Polyolefin multilayer micro-porous membrane and preparation method thereof

A microporous film and polyolefin technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor tensile effect of polypropylene layer and inability to industrialize wet-process polypropylene separators, etc. , to achieve high membrane rupture temperature, low heat shrinkage, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Use high-density polyethylene HDPE (Mw=3.0×10 5 , melting point 133°C), linear low density polyethylene LLDPE (Mw=2.0×10 5 , melting point 120°C) as the polyethylene raw material for the preparation of the middle layer, 22 parts by weight of HDPE and 3 parts of LLDPE are added to the twin-screw extruder, and 75 parts by weight of kerosene are added to the twin-screw extruder through the side feed port In the exit machine (length-to-diameter ratio: 48), it is melted at 220°C and mixed uniformly to form a polyethylene solution, which is extruded from the core layer of the three-layer die with a thickness of 400 μm.

[0044] Polypropylene PP (Mw=1.2×10 6 , melting point 166°C) and ultra-high molecular weight polyethylene UHMWPE (Mw=1.0×10 6 , melting point 136°C) as raw materials for preparing the surface layer, 12 parts by weight of PP and 8 parts by weight of UHMWPE are added to the twin-screw extruder, and then 80 parts by weight of kerosene is added to the twin-screw...

Embodiment 2

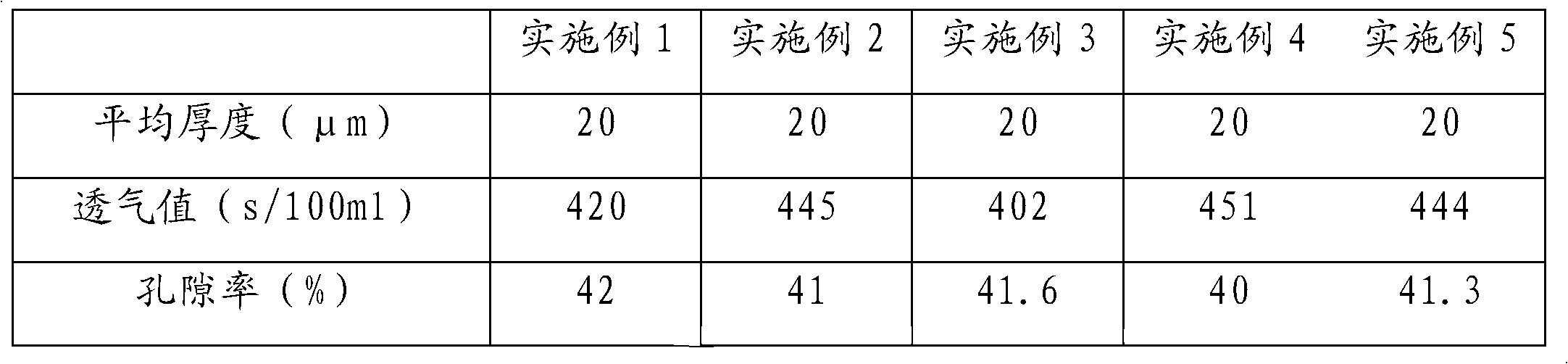

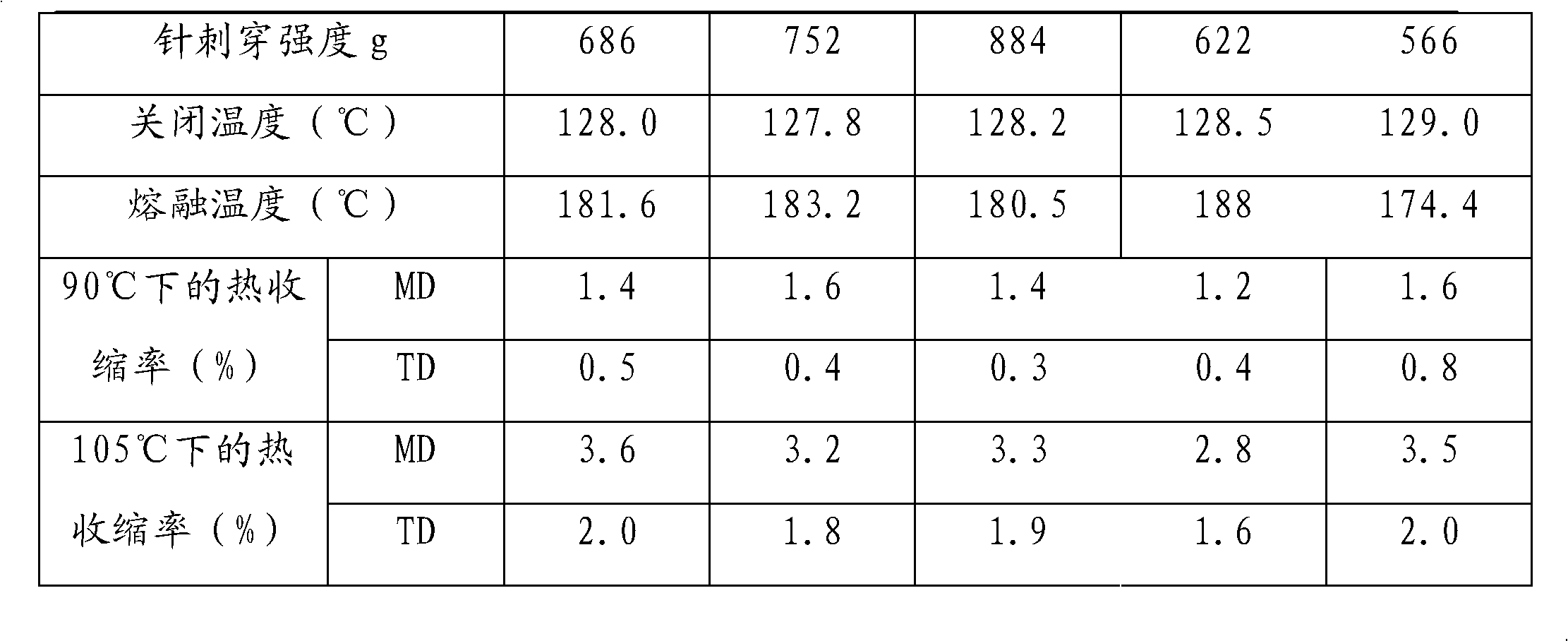

[0047] The difference from Example 1 is that the molecular weight of the surface layer is 2.1×10 6 The ultra-high molecular weight polyethylene, all the other are identical with embodiment 1. The performance of the separator is shown in Table 1.

Embodiment 3

[0049] The difference from Example 1 is that the molecular weight of the surface layer is 5.0×10 6 The ultra-high molecular weight polyethylene, all the other are identical with embodiment 1. The performance of the separator is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com