Ceramic coating membrane and preparation method thereof

A technology of ceramic coating and diaphragm, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problem of affecting the uniformity of the dispersion of the ceramic coating layer on the surface of the diaphragm, the agglomeration or uneven dispersion of ceramic powder, and the infiltration of electrolyte in the isolation membrane. Low capacity and other problems, to achieve the effect of improving the wetting capacity of the electrolyte, not easy to fall off and separate, improving hydrophilicity and ion exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

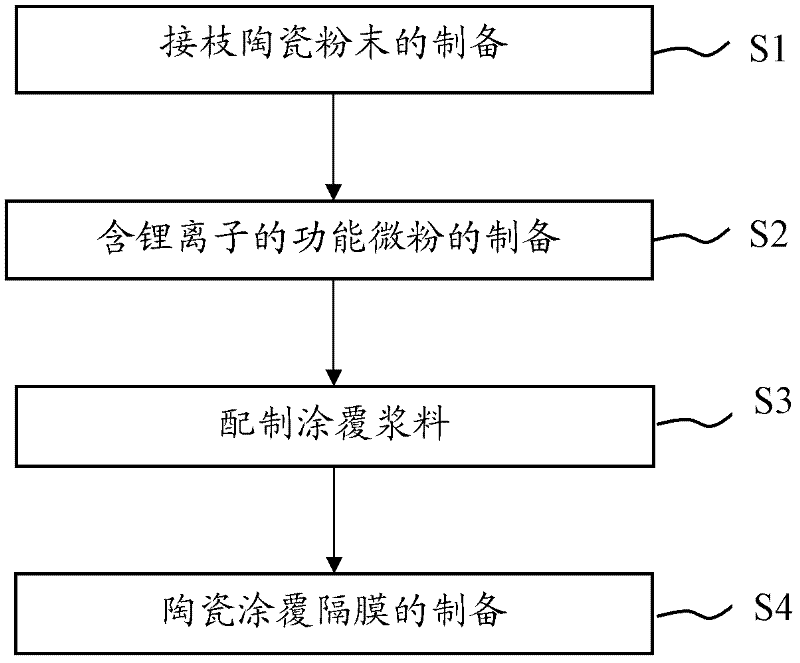

[0022] The embodiment of the present invention provides a method for preparing a ceramic coated diaphragm with electrolyte infiltration capability and high safety. The process flow is as follows: figure 1 Shown. The preparation method of the ceramic coated diaphragm includes the following steps:

[0023] S01. Preparation of grafted ceramic powder:

[0024] Grafting the benzenesulfonic acid derivative to the surface of the ceramic powder under the action of the dehydrating agent to obtain the grafted ceramic powder, and washing the grafted ceramic powder;

[0025] S02. Preparation of functional micropowders containing lithium ions:

[0026] Subjecting the washed grafted ceramic powder to an ion replacement reaction in a LiOH aqueous solution to obtain a functional micropowder containing lithium ions;

[0027] S03. Preparation of coating slurry:

[0028] Mixing the functional micropowder and the binder solution to prepare a coating slurry; wherein the mass ratio of the functional micropow...

Embodiment 1

[0045] A method for preparing a ceramic coated diaphragm includes the following steps:

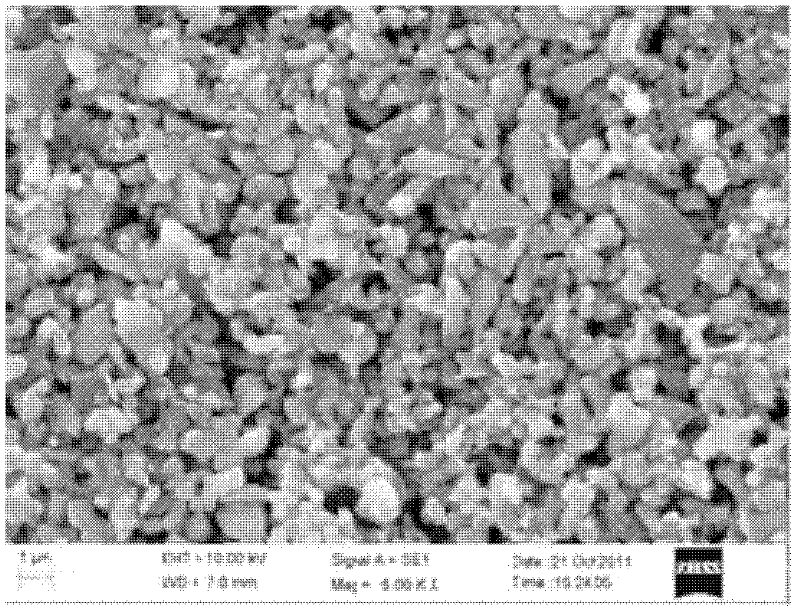

[0046] S11: Take 10g of submicron aluminum oxide powder, 5-sodium isophthalate and 2g DCC respectively, and dissolve 5-sodium isophthalate and DCC in 200ml ethanol at 65℃ , N 2 In a water bath for 2 hours under the atmosphere, the grafting reaction is carried out. After the grafting reaction is completed, the grafted ceramic powder is refluxed in ethanol for 4 hours for purification;

[0047] S12: Add a 27% LiOH aqueous solution to the washed grafted ceramic powder and reflux for 48 hours at 100°C to remove -SO on the surface of the grafted ceramic powder. 2 Na group is converted to SO 3 Li group, fully washed with water until the PH value is neutral, and the functional group on the surface is SO 3 Li's functional ceramic powder;

[0048] S13: Mix lithium polystyrene sulfonate and N,N-dimethylformamide at a mass ratio of 1:1 at 50°C for 2 hours, and then add the functional ceramic powder in step ...

Embodiment 2

[0051] A method for preparing a ceramic coated diaphragm includes the following steps:

[0052] S21: Refer to step S11 of Example 1, to obtain a purified grafted ceramic powder;

[0053] S22: Refer to step S12 of Example 1, to obtain the functional group on the surface as SO 3 Li's functional ceramic powder;

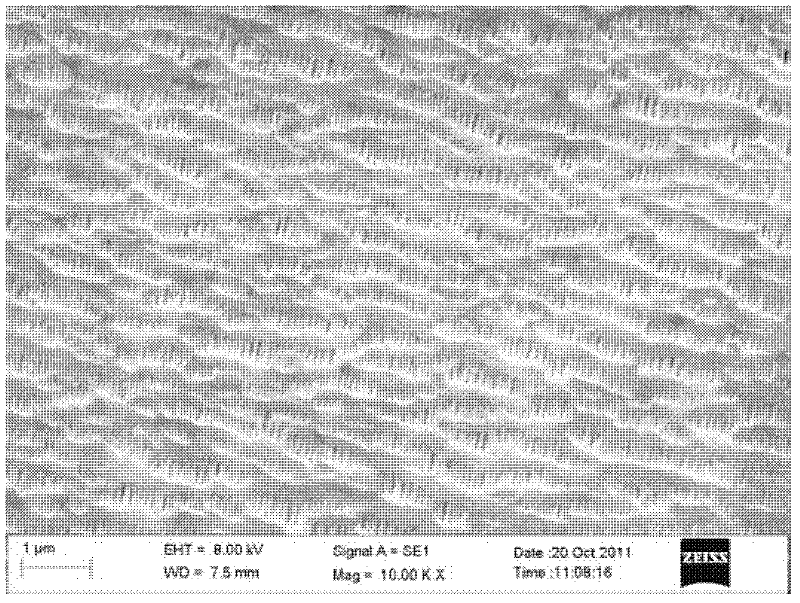

[0054] S23: Refer to step S12 of embodiment 1 to obtain a coating slurry;

[0055] S24: Immerse the PP microporous film in the coating slurry prepared in step S23 above, so that the PP microporous film (thickness 20um) is completely infiltrated by the coating slurry, then remove the film from the clip, and drain the remaining slurry on the surface , Spread it out and hang it in a vacuum drying box, and dry it at 80°C for 30 minutes to prepare a ceramic coated diaphragm with a functional layer on both sides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com