Patents

Literature

105results about How to "High membrane rupture temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

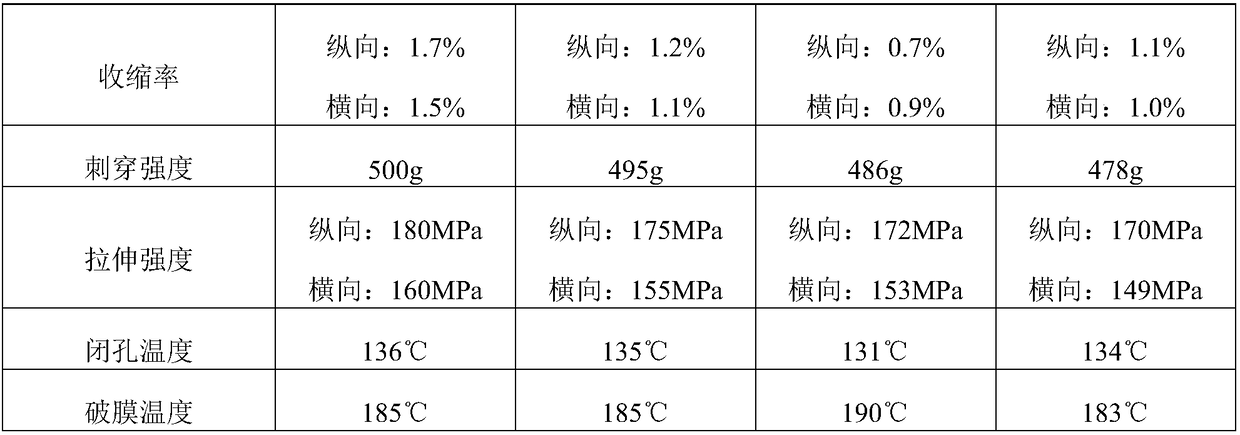

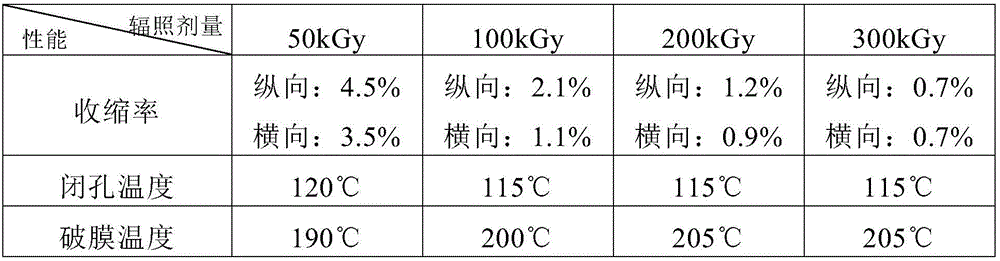

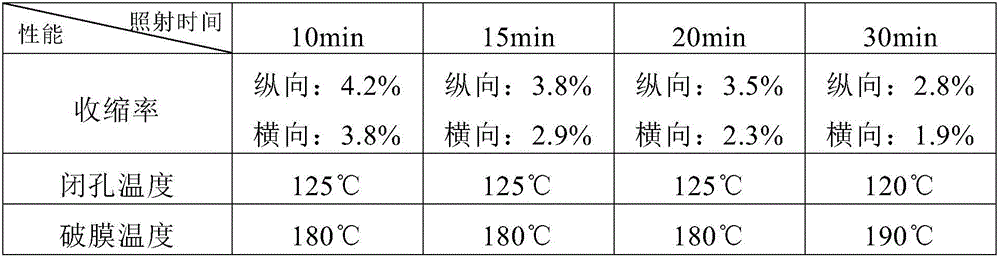

Irradiation cross-linking lithium-ion battery diaphragm and preparation method thereof

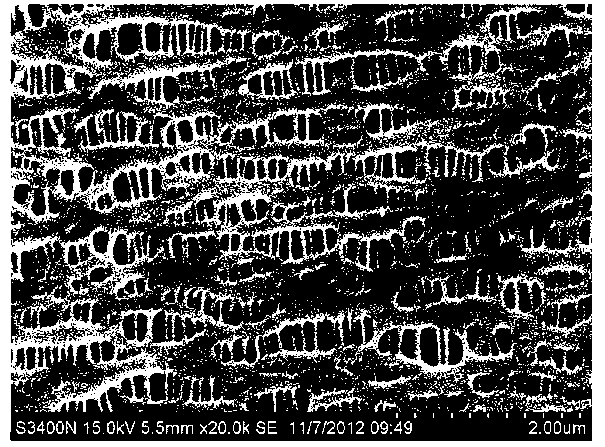

ActiveCN103421208AImprove securityLow closed cell temperatureCell component detailsCross-linkPolymer science

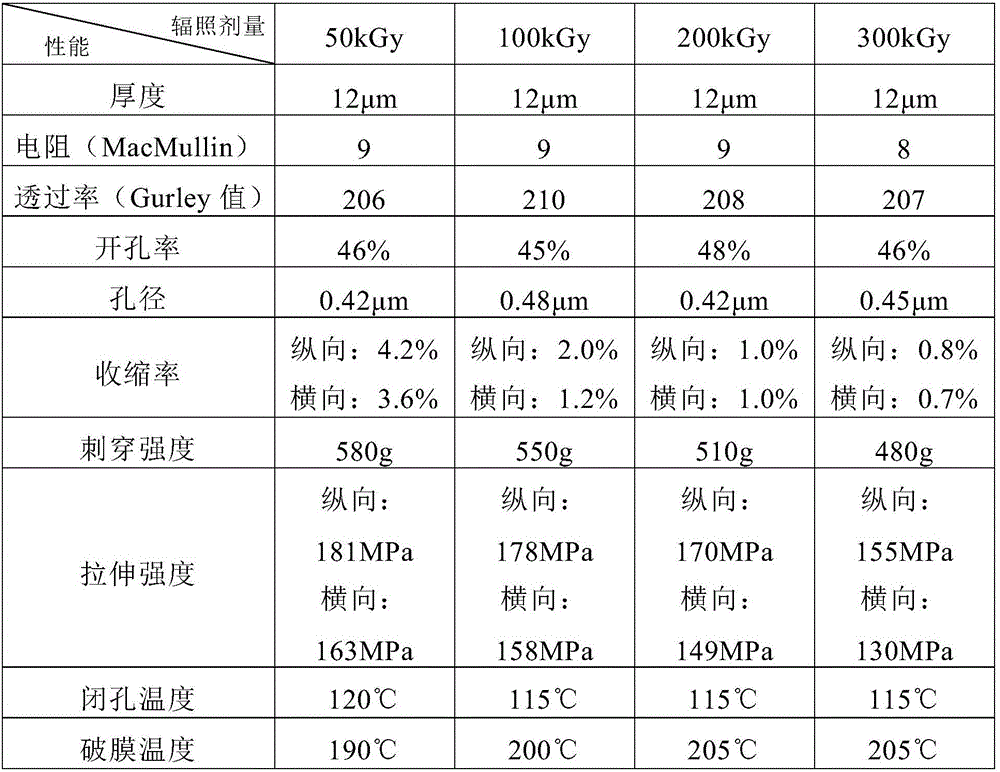

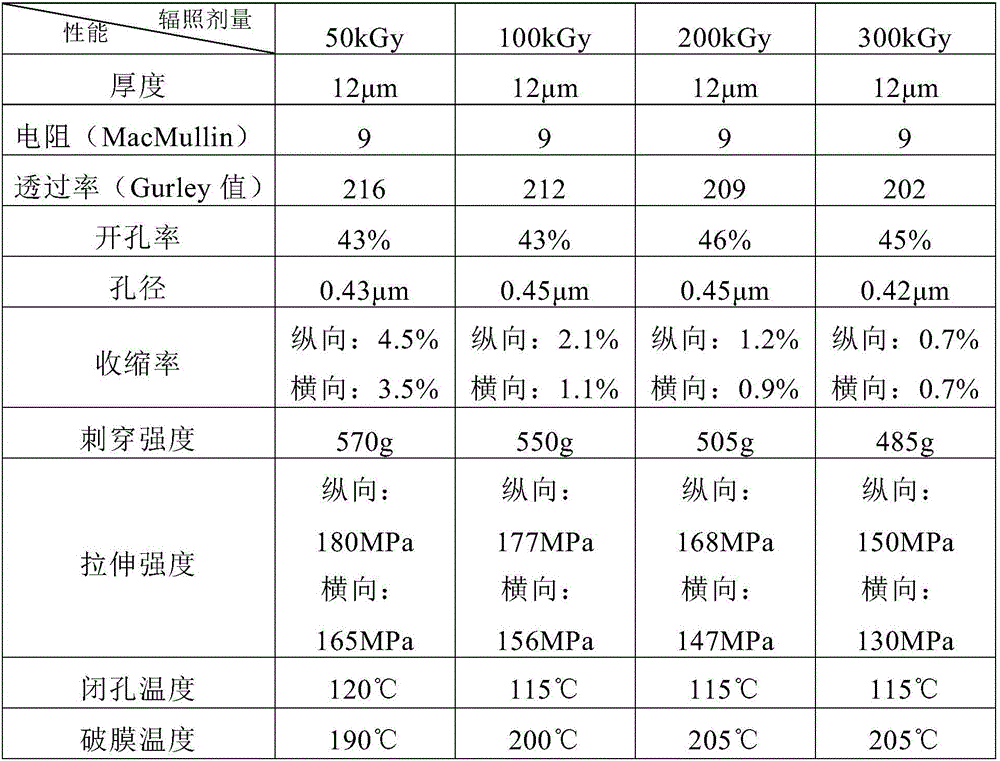

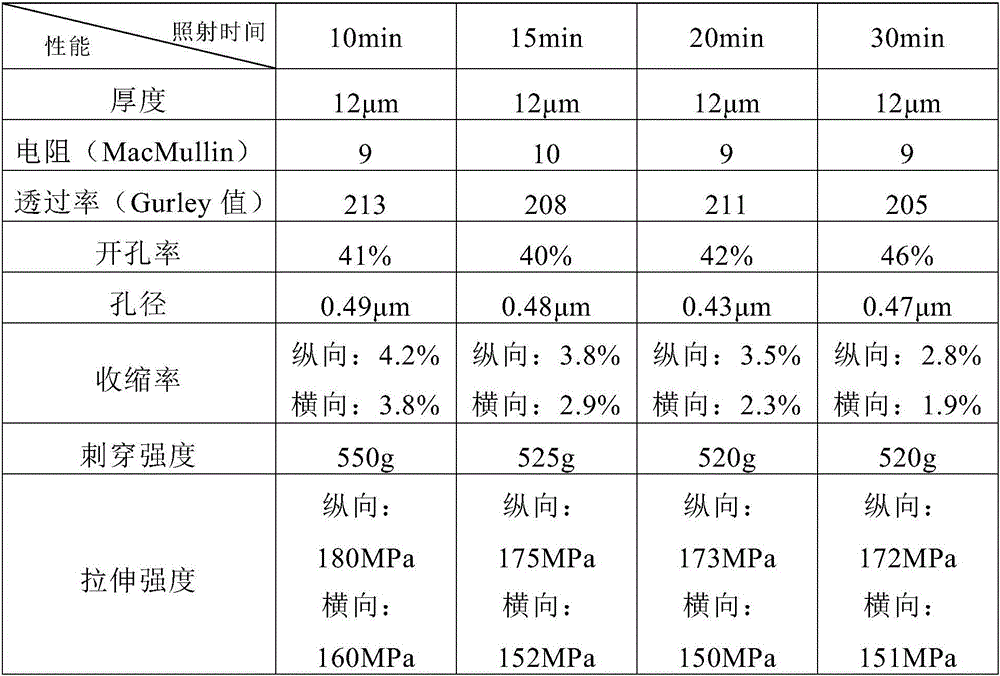

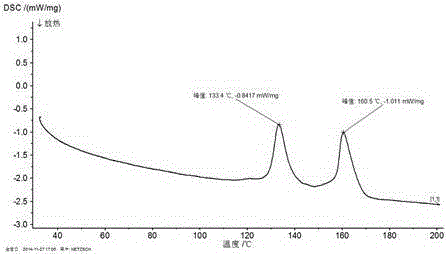

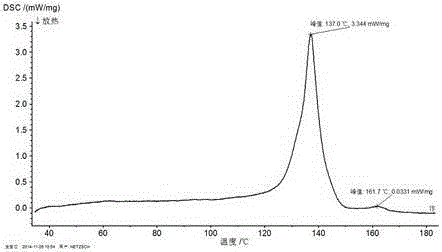

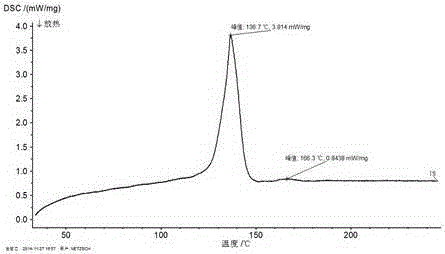

The invention discloses a preparation method of an irradiation cross-linking polyethylene porous diaphragm. According to the method, the polyethylene porous diaphragm is soaked in and adsorbs a volatile solvent containing initiator and cross-linking agent to lead initiator and cross-linking agent into the surface and the interior of the polyethylene porous diaphragm, and is then treated with irradiation cross-linking underwater or under the protection of inert gas, and a locally cross-linked diaphragm is obtained by controlling the cross-linking condition. The irradiation cross-linking lithium-ion battery diaphragm has the advantages that the tensile strength and the hydrophily are greatly improved; the high-temperature hot-shrinkage rate is greatly reduced; the defect of low membrane rupture temperature is overcome; the membrane rupture temperature is greatly raised while the normal hole closing of the diaphragm is guaranteed; the hole closing temperature of the diaphragm is 120 to 140 DEG C; the membrane rupture temperature is raised to be higher than 160 DEG C.

Owner:ZHEJIANG UNIV +2

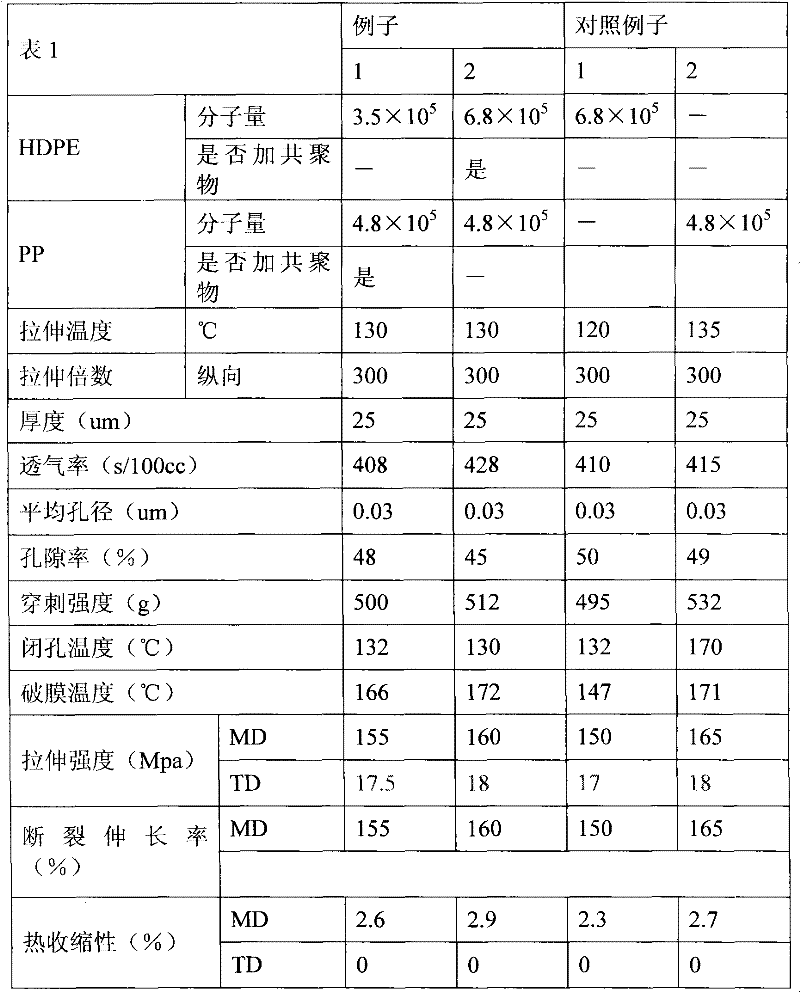

Microporous polyolefin laminated diaphragm for lithium-ion battery and its production

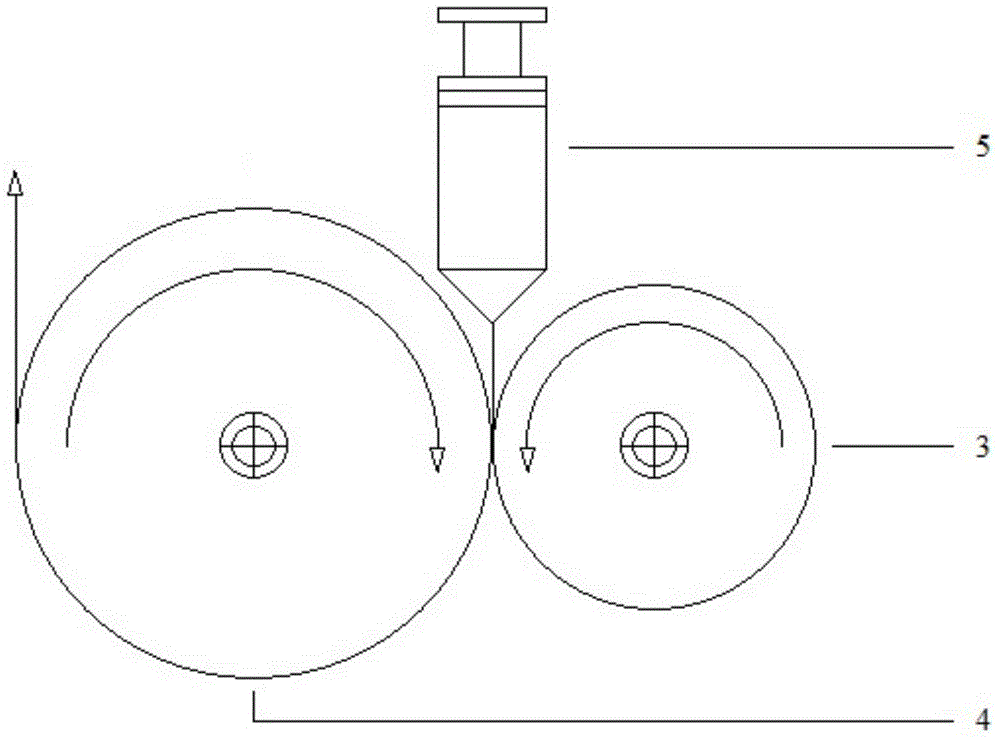

InactiveCN1897329ALow closed cell temperatureHigh membrane rupture temperatureCell component detailsPolyolefinBoiling point

The invention is concerned with the poly tiny porous multilayer septa for lithium ion battery, including several polyethylene layers and several polypropylene layers that cling at the polyethylene layers. The poly tiny porous multilayer septa manufacture method for lithium ion battery includes the following steps: mixes the polyethylene and the polypropylene with the high boiling-point small molecular weight compound solvent respectively, fusing plastifies the solution; extrudes the filming slice from the solution respectively using the double screw by the multi-layer die-head altogether, the cooling film forms the multi-layer gelatinous compound; heats and stretches the compound bidirectionally, cleans the solvent in the compound, dries the compound, and processes the heating finalize the design. The invention uses the whole structure compounding by the multi-layer poly film, the film is with the lower closing temperature by the low melting point polyethylene layer, the film is with the higher breaking temperature by the high melting point polypropylene layer.

Owner:SHENGCHAO AUTOMATION SCI & TECH SHANGHAI

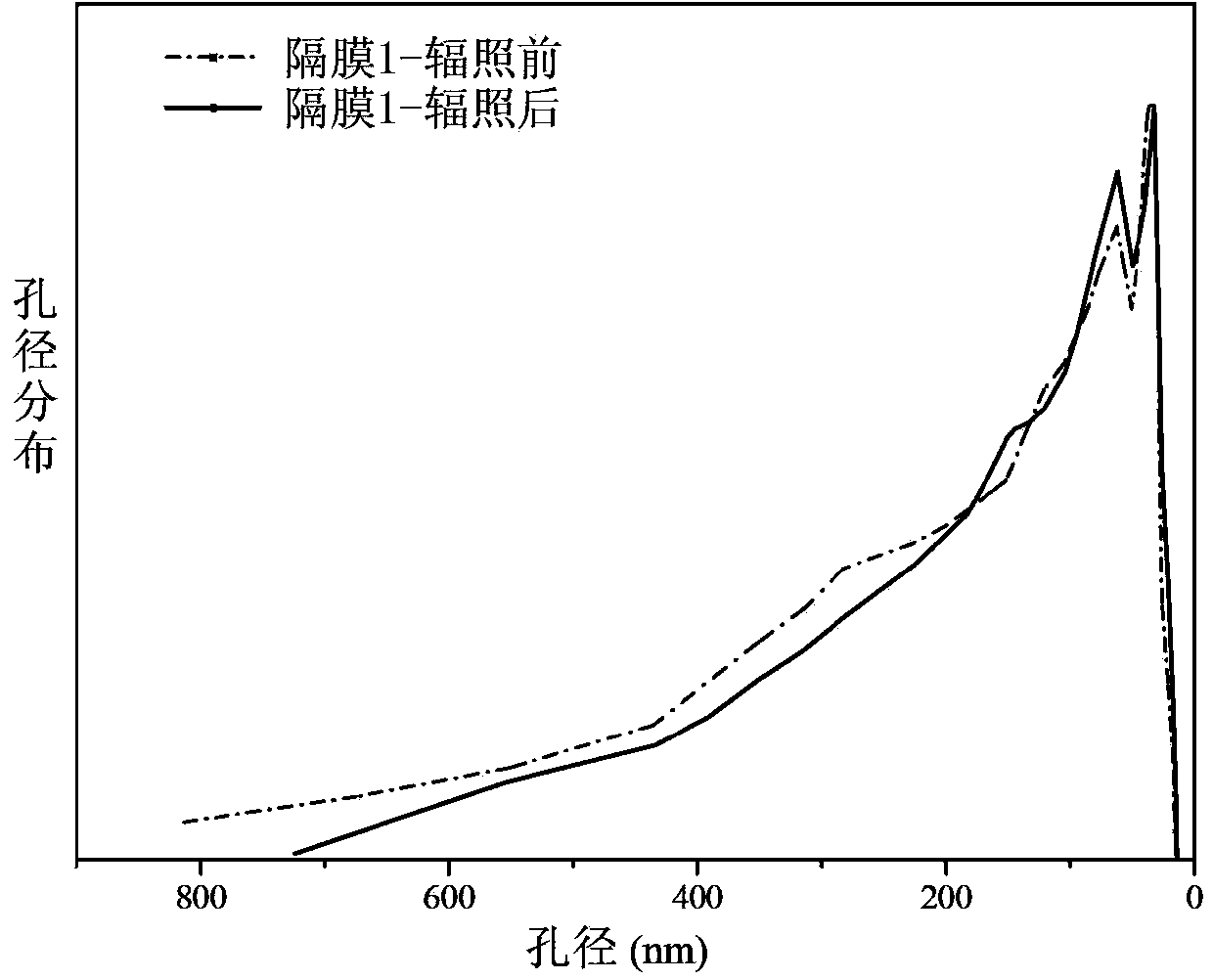

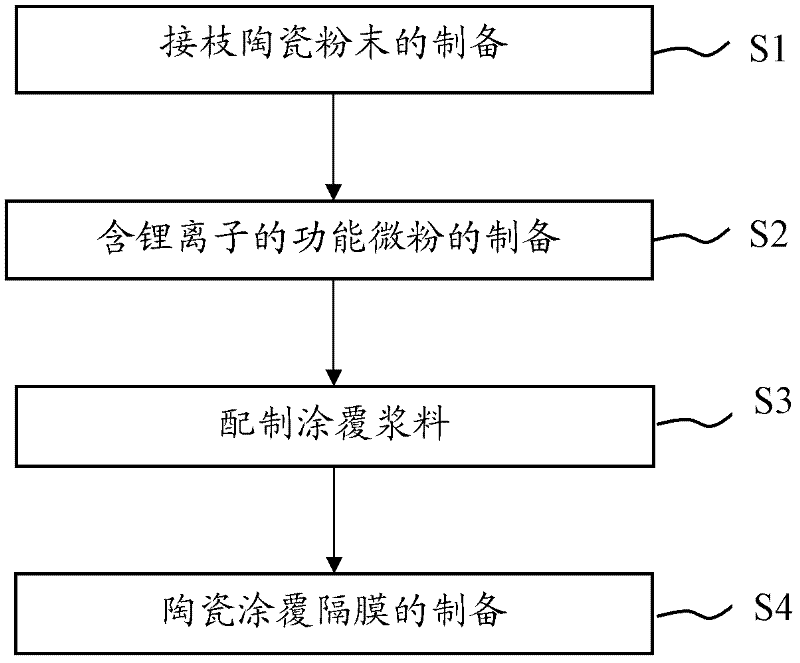

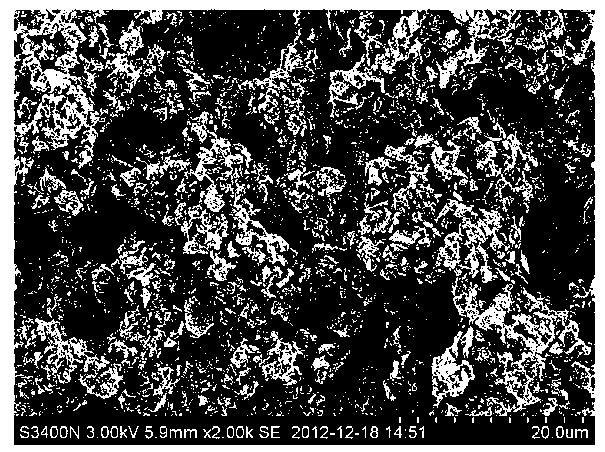

Ceramic coating membrane and preparation method thereof

ActiveCN102569700AImprove hydrophilicityHigh ion exchange capacityCell component detailsLithiumPolyolefin

The invention discloses a ceramic coating membrane and a preparation method thereof. The steps are as follows: the preparation of stem grafting ceramic powder, the preparation of functional power containing lithium-ion, the preparation of coating slurry and the preparation of ceramic coating membrane. The preparation method of ceramic coating membrane, provided by the invention is that: benzene sulfonate containing lithium is grafted on the surface of the ceramic powder, and then the ceramic powder grafted is coated on a polyolefin microporous membrane, thereby obtaining the ceramic coating membrane is obtained. The preparation method has the advantages of simple process, low requirements to equipment, easiness in condition control and low cost, and is suitable for industrial production. Due to the ion exchange capacity and hydrophily of the ceramic coating membrane prepared by the method, the ceramic coating membrane has a strong electrolyte infiltrating capability, is high in membrane breaking temperature, and has improved safety.

Owner:SHENZHEN SENIOR TECH MATERIAL

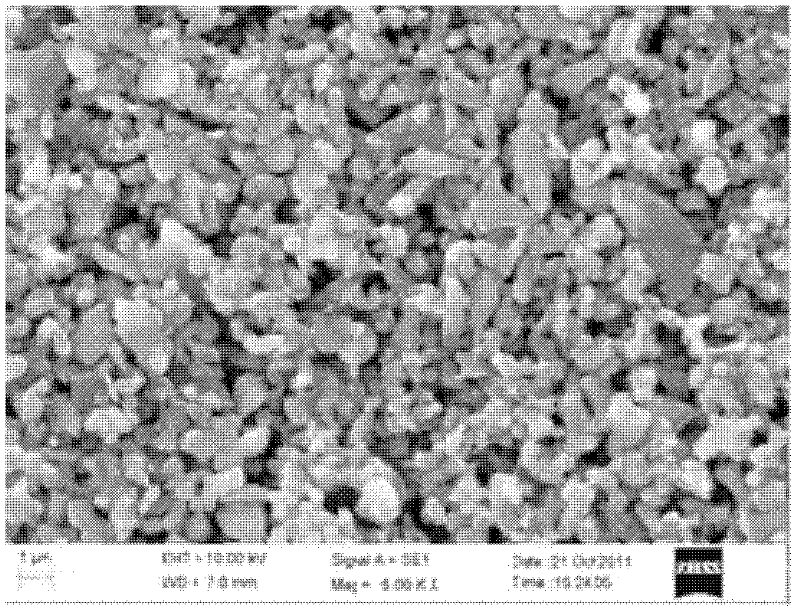

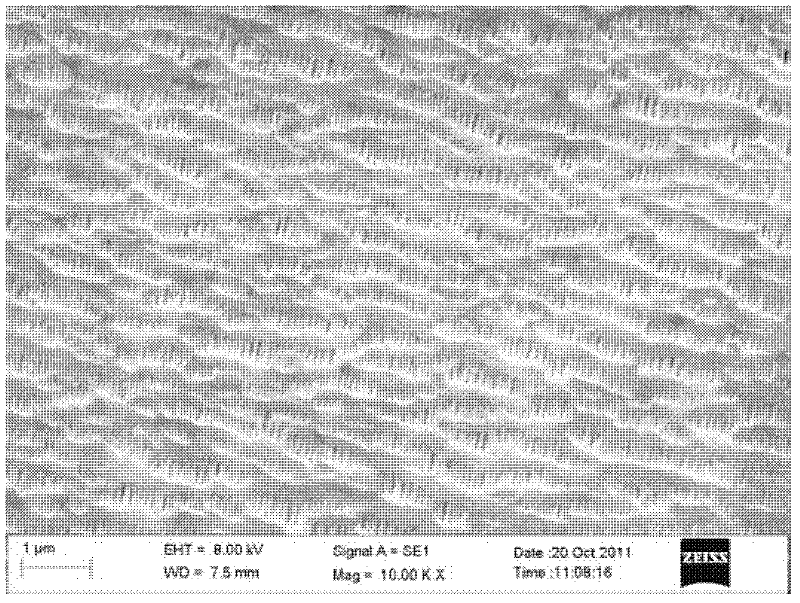

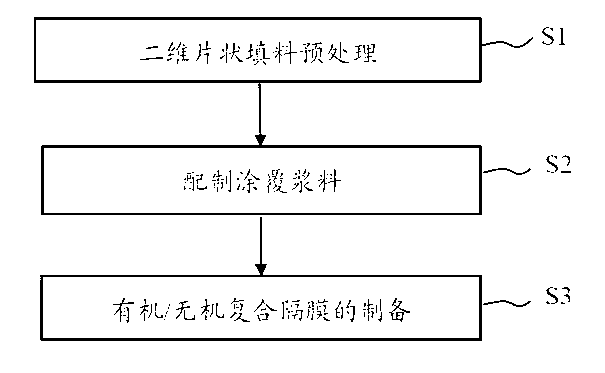

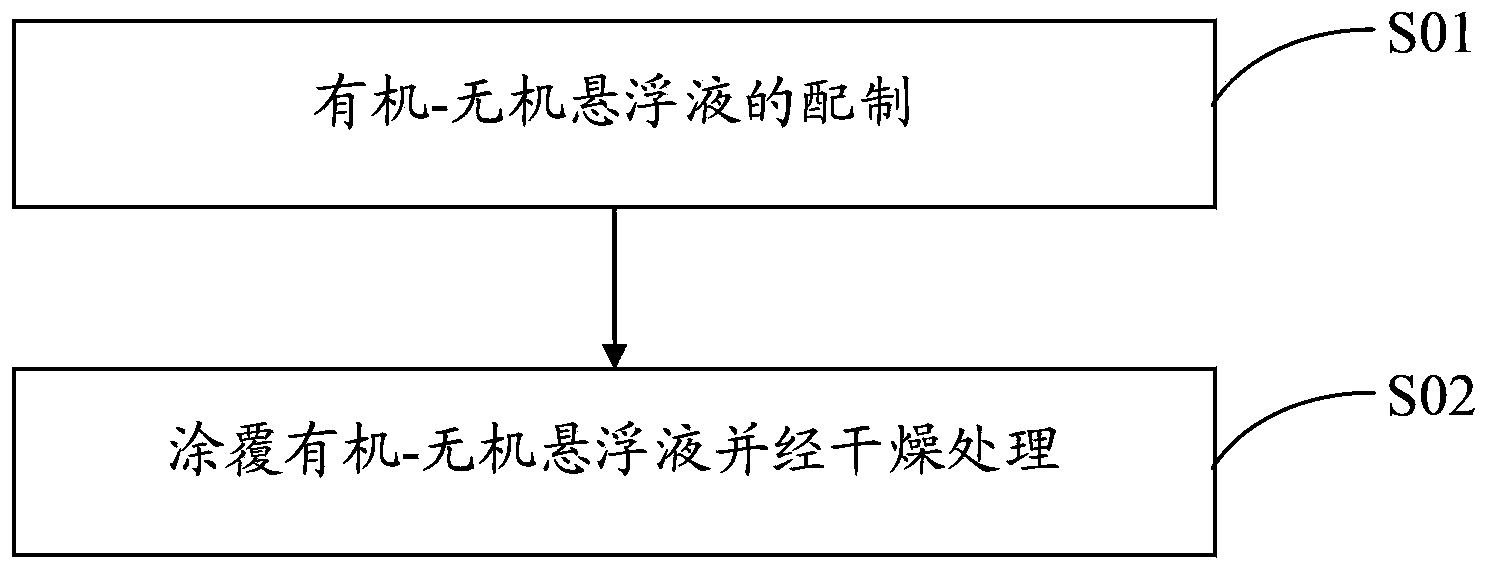

Preparation method of super-heat-resistant organic/inorganic composite film

ActiveCN103236511AImprove heat resistanceControlled contractionCell component detailsPower batteryComposite film

The invention discloses a preparation method of a super-heat-resistant organic / inorganic composite film. According to the invention, environment-friendly and nontoxic aqueous coating slurry is prepared; with a simple coating method, a coating comprising a two-dimensional flake-structured filling material is coated on one side or two sides of a porous medium, such that a composite film suitable for high-power batteries is prepared. The preparation method has the advantages of simple process, low requirement on equipment, easy-to-control conditions, low cost, and suitability for industrialized productions. Through simple coating, dimensional stability of a common film can be effectively improved, and heat resistance of the common film can be greatly improved. The film provided by the invention can maintain high dimensional stability under 200 DEG C, such that a common film is turned into a high-performance film.

Owner:GUANGDONG UNIV OF TECH

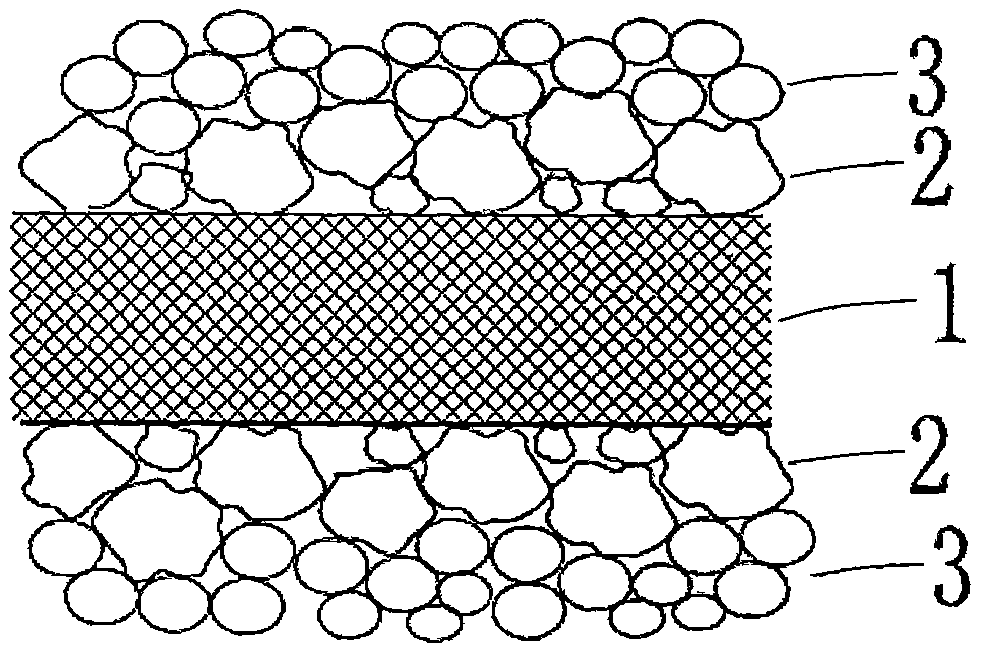

Polyolefin multilayer micro porous diaphragm for lithium ion battery and preparation method of polyolefin multilayer micro porous diaphragm

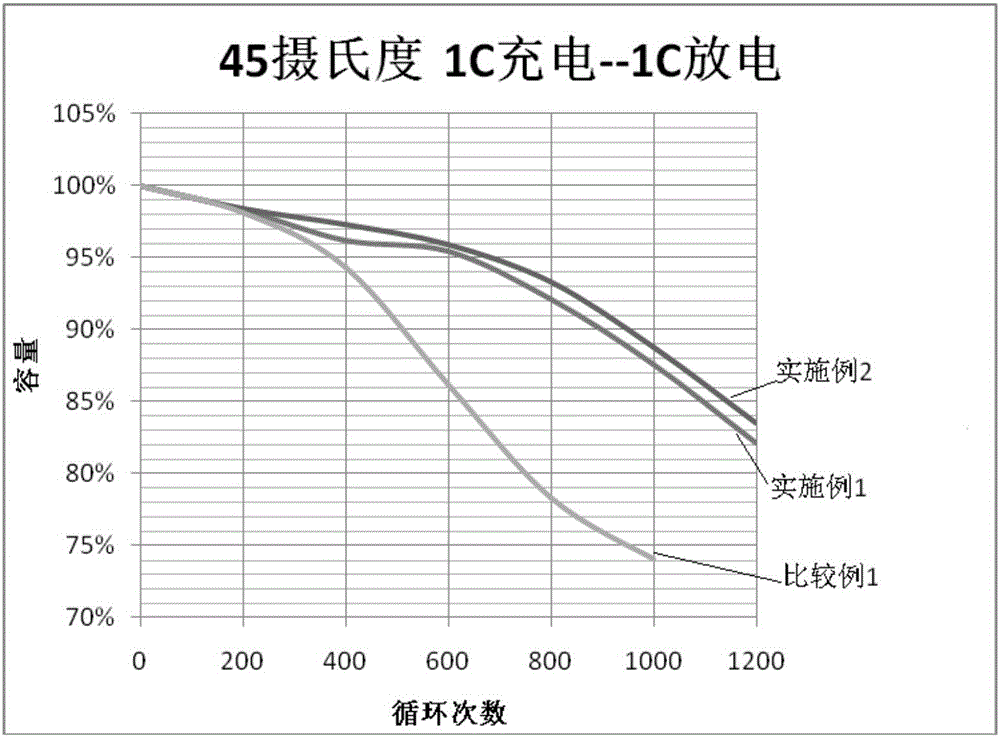

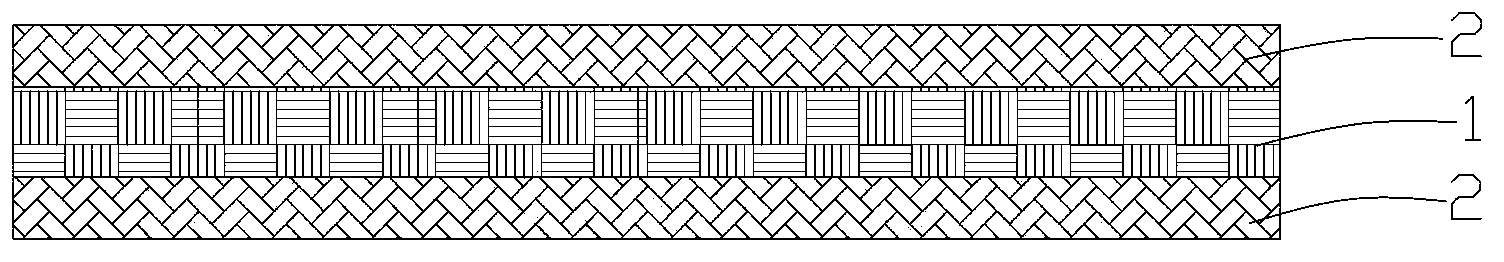

ActiveCN103531735AWith ion acceleration functionExcellent Adhesive FunctionCell component detailsPolyolefinHigh diaphragm

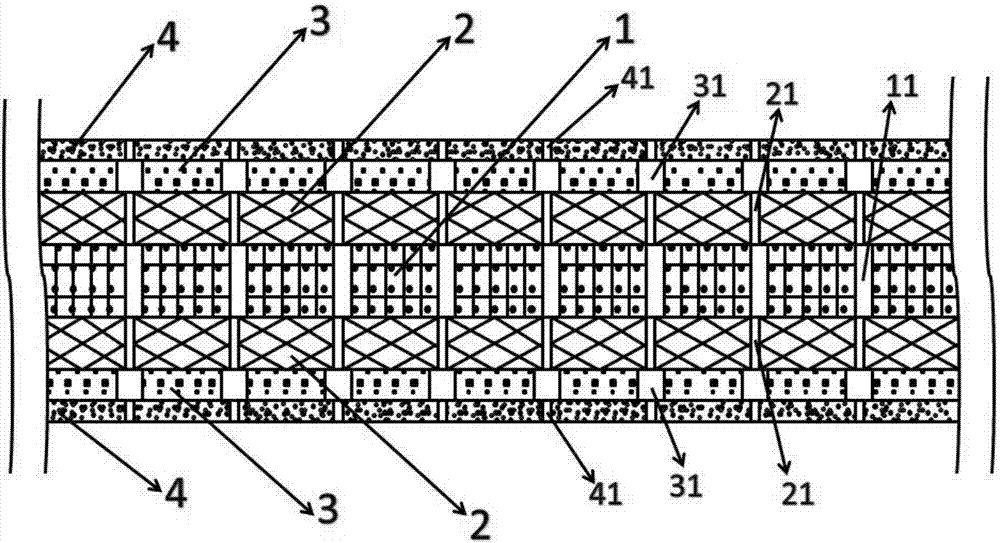

The invention relates to a polyolefin multilayer micro porous diaphragm for a lithium ion battery and a preparation method of the polyolefin multilayer micro porous diaphragm. The polyolefin multilayer micro porous diaphragm comprises a polyethylene micro porous layer, wherein an ion acceleration layer is arranged on each of the upper surface and the lower surface of the polyethylene micro porous layer, and a polypropylene micro porous layer is arranged on the outer surface of each ion acceleration layer. According to the polyolefin multilayer micro porous diaphragm, due to the adoption of a five-layer structure, a low hole closing temperature and a high diaphragm breaking temperature of the diaphragm can be provided, thus a safety window of the diaphragm is increased and the good safety performance is provided; and meanwhile, the ion acceleration layers provide low resistance, high electron conduction rate and good solution absorption performance and solution maintaining performance of the diaphragm, thus the charge-discharge power and the cycle service life of the lithium ion battery can be improved; and the ion acceleration layers have micro porous net-shaped structures and have excellent lyophilic performance and adhering performance, the ion transmission performance of the diaphragm is improved when all layers of the multilayer micro porous diaphragm are well compounded, and good gas permeability is kept.

Owner:河南惠强新能源材料科技股份有限公司

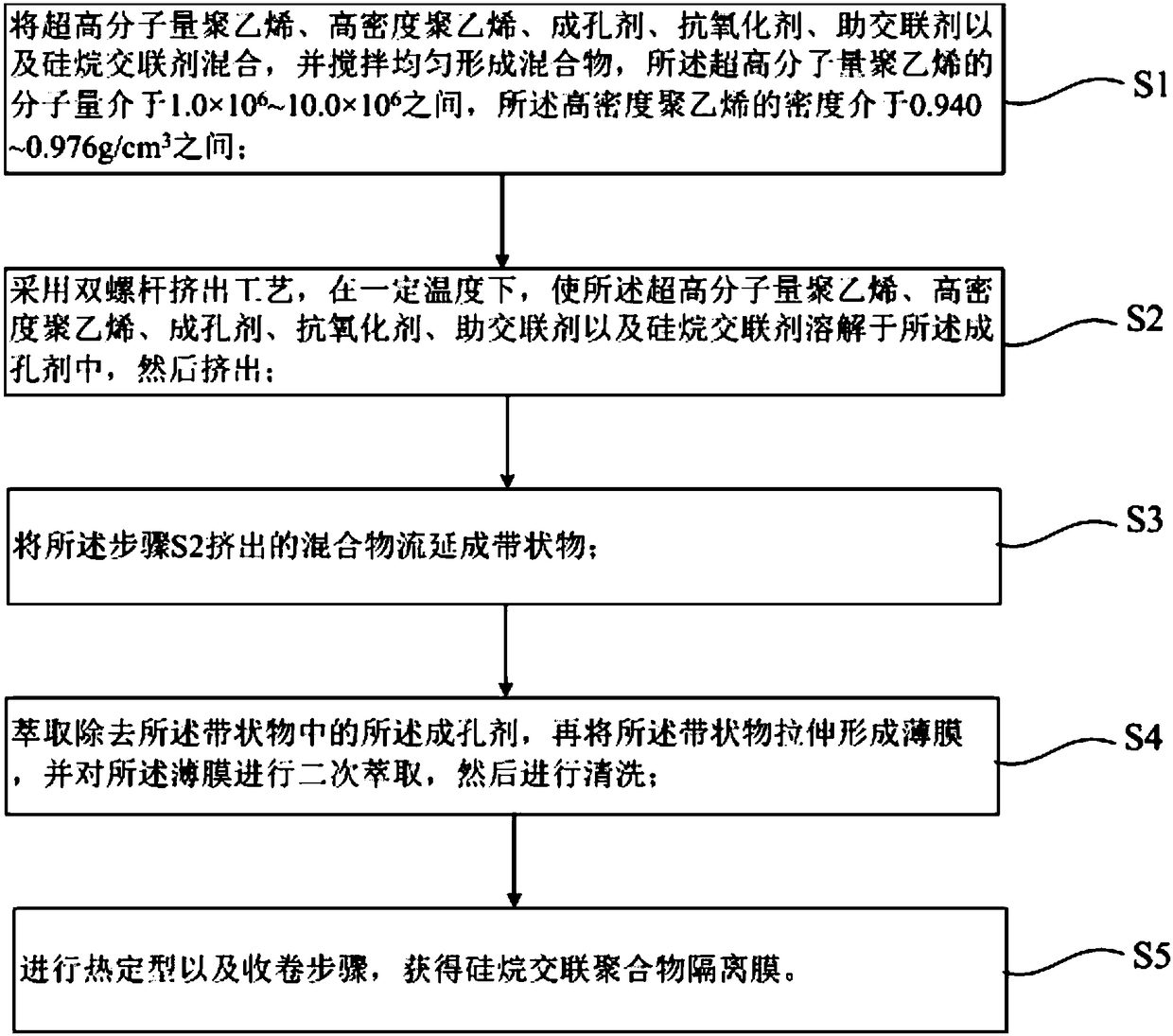

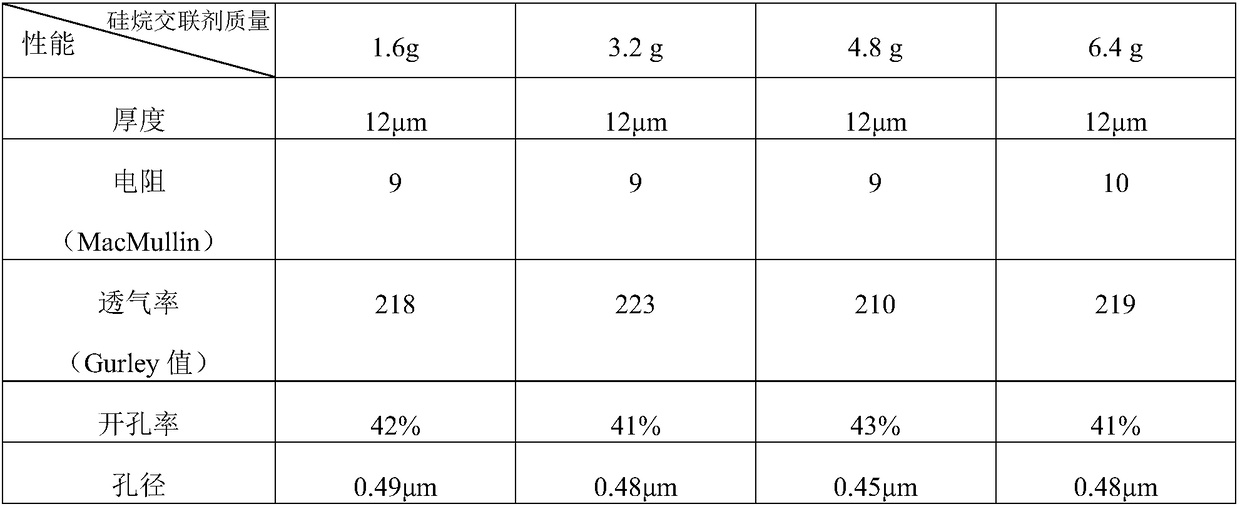

Silane crosslinked polymer separation film and preparation method thereof

InactiveCN108198986AReduce processing costsLow heat shrinkageCell seperators/membranes/diaphragms/spacersHigh densityAntioxidant

The invention provides a silane crosslinked polymer separation film, which comprises crosslinked polymerized ultrahigh molecular weight polyethylene, high-density polyethylene, an antioxidant, an assistant crosslinker and a silane crosslinking agent, wherein the molecular weight of the ultrahigh molecular weight polyethylene is 1.0*10<6> to 10.0*10<6>; the density of the high-density polyethyleneis 0.940-0.976g / cm<3>; and on the basis of 100 parts by weight of a mixture of the ultrahigh molecular weight polyethylene and the high-density polyethylene, the weight of the antioxidant is 0.5-20 parts, the weight of the assistant crosslinker is 0.1-10 parts and the weight of the silane crosslinking agent is 0.1-10 parts. The separation film is prepared through a chemical crosslinking method, sothat a difference value between the film rupture temperature and the obturator temperature of the prepared silane crosslinked polymer separation film and the hot shrinkage rate are improved and the safety performance of a battery is higher.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Battery diaphragm and fabrication method thereof

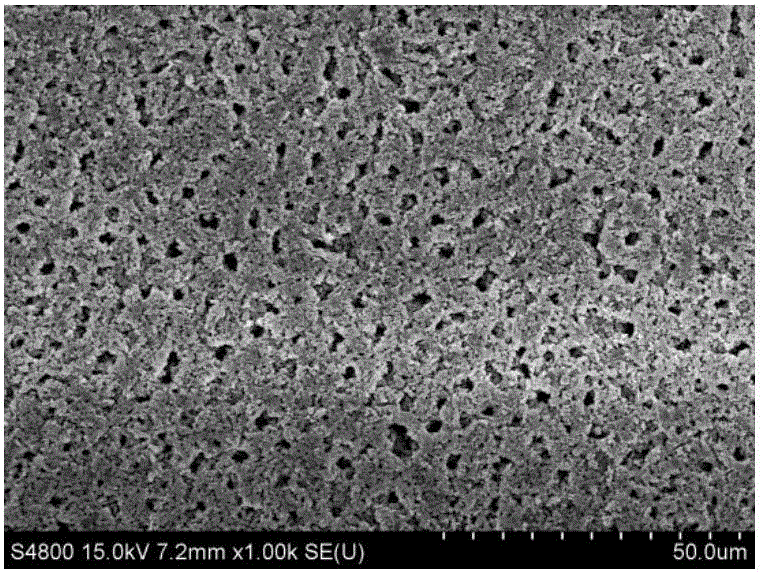

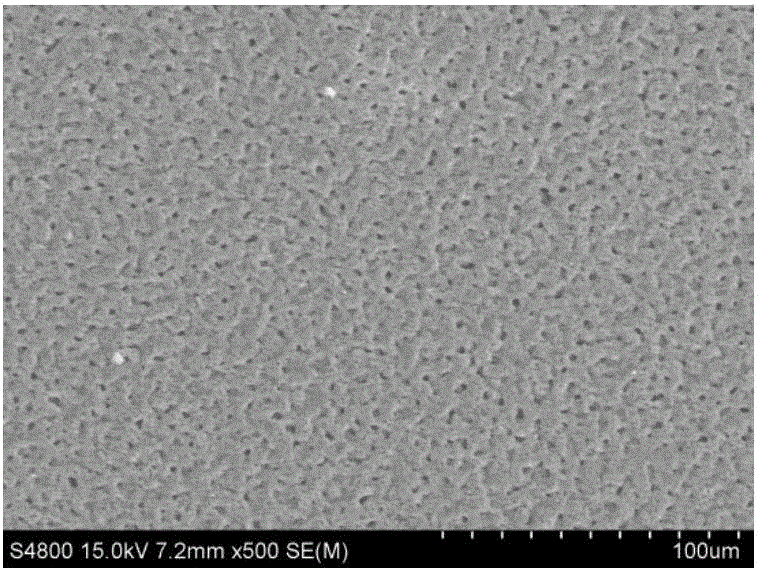

ActiveCN102820444ALow orientationUniform surface pore size distributionSynthetic resin layered productsSecondary cellsLow-density polyethyleneLinear low-density polyethylene

The invention provides a battery diaphragm. The base material of the diaphragm is a polyvinylidene fluoride non-woven fabric, coating layers are arranged on two sides of the polyvinylidene fluoride non-woven fabric, and the material of the coating layers includes an ultra high molecular weight polyethylene and a linear low density polyethylene. A fabrication method of the battery diaphragm is further provided. According to the battery diaphragm and the fabrication method thereof, the provided battery diaphragm has the advantages that the air permeability is remarkably improved, the closed pore temperature is remarkably lowered, the puncture strength and diaphragm breaking temperature are remarkably improved, a safe protective property is provided for a battery, and the battery diaphragm is applicable to power batteries.

Owner:BYD CO LTD

Battery isolating membrane preparation method

InactiveCN106450112AImprove performanceHigh membrane rupture temperatureCell component detailsHigh densityAntioxidant

The invention discloses a battery isolating membrane preparation method. Mixed raw materials are extruded, cooled, formed, extracted, stretched and heat-set to obtain a battery isolating membrane. The raw materials include ultra-high molecular weight polyethylene, high-density polyethylene, antioxidants and pore-forming agents, the molecular weight of the ultra-high molecular weight polyethylene is 1.0*10<6>-10.0*10<6>, the density of the high-density polyethylene ranges from 0.940g / cm<3> to 0.976g / cm<3>, and the method includes cross-linking.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Polyene microporous multilayer diaphragm and manufacturing method thereof

ActiveCN102248713AImprove securityRaise the temperature differenceSynthetic resin layered productsPolyeneEthylene propylene copolymer

The invention provides a polyene microporous multilayer diaphragm and a manufacturing method thereof. The diaphragm is formed by combing three or more than three polyene layers, wherein in a plurality of polyene layers, at least one polyene layer is a polyethylene layer, and at least one polyene layer is a polypropylene layer; the polyethylene layer and the polypropylene layer are tightly attached to each other; and in adjacent polyethylene and polypropylene layers, at least one layer is a polymer blend layer which contains a certain amount of ethylene-propylene copolymer. The invention has the advantages that: in the integrated structure of the polyene microporous multilayer diaphragm, the properties of porosity, puncture strength, pore size, ventilation ratio, tensile strength, breaking elongation and the like are also identical to the high properties of a single-layer diaphragm; simultaneously, the defects of the single-layer diaphragm is overcome, namely the safety of the diaphragm is improved.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

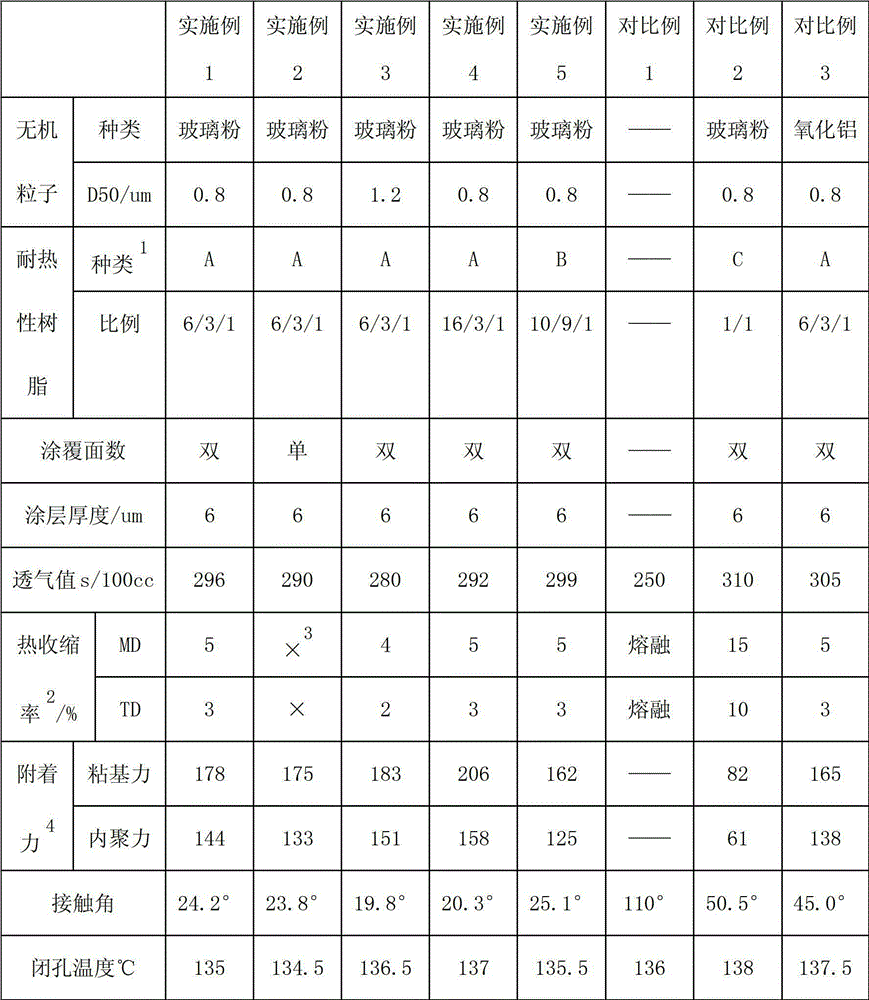

Coating composite for lithium ion secondary battery membrane and method for manufacturing membrane

ActiveCN102942831AHigh temperature resistantLow densityCell seperators/membranes/diaphragms/spacersSecondary cellsCoated surfaceLithium

The invention discloses a coating composite for a lithium ion secondary battery membrane and a method for manufacturing the membrane. The coating composite comprises heat resistant resins and inorganic non-conducting insulation particles, molecular chains of the heat resistant resins comprise oleophylic structural units, hydrophilic structural units and functional group structural units, and a thermal decomposition temperature is larger than 250 DEG C. The inorganic non-conducting insulation particles have the advantages of being high temperature resistant, low in density, rigidity and water absorption and the like; composite micro porous membranes prepared through the coating composite has the advantages of being low in hole closing temperature, high in membrane breaking temperature, low in thermal shrinkage rate, high in combining force between a heat resistant coating and a substrate, good in wettability of the heat resistant coating surface and the like simultaneously; and the membrane used for manufacturing a lithium ion secondary battery has good comprehensive properties and reliable safety performances.

Owner:河南惠强新能源材料科技股份有限公司

Manufacturing method of lithium ion battery diaphragm as well as battery diaphragm prepared by manufacturing method and battery

InactiveCN104362275ASolve the lack of hardnessImprove securitySecondary cellsCell component detailsMolecular materialsHardness

The invention discloses a manufacturing method of a lithium ion battery diaphragm as well as the battery diaphragm prepared by the manufacturing method and a battery. The manufacturing method comprises the following steps: a. covering the surface of ceramic power by one organic high molecular material layer through a solid-phase covering or liquid-phase covering manner to obtain ceramic grain powder covered with the organic high molecular material layer, and sieving the dried and granulated powder for later use; b. adding a solvent, glue and an impregnating compound into the ceramic powder coated in the last step to prepare ceramic slurry; and c. coating a lithium ion battery diaphragm base material by the ceramic slurry to prepare the lithium ion battery diaphragm. The ceramic is firstly covered with the high molecular material layer, and the enough rigidity of the lithium ion battery, and especially a thin, long and wide battery produced by the lithium ion battery diaphragm can be guaranteed; the shrinking percentage is low when the battery is heated, the diaphragm breaking temperature of the diaphragm is improved and the safety of the battery is improved; and the high molecular material layer only needs to be coated for one time, so that the cost is obviously reduced and the efficiency is improved by at least one time.

Owner:DONGGUAN ADVANCED ELECTRONICS TECH

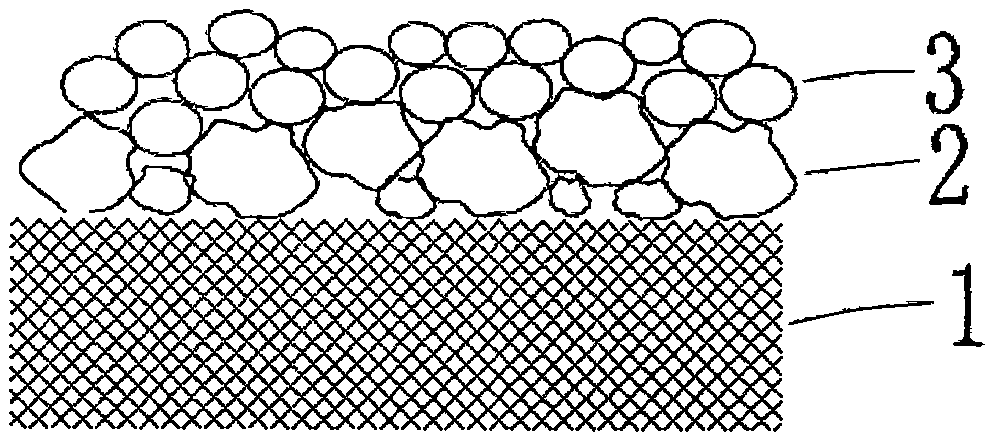

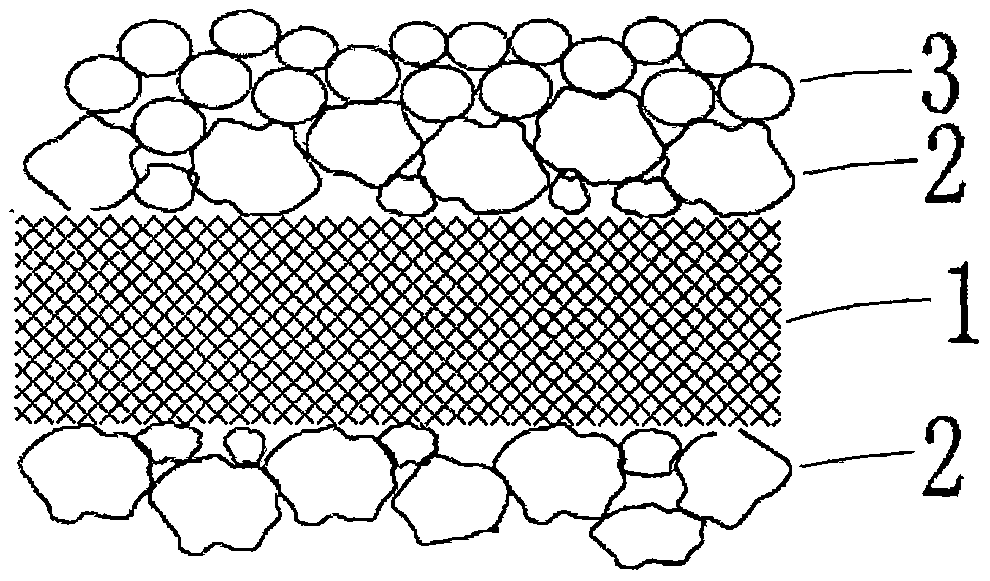

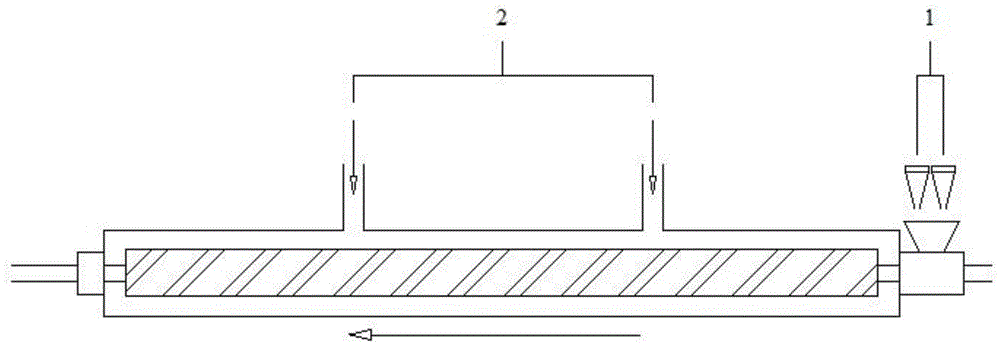

Polyolefin multilayer micro-porous membrane and preparation method thereof

ActiveCN102501419ALow closed cell temperatureHigh membrane rupture temperatureCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolyolefinSurface layer

The invention discloses a polyolefin multilayer micro-porous membrane and a preparation method thereof. The middle layer of the polyolefin multilayer micro-porous membrane is a polyethylene micro-porous membrane; both surface layers of the polyolefin multilayer micro-porous membrane are micro-porous membranes which respectively contain polypropylene and polyethylene with super-high molecular weight; the polyethylene of the middle layer has the molecular weight of 1*105 to 6*105; the polypropylene of the surface layers has the molecular weight of 1*105 to 1*106; and the polyethylene of the surface layers has the molecular weight of 5*105 to 5*106. The preparation method comprises the following steps: firstly, respectively fusing to mix the raw auxiliary material of the middle layer and the raw auxiliary materials of the surface layers; putting the raw auxiliary materials of the middle layer and the surface layers into a twin-screw extruder; extruding through a multilayer co-extrusion die head; cooling; and then, drawing to manufacture the membrane, extracting and shaping to obtain the polyolefin multilayer micro-porous membrane.

Owner:河南惠强新能源材料科技股份有限公司

Thermal shutdown heat-resistant high-safety coated and modified membrane and preparation method thereof

PendingCN108550766AHigh membrane rupture temperatureAvoid short circuitCell seperators/membranes/diaphragms/spacersSecondary cellsWater basedMicrosphere

The invention discloses a thermal shutdown heat-resistant high-safety coated and modified membrane, which comprises a base membrane, wherein a ceramic / resin coating and a polymer microsphere coating are arranged at one side or two sides of the base membrane; the ceramic / resin coating is prepared from the following components in percentages by mass: 30-60wt% of an inorganic ceramic material, 25-66wt% of deionized water, 3-10wt% of heat-resistant resin and 1-5wt% of a catalytic polyaddition organic matter; and the polymer microsphere coating is prepared from the following components in percentages by mass: 3-20wt% of polymer microspheres, 60-93wt% of deionized water, 3-10wt% of a water-based binder, 0.5-5wt% of a water-based wetting agent and 0.5-5wt% of a water soluble dispersant. The prepared thermal shutdown heat-resistant high-safety coated and modified membrane has a trigger effect of achieving thermal shutdown of the membrane at relatively low temperature, the thermal shutdown temperature of the membrane is lower than 130 DEG C, the thermal shutdown mechanism can be triggered at relatively low temperature in a thermal runaway exothermic process of a lithium-ion battery, the internal resistance of the battery is increased by two orders of magnitude after thermal shutdown, and further lithium ion exchange in the battery is prevented to reduce the generated heat.

Owner:CANGZHOU MINGZHU PLASTIC +2

High fused mass strength compound isolating film and preparation method and application thereof

InactiveCN101222034ASuperior performanceImprove securityCell component detailsMembrane rupturingPolyolefin

The invention relates to a battery polyolefin isolating membrane. The composite isolating film with high fused mass strength of the invention is a microporous membrane which takes the structure of B / A two-layer or B / A / B three-layer, wherein, A layer is a copolymer membrane of polyethylene or ethylene and 5 to 50 percent other olefins or a mixture membrane of the polyethylene or the ethylene and the 5 to 50 percent other olefins, and B layer is a copolymer membrane of propylene and 0.1 to 10 percent other olefins. The invention has the advantages that: a polymer A which provides low obturator temperature and a polymer B which provides high membrane rupture temperature and high fused mass strength are led in a formulation for preparation of the polyolefin composite microporous isolating membrane, thereby the isolating membrane with low obturator temperature, high membrane rupture temperature, high fused mass strength and high use safety is obtained.

Owner:SHENZHEN SENIOR TECH MATERIAL

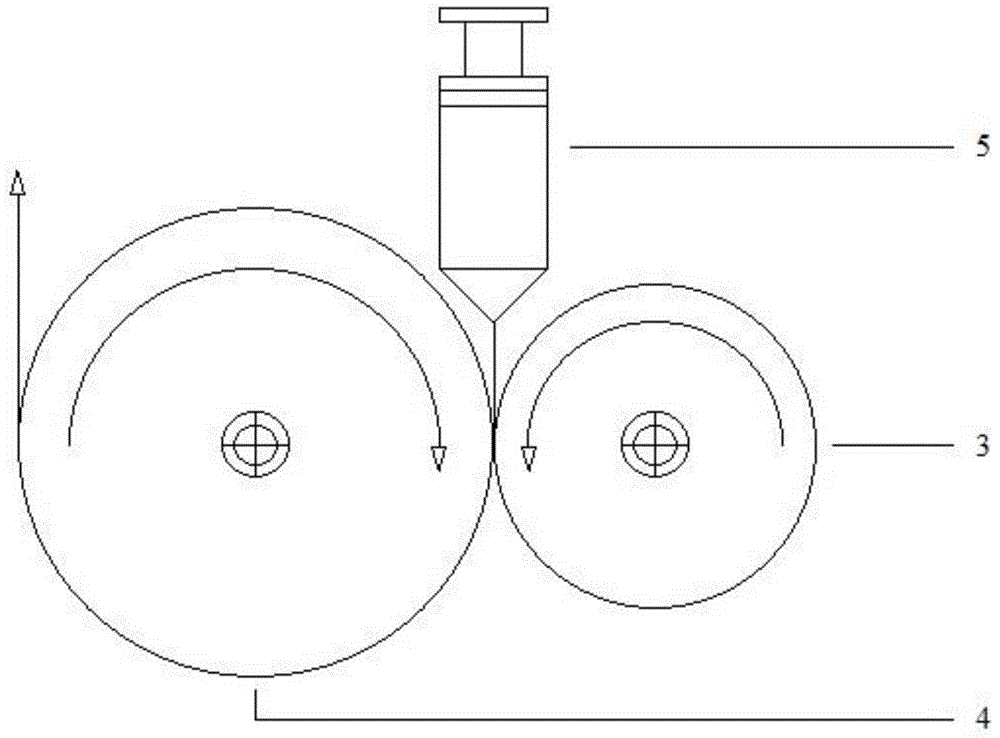

A compound diaphragm for lithium ion battery and its making method

InactiveCN101241984ALow closed cell temperatureHigh membrane rupture temperatureSynthetic resin layered productsLaminationHigh fluxLithium-ion battery

The present invention discloses a composite isolating film used by the lithium cell which is the microporous film with B / A / B three-layer structure, wherein layer A is a copolymer film of ethene and other alkene for 1-25(weight percentage); layer B is a copolymer film of propylene and other alkene for 1-5(weight percentage). The originator of the invention adopts the copolymer film of ethene and other alkene, and adopts the copolymer film of propylene and other alkene for a minute quantity in the other layer for preparing a microporous film with B / A / B three-layer sandwich. The copolymer of ethene and other alkene provides a low pore closing temperature, the copolymer film of propylene and minute-quantity other alkene provides high film breaking temperature, high flux strength and adhesive force in the layer A formed by polythene or vinyl copolymer, thereby obtaining an isolating film which has the advantages of low pore closing temperature, high film breaking temperature, high flux strength and high using security.

Owner:SHENZHEN SENIOR TECH MATERIAL

Battery isolating membrane and preparing method thereof

InactiveCN106486632AImprove performanceAverage pore sizeCell component detailsThermoformingUltrahigh molecular weight polyethylene

The invention discloses a battery isolating membrane and a preparing method thereof. The preparing method includes the steps that extrusion, cooling molding, extraction, stretching and thermoforming are carried out on mixed raw materials to obtain the battery isolating membrane. The raw materials include ultrahigh molecular weight polyethylene with the molecular weight of 1.0*10<6>-10.0*10<6>, high-density polyethylene with the density within the range of 0.940-0.976 g / cm<3>, antioxidant and a pore-forming agent. The method includes the step of crosslinking.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Polyolefin microporous membrane, making method thereof, and lithium ion battery

ActiveCN105355811AIncrease temperatureImprove integrityCell seperators/membranes/diaphragms/spacersSecondary cellsPolymer sciencePolyolefin

The invention relates to a polyolefin microporous membrane, a making method thereof, and a lithium ion battery. The skeleton structure of the microporous membrane is formed by a polypropylene and polyethylene two-phase continuous phase, wherein the mass percentage of polypropylene resin is 50-65%, the mass percentage of polyethylene resin is 35-50%, the intrinsic viscosities of the polypropylene resin and the polyethylene resin are 200-1000ml / g respectively, and a difference between the intrinsic viscosities of the polypropylene resin and the polyethylene resin is 100ml / g. The microporous membrane has the advantages of large safety window, excellent integrity of a high temperature melt, and great improvement of the safety performance of the battery when the microporous membrane is used in the lithium ion battery.

Owner:乐凯胶片股份有限公司

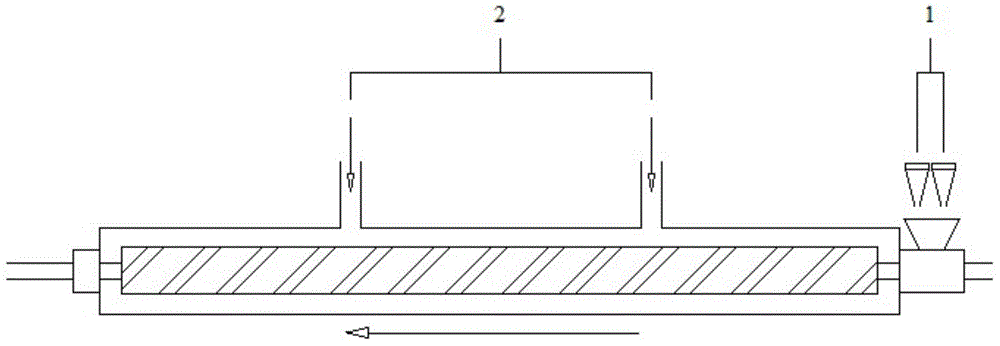

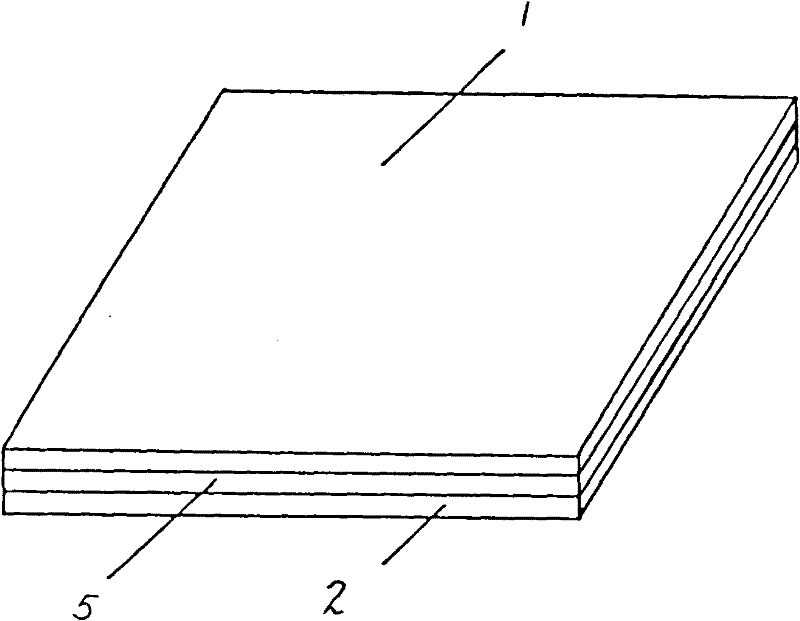

Preparation method of special composite coating diaphragm for lithium battery

ActiveCN107994183ALow closed cell temperatureHigh membrane rupture temperatureCell seperators/membranes/diaphragms/spacersBoehmiteSurface modification

The invention discloses a special composite coating diaphragm for a lithium battery. The special composite coating diaphragm comprises a microporous membrane, resin layers, ceramic layers and acrylicadhesive layers; the special composite coating diaphragm is characterized in that the resin layers coat the upper surface and the lower surface of the microporous membrane; one ceramic layer coats theouter side of each resin layer; one acrylic adhesive layer coats the outside of each ceramic layer; first micropores are formed in the microporous membrane; second micropores are formed in each resinlayer; third micropores are formed in each ceramic layer; and fourth micropores are formed in each acrylic adhesive layer. A preparation method of the special composite coating diaphragm for the lithium battery comprises the following steps of surface modification of boehmite alumina, preparation of the microporous membrane, preparation of a polymer composite membrane, preparation of modified boehmite alumina slurry, coating of the modified boehmite alumina slurry and bonding forming of an acrylic adhesive, thereby obtaining the special composite coating diaphragm for the lithium battery. According to the composite coating diaphragm, the security problem of a high-energy density battery core can be well solved.

Owner:桑顿新能源科技(长沙)有限公司

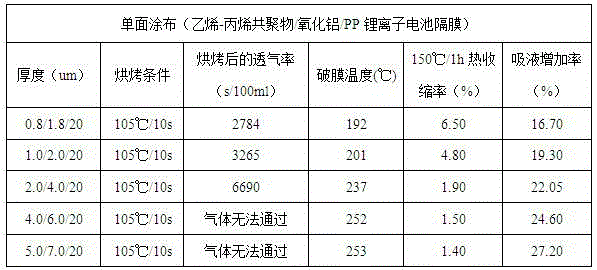

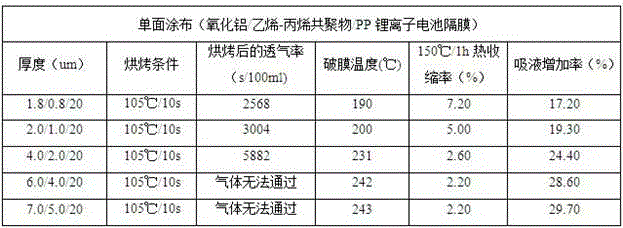

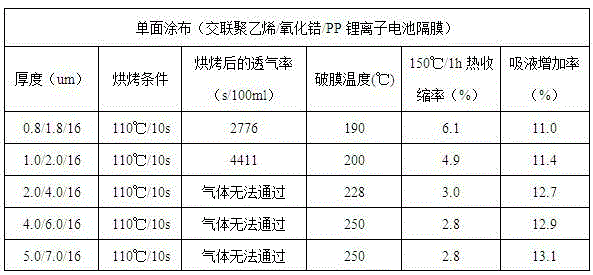

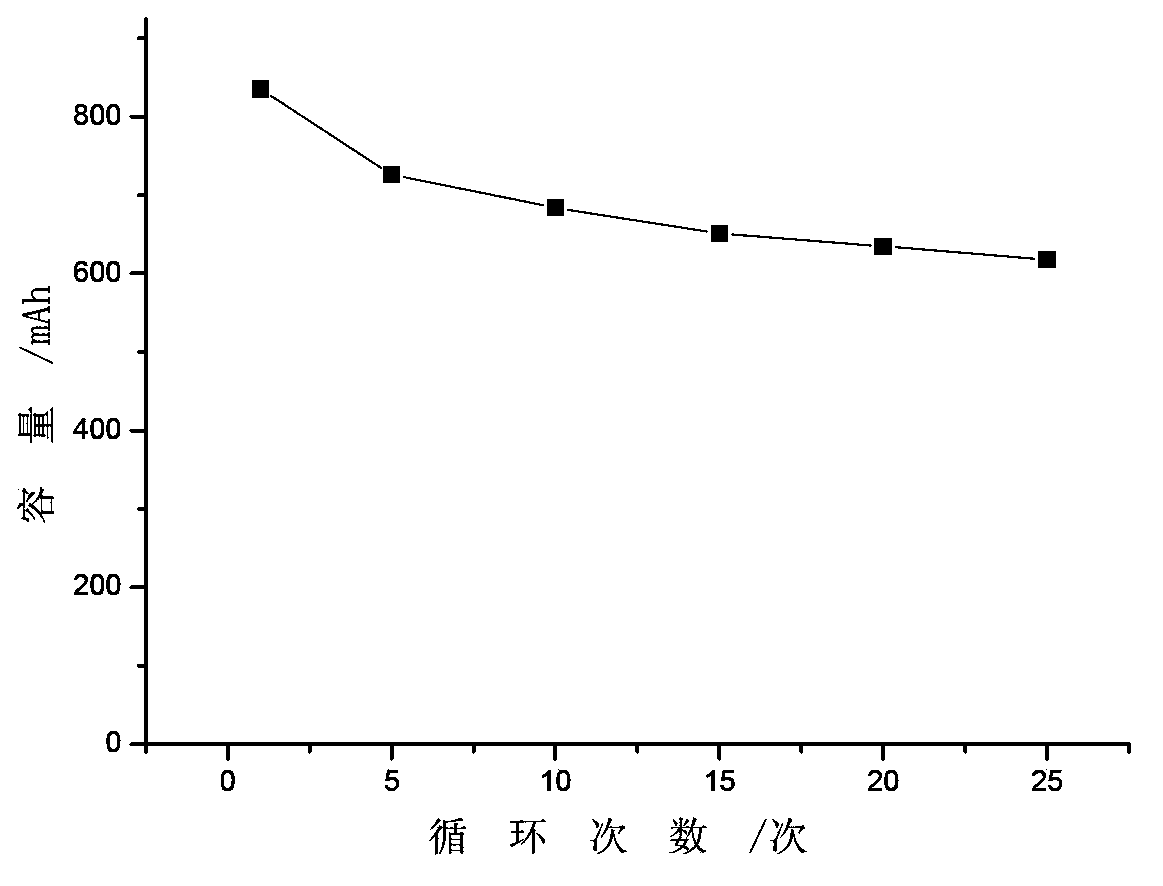

Lithium ion battery diaphragm and preparation method

ActiveCN104022250ALow closed cell temperatureAvoid thermal runawayCell component detailsPolyolefinPhysical chemistry

The invention discloses a lithium ion battery diaphragm and a preparation method thereof. The ion battery diaphragm comprises a diaphragm base material, wherein the surface of the diaphragm base material is coated with a polyolefin coating, and the coating thickness of the polyolefin coating is 1 to 4 micrometers. The diaphragm base material is coated with the polyolefin coating, and an effect for reducing the obturator temperature can be realized, so that the worsening of a thermal runaway can be prevented, when the temperature in a lithium ion battery reaches the obturator temperature, current can be disconnected at the first time, an effect for protecting the lithium ion battery can be realized, the thermal shrinkage rate of the lithium ion battery diaphragm after being roasted for 1h under the temperature of 150DEG C is less than 5 percent; compared with a non-coated lithium ion battery diaphragm, for the lithium ion battery diaphragm disclosed by the invention, the liquid absorption addition rate is 10 to 28 percent, and the charging-discharging cycling efficiency of the lithium ion battery can be further improved.

Owner:FOSHAN YINGBOLAI TECH

Coating diaphragm for lithium ion battery and preparation method thereof

ActiveCN106784552AHigh hardnessImprove securityCell component detailsSecondary cells servicing/maintenanceSodium-ion batteryTemperature resistance

The invention provides a preparation method for a coating diaphragm for a lithium ion battery. The method comprises the following steps: mixing PVDF powder, an additive, a first solvent and a second solvent and then stirring, thereby obtaining a mixed sizing agent; coating the mixed sizing agent on one side or two sides of a polyvinyl membrane; and pre-solidifying, washing with water and drying, thereby obtaining the coating diaphragm for the lithium ion battery. The diaphragm prepared according to the invention has excellent adhesiveness; the hardness of the battery is increased; the adopted additive has the characteristics of high temperature resistance and incapability of being dissolved and swelled by electrolyte; the skeleton structure of the coating is effectively enhanced; the membrane breaking temperature of the polyvinyl membrane is increased; and when the temperature in the battery is increased, the coating still can achieve the function of isolating an anode from a cathode. The hole closing / membrane breaking temperature difference of the coating diaphragm prepared according to the invention can reach above 35 DEG C; the safety performance of the battery is greatly promoted; due to the rigid enhancing function of the additive, the curling phenomenon of the coating in a drying process can be avoided; and the preparation method is simple in preparation process, low in cost, safe and controllable.

Owner:SHENZHEN SENIOR TECH MATERIAL

Heat-shrinkage-resistant lithium ion battery diaphragm and polyethylene composition adopted by same

ActiveCN106328859ALow costWide variety of sourcesCell seperators/membranes/diaphragms/spacersSecondary cellsHigh diaphragmPhysical chemistry

The invention provides a polyethylene composition for preparing a heat-shrinkage-resistant lithium ion battery diaphragm. The composition comprises high-molecular polyethylene, ultra-high-molecular polyethylene and an optional additive. The lithium ion battery diaphragm prepared from the composition has high heat shrinkage resistance, high tensile strength, high puncture strength, relatively high diaphragm-rupture temperature and relatively low closed-hole temperature, thereby ensuring safety in preparation and usage of the lithium ion battery.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

High-temperature resistant diaphragm material of lithium ion battery and preparation method of high-temperature resistant diaphragm material

ActiveCN105374972AImprove the heat absorption effectLower operating temperatureCell seperators/membranes/diaphragms/spacersSecondary cellsBoPETLithium-ion battery

The invention discloses a high-temperature resistant diaphragm material of a lithium ion battery and a preparation method of the high-temperature resistant diaphragm material. The diaphragm material comprises a modified nylon membrane and a cooling coating layer, wherein the two surfaces of the modified nylon membrane are coated with the cooling coating layer. The preparation method of the diaphragm material comprises the following steps of 1, taking the modified nylon membrane as a base membrane, and coating the two surfaces of the modified nylon membrane with a cooling coating to form the cooling coating layer and obtain a composite membrane; 2, carrying out vacuum drying on the composite membrane in the step 1, and then carrying out bidirectional stretching on the composite membrane; and 3, carrying out plasma processing on the stretched composite membrane in the step 2 to obtain the finished diaphragm. The diaphragm material has the characteristics of uniform pore distribution, excellent cooling performance, low high-temperature thermal shrinkage rate, high liquid absorption rate and high application safety.

Owner:浙江锂盾储能材料技术有限公司

Electrochemical power source membrane, preparation method of electrochemical power source membrane and electrochemical battery or capacitor

ActiveCN103971950AHigh membrane rupture temperatureImprove securityHybrid capacitor separatorsCell component detailsSolventEmulsion

The invention provides an electrochemical power source membrane and a preparation method of the electrochemical power source membrane. The preparation method includes the steps of dissolving binders in a solvent to form emulsions, wherein the mass percentage composition of the binders in the emulsions ranges from 1% to 10%; adding tetraethoxysilane with the mass 5-30 times that of the binders in the emulsions, evenly mixing the tetraethoxysilane and the emulsions, then dropping ammonium hydroxide with the mass concentration ranging from 20% to 35% in the emulsions, conducting stirring for 4-12 hours, and obtaining mixed liquid, wherein the ratio of the mass of the dropped ammonium hydroxide to the mass of the tetraethoxysilane ranges from 1:1.5 to 1:4; immersing a non-woven fabric membrane into the mixed liquid for 0.5-3 hours, taking out the non-woven fabric membrane, drying the non-woven fabric membrane, and then obtaining the non-woven fabric electrochemical power source membrane with the surface wrapped by silicon dioxide. The electrochemical power source membrane is appropriate in hole diameter, good in heat-resistant quality and high in safety, and the safety of an electrochemical battery or capacitor can be effectively and accordingly improved. The invention further provides the electrochemical battery or capacitor with the electrochemical power source membrane.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparation method of modified polyethylene diaphragm for lithium ion battery

ActiveCN102993452AImprove thermal deformation resistanceGood adhesivenessPolyurea/polyurethane coatingsCell component detailsParticulatesPolyurethane adhesive

The invention discloses a preparation method of a modified polyethylene diaphragm for a lithium ion battery. The preparation method of the modified polyethylene diaphragm is characterized in that a high-temperature resistance coating is uniformly coated on the two surfaces of the polyethylene diaphragm, and the modified polyethylene diaphragm is formed after drying; and the high-temperature resistance coating comprises inorganic particulate matters, a polyurethane adhesive, a dispersing agent and an ethanol solution. The high-temperature resistance coating adopted in the invention has low surface tension and is more environment-friendly by taking an ethanol solution as a solvent; dispersed phases in the high-temperature resistance coating are coated on the two surfaces of the polyethylene diaphragm to form a high-temperature resistance Al2O3 coating which can stop a positive electrode and a negative electrode from directly contacting when a base material melts, slows down the release of heat energy and improves the safety performance of the battery; and the polyurethane adhesive synthesized in the invention increases an interface bonding force between Al2O3 particles and the base material of the polyethylene diaphragm, enhances the adhesion between the Al2O3 particles and the base material, and simultaneously increases the imbibition capacity and heat resistance performance of the modified polyethylene diaphragm.

Owner:CHINA HAISUM ENG

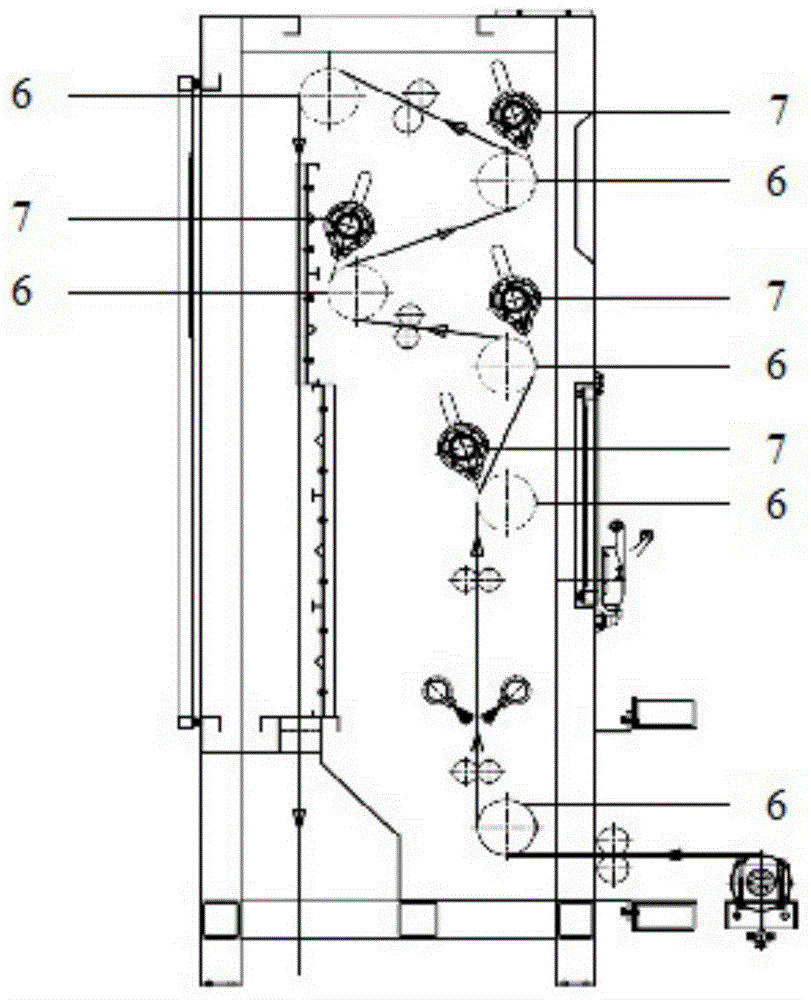

Production method of lithium ion battery separation film

InactiveCN103178230AReduce thicknessHigh membrane rupture temperatureCell component detailsDraw ratioLithium-ion battery

The invention discloses a production method of a lithium ion battery separation film. The method comprises the steps that: polyphenylene sulfide is subjected to melt extrusion, wherein an extrusion die head slit width is 5-500 micrometers; extruded polyphenylene sulfide is processed by using a cooling roll, such that a cast film is formed; the polyphenylene sulfide cast film is drawn, and heat setting is carried out. According to the invention, polyphenylene sulfide is extruded, and is drawn under a preset temperature; a drawing ratio is controlled, such that a micro-pore average size regulating effect is achieved. With the method, the thickness of producible lithium ion battery separation film is reduced, resource is effectively saved, lithium ion battery separation film breakage temperature is increased, and lithium ion battery separation film safety is improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Composite Separators for Li-ion Batteries

InactiveCN102270756AIntegrity guaranteedQuick breakCell component detailsPorous membranePolypropylene

The invention discloses a polytetrafluoroethylene composite diaphragm for a lithium ion battery. It includes a diaphragm, the diaphragm is formed by the upper polypropylene microporous membrane and the lower polypropylene microporous membrane or the upper polyethylene microporous membrane and the lower polyethylene microporous membrane, characterized in that the upper polypropylene microporous membrane A polytetrafluoroethylene microporous membrane is arranged between the porous membrane and the lower polypropylene microporous membrane or between the upper polyethylene microporous membrane and the lower polyethylene microporous membrane. The polytetrafluoroethylene composite diaphragm for lithium ion battery of the present invention not only has the low closed cell temperature of the lithium ion battery diaphragm, but also has the performance of high membrane rupture temperature, and effectively guarantees the safety and reliability of the lithium ion battery during use sex. The polytetrafluoroethylene composite separator for the lithium ion battery of the present invention can be used as a separator between the positive electrode and the negative electrode of the lithium ion battery.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

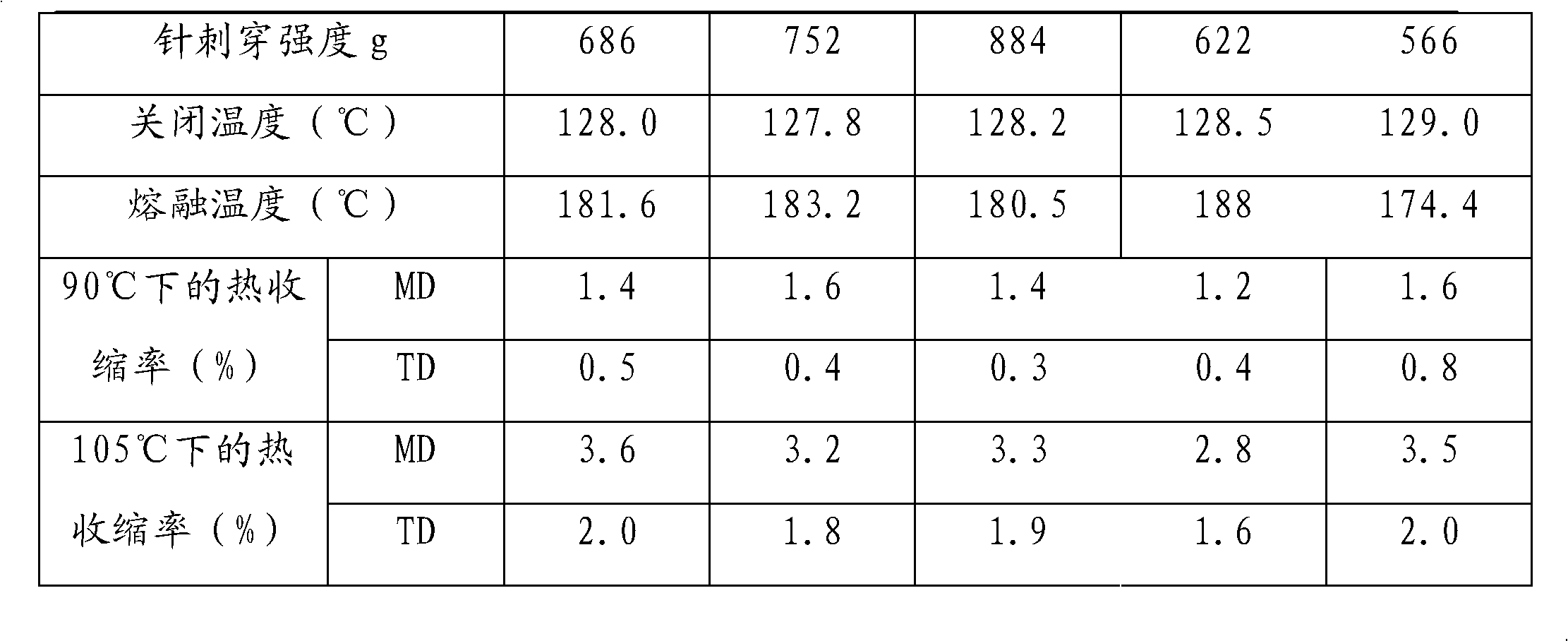

Heat shrinkage-resistant lithium-ion battery separator

ActiveCN106328867AExcellent heat shrinkage resistanceImprove performanceSecondary cellsCell component detailsPorosityInternal resistance

The invention discloses a heat shrinkage-resistant lithium-ion battery separator, which comprises a first outer layer, a second outer layer and an inner layer clamped between the first outer layer and the second outer layer, wherein the first outer layer, the second outer layer and the inner layer have different micropore structures. The heat shrinkage-resistant lithium-ion battery separator disclosed by the invention has excellent heat shrinkage resistance and good overall performance, has high puncture strength and tensile strength when reaching a relatively low thickness, can be applied to a relatively small battery and is not easily damaged in the installation process; a plurality of physical properties are taken into account; meanwhile, the heat shrinkage-resistant lithium-ion battery separator has good air permeability and porosity and small internal resistance; the capacity and the cycle performance of the battery are improved; and furthermore, the heat shrinkage-resistant lithium-ion battery separator also has relatively low closed pore temperature and membrane rupture temperature and high safety.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Lithium ion battery diaphragm with three kinds of microporous structures, and polyethylene composition adopted by same

ActiveCN106328858ALow costWide variety of sourcesCell seperators/membranes/diaphragms/spacersSecondary cellsPhysical chemistryLithium-ion battery

The invention discloses a lithium ion battery diaphragm with three kinds of microporous structures, and a polyethylene composition adopted by the same. The composition comprises high-molecular polyethylene, ultra-high-molecular polyethylene and an optional additive. The lithium ion battery diaphragm prepared from the composition has integrally-formed three kinds of microporous structures; and in addition, the lithium ion battery diaphragm has relatively low closed-hole temperature, high heat resistance shrinkage, high tensile strength, high puncture strength and relatively high membrane-rupture temperature, thereby ensuring safety in preparation and usage of the lithium ion battery.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

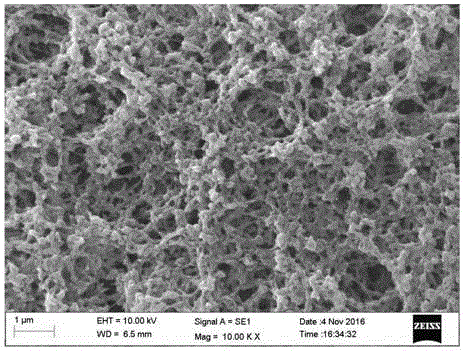

Reticular porous composite isolation film and preparation method thereof

InactiveCN106374075AHigh ion exchange capacityImprove lyophilicityCell seperators/membranes/diaphragms/spacersSecondary cellsIon exchangeDielectric layer

The invention discloses a reticular porous composite isolation film and a preparation method thereof. The reticular porous composite isolation film comprises a porous film layer and a reticular porous dielectric layer compounded on the porous film layer, wherein the aperture on the reticular porous dielectric layer is 0.1-1 micron; and the porosity of the reticular porous dielectric layer is 38%-43%. The reticular porous composite isolation film disclosed by the invention has relatively high ion-exchange capacity and lyophilic property; and the infiltrating ability of an electrolyte is high, the thermal shrinkage rate is low, the film rupture temperature is high and the safety is improved. Furthermore, according to the preparation method of the reticular porous composite isolation film, the technology is simple, the demand on equipment is low, the conditions are easy to control, the cost is low and the preparation method is suitable for industrial production. The prepared lithium battery is significantly improved in the aspects of the safety, the cyclicity, the rate capability and the like.

Owner:SINOMA SCI & TECH

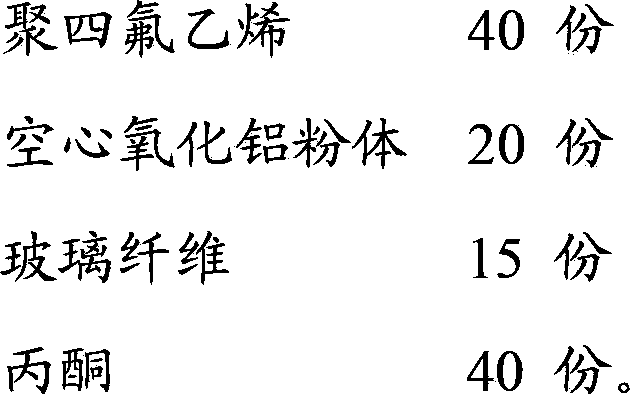

Electrochemical power-supply composite membrane and preparation method thereof

InactiveCN103579554ASimple processConditions are easy to controlSynthetic resin layered productsCell component detailsMembrane ruptureWoven fabric

The invention provides an electrochemical power-supply composite membrane and a preparation method thereof. The electrochemical power-supply composite membrane comprises a non-woven fabrics membrane layer and an organic-inorganic composite layer combining with the surface of the non-woven fabrics membrane layer; the organic-inorganic composite layer comprises an organic binder, a hollow inorganic powder, inorganic nanometer fiber and an organic solvent formula component, wherein the organic binder accounts for 1%-50% by mass of the sum of the organic binder and the organic solvent; the hollow inorganic powder and the inorganic nanometer fiber respectively accounts for 0.5%-25% by mass of the sum of the organic binder the hollow inorganic powder, the inorganic nanometer fiber and the organic solvent; the sum of the hollow inorganic powder and the inorganic nanometer fiber accounts for 25.5%-50% by mass of the sum of the organic binder, the hollow inorganic powder, the inorganic nanometer fiber and the organic solvent. The composite membrane is high in membrane rupture temperature and strength, light in weight and high in safety. The preparation method of the composite membrane is simple in technology and high in production efficiency, and is suitable for industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com