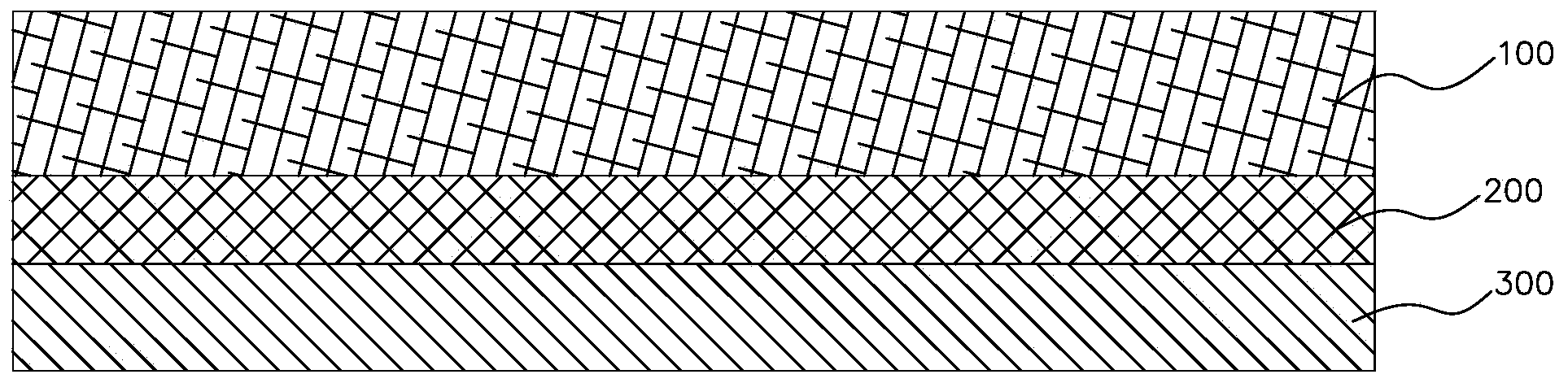

Composite diaphragm with excellent high temperature performance and pore closing performance and preparation method thereof

A composite diaphragm, high temperature resistant technology, applied in electrical components, circuits, battery pack components, etc., can solve the problems of difficulty in meeting the requirements of high-performance lithium battery diaphragms, low strength of porosity diaphragms, and no self-closing pore performance. Achieve excellent heat resistance, provide safety, and improve thermal safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

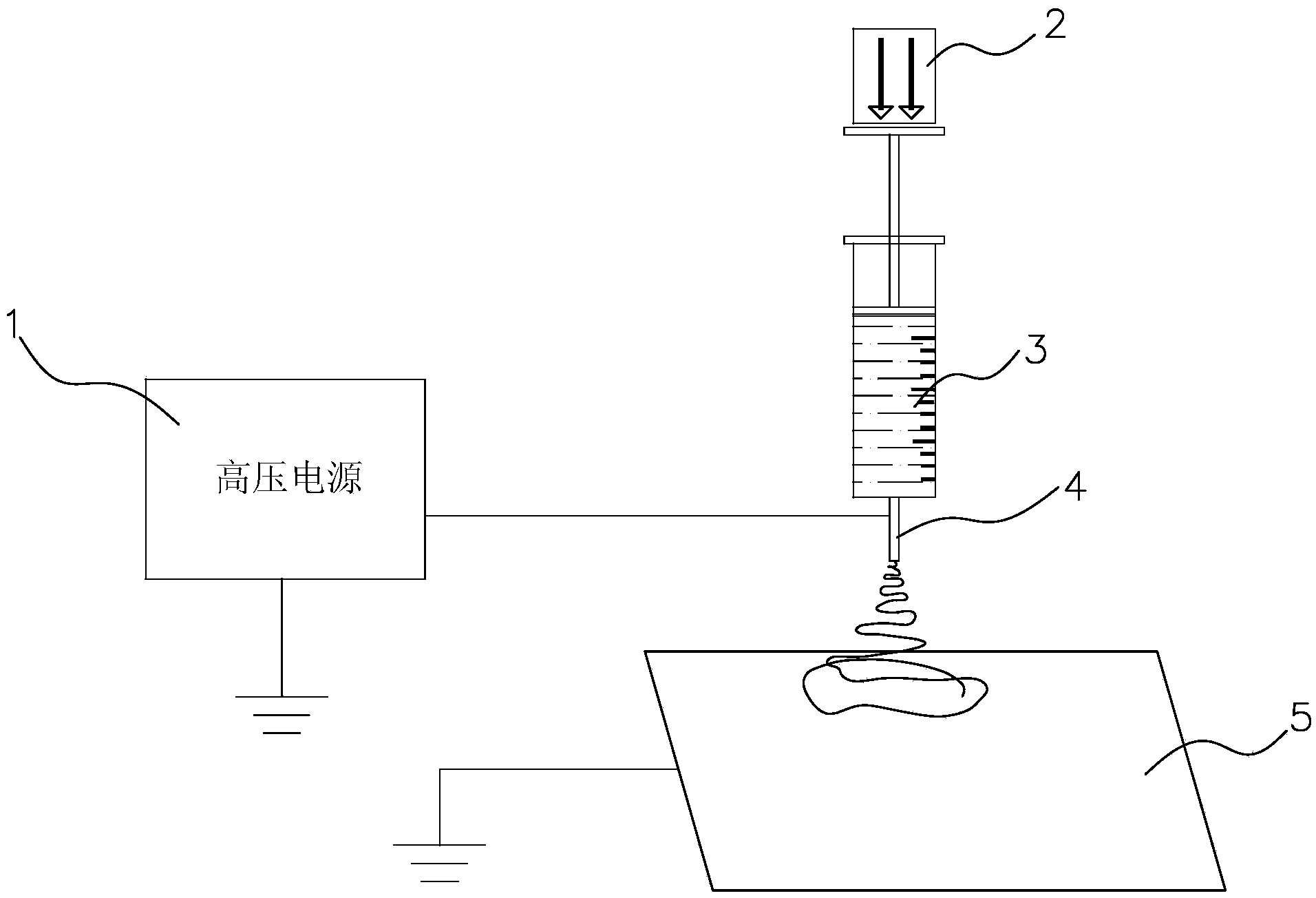

[0038] The preparation method of the composite diaphragm in this embodiment can be based on the previous technical solution, specifically, the treatment solution in step 2 is a modified acrylic adhesive or a polyurethane two-component adhesive with a concentration of less than 1%. For the preparation of polyimide electrospinning layer by spraying electrospinning method, polyimide is prepared by reacting organic diamine, dibasic organic acid anhydride and polar aprotic solvent at a certain temperature, and then the polyimide The imide is dissolved in a solvent to obtain a spinning dope; refer to figure 2, the spinning stock solution is placed in the syringe 3 of the propeller of the electrospinning device, pressurized by the micro-injection pump 2 above the syringe 3, and a high voltage is applied between the spinneret 4 and the receiving plate 5 by the high-voltage power supply 1 Electrospinning, the PE surface of the PE / PP composite film is used to receive nanofibers, and af...

Embodiment 1

[0046] Accurately weigh 2.1812g of pyromellitic anhydride (PMDA) and 2.0023g of 4,4'-diaminodiphenyl ether (ODA) into 25ml of N,N-dimethylacetamide (DMAc), stir at low temperature for 8 Hours, polyamic acid (PAA-1) solution was obtained. Then add the mixed solution of acetic anhydride and triethylamine (volume ratio 1:1.5), and continue the reaction for 24 hours to obtain a yellow homogeneous and transparent polyimide solution. The solution was deposited in excess ethanol / water mixture, washed, filtered and dried to obtain polyimide (PI-1).

[0047] Weigh an appropriate amount of PI-1 and redissolve it in DMAc to make a spinning dope with a solid content of 15% for electrospinning. The spinning conditions are: spinning voltage 20kv, advancing speed 2.0mm / min, receiving distance 25mm, ambient temperature 25°C, ambient humidity 35%. The receiving substrate is the above-mentioned PE / PP composite film, and the PE side is facing the spinneret, and a layer of two-component PU adhe...

Embodiment 2

[0049] The preparation of spinning dope is the same as in Example 1.

[0050] Spinning conditions: spinning voltage 15kv, advancing speed 1.5mm / min, receiving distance 15mm, ambient temperature 25°C, ambient humidity 35%. The receiving substrate is the above-mentioned PE / PP composite film, and the PE side is facing the spinneret, and a layer of two-component PU adhesive is applied to increase the connectivity with the nanofibers. The thickness of the nanofiber layer is 20 μm. The prepared composite film was subjected to hot pressing at 60° C. and the residual solvent was removed to obtain a PP / PE / polyimide nanofiber composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com