High-safety diaphragm and battery

A high-safety diaphragm technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as high closed-cell temperature, adhesive functional coating does not have self-closing function, etc., to reduce closed-cell Pore temperature, enhanced battery safety, and increased membrane rupture temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned high-safety diaphragm includes:

[0028] S1, respectively dissolving and dispersing the heat-resistant resin and the inorganic particles in an organic solvent and mixing them to prepare a heat-resistant coating slurry;

[0029] S2. Coating the heat-resistant coating slurry on at least one surface of the porous substrate, removing the solvent by thermal or non-solvent-induced film formation, and drying to obtain a heat-resistant coating film;

[0030] S3, dispersing the adhesive resin with low melting point / viscosity temperature, inorganic particles and adhesive resin in water to form an aqueous coating slurry;

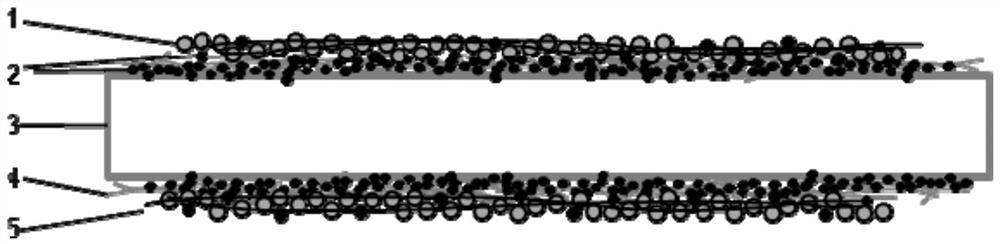

[0031] S4, coating the water-based coating slurry on at least one surface of the heat-resistant coating film, and drying to obtain the following: figure 1 High Security Coated Diaphragms shown.

[0032] The above-mentioned coating method is not limited, and various known methods such as wire rod, gravure roll, and ro...

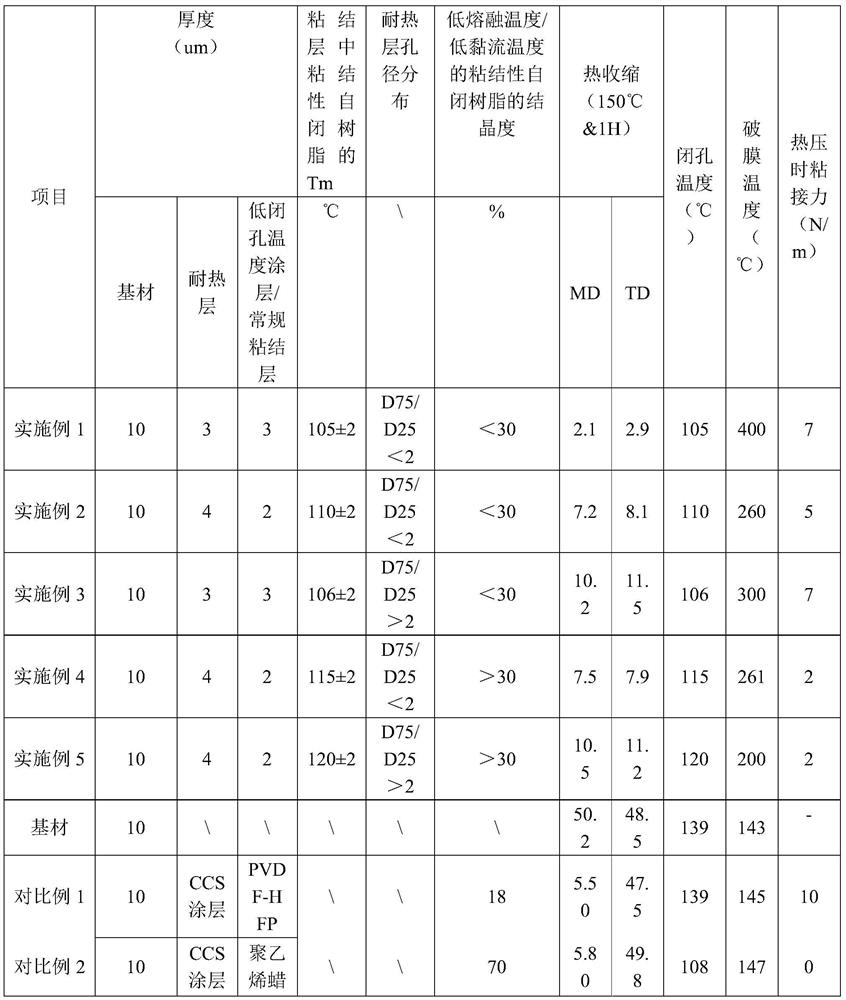

Embodiment 1

[0036] Weigh 0.4Kg of modified para-aramid and dissolve it into 6kg of DMAC containing 4% calcium chloride co-solvent, then grind and disperse 0.6kg of alumina into 4kg of DMAC, and disperse the aramid solution and alumina The aramid fiber coating slurry is obtained by mixing liquid and liquid; the aramid fiber slurry is coated on one side of a 10um polyethylene-based film by extrusion coating, and after passing through a humidified oven, it is washed and dried to obtain the thickness of the aramid fiber coating film It is 13um, and the thickness of the aramid coating is 3um.

[0037] Weigh 0.7kg of modified polyethylene wax, 0.2kg of large particle size PMMA, and 0.2kg of polyacrylic acid emulsion adhesive and stir evenly in 10kg of water to prepare the adhesive layer coating slurry, which is applied by roller coating. Coated on both sides of the aramid fiber coating film, after drying, the thickness of the diaphragm is 16um, and the thickness of the double-sided adhesive coa...

Embodiment 2

[0039] Weigh 0.7Kg of meta-aramid and dissolve it into 6kg of NMP, then grind and disperse 0.3kg of alumina into 4kg of NMP, mix the aramid solution and alumina dispersion to prepare aramid coating slurry Material: Aramid slurry is coated on both sides of a 10um polyethylene-based film by micro-gravure roller coating. After washing and drying, the thickness of the aramid coating film is 14um, and the thickness of the aramid coating is 4um.

[0040] Weigh 0.6kg of modified polybutene, 0.15kg of PVDF powder, and 0.15kg of polyacrylate emulsion adhesive in 10kg of water and stir evenly to prepare the adhesive layer coating slurry, which is applied by roller coating Coated on one side of the aramid fiber coating film, after drying, the thickness of the diaphragm is 16um, and the thickness of the double-sided adhesive coating is 2um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| membrane rupture temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com