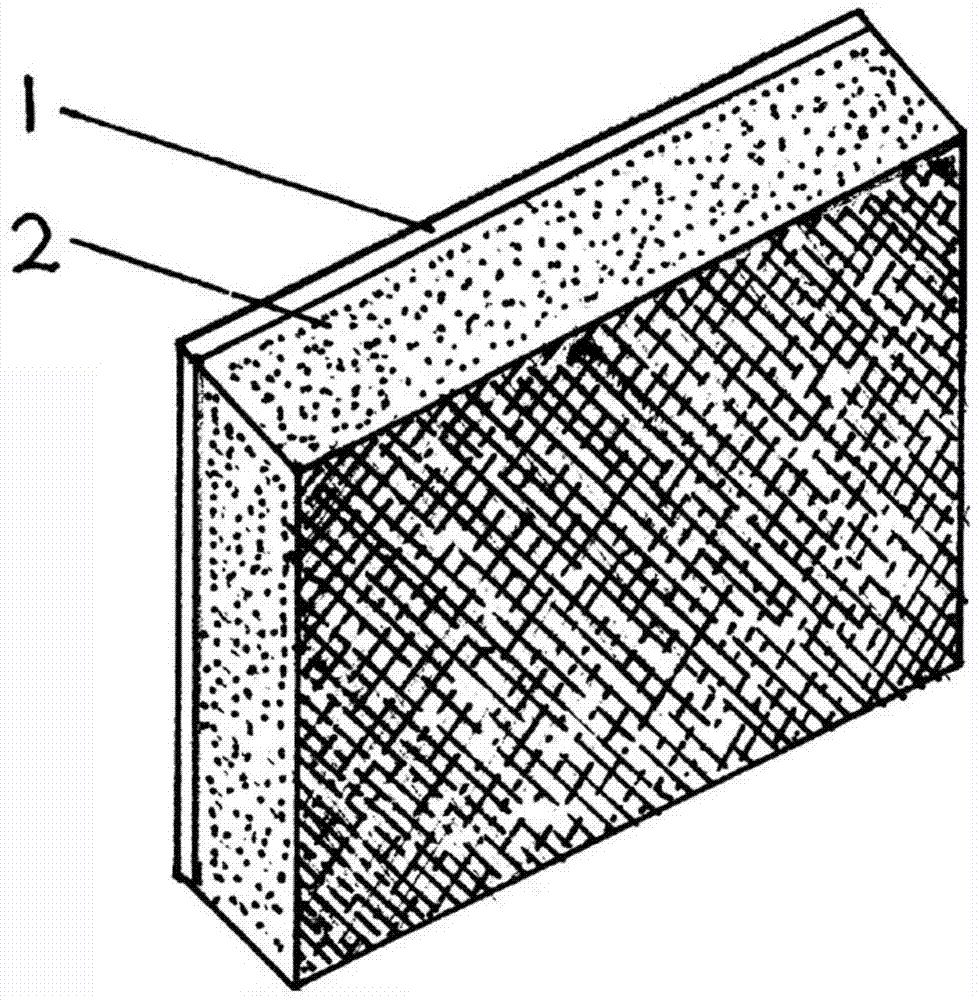

Health nursing pad absorber processing method and equipment thereof

ActiveCN103381114AImprove liquid absorption capacityIncrease liquid absorptionAbsorbent padsBaby linensEngineeringFiber

The invention discloses a health nursing pad absorber processing method and equipment thereof. The method comprises the following three steps: A, adsorbing wood pulp fiber and mixing the wood pulp fiber with polymer absorbent materials, B, compacting and dotted solidifying the absorber, and C, forming the absorber; the equipment is provided to realize the method. The method provided by the invention is suitable for various nursing pad products, can enhance extension strength of the nursing pad product, simplifies and realizes the manufacturing of absorber of nursing pad product, and reduces manufacturing cost of the nursing pad. The absorber produced by the invention adopts a novel structure made of polymer absorbent materials and wood pulp fiber, the polymer absorbent materials are uniformly disturbed in the wood pulp fiber, the sliding and moving of polymer absorbent materials are confined through doted solidification, so as to guarantee liquid absorption of the nursing pad product.

Owner:BEIJING BEISHUTE MATERNITY & CHILD ARTICLES

An alginate dressing for treating bedsore and a preparing method thereof

ActiveCN104758977APromote healingNo tissue proliferationAbsorbent padsBandagesPorosityComposite film

The invention relates to an alginate dressing for treating bedsore and a preparing method thereof. The dressing has a double-layer composite structure, namely the dressing comprises a base layer and a surface layer. The base layer is an alginate composite film layer. The surface layer is a natural rubber film layer. The preparing method includes following steps of: A) preparing a shark collagen solution, B) preparing a coaxial electrospinning outer layer solution, C) preparing a coaxial electrospinning core layer solution, D) spinning, E) crosslinking, F) dipping, G) preparing an epoxy natural rubber film, and H) compositing. The dressing has good biocompatibility, and has controllable growth regulation, good hygroscopicity, good anti-inflammation performance and good antibacterial performance of synthetic biological materials. The dressing is capable of improving local blood supply of wounds, promoting tissue growth and accelerating wound healing, shows good multifunctional properties, has good porosity, soft and comfort hand feeling, good compliance and using convenience, and can be used in the field of modern biomedicine, especially in the field of bedsore treatment and nursing, and the like.

Owner:HENAN YADU IND

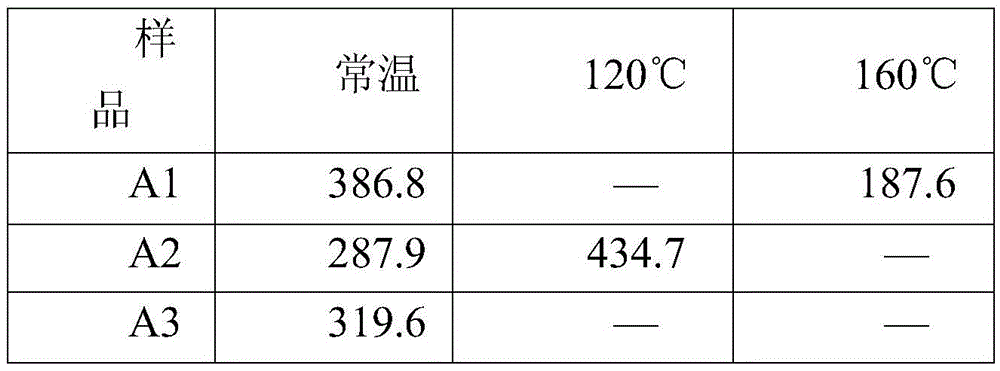

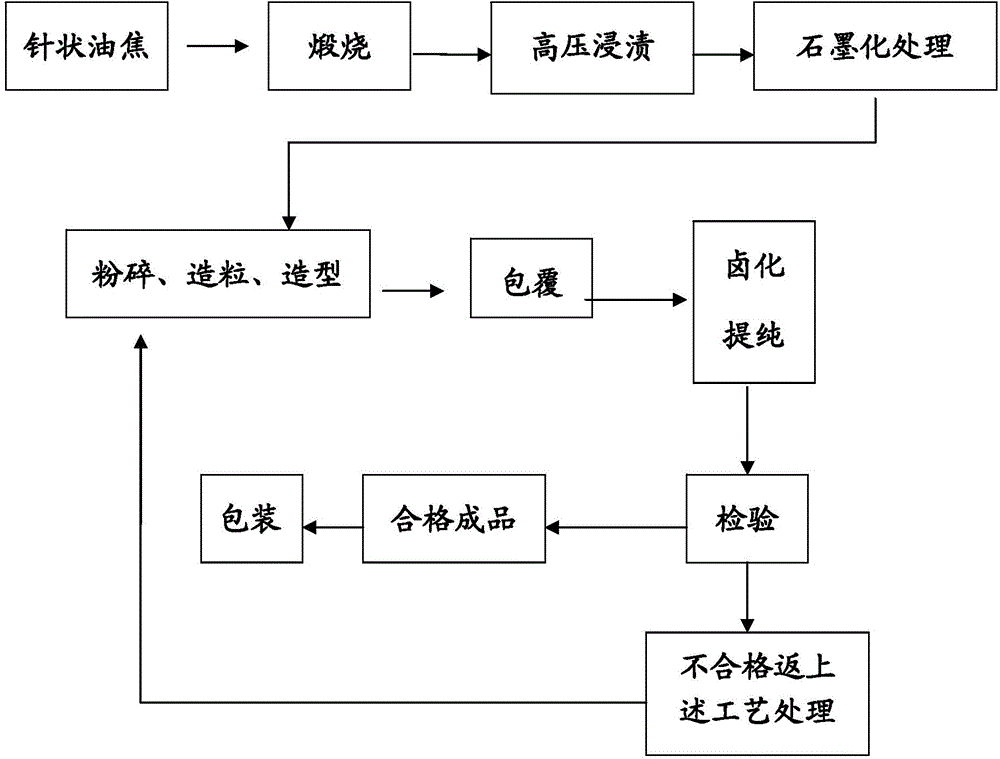

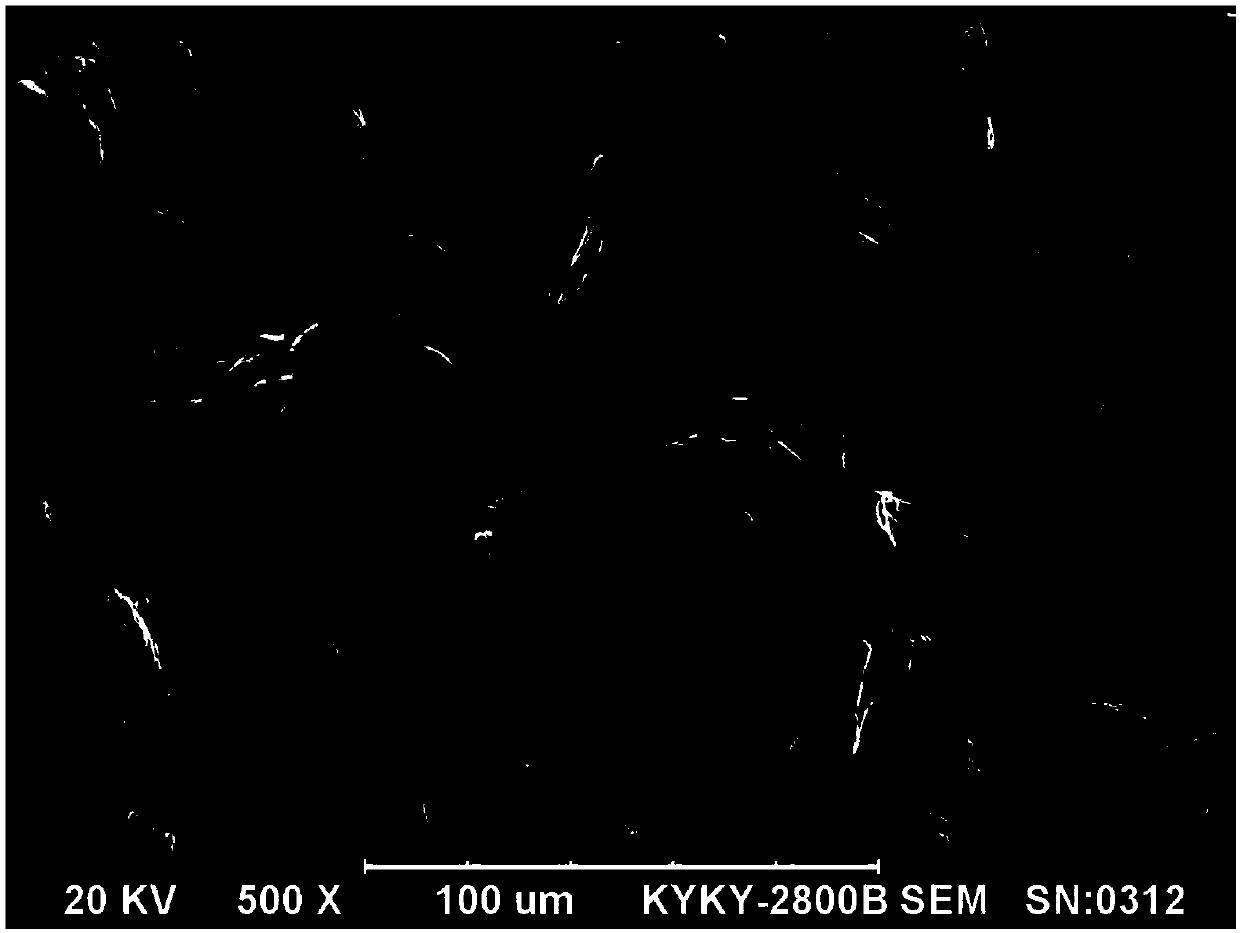

Method for improving durability of lithium-ion power battery, and lithium-ion power battery

ActiveCN104617260AStrong ability to absorb electrolyteIncrease liquid absorptionCell electrodesPower batteryLithium

The invention relates to a method for improving the durability of a lithium-ion power battery, and the lithium-ion power battery. The method comprises the following steps: conducting calcination on needle coke, and then carrying out high-pressure impregnation, graphitization treatment, pulverization for granulation, coating, and halogenation for purification to obtain an anode material capable of effectively improving the durability of the lithium-ion power battery; on the basis of the anode material, further preparing a negative pole piece and the lithium-ion power battery. The method has the advantages that the electrolyte absorptivity and the preserving capability of the anode material are improved, so that the negative pole piece made of the anode material can preserve more electrolyte; when the method is applied to a lithium-ion power battery encapsulated in a vacuum manner with an aluminum-plastic film, the defect that the quantity of preserved electrolyte is too small as the space between an aluminum-plastic film shell body and a battery core is too small can be overcome. Therefore, the aim to improve the durability of the lithium-ion power battery can be achieved.

Owner:苏州悦钠新能源科技有限公司

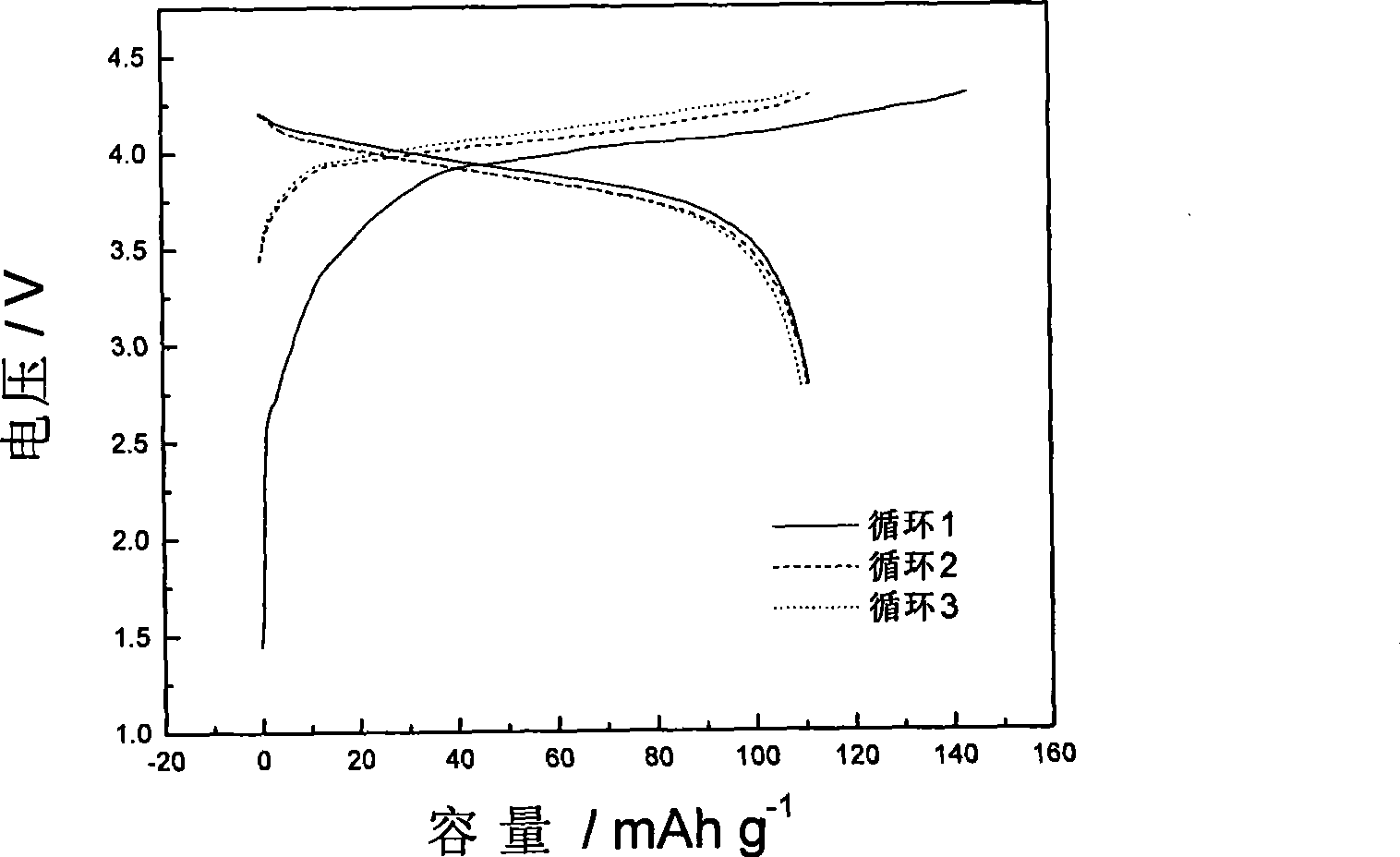

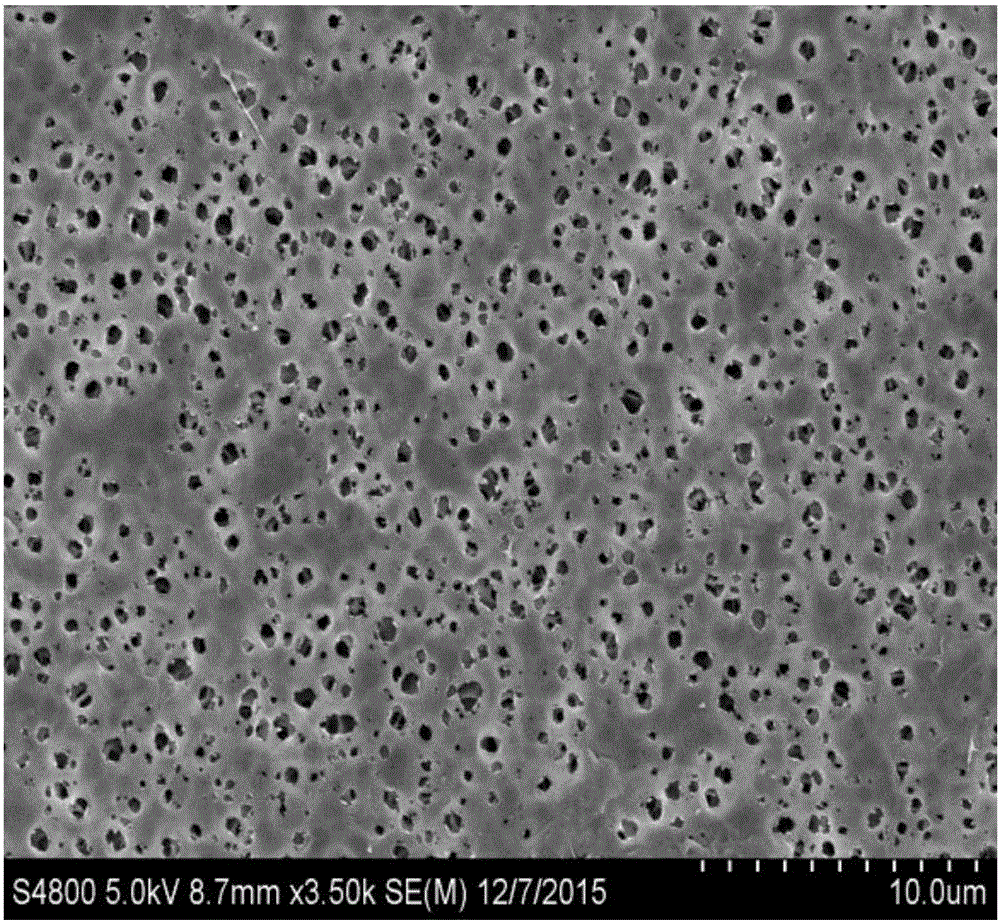

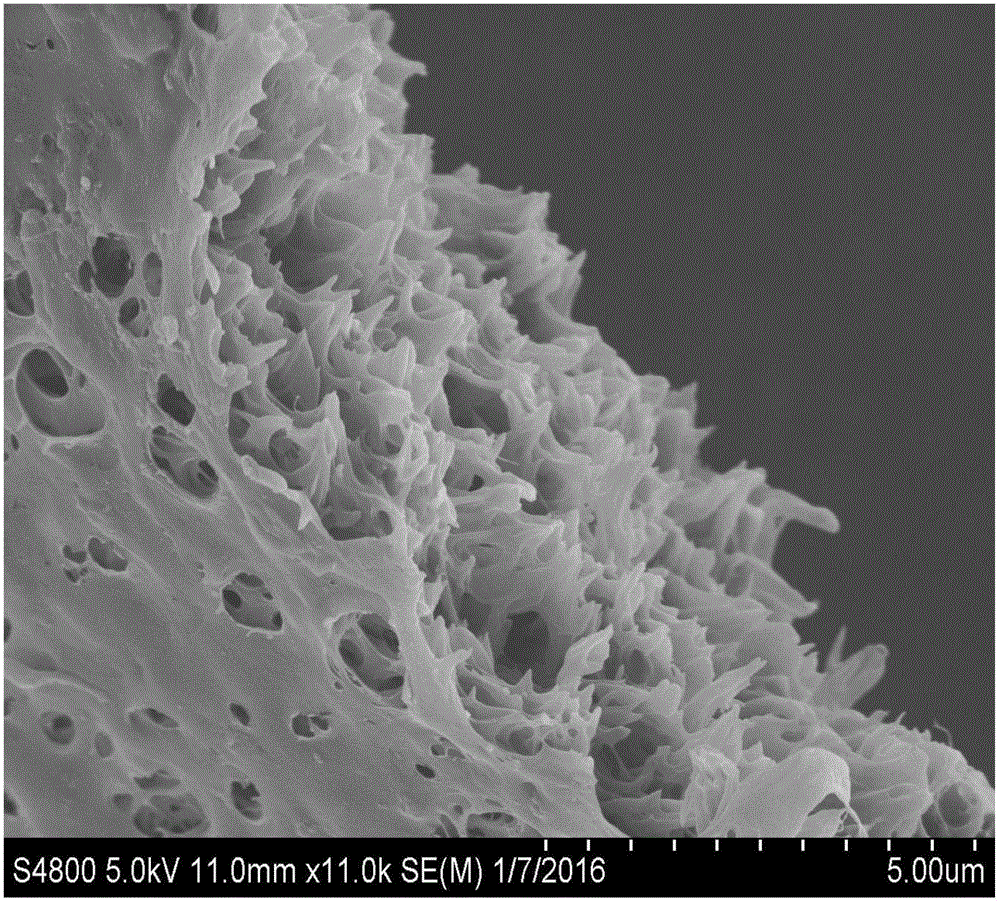

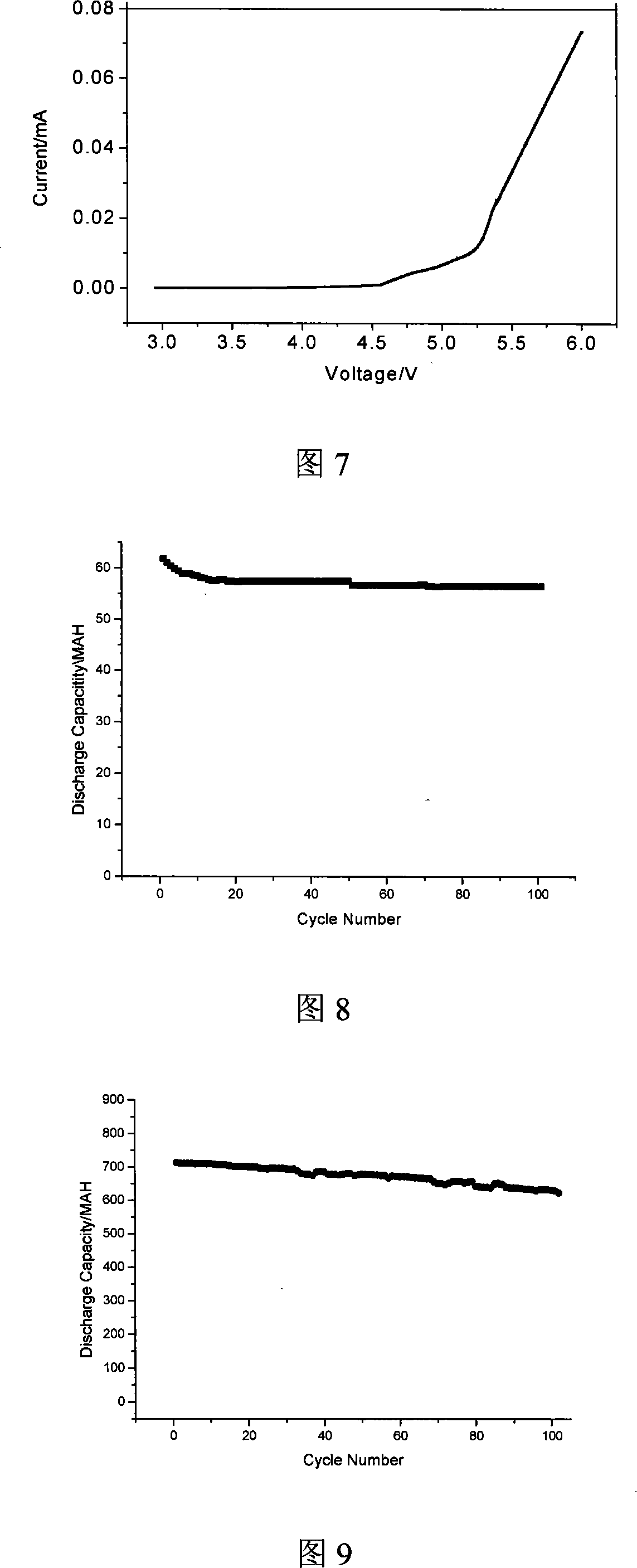

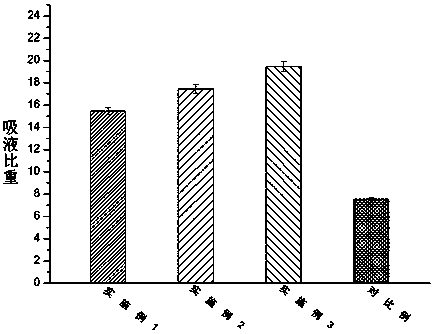

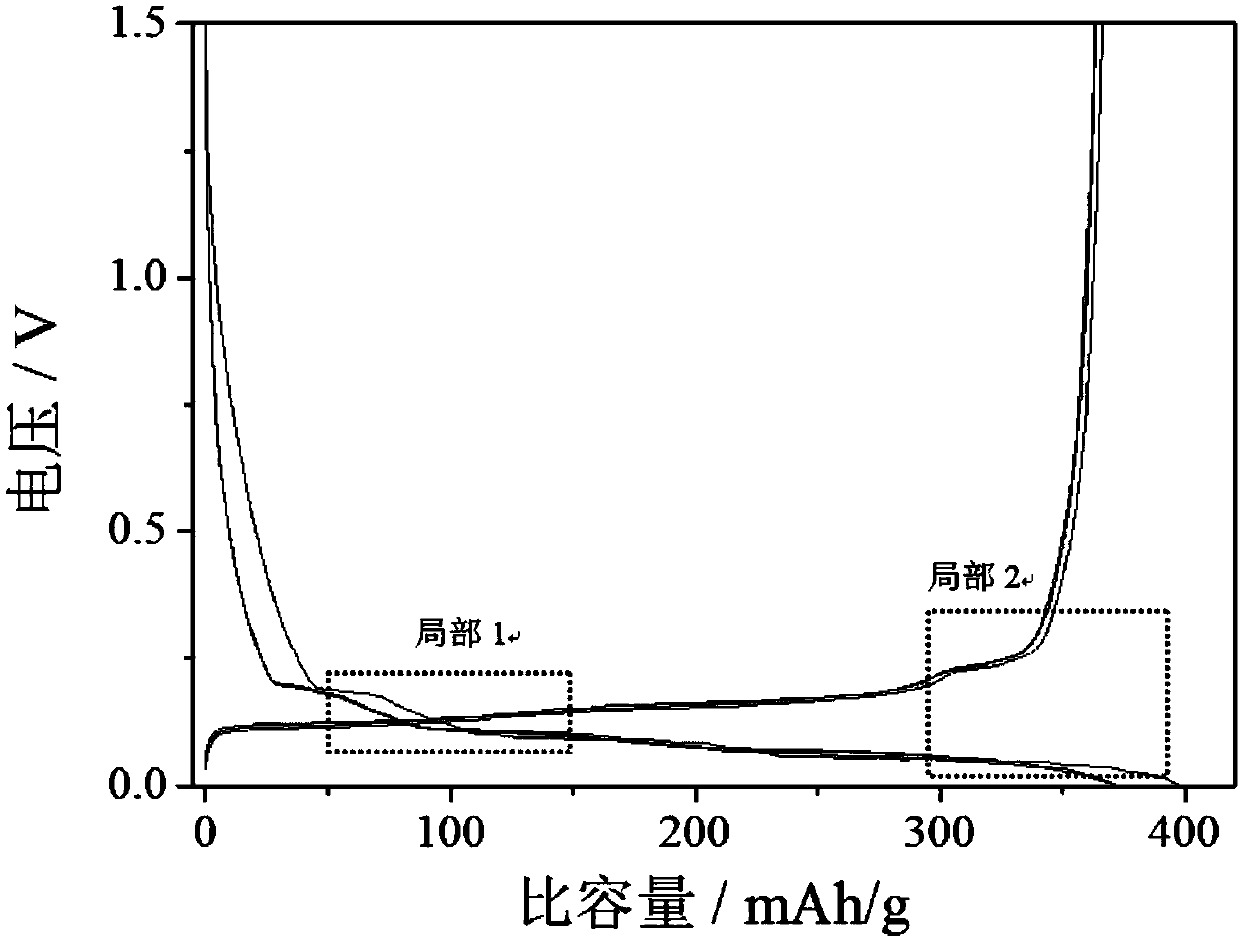

Gel state polymer lithium ion battery electrolyte and preparation method thereof

InactiveCN102244291AImprove performanceIncrease liquid absorptionSecondary cellsPolyvinylidene fluorideIon

The invention belongs to lithium ion battery field, and relates to gel state polymer lithium ion battery electrolyte and a preparation method thereof. The electrolyte is polyvinylidene fluoride gel electrolyte which is added with a modified glass fibre. Through blending P(VDF-HFP) with ball milled modified glass fibre, selfsupporting polymer membrane with excellent mechanics performance is obtained. Since the modified glass fibre has a certain amount of nanoparticles and the glass fibre constructs a strong support network, the polymer has an extremely good crosslinking micropore structure, extremely good imbibition performance and strong mechanical strength. The polymer is immersed in gel polymer electrolyte formed in electrolyte. After being assembled into a battery, an electrochemical test shows that the gel polymer electrolyte has good ion transmission performance, good electrochemical stabilization performance and high ion conductivity, and can be used as electrolyte of a polymer ion battery.

Owner:SOUTH CHINA NORMAL UNIVERSITY

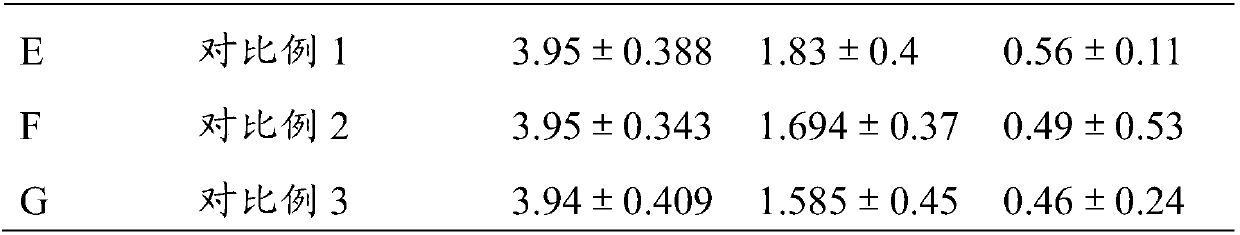

Hydrocolloid oil yarn and preparation method thereof

ActiveCN108126232AGood air permeabilityGood compatibilityAbsorbent padsBandagesParaffin waxSodium carboxymethylcellulose

The invention relates to a hydrocolloid oil yarn. The hydrocolloid oil yarn comprises a base material and a hydrocolloid ingredient, wherein the base material is netty polyester fiber; the hydrocolloid ingredient comprises the following raw materials in parts by weight: 8 to 10 parts of thermoplastic elastomers, 16 to 30 parts of sodium carboxymethylcellulose, 1 to 5 parts of growth factor microspheres, 1 to 5 parts of chitosan, 100 to 200 parts of liquid paraffin, 30 to 40 parts of Vaseline and 5 to 10 parts of wool fat. The content of grown factors inside the grown factor microspheres is 0.01wt% to 0.03wt%.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Composite graphite cathode material for high-capacity lithium ion battery, and its preparation method

ActiveCN103078089ALow costThe preparation process is simpleCell electrodesChemistryElectrical battery

The invention relates to a composite graphite cathode material for a lithium ion battery, and its preparation method, mainly relates to a composite graphite cathode material for a high-capacity lithium ion battery, and its preparation method, and belongs to the field of cathode materials for the lithium ion battery. The composite graphite cathode material for the high-capacity lithium ion battery is formed by blocky powder and spheroidic powder, and is characterized in that the specific surface area is 1.5-3.5m<2> / g, the average particle size is 7-30mum, the Raman ratio R is 0.1-0.3, and the interlamellar spacing of a crystal face (002) is 0.335-0.337nm. The composite graphite cathode material for the lithium ion battery has the advantages of excellent compact density, excellent gram specific capacity and excellent cycle stability, so the energy density per unit volume of the lithium ion battery is improved, and the electrical performances of the cathode material in the lithium ion battery are comprehensively improved.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

Micro joint gel state lithium ion battery polymer electrolyte film and its making method

ActiveCN101127408AIncrease polarityImprove ionic conductivitySolid electrolyte cellsSecondary cellsAcrylonitrileElectrochemistry

The utility model relates to a polymer electrolyte film for a micro cross-linking gel state lithium-ion battery and a preparation method, which is used for making the battery. The utility model discloses the poly-acrylonitrile-methyl methacrylate with the cross-linking degree of 0.1 to 0.4 % is obtained after suspension polymerization with the monomer component mass ratio of a methyl methacrylate and an acrylonitrile of 1:9 to 4:6, then the poly-acrylonitrile-methyl methacrylate is dissolved by a polar organic solvent and coated on a formed die, finally the micro cross-linking degree polymer electrolyte film is obtained when the film is removed from the formed die, the thickness of the film is 20 to 50um, the tensile strength is 7 to 22Mpa, and the average hole diameter is 0.1to 3um. The utility model has advantages of good conductivity, good absorbing capability, good heat stability, good electrochemical stability and good mechanical property under the ambient temperature, and simple manufacturing operation, high transforming rate of polymer, economy and environmental friendliness.

Owner:GUANGZHOU TINCI MATERIALS TECH

Antibacterial alginate hydrocolloid dressing and preparation method thereof

InactiveCN107693836AIncrease liquid absorptionGood moisturizing effectAbsorbent padsBandagesPolyethylene glycolColloid

The invention belongs to the technical field of a medical apparatus, and discloses an antibacterial alginate hydrocolloid dressing and a preparation method thereof. The antibacterial alginate hydrocolloid dressing comprises, by weight, 10-30 parts of gelatin, 5-15 parts of modified sodium alginate, 10-20 parts of polyethylene glycol, 20-40 parts of polyvinyl alcohol and 0.05-0.1 part of antibacterial peptide D2A21. The preparation method includes preparation of a gelatin-modified alginate composite material, preparation of a polyvinyl alcohol and antibacterial peptide D2A21 fibrous membrane, and preparation of a hydrocolloid dressing. The method is simple and is low in cost. The prepared hydrocolloid dressing is great in water absorption and excellent in performance, and has good compatibility and antibacterial effect.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

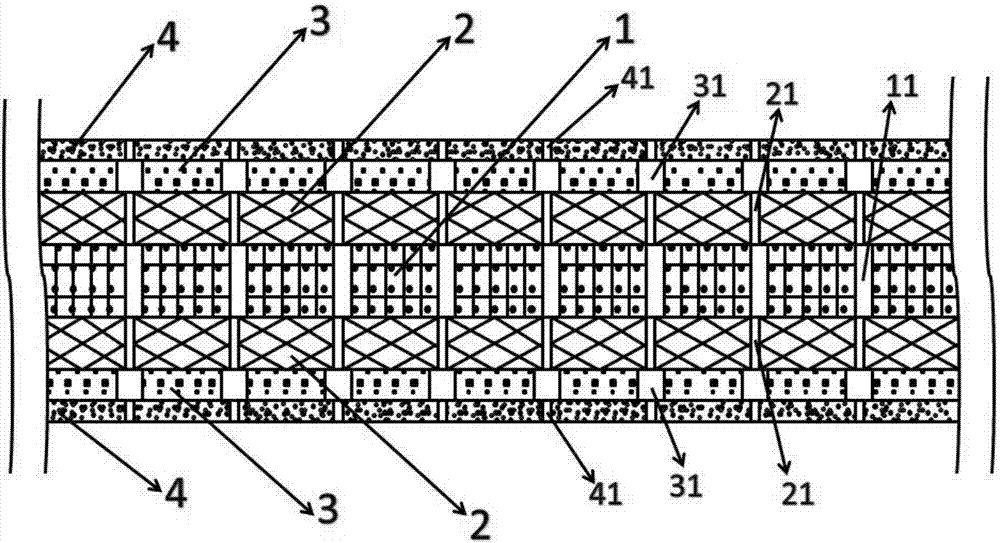

Preparation method of special composite coating diaphragm for lithium battery

ActiveCN107994183ALow closed cell temperatureHigh membrane rupture temperatureCell seperators/membranes/diaphragms/spacersBoehmiteSurface modification

The invention discloses a special composite coating diaphragm for a lithium battery. The special composite coating diaphragm comprises a microporous membrane, resin layers, ceramic layers and acrylicadhesive layers; the special composite coating diaphragm is characterized in that the resin layers coat the upper surface and the lower surface of the microporous membrane; one ceramic layer coats theouter side of each resin layer; one acrylic adhesive layer coats the outside of each ceramic layer; first micropores are formed in the microporous membrane; second micropores are formed in each resinlayer; third micropores are formed in each ceramic layer; and fourth micropores are formed in each acrylic adhesive layer. A preparation method of the special composite coating diaphragm for the lithium battery comprises the following steps of surface modification of boehmite alumina, preparation of the microporous membrane, preparation of a polymer composite membrane, preparation of modified boehmite alumina slurry, coating of the modified boehmite alumina slurry and bonding forming of an acrylic adhesive, thereby obtaining the special composite coating diaphragm for the lithium battery. According to the composite coating diaphragm, the security problem of a high-energy density battery core can be well solved.

Owner:桑顿新能源科技(长沙)有限公司

Yellow ceramic diaphragm for lithium ion battery and application thereof

InactiveCN103633269AImprove stabilityWon't settleSecondary cellsCell component detailsSlurryLithium-ion battery

The invention relates to the technical field of lithium ion batteries and especially to an aqueous yellow ceramic slurry for a lithium ion battery and application thereof. The aqueous yellow ceramic slurry comprises, by weight, 0.1 to 2% of a water-soluble polymer thickening agent, 0.1 to 2% of an aqueous disperser, 80 to 99.7% of a ceramic particle, 1 to 2% of yellow zirconium silicate and 0.1 to 5% of aqueous latex. The aqueous yellow ceramic slurry provided by the invention has the advantages of a stable system, stable viscosity, stable granularity, uneasy deposition, capacity of infiltrating PP and PE substrates, no need for surface treatment like corona treatment, high adhesion on the PP and PE substrates and high cost performance.

Owner:DONGGUAN YIWEIKE ELECTRONICS TECH CO LTD +1

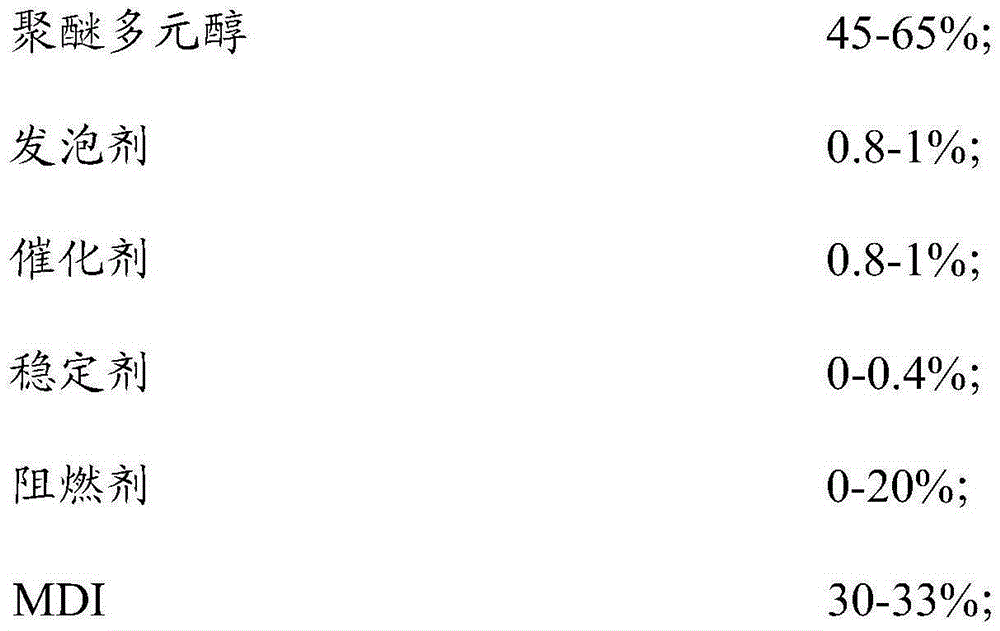

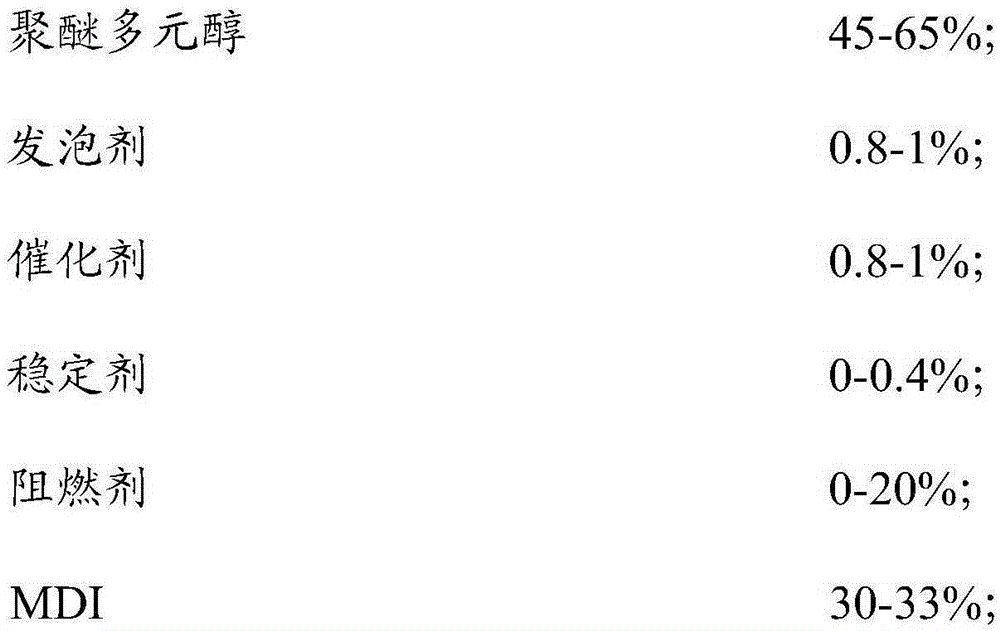

Heat-resisting lithium battery diaphragm and preparation method thereof

The invention provides a heat-resisting lithium battery diaphragm and a preparation method thereof. The method comprises the following steps: (a) weighing a component A, which comprises the following materials: polyether polyol, a foaming agent, a catalyst, a stabilizer and a fire retardant in weight ratio, pouring the materials into stirring equipment and mixing the materials evenly; (b) weighing a component B MDI in the weight ratio, respectively feeding the weighed materials of the component A and the material of the component B into a material jar A and a material jar B of a polyurethane foaming machine, stirring the materials in the polyurethane foaming machine, filling the materials into a rectangular or square mold, and carrying out foaming molding; and (c) putting a pelletized product which is molded in a foaming manner on a special foam horizontal cutting machine, cutting the pelletized product into slices according to the thickness requirement, and carrying out punch forming on the slices according to the size specification requirements, wherein the thicknesses of the slices are 5-41 microns; the porosity is 70%-75%; and the air permeability is 15-30 sec / 100cc. The heat-resisting lithium battery diaphragm has the advantages of high porosity, low thickness, high absorption amount, high ion permeability, low resistance, good compressive property, stable electrochemical properties, simplicity in manufacturing process, low cost, high quality and the like.

Owner:浙江清优材料科技有限公司

Composite negative electrode material and preparation method therefor and lithium ion battery

ActiveCN107706387AShorten the diffusion pathImprove electrochemical performanceCell electrodesSecondary cellsHigh rateLithium electrode

The invention relates to a composite negative electrode material and a preparation method therefor and a lithium ion battery. The composite negative electrode material comprises a carbonaceous material with an embedding structure and formed by embedding first carbon component small particles into a second carbon component framework carrier, wherein the first carbon component is converted by a small particle precursor (green coke and / or burning coke and / or carbon microspheres); and the second carbon component framework carrier is converted by a binder. The composite negative electrode materialdisclosed in the invention combines the "embedding type" structure and a "gradient type crystal form" structure; the small particles of different appearances are embedded in the relatively thick framework carrier to form a bigger particle; the small particles embedded in the interior adopt a graphite structure with the best crystal form; the framework carrier adopts a graphite structure with the ordinary crystal form; and the outermost layer also can be coated with an amorphous carbon structure with the worst crystal form. The composite negative electrode material provided by the invention hasstructural stability, high orientation, low expansion, high rate capability, excellent liquid absorption performance and cycle performance, and can satisfy various kinds of demands in the application.

Owner:贝特瑞(四川)新材料科技有限公司

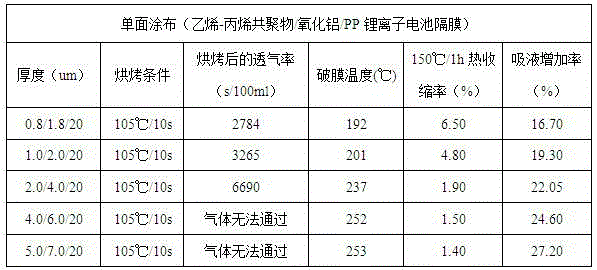

Lithium ion battery diaphragm and preparation method

ActiveCN104022250ALow closed cell temperatureAvoid thermal runawayCell component detailsPolyolefinPhysical chemistry

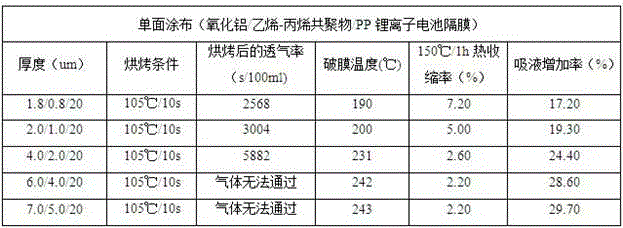

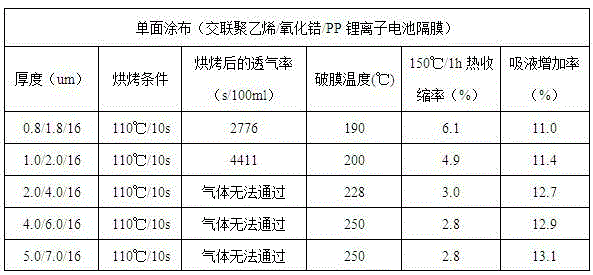

The invention discloses a lithium ion battery diaphragm and a preparation method thereof. The ion battery diaphragm comprises a diaphragm base material, wherein the surface of the diaphragm base material is coated with a polyolefin coating, and the coating thickness of the polyolefin coating is 1 to 4 micrometers. The diaphragm base material is coated with the polyolefin coating, and an effect for reducing the obturator temperature can be realized, so that the worsening of a thermal runaway can be prevented, when the temperature in a lithium ion battery reaches the obturator temperature, current can be disconnected at the first time, an effect for protecting the lithium ion battery can be realized, the thermal shrinkage rate of the lithium ion battery diaphragm after being roasted for 1h under the temperature of 150DEG C is less than 5 percent; compared with a non-coated lithium ion battery diaphragm, for the lithium ion battery diaphragm disclosed by the invention, the liquid absorption addition rate is 10 to 28 percent, and the charging-discharging cycling efficiency of the lithium ion battery can be further improved.

Owner:FOSHAN YINGBOLAI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com