Electrochemical power-supply composite membrane and preparation method thereof

A composite diaphragm and electrochemical technology, applied in the field of electrochemical power supply, can solve the problems of increasing the weight of porous polyolefin diaphragm, reducing the energy density of power supply, reducing the specific energy of power supply, etc., achieving low production cost, low equipment requirements, and easy control of conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A composite separator for electrochemical power supply and its preparation method:

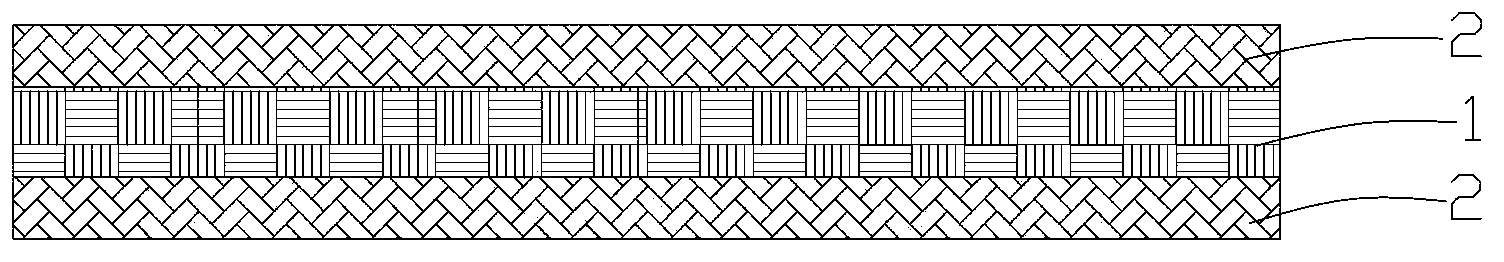

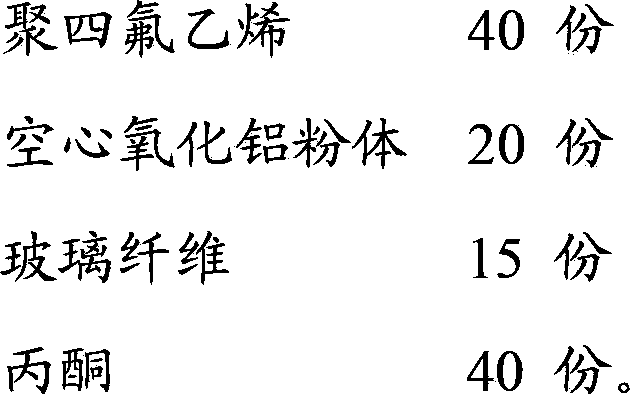

[0037] The composite diaphragm structure of the electrochemical power source is as follows figure 1 As shown, it includes a PET non-woven membrane layer 1 and an organic-inorganic composite layer 2 combining both sides of the non-woven membrane layer 1 . Wherein, the thickness of the PET non-woven membrane is 30 microns, and the thickness of the organic-inorganic composite layer 2 is 5 microns. The organic-inorganic composite layer 2 comprises the following formula components in parts by mass:

[0038]

[0039] Among them, the average particle size of the hollow alumina is 500 nm, the average length of the glass fiber is 1 μm, and the diameter is 50 nm.

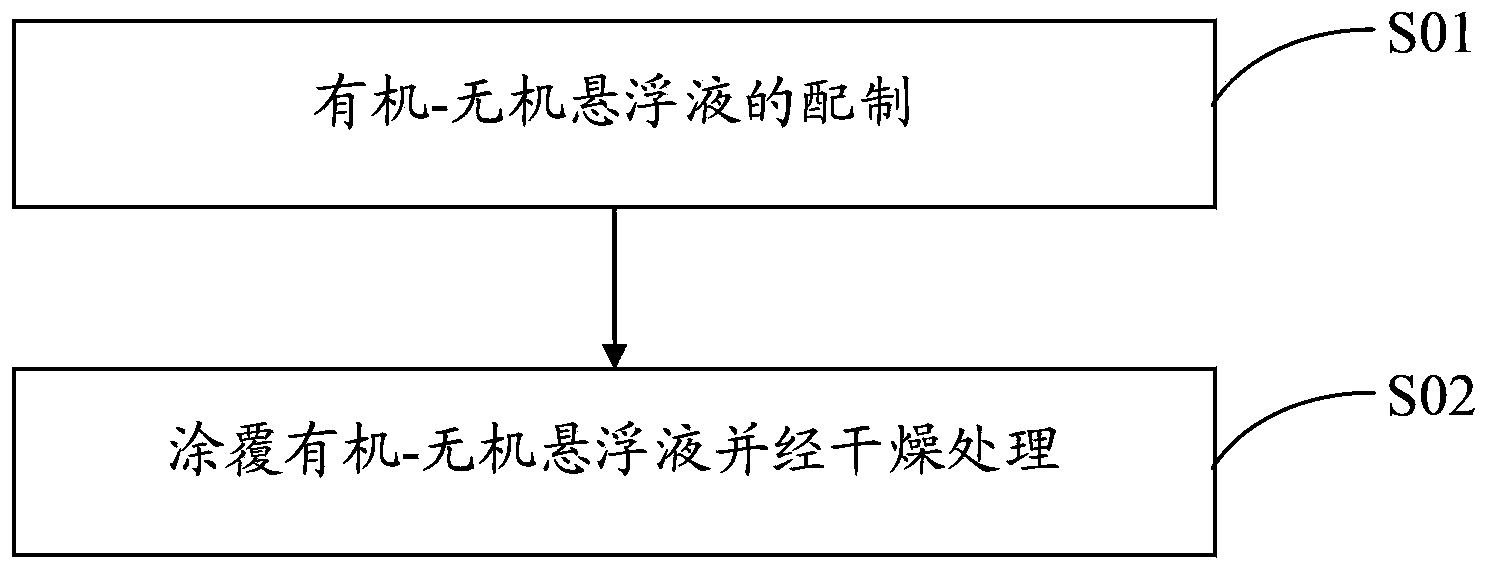

[0040] The preparation method of the electrochemical power composite diaphragm:

[0041] Step S11. Preparation of organic-inorganic suspension: according to the formulation components of the organic-inorganic composite layer 2 in...

Embodiment 2

[0045] A composite separator for electrochemical power supply and its preparation method:

[0046] The composite diaphragm structure of the electrochemical power source is the same as the composite diaphragm structure of the electrochemical power source in Embodiment 1. Among them, the thickness of the PET non-woven membrane is 26 microns, and the thickness of the organic-inorganic composite layer is 8 microns. The organic-inorganic composite layer comprises the following formula components in parts by mass:

[0047]

[0048] Wherein, the average particle size of the hollow silicon oxide is 200 nm, the average length of the glass fiber is 1 μm, and the diameter is 50 nm.

[0049] The preparation method of the electrochemical power composite diaphragm:

[0050] Step S21. Preparation of organic-inorganic suspension: according to the formulation components of the organic-inorganic composite layer in Example 2, polyvinyl alcohol is first dissolved in methylene chloride, and t...

Embodiment 3

[0054] A composite separator for electrochemical power supply and its preparation method:

[0055] The composite membrane structure of the electrochemical power source is the same as the composite membrane structure of the electrochemical power source in Example 1, wherein the non-woven fabric is a PAN non-woven fabric membrane with a thickness of 40 microns, and the thickness of the organic-inorganic composite layer is 15 microns. -The inorganic composite layer comprises the following formula components in parts by mass:

[0056]

[0057] Wherein, the average particle diameter of the hollow silica is 200nm, the average length of the glass fiber is 100nm, and the diameter is 50nm.

[0058] The preparation method of the electrochemical power composite diaphragm:

[0059] Step S31. Preparation of organic-inorganic suspension: according to the formulation components of the organic-inorganic composite layer in Example 3, first dissolve the modified styrene-butadiene rubber in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com