Gel state polymer lithium ion battery electrolyte and preparation method thereof

A lithium-ion battery and gel polymer technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as low conductivity, difficult industrialization, and complicated preparation process, and achieve strong mechanical strength and good cross-linking Excellent microporous structure and high electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Dissolve PVDF-HFP in DMF at a mass percentage of 10%, and heat and stir in a water bath at 40°C for 3 hours.

[0041] (2) After completely dissolving, pour the coating solution on a glass plate, scrape it flat with a scraper, let it stand for 1 minute, then transfer it to tap water at room temperature, soak it in water for 10 minutes, and then transfer the polymer film to room temperature. deionized water and removed after 6 hours. Naturally air-dried, that is, a self-supporting lithium-ion battery gel polymer film with a certain thickness is prepared.

[0042] (3) Place the prepared film in a vacuum drying oven at 80°C for 6 hours in vacuum, take it out, cut the polymer film into an appropriate size, and quickly transfer it to a glove box. After the polymer membrane was soaked in the electrolyte for 1 hour, a self-supporting gel polymer electrolyte for lithium-ion batteries was obtained. The electrolyte is: LiPF6 is dissolved in an ester mixture, and the ester mi...

Embodiment 3

[0048] (1) Dissolve PVDF-HFP in acetone at a mass percentage of 10%, and ball-mill the medium-alkali glass fiber with a diameter of 0.7 μm and a length of 4 μm (the model is valve-controlled Glass fibers for lead-acid batteries (purchased from Puyang Taixin Glass Fiber Products Co., Ltd.) were added to the solution, heated and stirred in a water bath at 60°C for 4 hours.

[0049] (2) After completely dissolving, pour the coating solution on a glass plate, scrape it flat with a scraper, let it stand for 30 minutes, then transfer it to tap water at 50°C, soak it in water for 1 hour, and transfer the polymer film to In deionized water at room temperature, take it out after 2 hours. Naturally air-dried to obtain a self-supporting lithium-ion battery gel polymer film doped with modified glass fibers with a certain thickness.

[0050] (3) Place the prepared film in a vacuum drying oven at 70°C for 10 hours in vacuum, take it out, cut the polymer film into an appropriate size, and q...

Embodiment 4

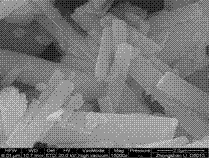

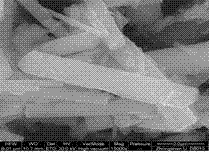

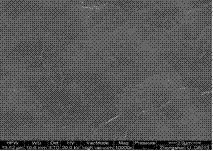

[0052] Liquid absorption, conductivity, porosity, decomposition temperature and scanning electron microscope tests were carried out on the above-mentioned lithium ion battery gel polymer electrolyte obtained by the method of embodiment 2 or 3, and the glass added in the lithium ion battery gel polymer electrolyte The amount of fiber was 5%, 10%, 15%, 20%, 30%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com