Metal capacitor and manufacturing method thereof

A metal capacitor and manufacturing method technology, applied in the direction of capacitors, electrolytic capacitors, capacitor terminals, etc., can solve the problems of reduced reliability of capacitors, increased loss, low electrical conductivity, etc., achieve non-flammable environment tolerance, and improve heat-resistant safety. performance, improve electrical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 》

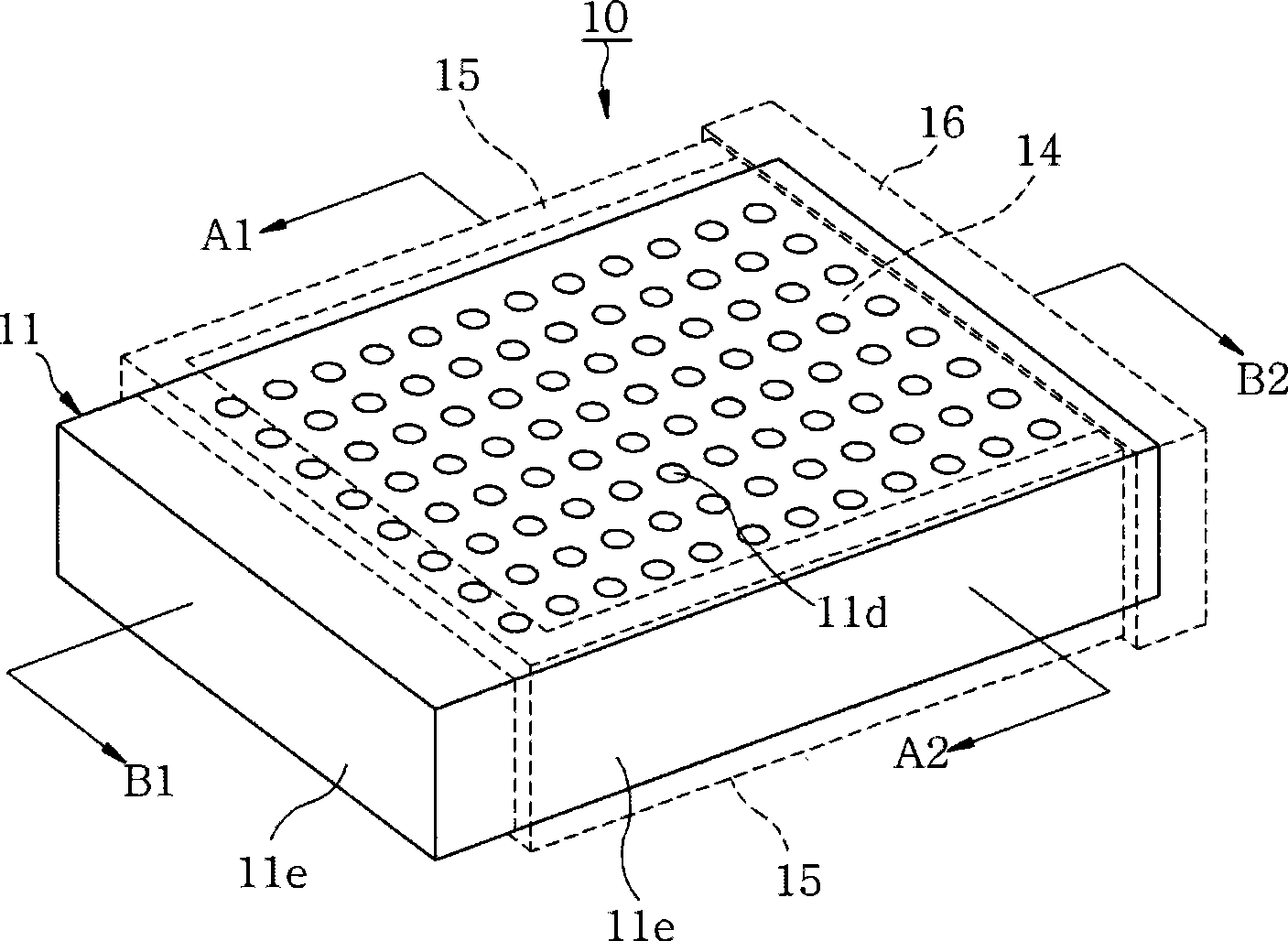

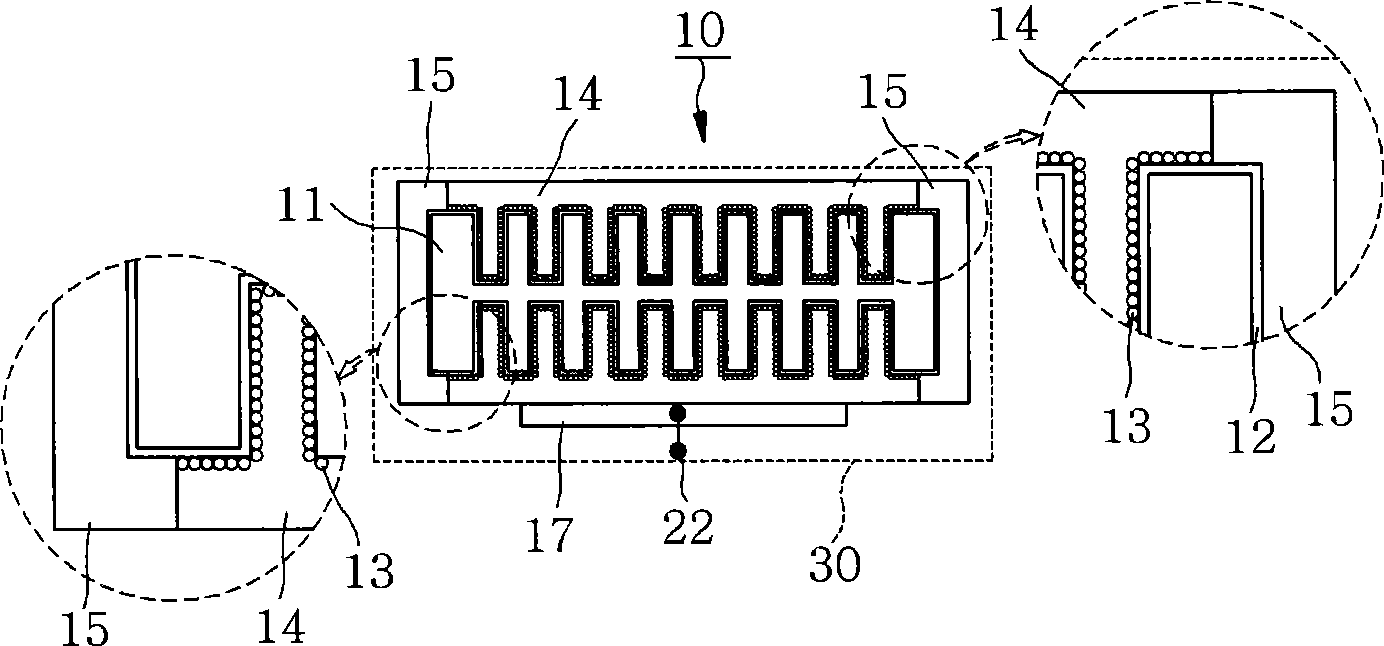

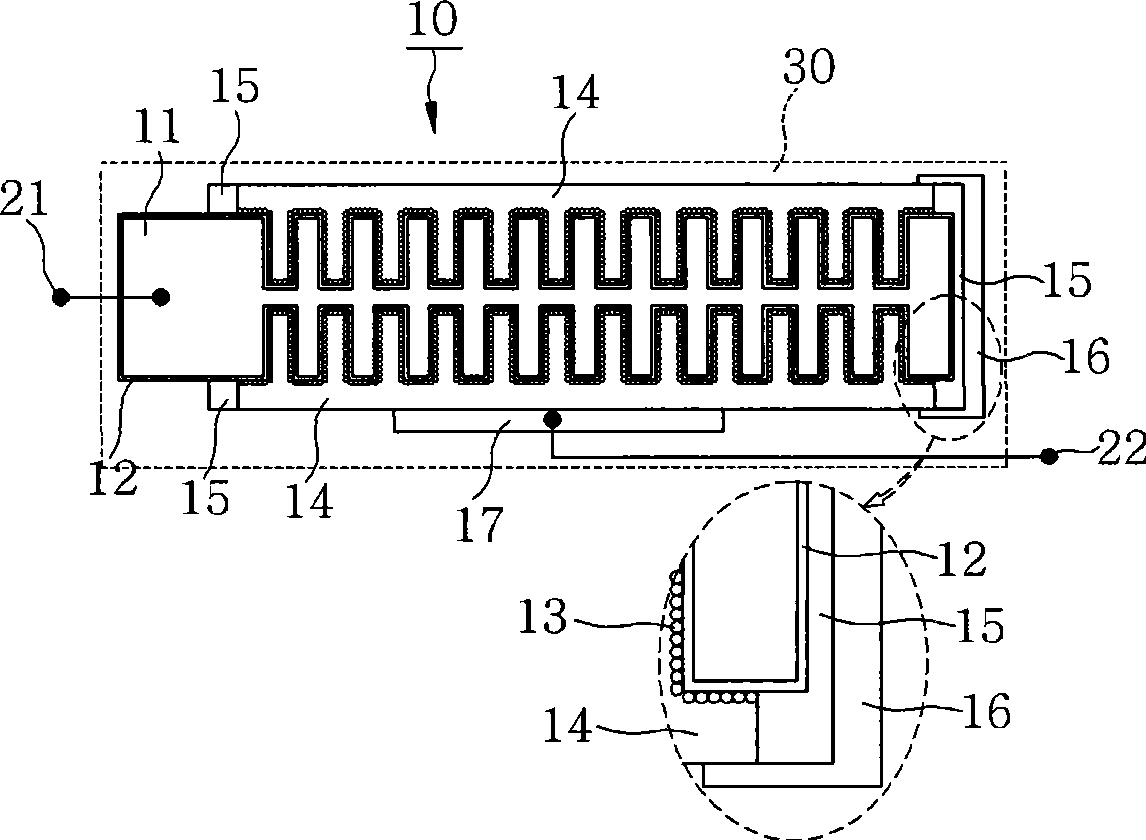

[0033] Refer to the following Figures 1 to 3 The description is as follows, Figures 1 to 3 A metal capacitor structure according to the first embodiment of the present invention is added.

[0034] figure 1 is a perspective view of a metal capacitor according to a first embodiment of the present invention, figure 2 yes figure 1 A cross-sectional view of the metal capacitor shown along line A1-A2, image 3 yes figure 1 A cross-sectional view of the metal capacitor shown along line B1-B2. Such as Figure 1 to Figure 3 As shown, the metal capacitor 10 according to the first embodiment of the present invention consists of a metal component 11, a metal oxide layer 12, a plurality of seed electrode layers 13, a plurality of main electrode layers 14, an insulating layer 15, a conductive connection layer 16, a first lead terminal 21, second lead terminal 22, and sealing member 30, but there are cases where the seed electrode layer 13 is not used depending on user needs. The ...

no. 2 example 》

[0060] The metal capacitor 110 will be described below with reference to the drawings. Among them, the metal capacitor 110 uses the non-through-type metal member 10a constituting the metal capacitor 10 according to the first embodiment of the present invention.

[0061] Such as Figure 5 As shown, the metal capacitor 110 according to the second embodiment of the present invention is composed of a plurality of non-penetrating metal parts 10a, a conductive adhesive layer 17, a third lead terminal 23, a fourth lead terminal 24, and a sealing member 30. The following sequence describes each structure.

[0062] Such as Figure 4g as well as Figure 4h As shown respectively, a plurality of non-penetrating metal parts 10a are composed of a metal part 11, a metal oxide layer 12, a plurality of seed electrode layers 13, a plurality of main electrode layers 14, an insulating layer 15, and a conductive connection layer 16. The detailed description has already been made in the descrip...

no. 3 example 》

[0069] Next, the metal capacitor 120 will be described with reference to the drawings. Among them, the metal capacitor 120 uses the non-through-type metal member 10a constituting the metal capacitor 10 according to the first embodiment of the present invention.

[0070] Such as Figure 6 As shown, the metal capacitor 120 according to the third embodiment of the present invention is composed of a plurality of non-penetrating metal parts 10a, a conductive adhesive layer 17, a first polarity lead terminal 25 and a second polarity lead terminal 26, and the following sequence describes each structure.

[0071] Such as Figure 4g as well as Figure 4h As shown respectively, a plurality of non-penetrating metal parts 10a are composed of a metal part 11, a metal oxide layer 12, a plurality of seed electrode layers 13, a plurality of main electrode layers 14, an insulating layer 15, and a conductive connection layer 16. The detailed description has already been made in the descriptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com