Coating composite for lithium ion secondary battery membrane and method for manufacturing membrane

A coating composition and secondary battery technology, applied in the direction of secondary batteries, battery components, separators/films/diaphragms/spacers, etc., can solve diaphragm rupture, explosion, high melt rupture temperature, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]The copolymer emulsion of lipophilic monomer n-butyl acrylate, hydrophilic monomer sodium acrylate and functional group monomer acrylic acid is selected as (the composition of the copolymer is, n-butyl acrylate: sodium acrylate: acrylic acid=6:3:1, weight ratio ) is a heat-resistant resin binder, which is dissolved and dispersed for 1 hour at room temperature with water as a solvent. Then add 80 parts of glass powder (average particle size of 0.8 μm) and 20 parts of the above heat-resistant resin binder solution into 100 parts of deionized water, and then disperse and mix it through a sand mill for 3 hours to obtain Coating solution.

[0048] Coat the coating solution prepared above with a wire bar on both surfaces of a 20 μm ultra-high molecular weight polyethylene-based film (abbreviated as UHMWPE, the same below), and then dry it in a blast drying oven at a temperature of 50 ℃. Composite microporous membranes with a total thickness of 6 μm (3 μm respectively) on bot...

Embodiment 2

[0051] The difference between this example and Example 1 is that: the coating solution prepared in Example 1 is coated on one surface of the UHMWPE base film, and then dried in an oven at 50°C. A composite microporous membrane with a coating thickness of 6 μm on one side was prepared.

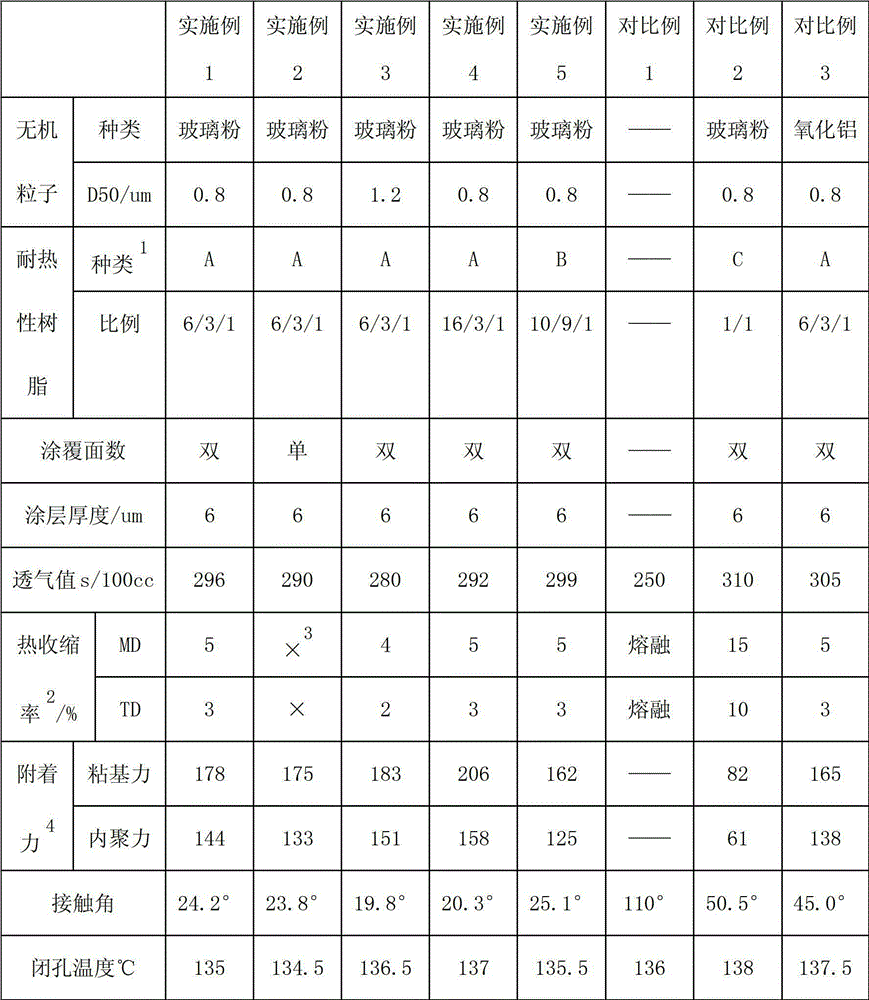

[0052] Table 1 shows the properties of the composite microporous membrane for lithium-ion secondary batteries prepared above.

Embodiment 3

[0054] The difference between this embodiment and embodiment 1 lies in that the average particle diameter of the inorganic non-conductive insulating particles (glass frit) is 1.2 μm, which is the same as that of embodiment 1.

[0055] Table 1 shows the properties of the composite microporous membrane for lithium-ion secondary batteries prepared above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com