Patents

Literature

51 results about "Diaphragm rupture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

[edit on Wikidata] Diaphragmatic rupture (also called diaphragmatic injury or tear) is a tear of the diaphragm, the muscle across the bottom of the ribcage that plays a crucial role in respiration. Most commonly, acquired diaphragmatic tears result from physical trauma.

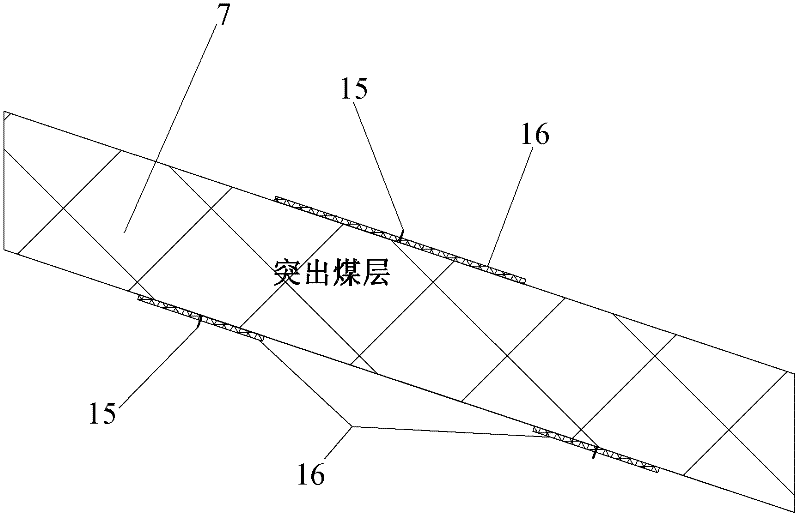

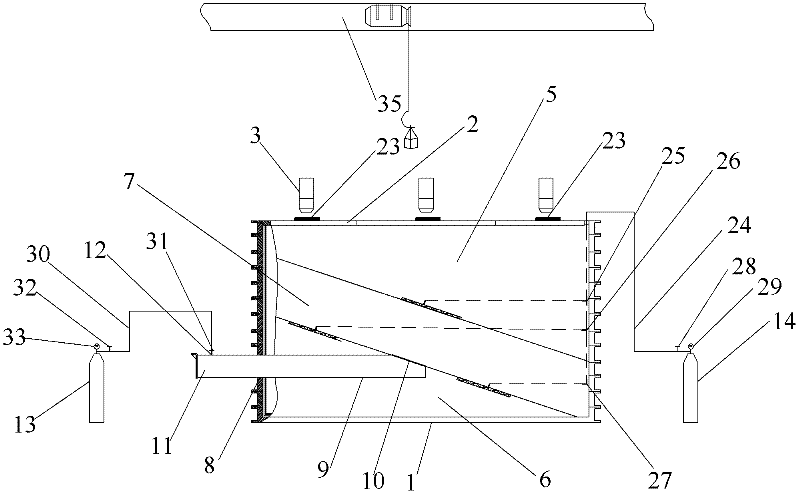

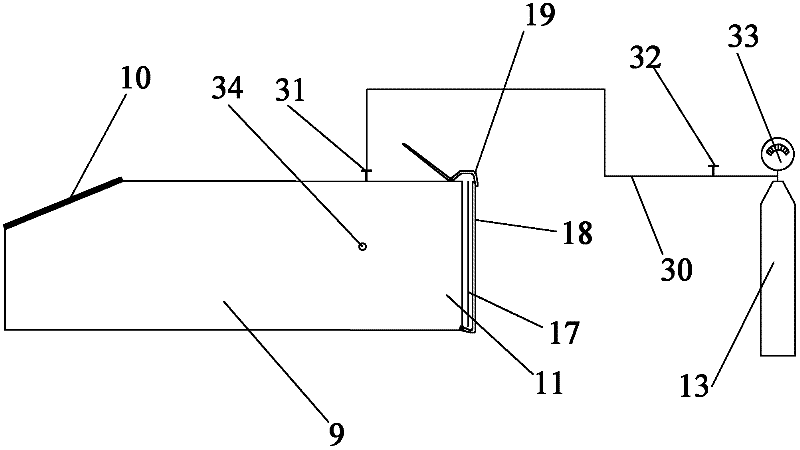

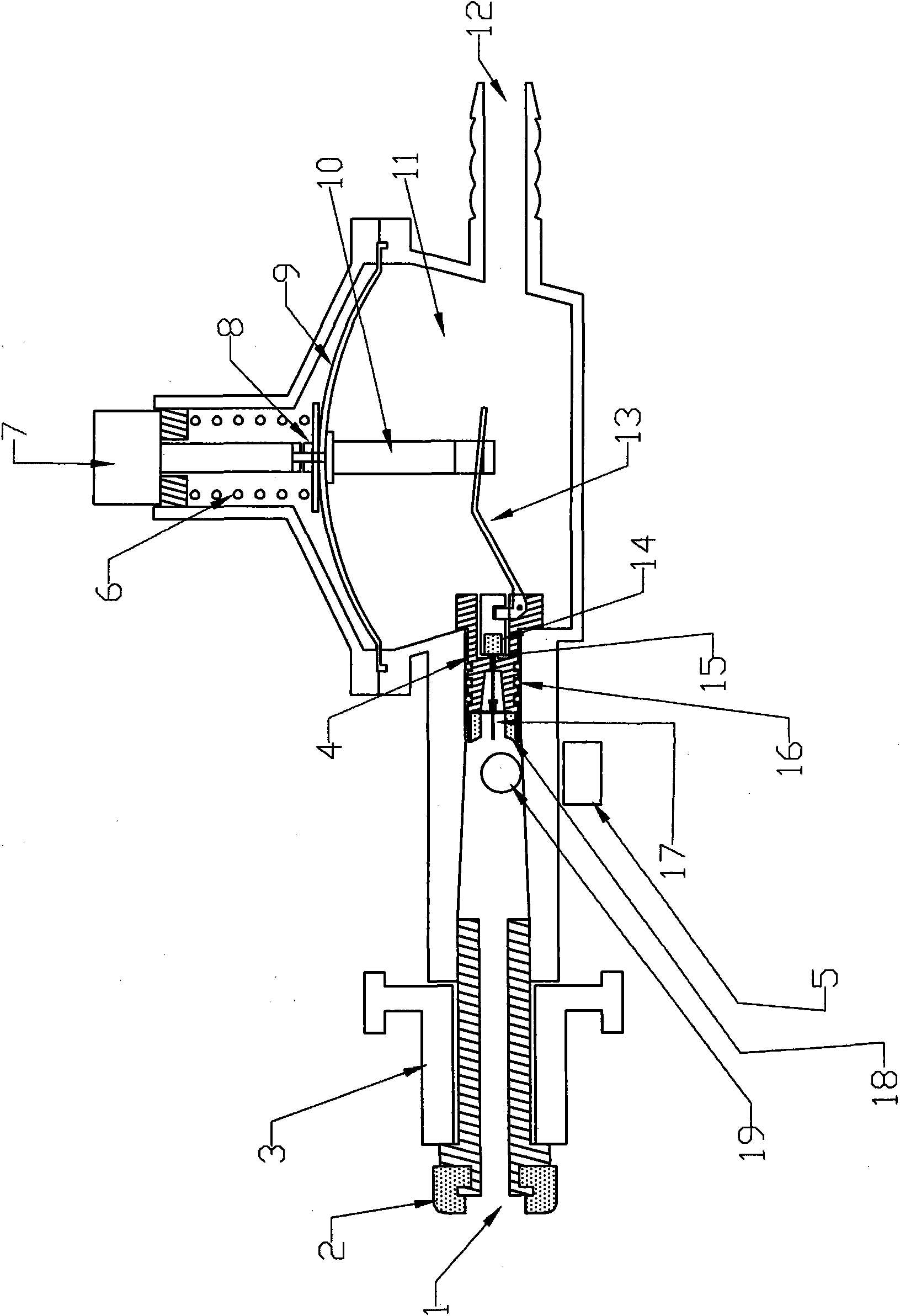

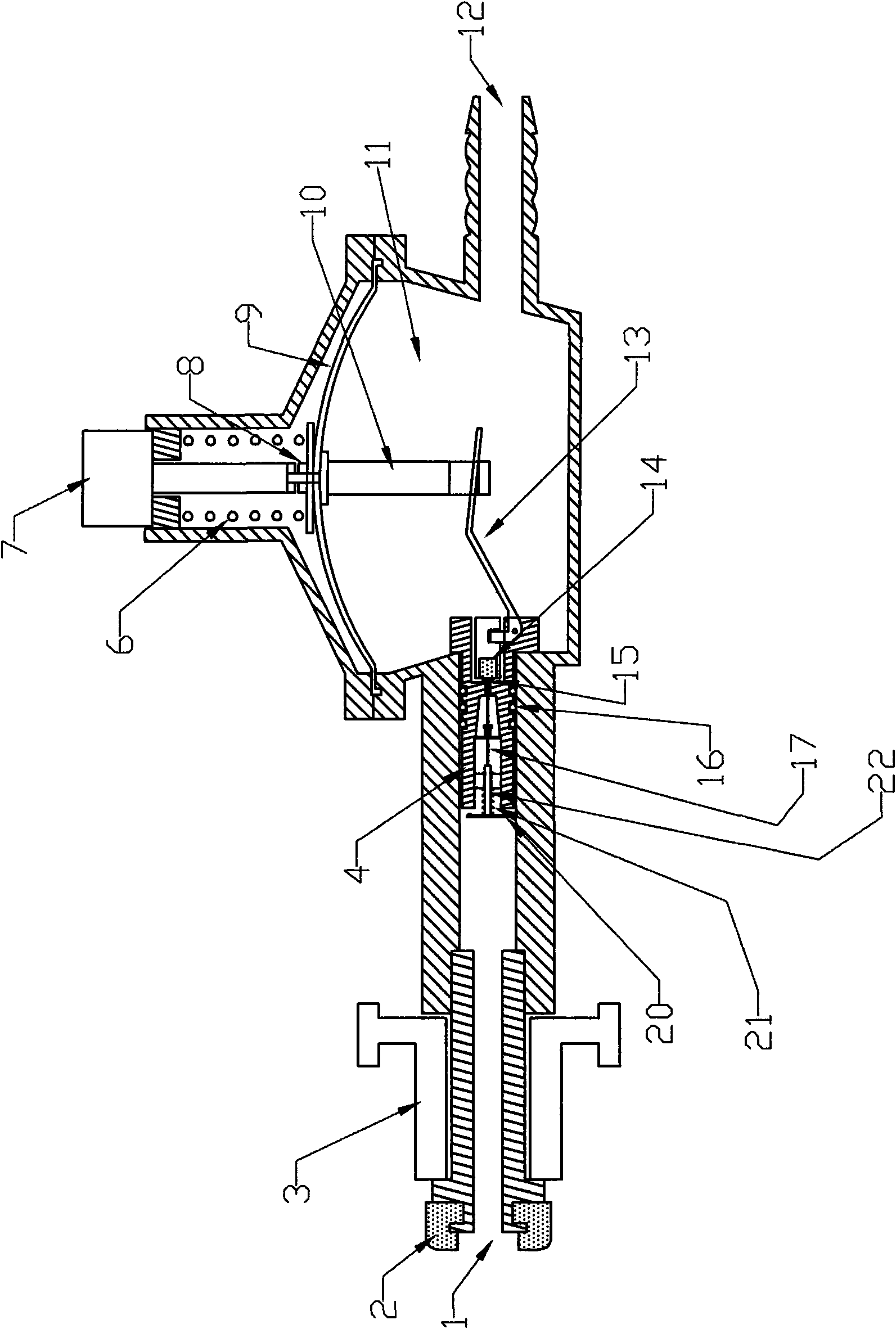

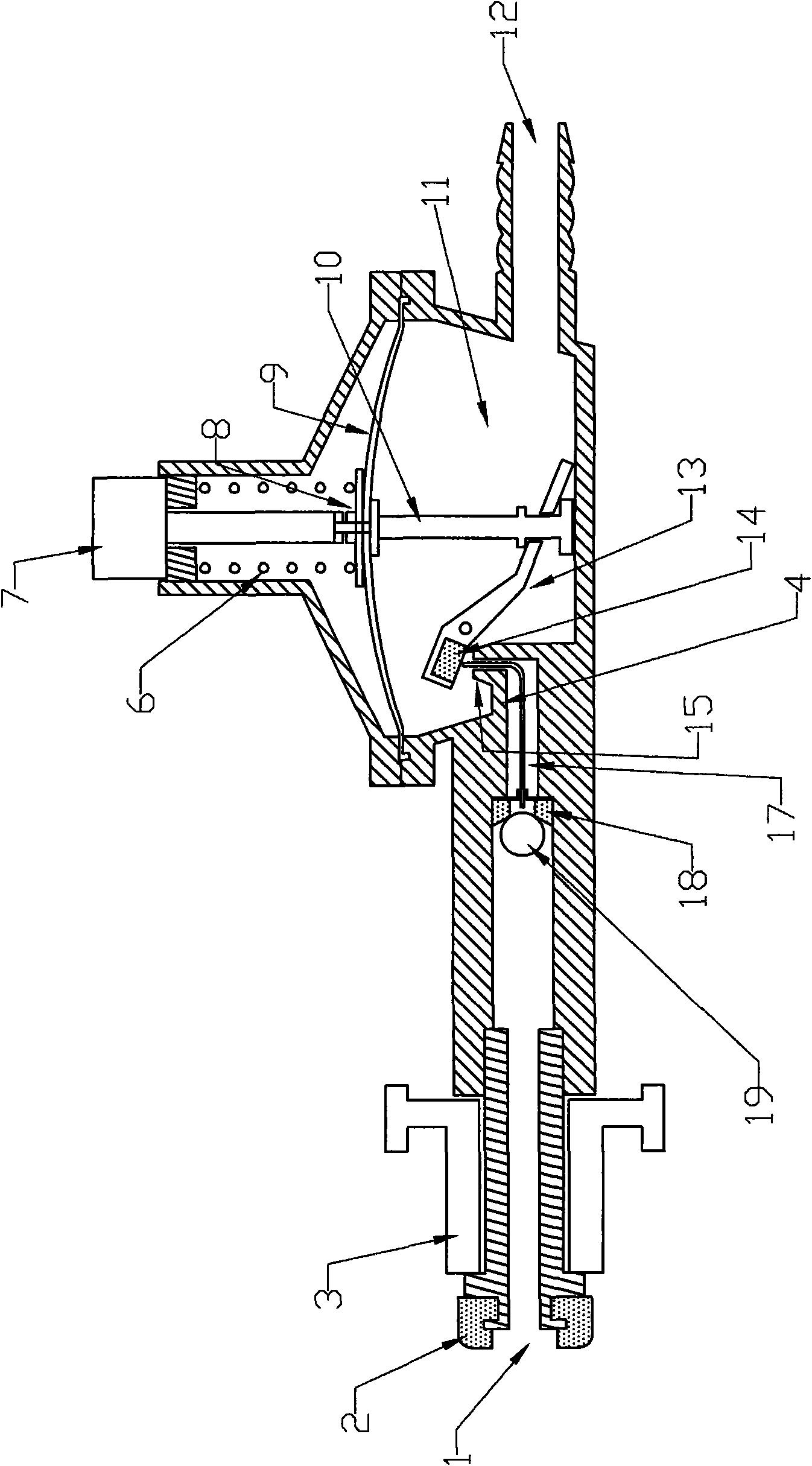

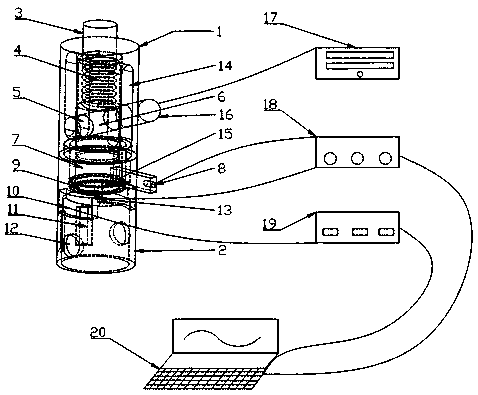

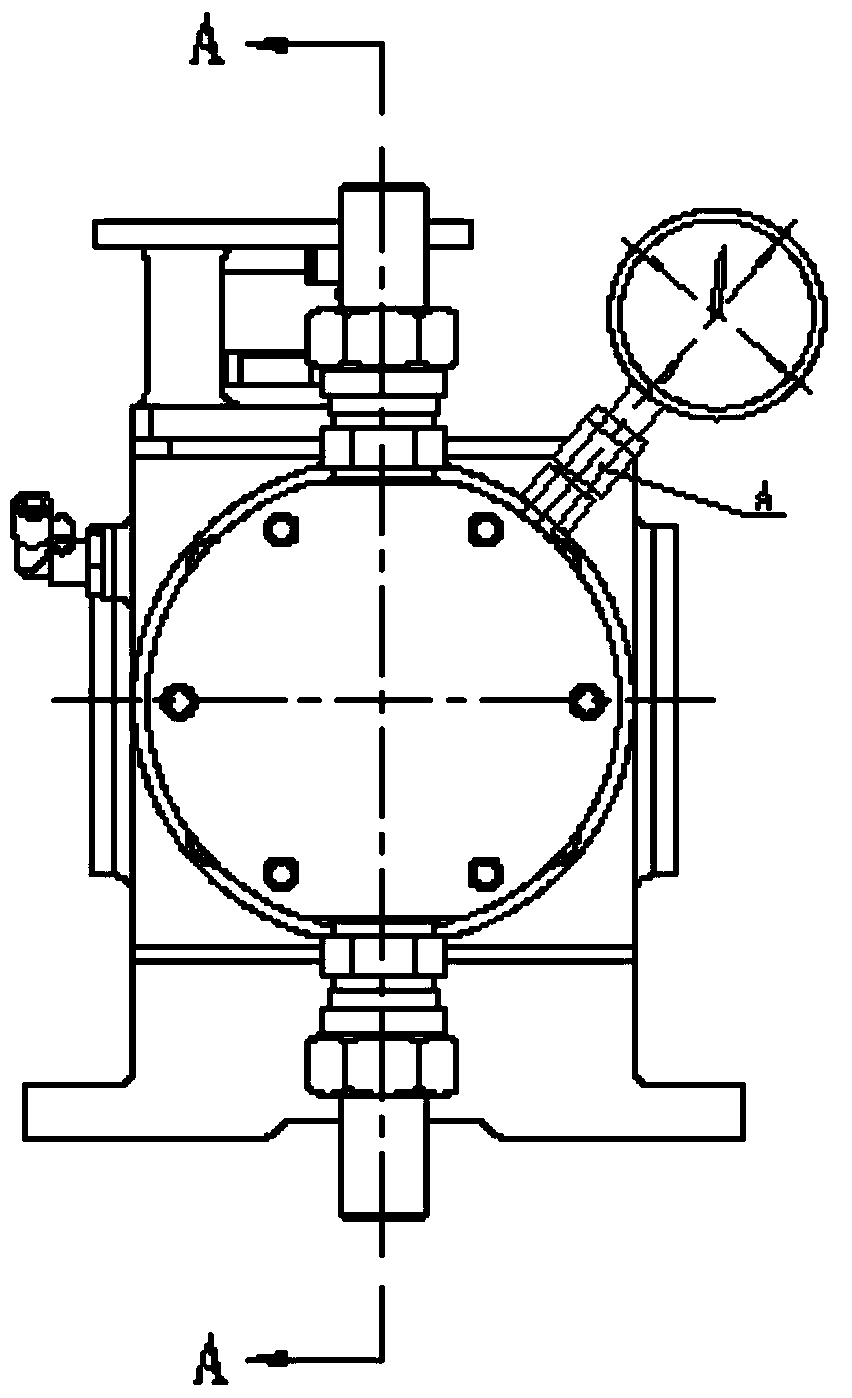

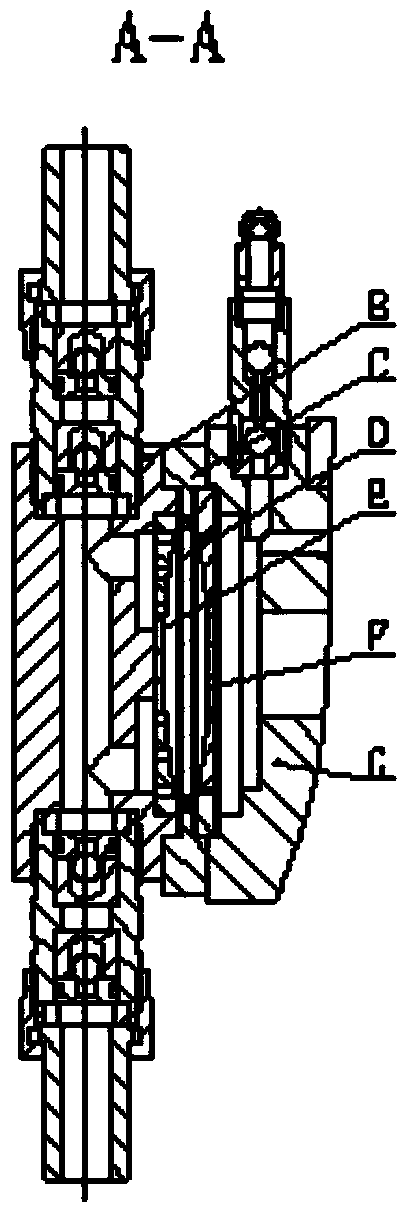

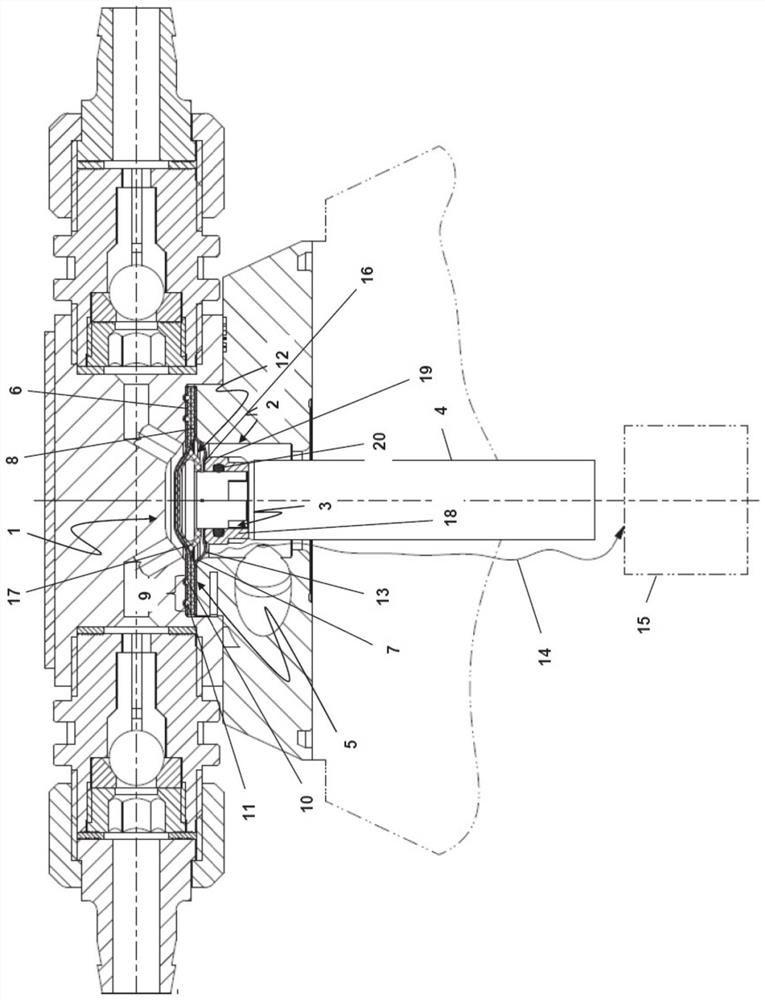

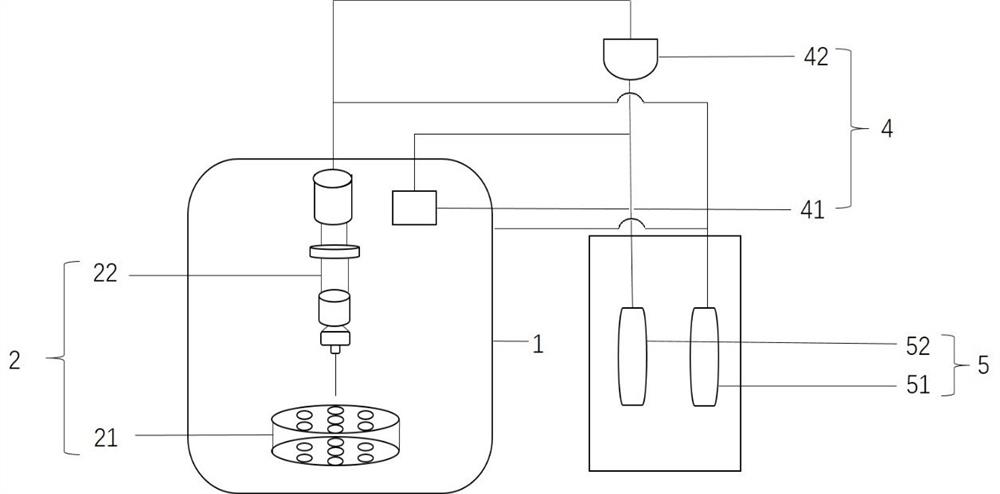

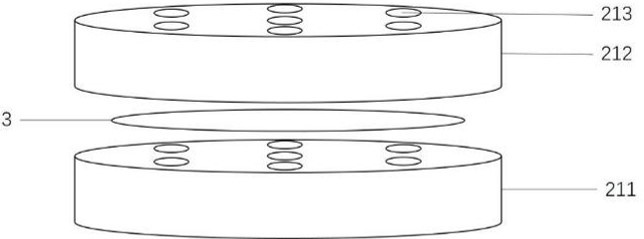

Simulation test system of coal-gas outburst during rock cross-cut coal uncovering

The invention discloses a simulation test system of coal-gas outburst during rock cross-cut coal uncovering, comprising a box provided with an opening at the top thereof, wherein the opening is equipped with a loading steel plate; a top plate and a bottom plate are paved in a closed cavity; a coal layer is paved between the top plate and the bottom plate; a slant angle is formed between the coal layer and the horizontal plane; an outburst simulation roadway is stretched in the bottom plate till being intersected with the coal layer; a notch attached to the coal layer is arranged at the intersection of the outburst simulation roadway; a diaphragm is arranged at the notch; an outburst opening and a gas balance opening are arranged at a part of outburst simulation roadway, which is exposed out of the box; the outburst opening is provided with a quick-opening seal structure; the gas balance opening is communicated with an air pressure tank; surface inflatable structures are respectively arranged on the contact surface of the coal layer and the top plate as well as the contact surface of the coal layer and the bottom plate; and the surface inflatable structures are communicated with a gas pressure tank. According to the invention, a mechanical release-diaphragm rupture method is adopted to ensure that the whole-process simulation of the coal-gas outburst during the rock cross-cut coal uncovering is realized.

Owner:SHANDONG UNIV OF SCI & TECH

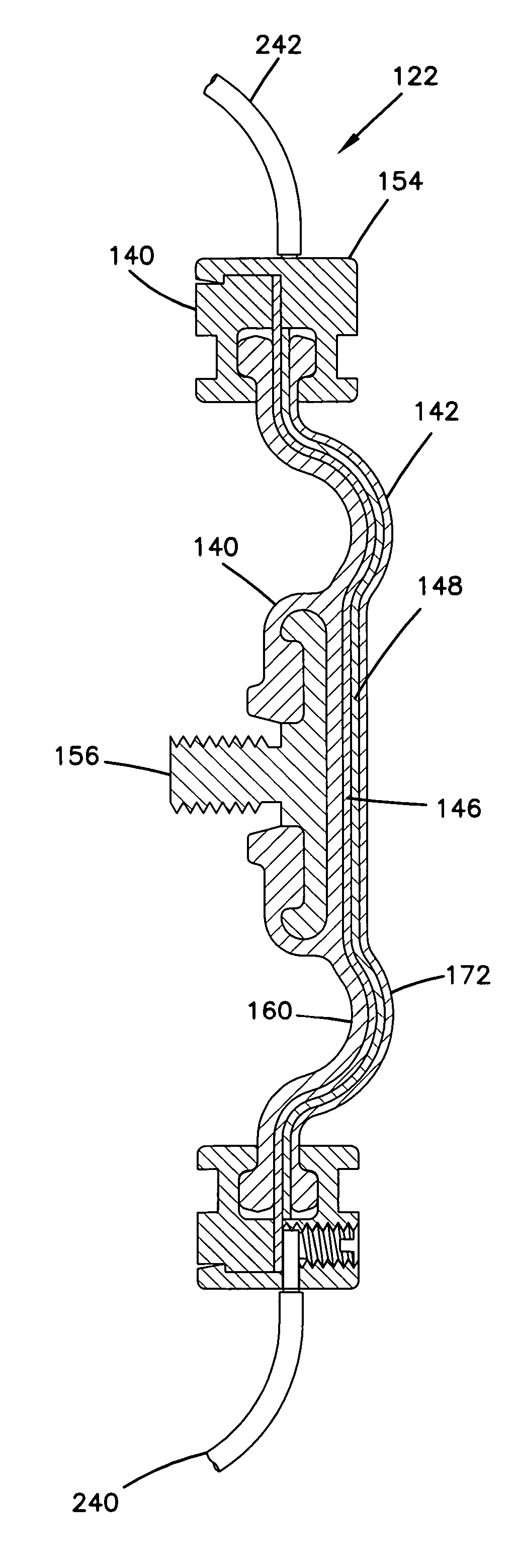

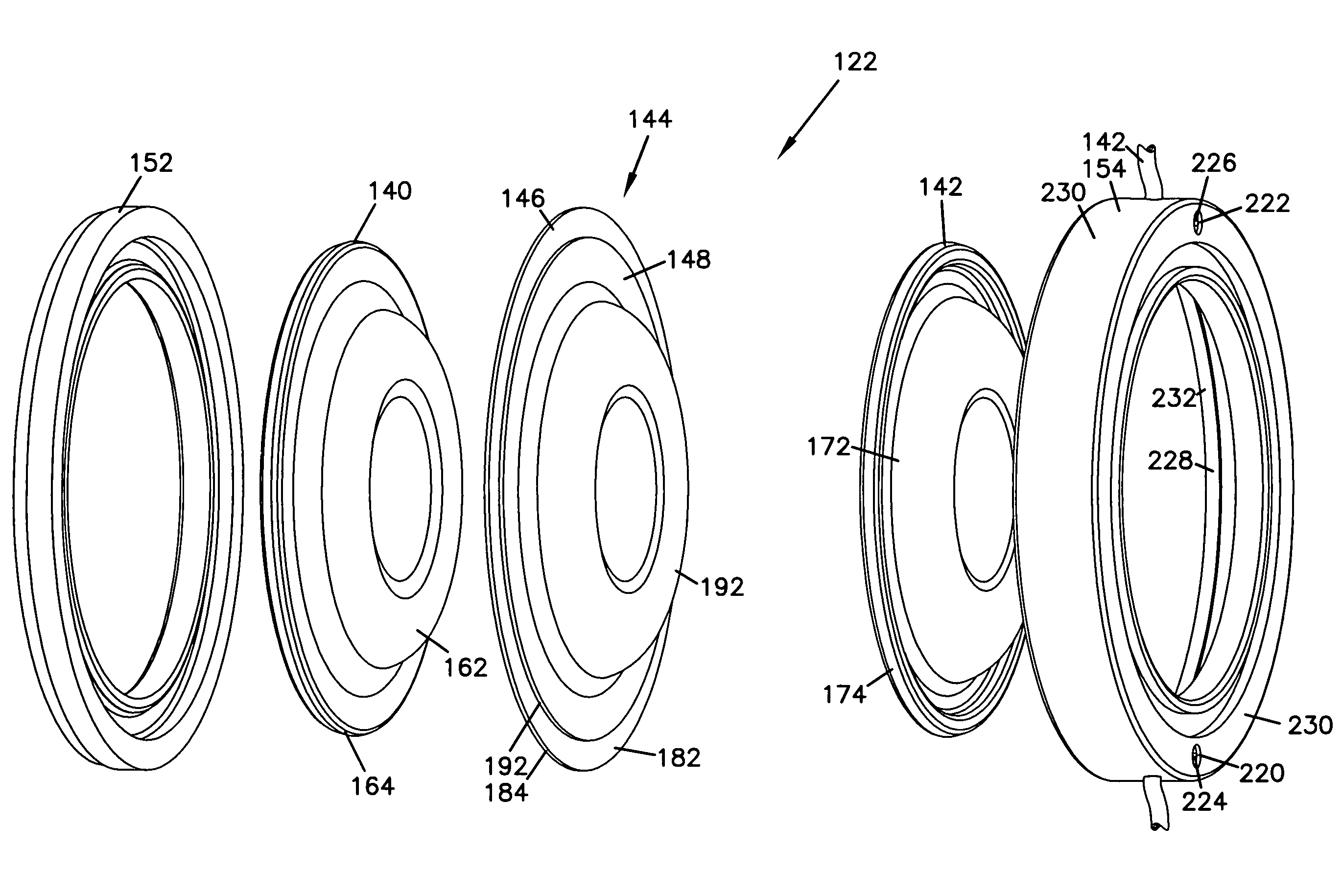

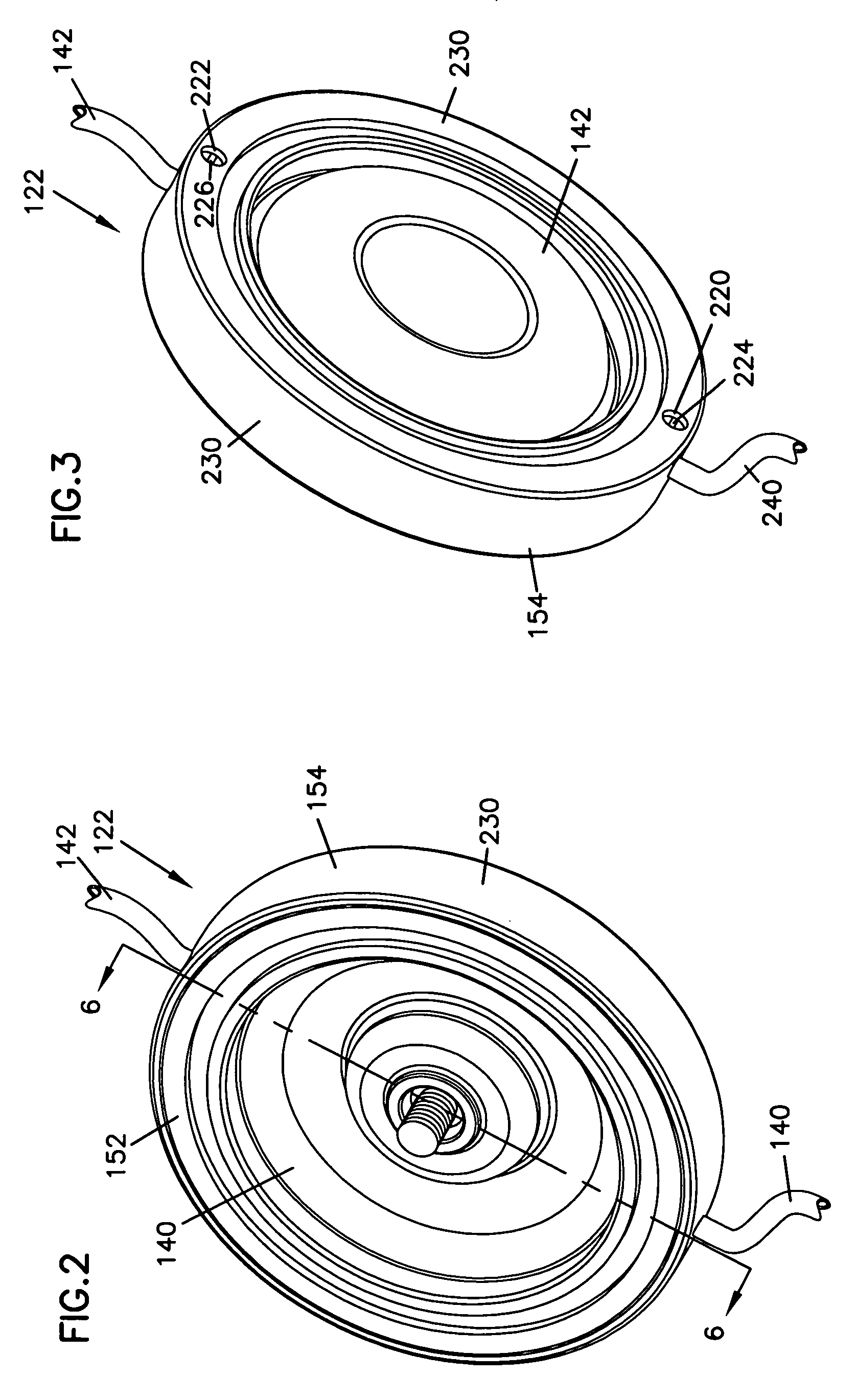

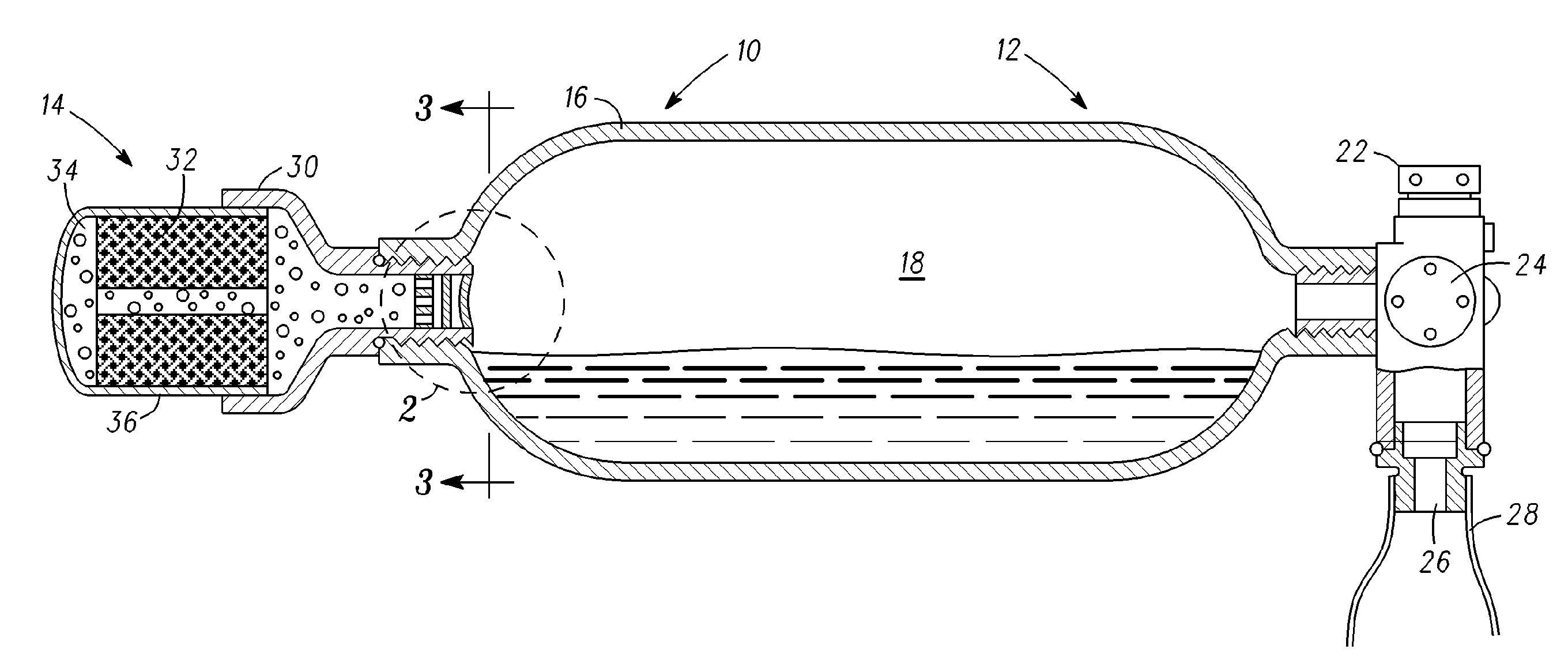

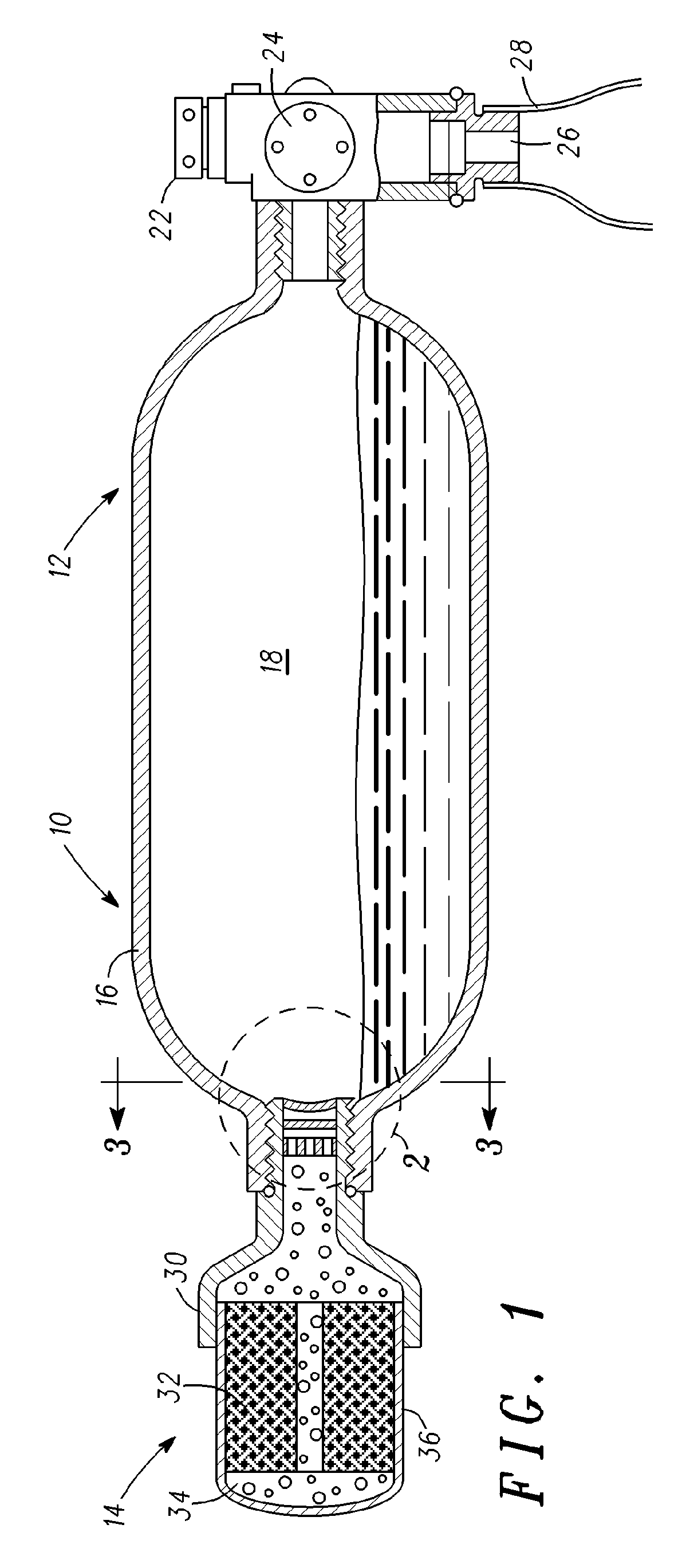

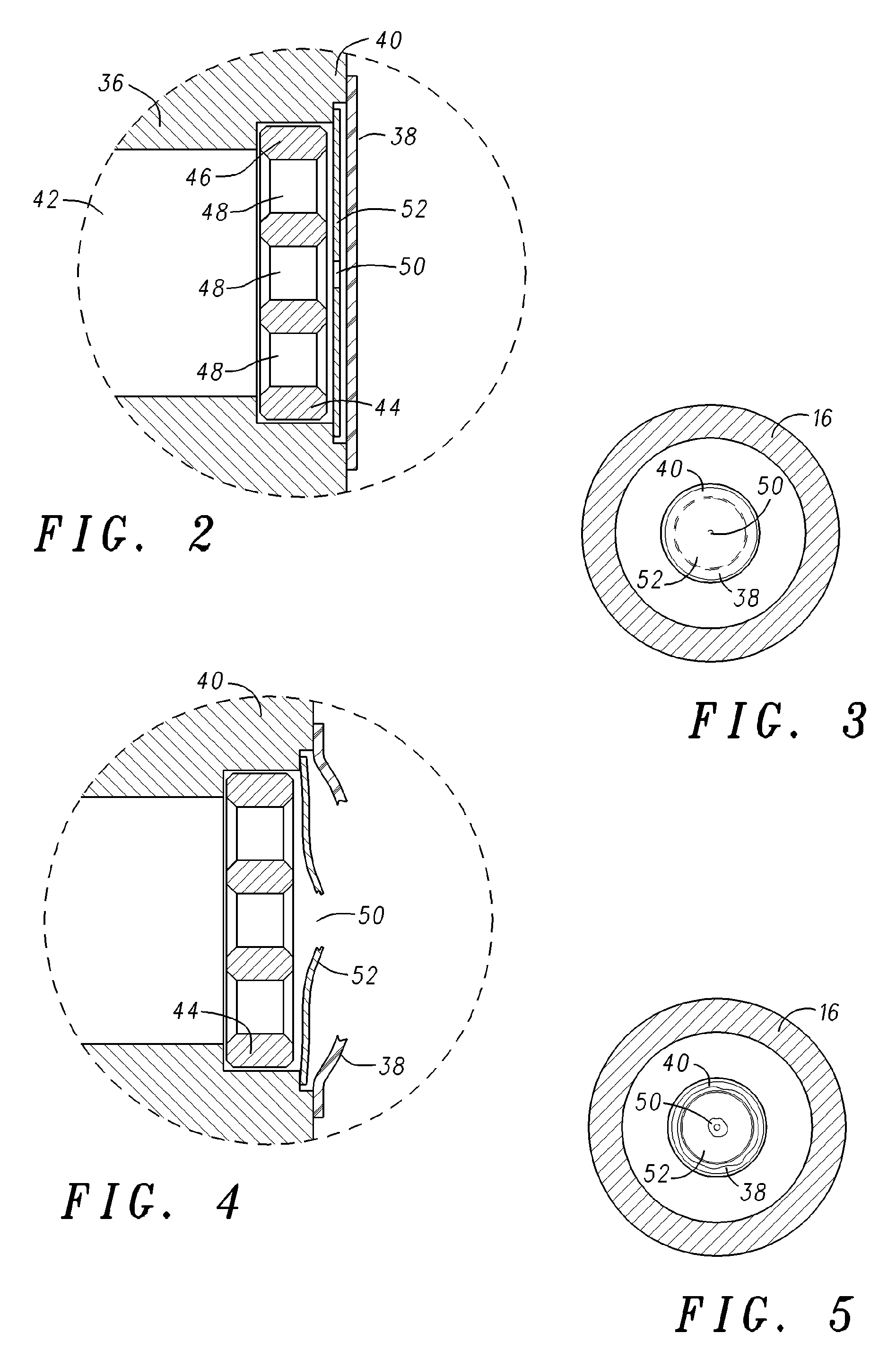

Pump diaphragm rupture detection

ActiveUS20050115402A1Layer failureFlexible wall reciprocating enginesEngine diaphragmsElastomerDiaphragm rupture

A hydraulically driven pump includes a first chamber exposed to a process fluid, a second chamber configured to retain a hydraulic fluid, and a multi-layer diaphragm positioned between the first and second chambers. The diaphragm includes a first layer in contact with the process fluid being pumped, a second layer in contact with the hydraulic fluid, and a third layer that includes an elastomeric base material and an elastomeric conductive trace embedded in the elastomeric base material. The third layer is positioned between the first and second layers and being movable relative to the first and second layers. Changes in an electrical resistance of the conductive trace indicate a failure condition in one of the first, second and third layers.

Owner:WANNER EGINEERING INC

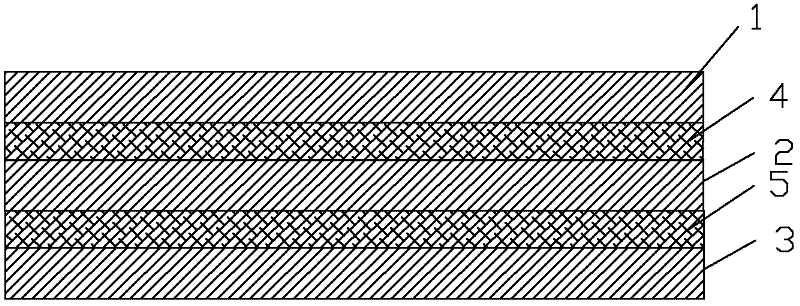

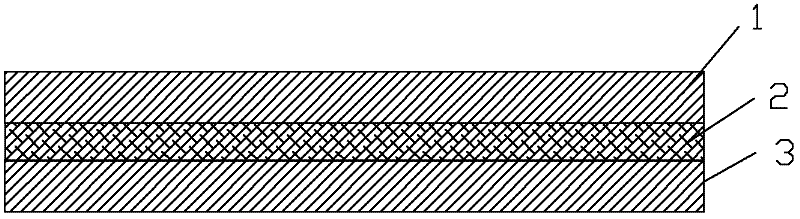

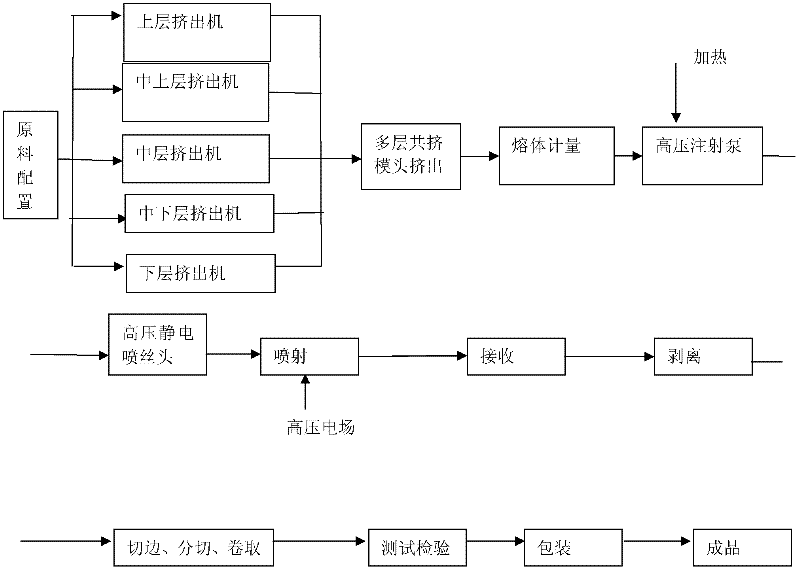

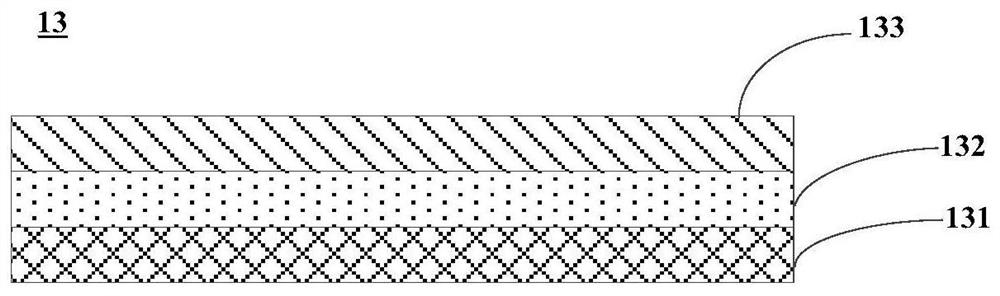

Compound nanofiber diaphragm for lithium ion power battery and manufacturing method

InactiveCN102231431AImprove heat resistanceIncrease temperatureSynthetic resin layered productsCell component detailsFiberLithium

The invention discloses a compound nanofiber diaphragm for a lithium ion power battery. The compound nanofiber diaphragm comprises an upper layer, an upper middle layer, a middle layer, a lower middle layer and a lower layer, wherein the upper, middle and lower layers are polyethylene terephthalate (PET) nanofiber layers; the upper and lower middle layers are polyethylene nanofiber layers; the lower middle layer is covered on the lower layer; the middle layer is covered on the lower middle layer; the upper middle layer is covered on the middle layer; and the upper layer is covered on the upper middle layer. Or the compound nanofiber diaphragm adopts a three-layer structure form. The invention also provides the compound nanofiber diaphragm for the lithium ion power battery and a manufacturing method thereof. By the compound nanofiber diaphragm for the lithium ion power battery and the manufacturing method thereof, heat resistance is improved, a difference value between diaphragm rupturing temperature and obturating temperature is increased, and security is enhanced.

Owner:CHINA ZHEJIANG GREAT SOUTHEAST GRP

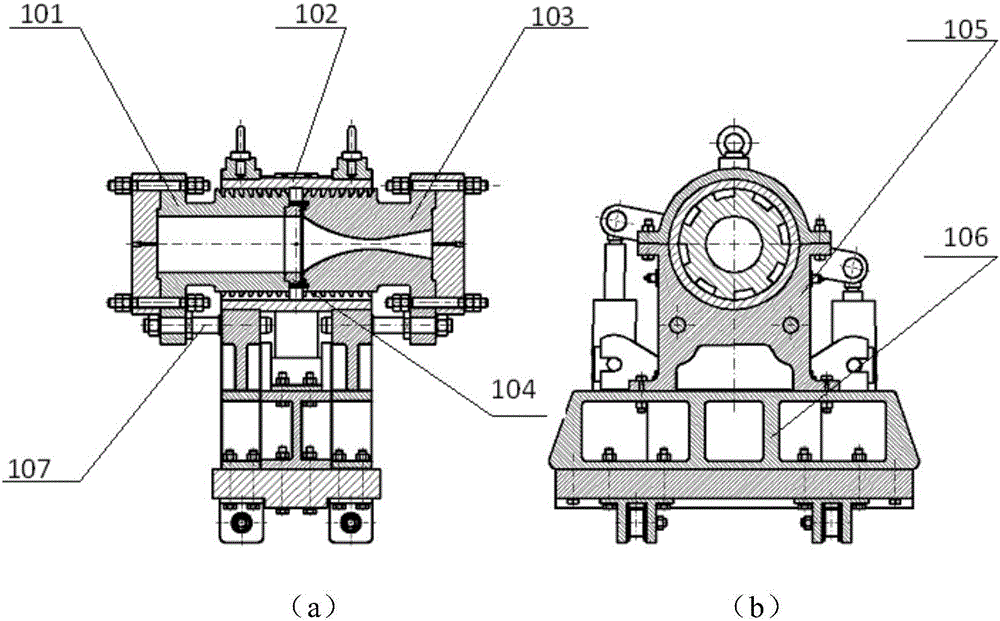

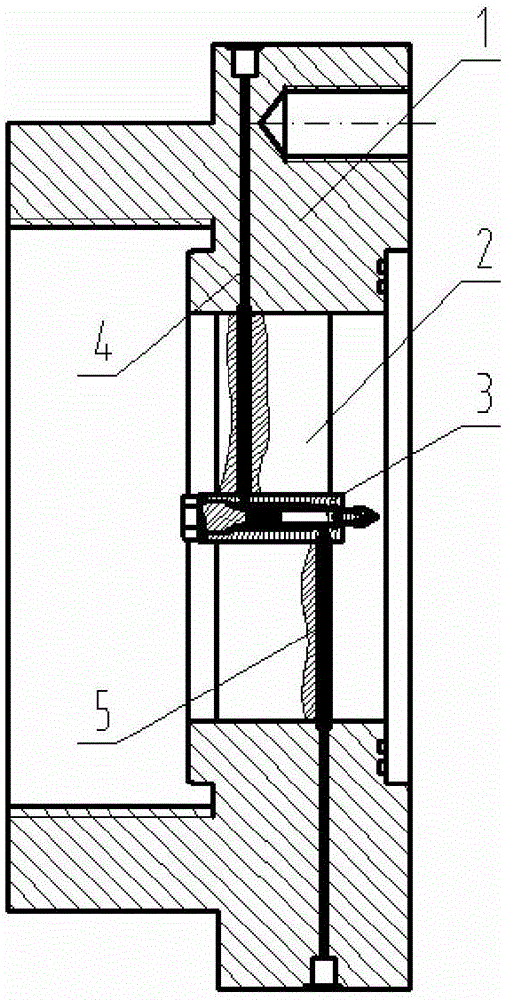

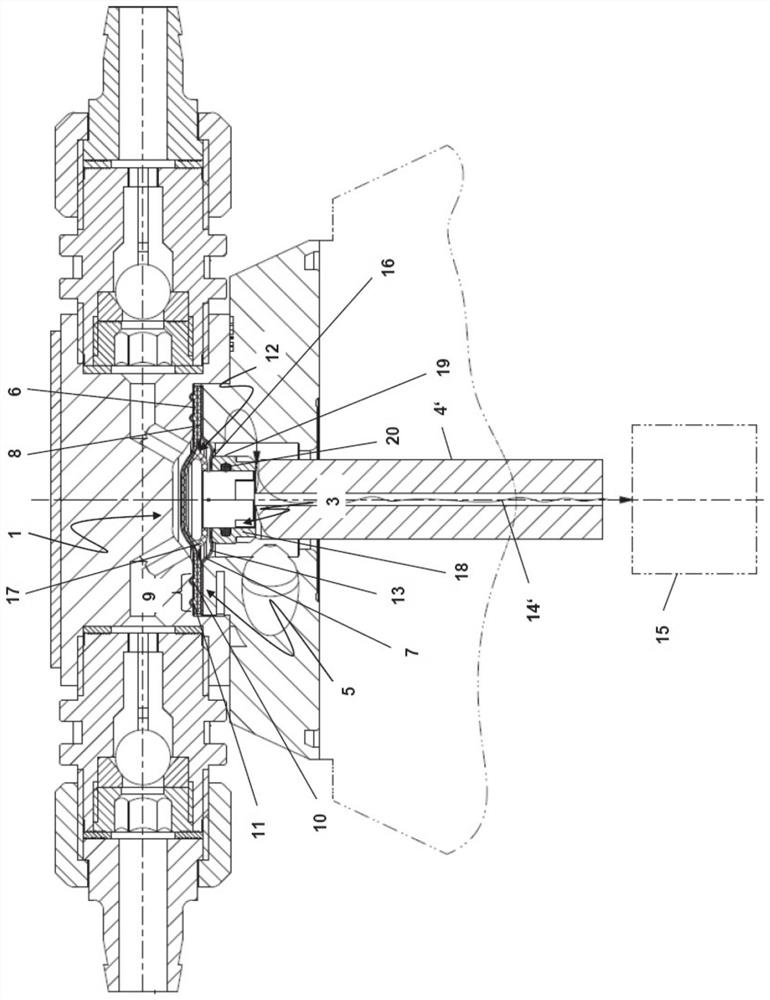

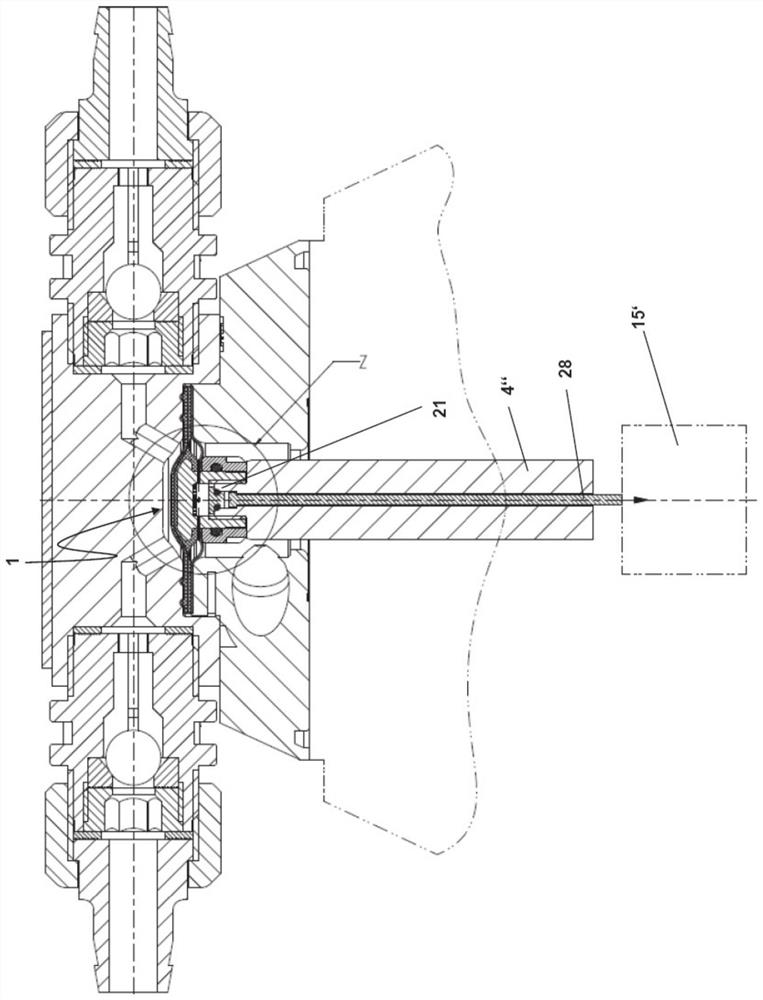

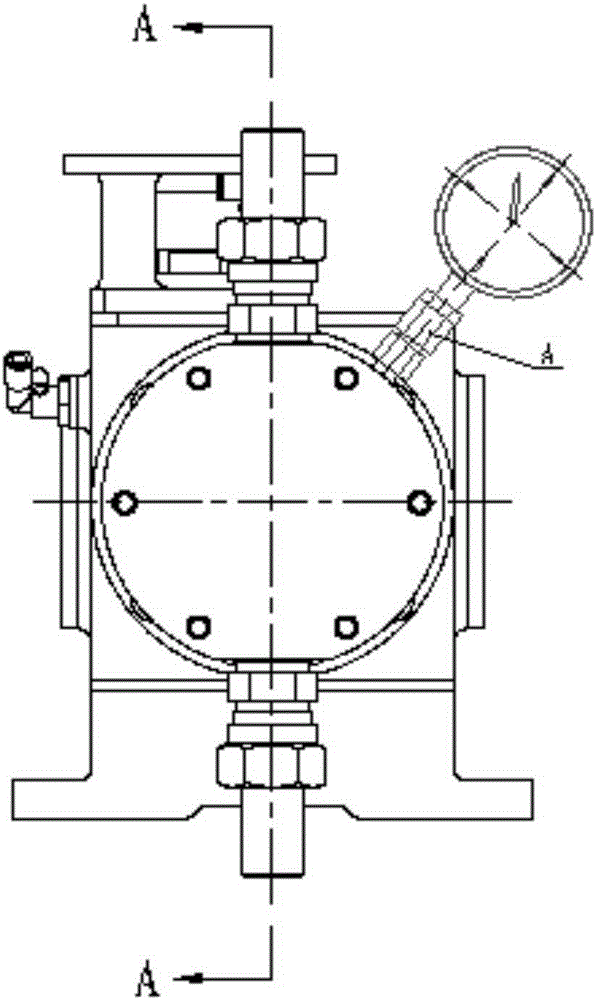

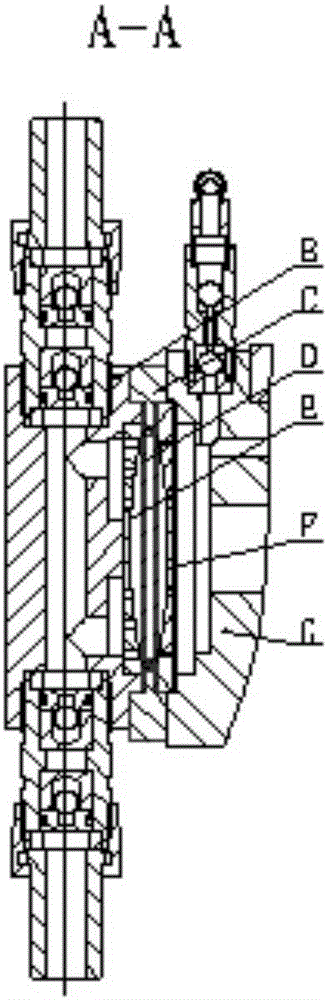

Diaphragm positioning and clamping device

ActiveCN106840580AMake sure the positioning is clampedUniform clamping forceAerodynamic testingHydraulic cylinderShock wave

The invention relates to a diaphragm positioning and clamping device. The diaphragm positioning and clamping device comprises slotted nuts, left-handed screws, right-hand screws, and adjusting rings; the external screw-thread of the left-hand screws matches the inner thread of the left-hand threaded hole of the slotted nuts and the external screw-thread forms a alveolar interleaving structure along the circumferential direction; through-holes with the same diameter as the shock tube of the wind tunnel are formed inside of the left-handed screw; the external screw-thread of the right-hand screw is matched with the inner thread of the slotted nuts and the right-hand threaded hole, and the external screw-thread forms an alternating structure of the teeth along the circumferential direction; the through holes of the right-hand screw are in the throat section of the wind tunnel nozzle; the compressed air is adjusted inside the ring through the long slot of the left screw rod, acting at the left end of the diaphragm; When the diaphragm ruptures, the compressed air enters the wind tunnel nozzle via a long slot of the right-hand screw; The diaphragm positioning and clamping device can insert the rod into the slotted nuts through a hydraulic push and a pull mechanism of the shock tube and the nozzle; by setting the swinging hydraulic cylinder to drive the slotted nut to rotate, the meshing, clamping and releasing can be realized, and the device is simple to operate and has high degree of automation.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Pump diaphragm rupture detection

ActiveUS6941853B2Layer failureFlexible wall reciprocating enginesEngine diaphragmsElastomerDiaphragm rupture

A hydraulically driven pump includes a first chamber exposed to a process fluid, a second chamber configured to retain a hydraulic fluid, and a multi-layer diaphragm positioned between the first and second chambers. The diaphragm includes a first layer in contact with the process fluid being pumped, a second layer in contact with the hydraulic fluid, and a third layer that includes an elastomeric base material and an elastomeric conductive trace embedded in the elastomeric base material. The third layer is positioned between the first and second layers and being movable relative to the first and second layers. Changes in an electrical resistance of the conductive trace indicate a failure condition in one of the first, second and third layers.

Owner:WANNER EGINEERING INC

Battery diaphragm, preparation method thereof and battery comprising battery diaphragm

ActiveCN110600664AHigh strengthImprove ionic conductivitySecondary cellsCell component detailsPolymer electrolytesLithium

The invention provides a battery diaphragm, a preparation method thereof and a battery comprising the battery diaphragm. The battery diaphragm comprises a ceramic layer, and a first polymer electrolyte layer and a second polymer electrolyte layer which are arranged on two sides of the ceramic layer, wherein the first polymer electrolyte layer and the second polymer electrolyte layer respectively and independently comprise components in percentage by weight, 10-87% of polymer, 2-30% of ceramic powder, 1-30% of lithium salt and 10-30% of plasticizer. The battery diaphragm is prepared by dispersing materials of the first polymer electrolyte layer and the second polymer electrolyte layer in solvent to prepare the slurry, and then forming a film with the ceramic layer in sequence. The battery diaphragm is advantaged in that the battery diaphragm has a relatively high liquid absorption rate, ionic conductivity and elongation at break, can effectively reduce the risk of diaphragm rupture, andimproves the rate capability and cycle performance of the battery.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

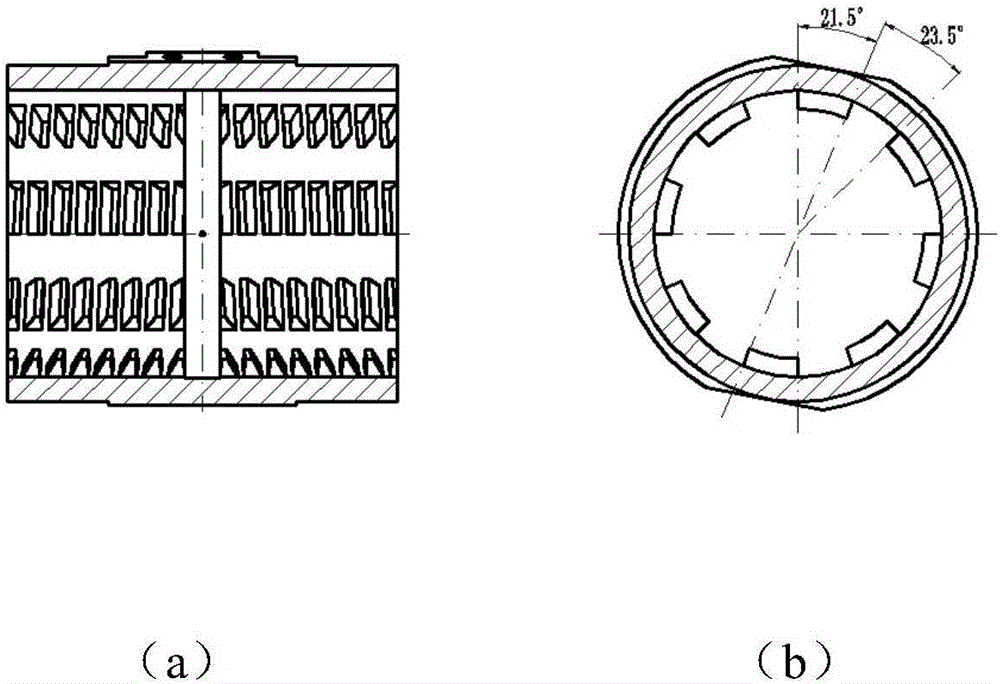

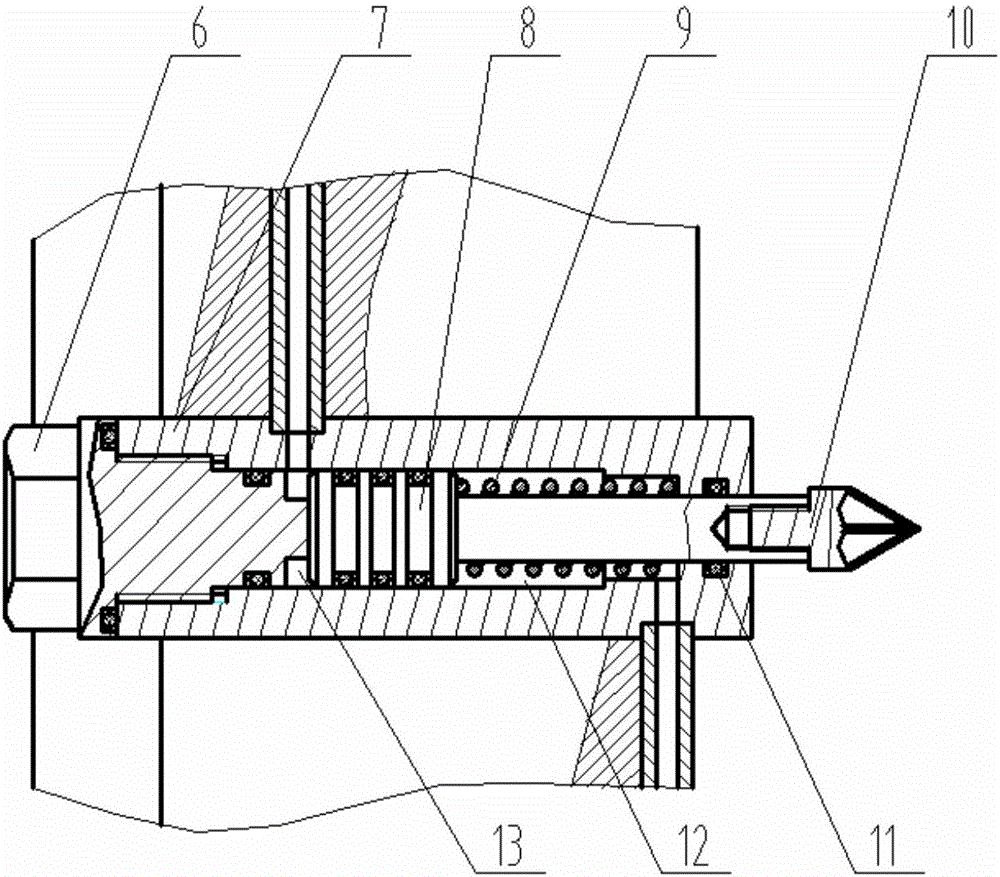

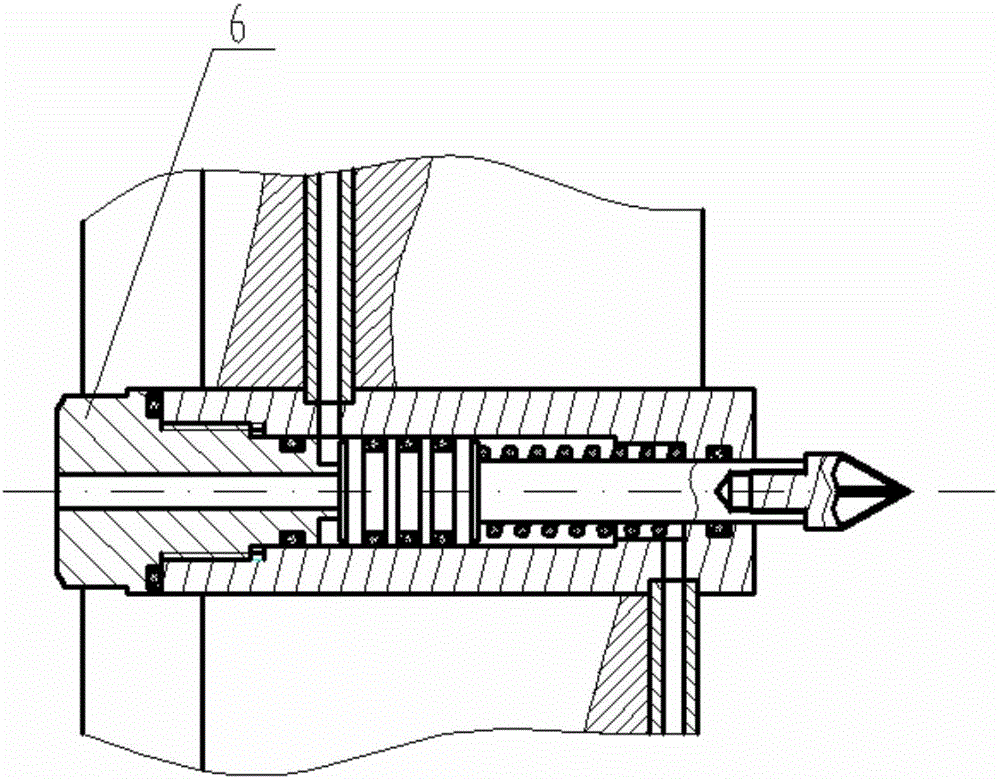

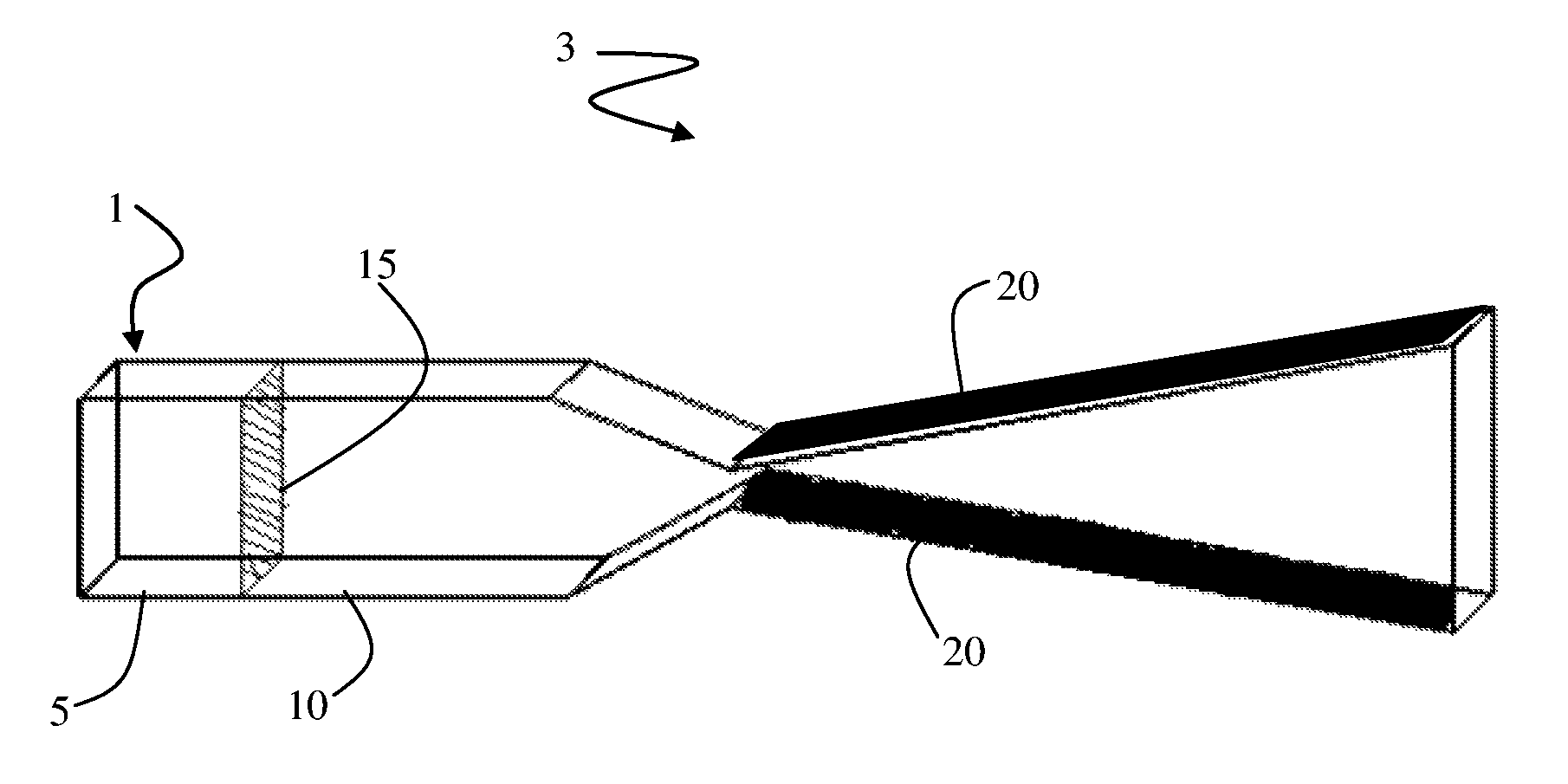

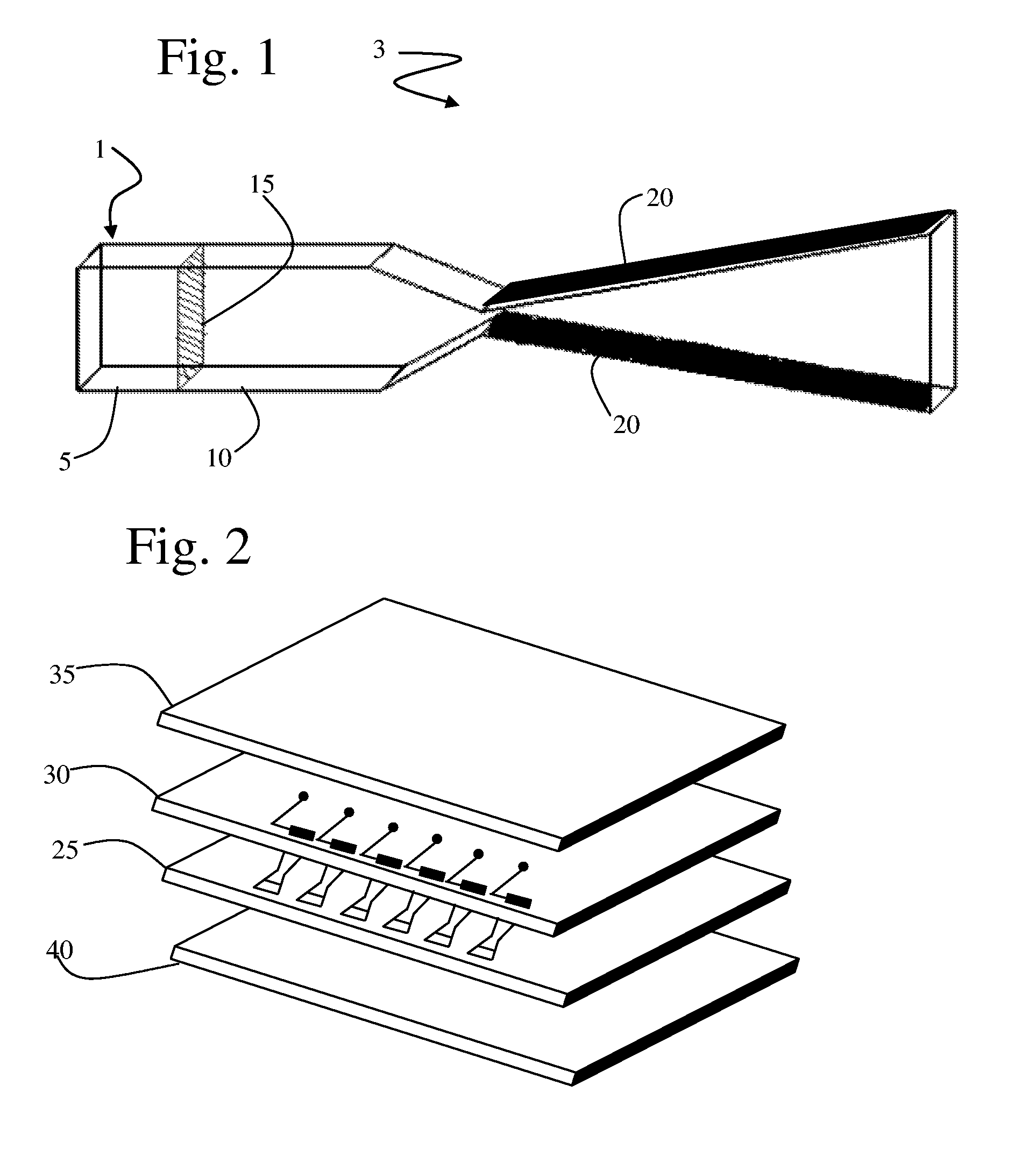

Shock tunnel diaphragm rupture device

ActiveCN106644358ASaving processabilitySave equipment investmentAerodynamic testingDiaphragm ruptureEngineering

The invention relates to a shock tunnel diaphragm rupture device and belongs to the hypersonic shock tunnel engineering field. The shock tunnel diaphragm rupture device includes a gun barrel connection structure, a cone supporting plate, a diaphragm rupture cone, a high-pressure cavity pipeline, a low-pressure cavity pipeline, a shock tube high-pressure section gun barrel, a shock tube low-pressure section gun barrel and a diaphragm; the left side of the gun barrel connection structure is fixedly connected with the shock tube high-pressure section gun barrel; the right side of the gun barrel connection structure is fixedly connected with the shock tube low-pressure section gun barrel; the cone supporting plate is fixedly installed in the gun barrel connection structure; the diaphragm rupture cone is axially and fixedly installed at the axis of the cone supporting plate through the gun barrel connection structure; the high-pressure cavity pipeline and the low-pressure cavity pipeline are arranged at the outer wall of the diaphragm rupture cone along the radial direction of the gun barrel connection structure; and the diaphragm is fixed between the gun barrel connection structure and the shock tube low-pressure section gun barrel. The diaphragm rupture of a shock tunnel can be both realized under high driving pressure or low driving pressure, diaphragm rupture time is significantly shortened, and the controllability of the diaphragm rupture process is high.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

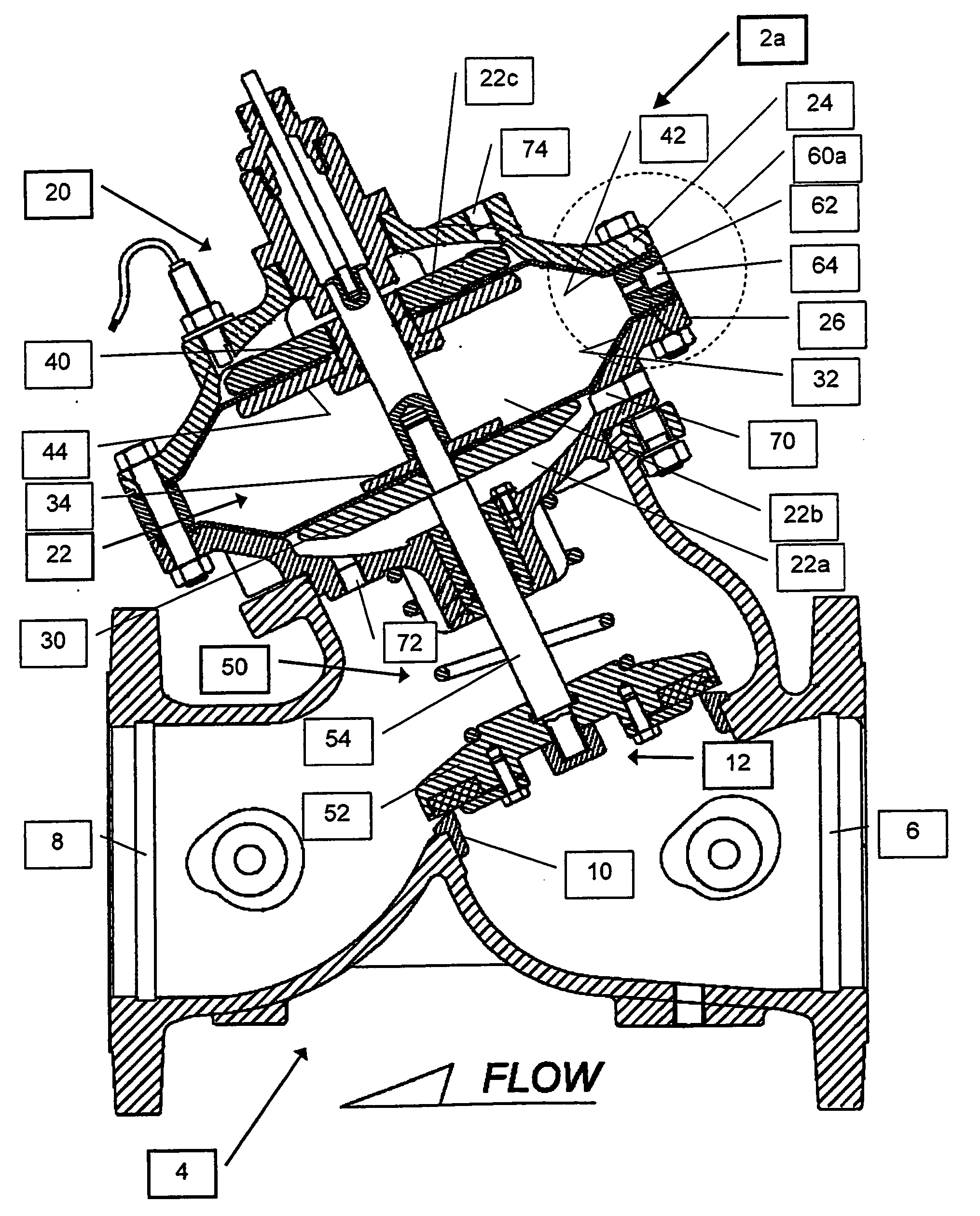

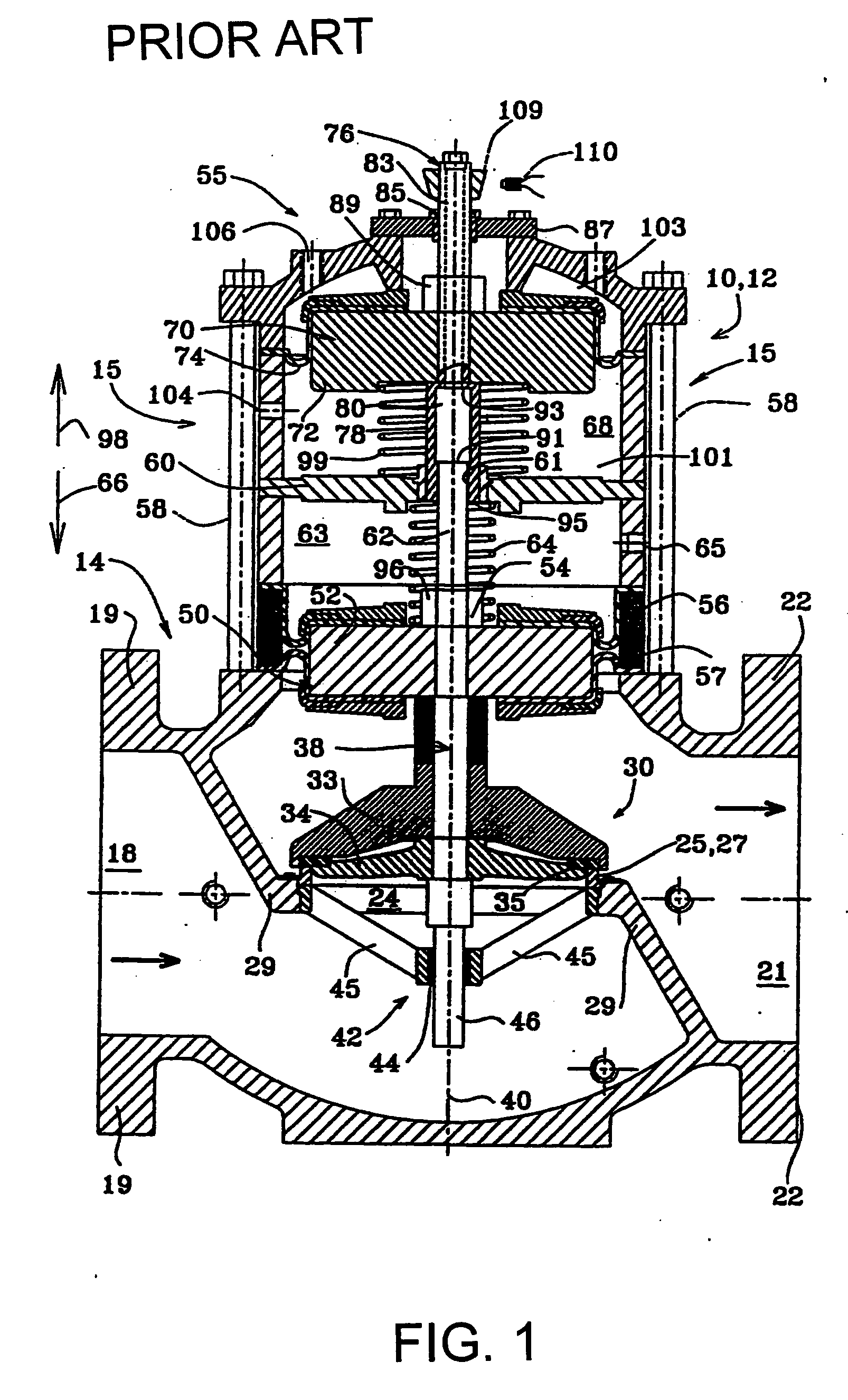

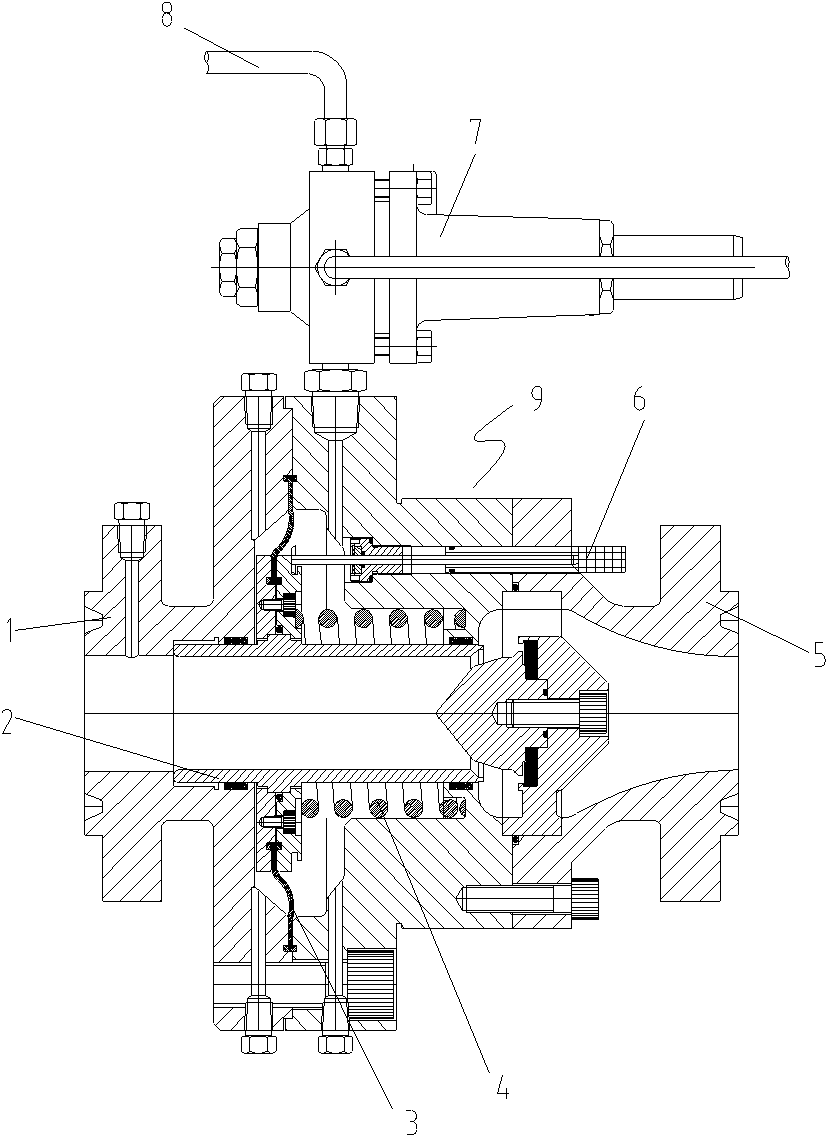

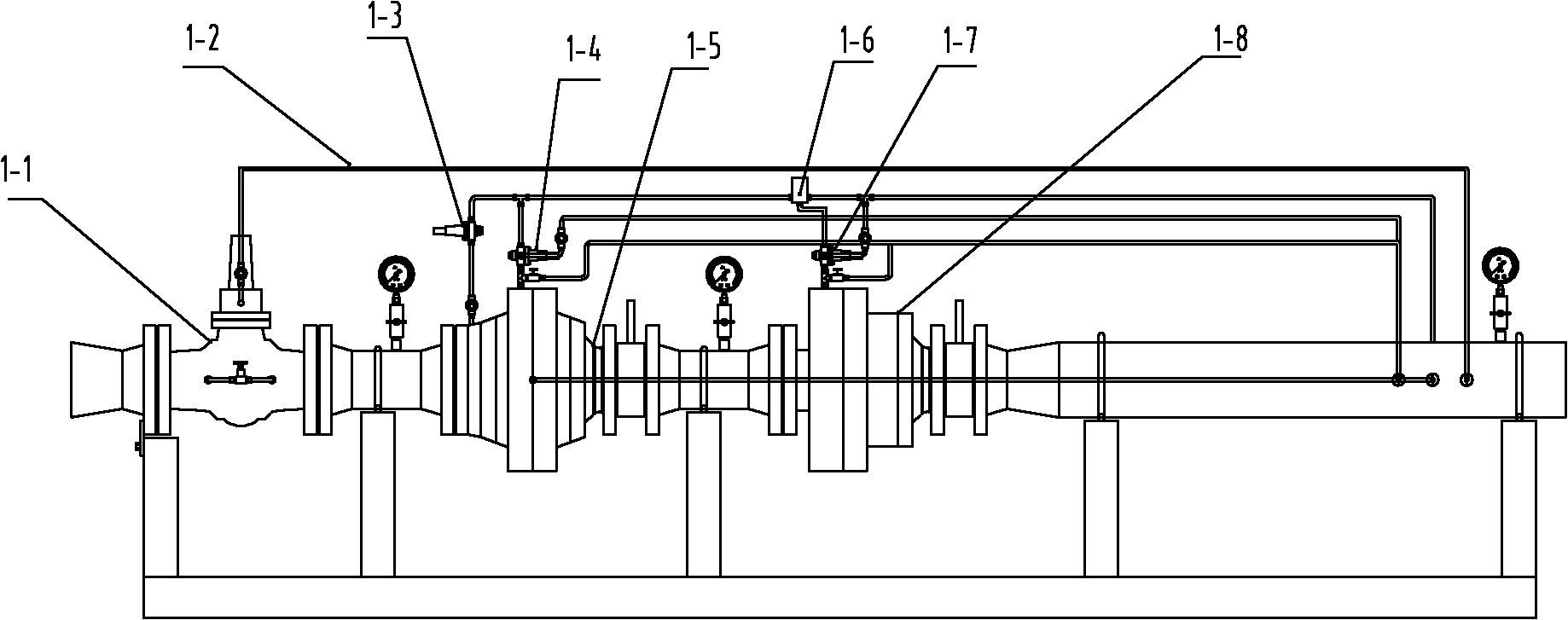

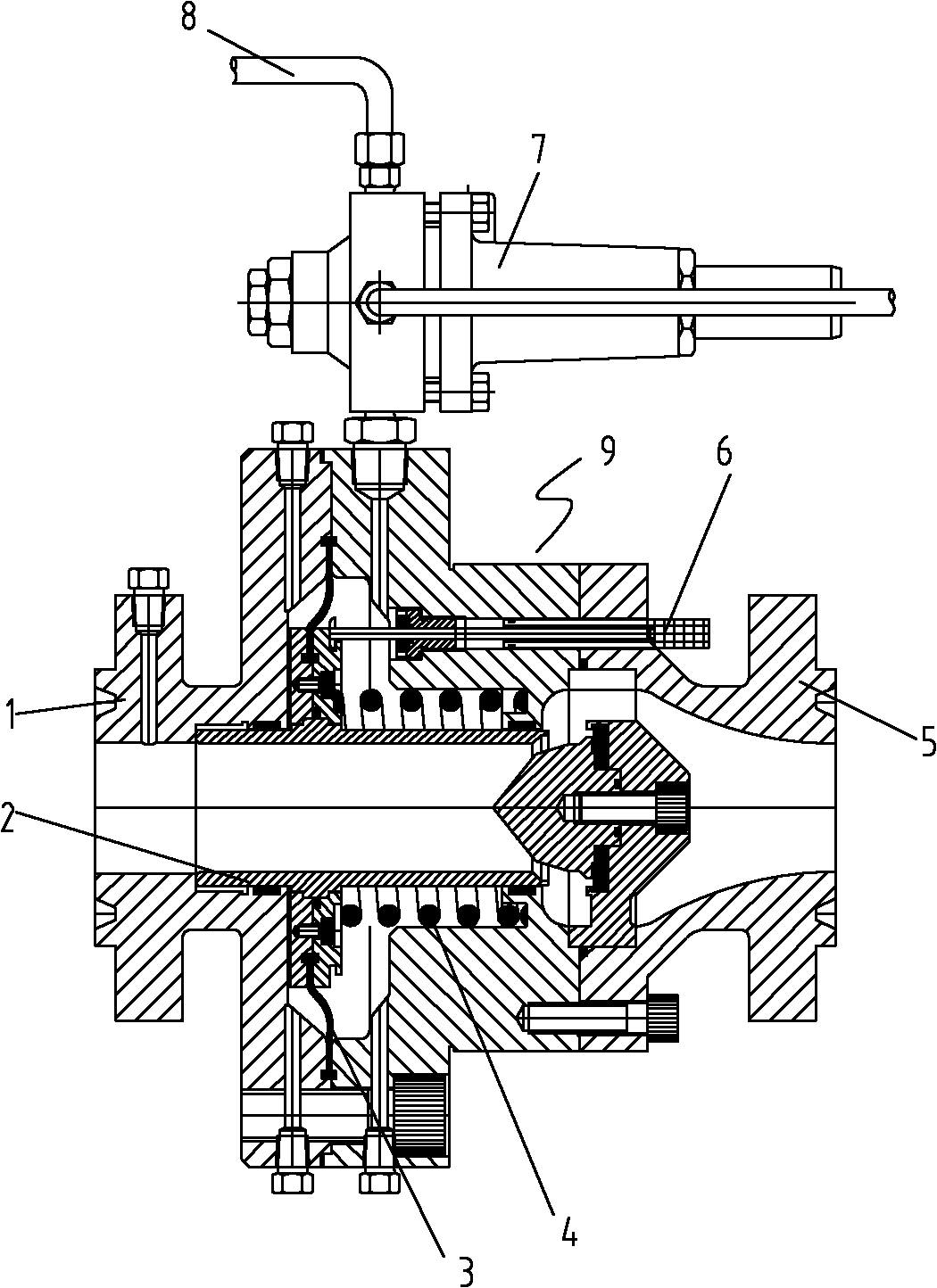

Hydraulic control valve with integrated dual actuators

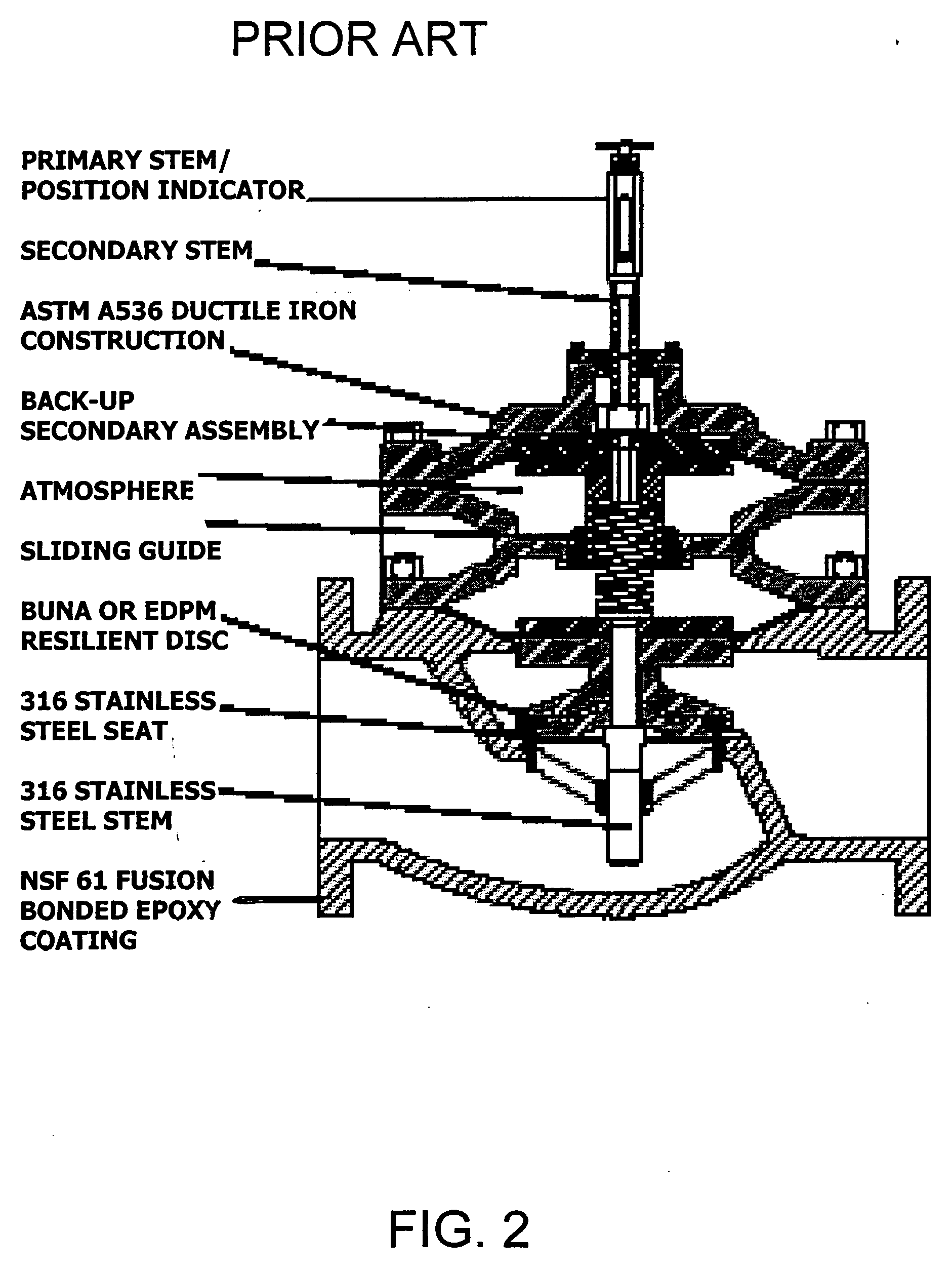

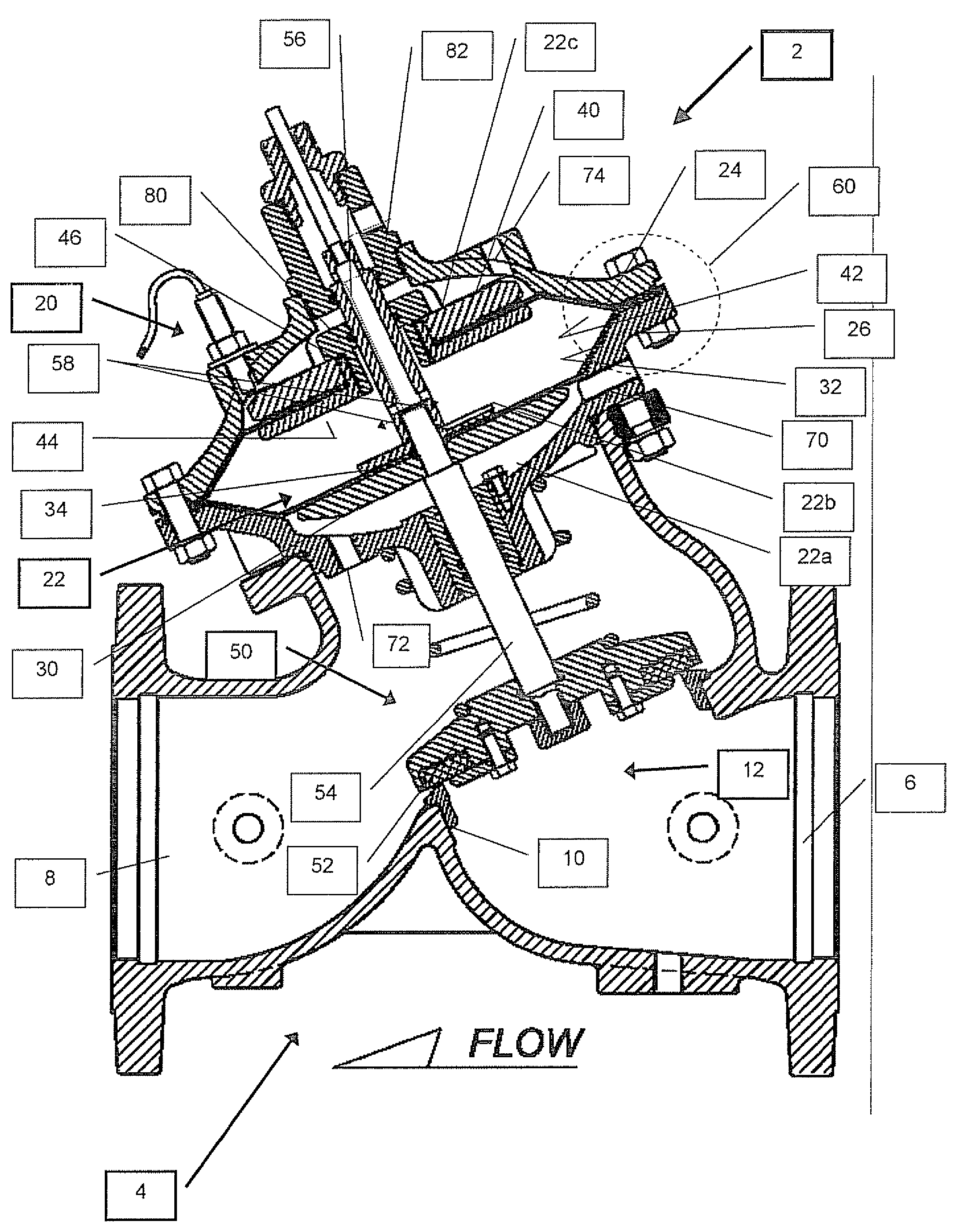

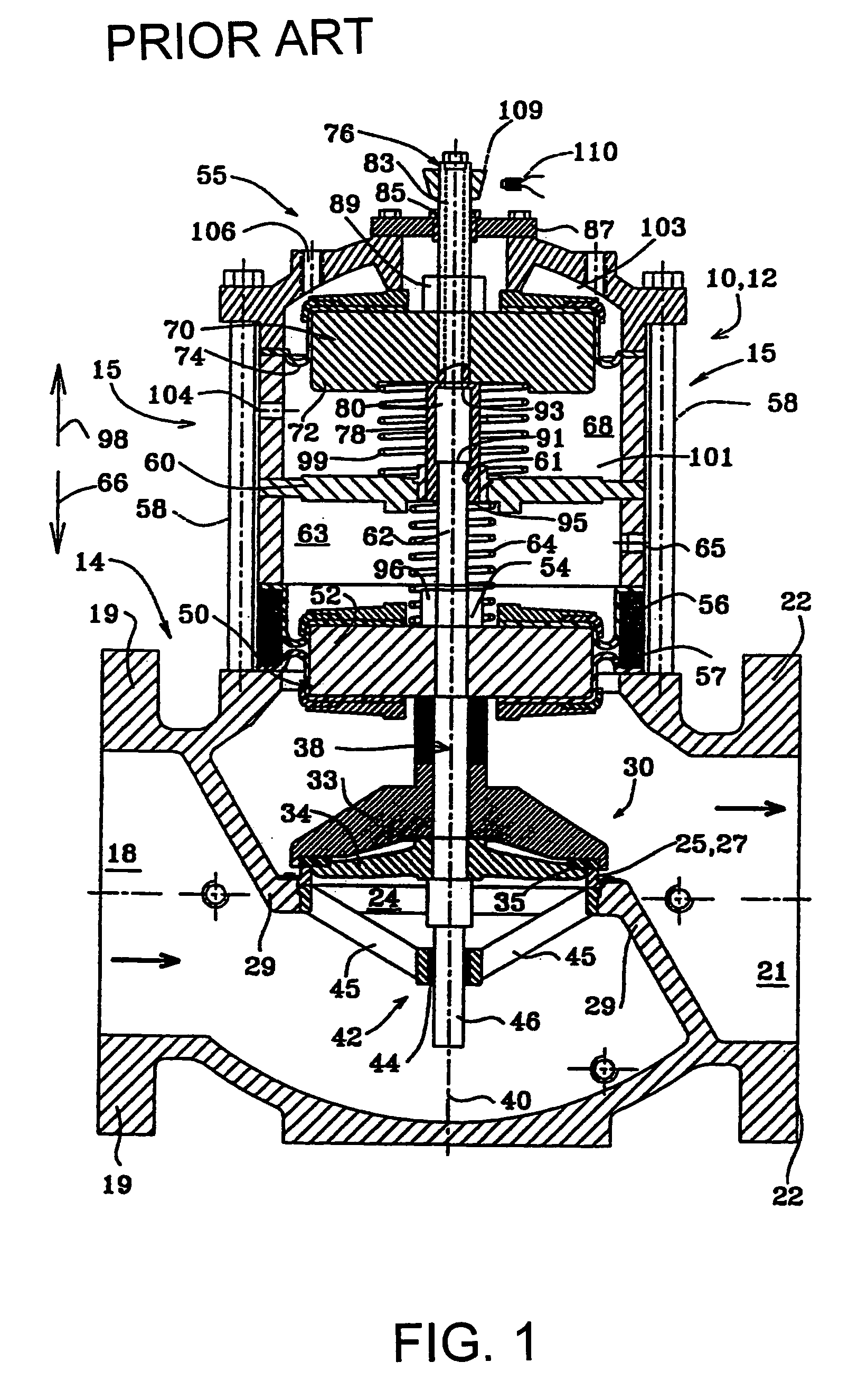

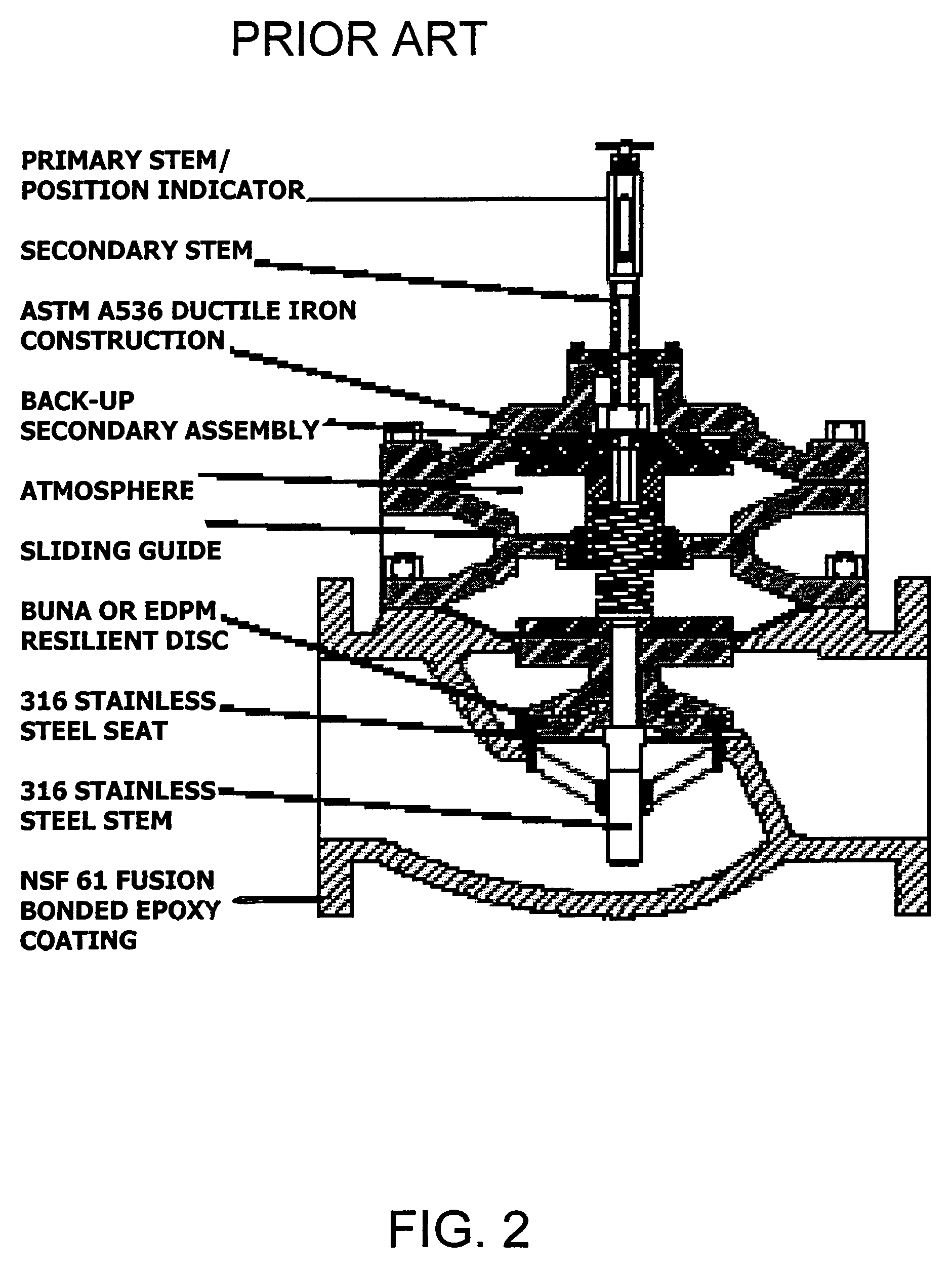

ActiveUS20060289816A1Reciprocating combination enginesOperating means/releasing devices for valvesControl systemDiaphragm rupture

The dual actuator valve of the present invention deploys both the primary and secondary actuator elements in a single, common control chamber. Therefore, the present invention provides a dual actuator valve having dimensions that are the same as, or similar to, the dimensions of a single actuator control valve. It will be appreciated that the actuator elements may be of diaphragm type or piston type actuator elements. The primary actuator element is mechanically linked to the valve plug and regulates the flow though the valve, while the secondary actuator element remains in a fully open position. Should the primary actuator element fail to operate the valve due, for example, to diaphragm rupture, failure of the primary control system, or any other reason, the secondary control system activates the secondary actuator element, which then effects movement of the primary actuator element thereby resuming flow regulation or closure of the valve as necessary.

Owner:BERMAD CS LTD

Hydraulic control valve with integrated dual actuators

ActiveUS7455279B2Reciprocating combination enginesOperating means/releasing devices for valvesControl systemDiaphragm rupture

The dual actuator valve of the present invention deploys both the primary and secondary actuator elements in a single, common control chamber. Therefore, the present invention provides a dual actuator valve having dimensions that are the same as, or similar to, the dimensions of a single actuator control valve. It will be appreciated that the actuator elements may be of diaphragm type or piston type actuator elements. The primary actuator element is mechanically linked to the valve plug and regulates the flow though the valve, while the secondary actuator element remains in a fully open position. Should the primary actuator element fail to operate the valve due, for example, to diaphragm rupture, failure of the primary control system, or any other reason, the secondary control system activates the secondary actuator element, which then effects movement of the primary actuator element thereby resuming flow regulation or closure of the valve as necessary.

Owner:BERMAD CS LTD

Safe anti-explosion gas pressure regulator

InactiveCN101672427AInhibit sheddingPrevent Gas Safety AccidentsPipeline systemsDiaphragm ruptureGas leak

The invention relates to a safe anti-explosion gas pressure regulator. A throttling safety device is arranged at an interface position of a pressure regulating gas chamber and an inlet pipe; a safetybase of the throttling safety device is sealed and fixed on the inlet pipe; a vent hole is arranged in the safety base; a throttling safety valve core is arranged in the inlet pipe and matched with asealing surface of one opening at one end of the safety base; a reset ejecting bar penetrates through the vent hole; two ends of the reset ejecting bar are respectively matched with the throttling safety valve core and a closing plug; the closing plug is linked with one end of a hinge rod hinged on the safety base, while the other end of the hinge rod is connected with the connecting rod; and theconnecting rod penetrates through a flexible diaphragm and is connected with a reset switch outside the pressure regulator. The safe anti-explosion gas pressure regulator overcomes the defect that thecommon pressure regulator can not cut off gas source automatically when gas leaks. By adopting the specific design, the safe anti-explosion gas pressure regulator can eliminates gas safety accidentscaused by self-owned diaphragm rupture of the pressure regulator, or falling off, aging crack and rupturing by rat-bite of a gas rubber tube (hose), and the like, and the safe anti-explosion gas pressure regulator has the advantages of simple structure, high sensitivity, convenient reset operation and safe and reliable use.

Owner:陈朋海

Preparation method of lithium-ion battery safe diaphragm material

InactiveCN105355814ALow closed cell temperatureImprove securityCell seperators/membranes/diaphragms/spacersSecondary cellsPolyolefinDiaphragm rupture

The invention discloses a preparation method of a lithium-ion battery safe diaphragm material, comprising the following steps: step 1, blending polyolefin and a fluorine-containing polymer, performing melting extrusion, cooling and performing grain-sized dicing, wherein a melting co-extrusion temperature is 230-270 DEG C; step 2, performing secondary melting extrusion on granules, cooling and tabletting, wherein a secondary melting co-extrusion temperature is 230-270 DEG C; step 3, biaxially stretching a sheet produced in step 2, thus forming a semi-finished product of the diaphragm material with a microcrystalline structure; step 4, soaking the semi-finished product of the diaphragm material in hydrogen peroxide for treating; step 5, taking out, and vacuum-drying, thus obtaining the finished diaphragm material. By adopting the fluorine-containing polymer as a diaphragm base material, dissolution to the diaphragm material in a process that electrolyte temperature rises can be effectively resisted, and the diaphragm rupture probability is lowered; secondly, by adding polyethylene in raw materials for preparing the diaphragm material, the pore closing temperature of the diaphragm material can be effectively lowered, so that the safety of the diaphragm material is further improved.

Owner:浙江锂盾储能材料技术有限公司

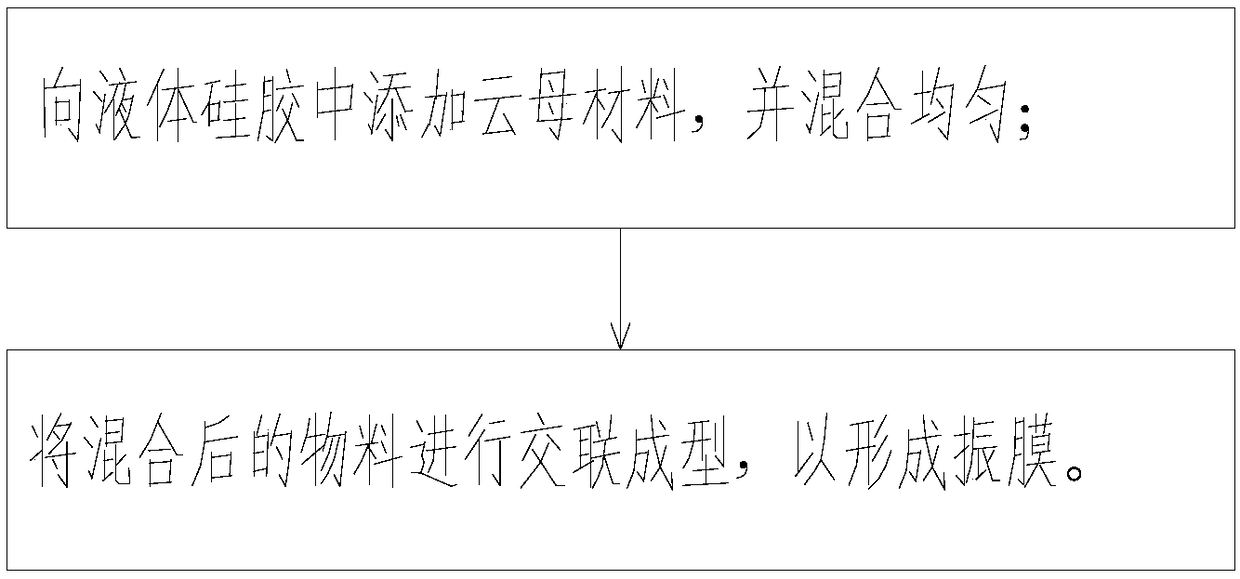

Vibrating diaphragm preparation method and vibrating diaphragm

The invention discloses a vibrating diaphragm preparation method and a vibrating diaphragm. The preparation method comprises the steps: adding a mica material into liquid silica gel and evenly mixing;performing cross-linking formation on the mixed materials to obtain the vibrating diaphragm. The liquid silica gel is modified by the mica material, so that the damping capacity and the elasticity modulus can be obviously improved, partition vibration of the vibrating diaphragm can be obviously reduced, and noise can be absorbed; thus, audition performance of a sound production device is improved, F0 (resonant frequency) of the vibrating diaphragm is adjusted, nonlinear distortion of the vibrating diaphragm is reduced, and the phenomenon of vibrating diaphragm rupture is reduced.

Owner:GOERTEK INC

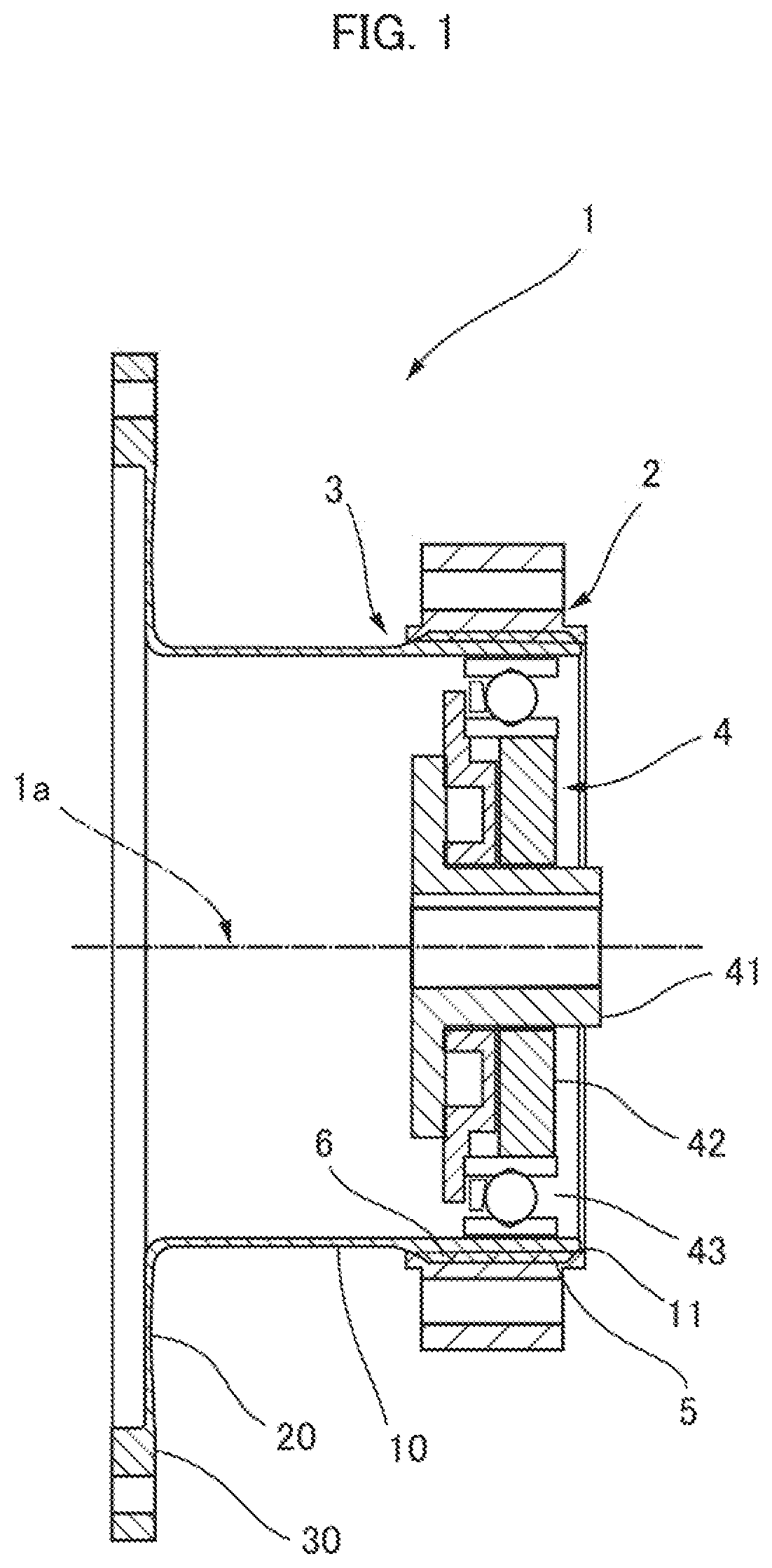

Self-operated axial flow pressure regulating valve fully open in case of failure

InactiveCN102269288ALow investment costReduce design and manufacturing costsEqualizing valvesSafety valvesAxial pressureDiaphragm rupture

The invention relates to a self-operated axial-flow pressure regulating valve that can be fully opened when a failure occurs, including a valve body with an inlet before pressure regulation and an outlet after pressure regulation, a valve core, a film, an opening spring, a position sensor, a preposition and a control command The device and the pressure-taking nozzle are characterized in that: the opening spring of the inner cavity of the valve is placed at the rear of the membrane diaphragm. Beneficial effects: the opening spring in the main valve body is arranged at the rear of the main diaphragm of the film, which can realize that when the main diaphragm of the pressure regulating valve is broken or damaged or the control pilot (pilot valve) is damaged and the load control pressure is lost, the pressure regulating valve valve The core uses the force of the opening spring to open the pressure regulating valve and maintain the fully open state, and at the same time the sensor sends out an alarm signal to remind the user of the function of timely maintenance.

Owner:BEST ENERGY EQUIP TIANJIN

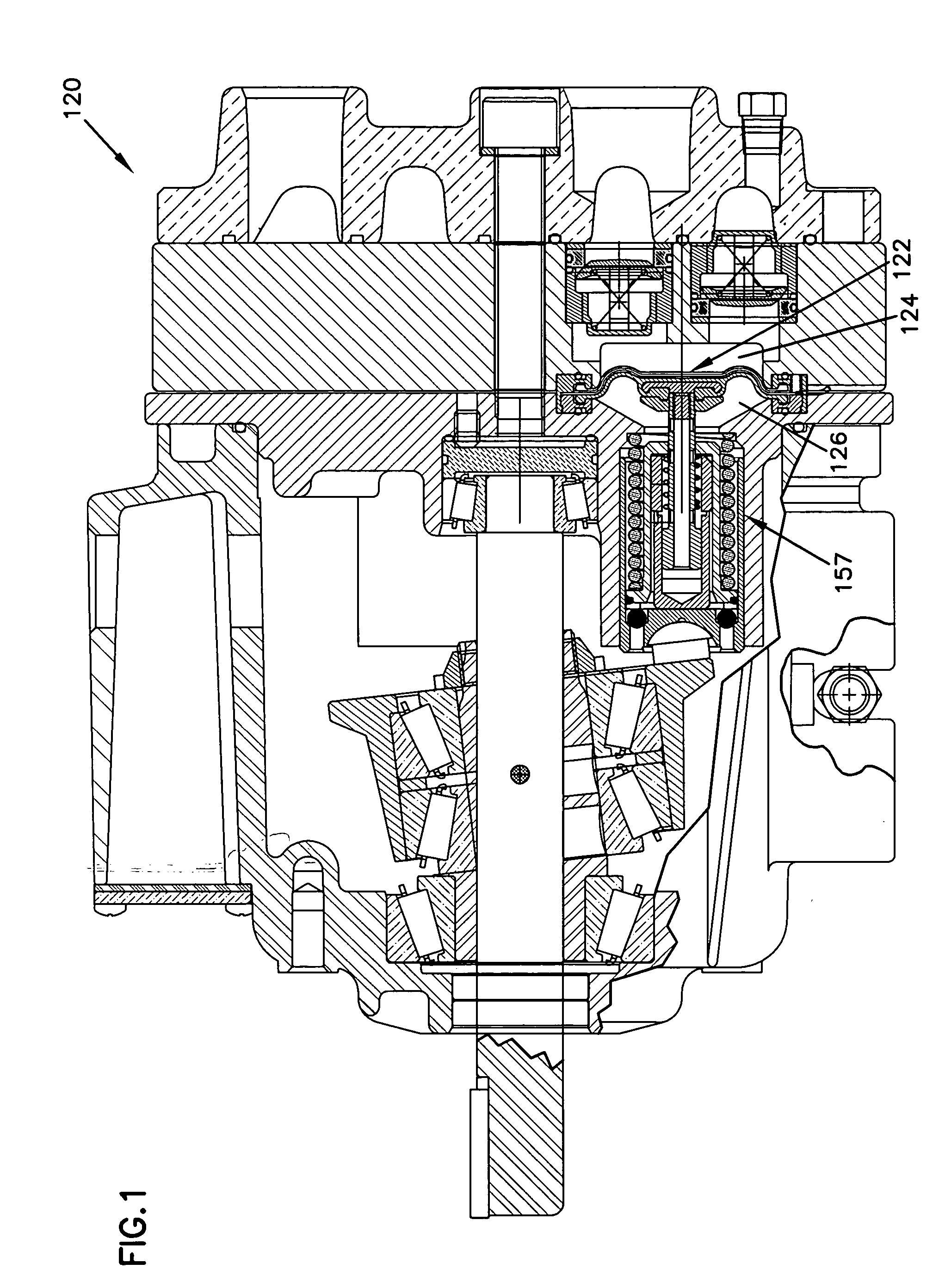

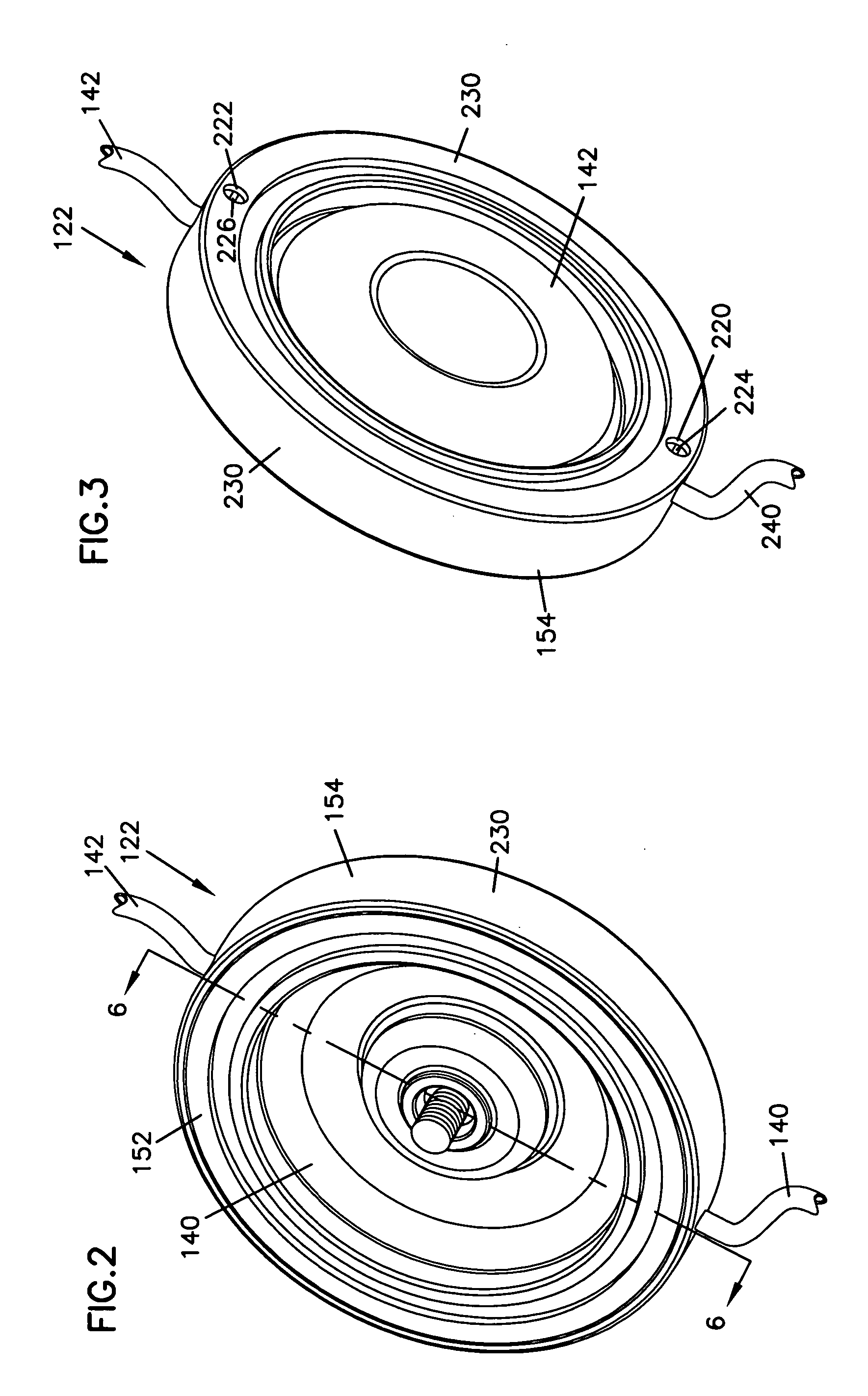

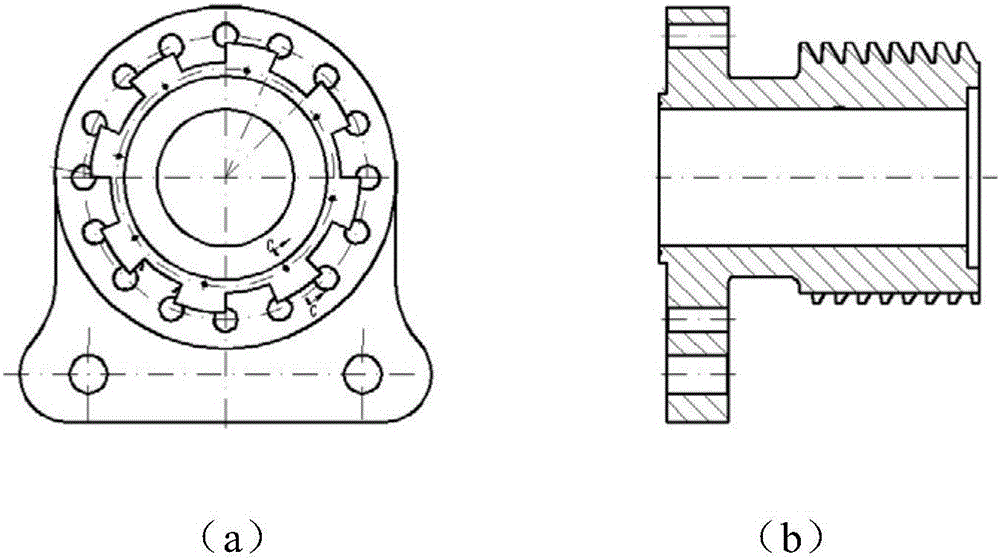

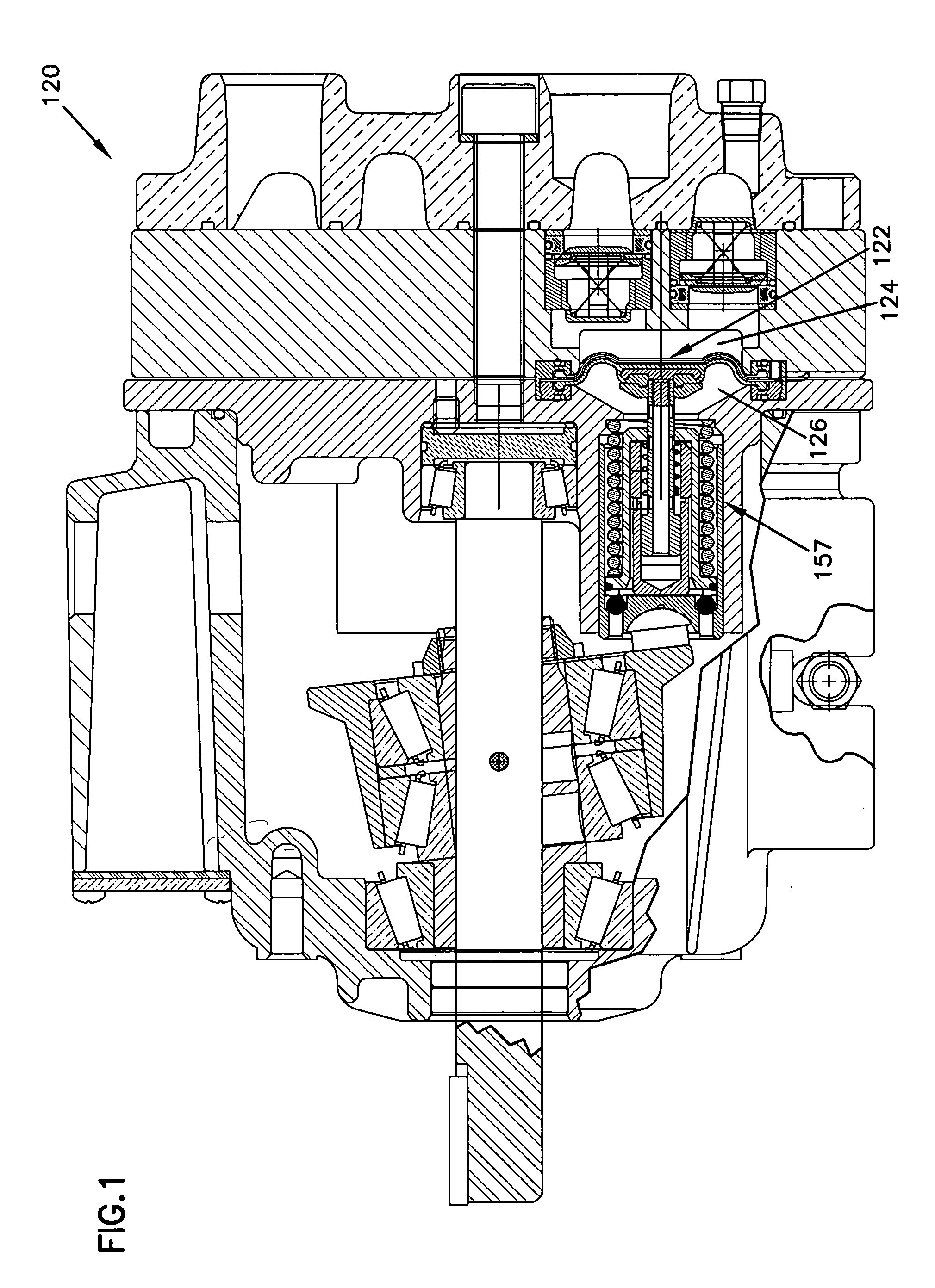

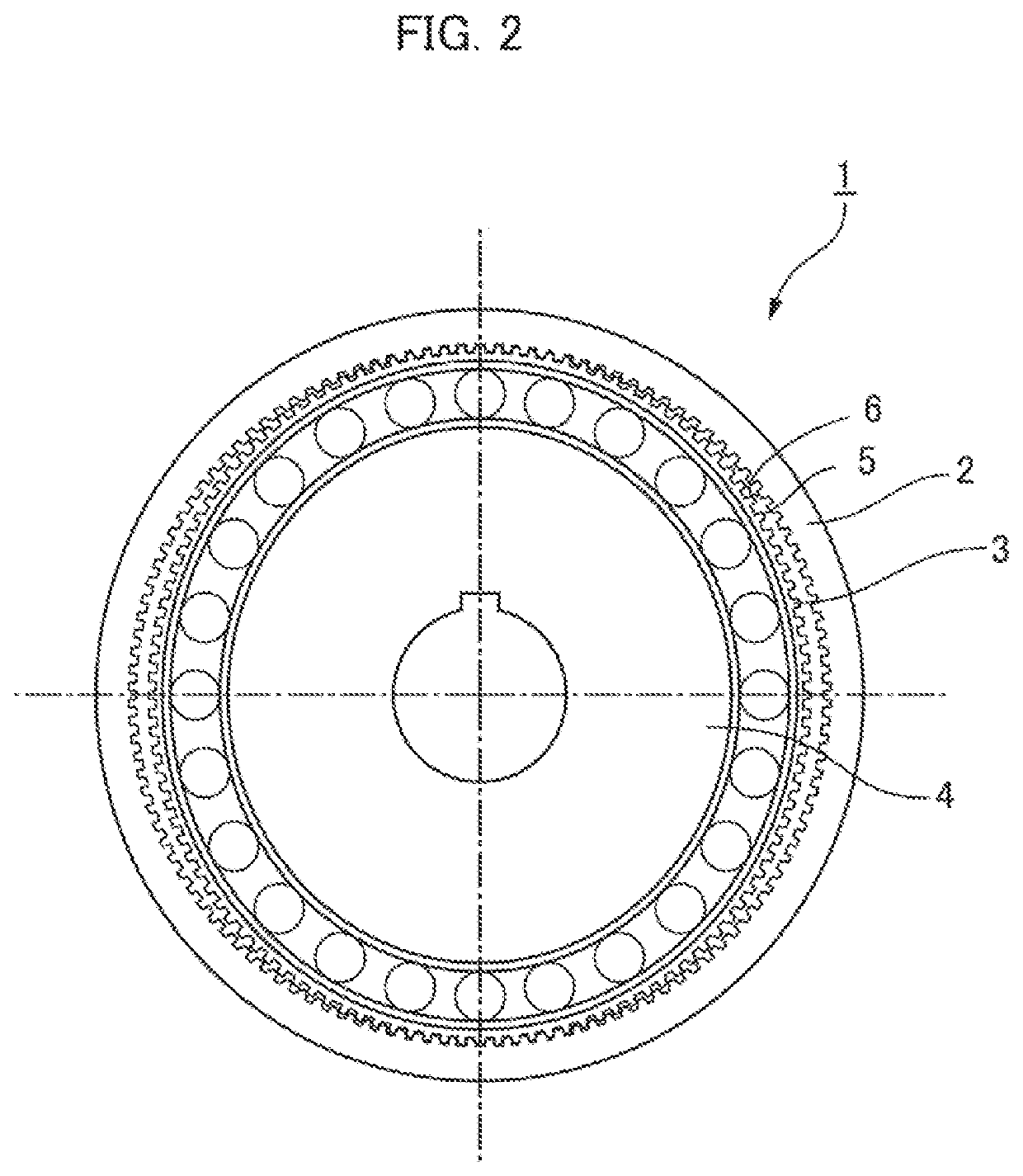

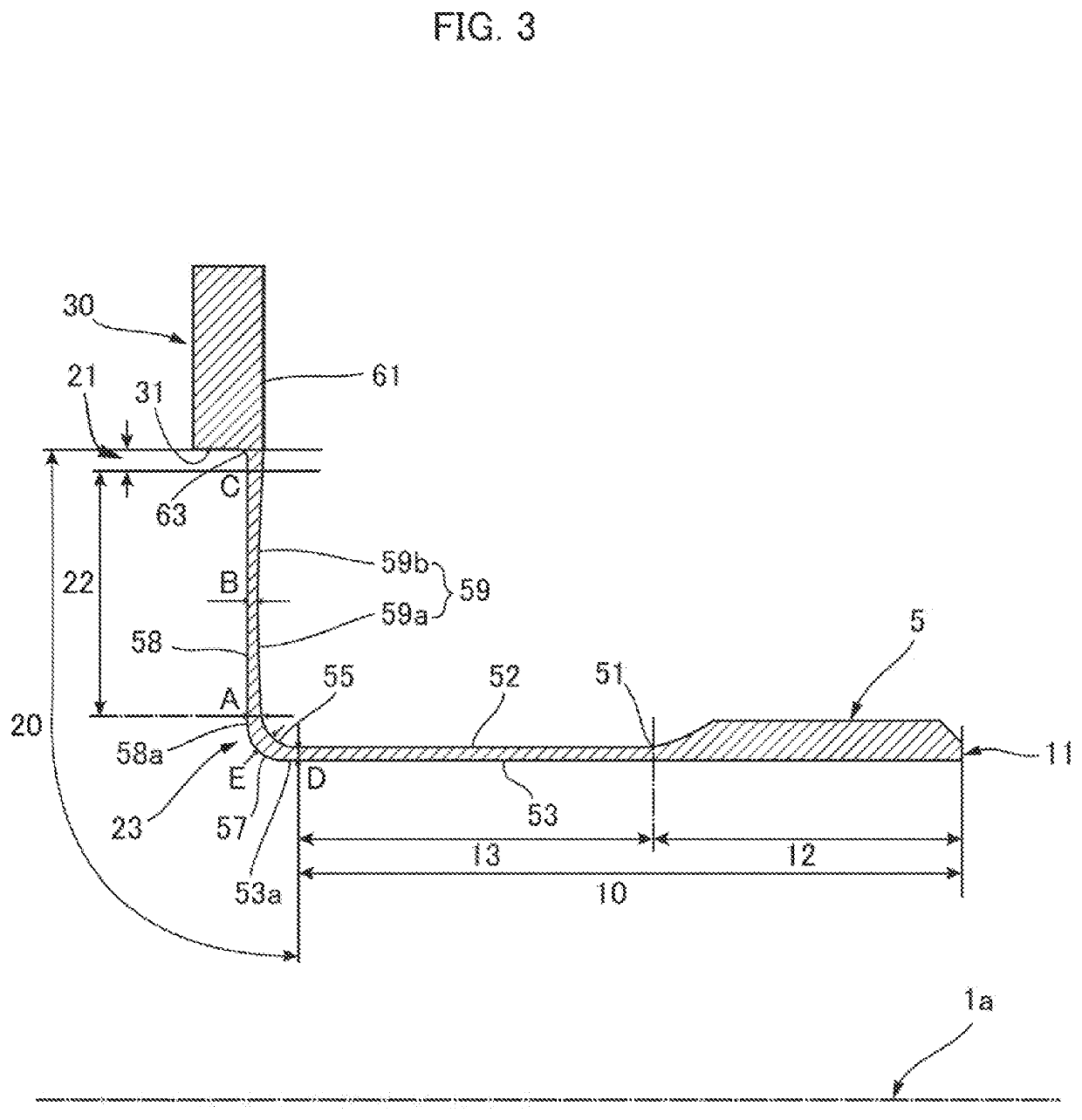

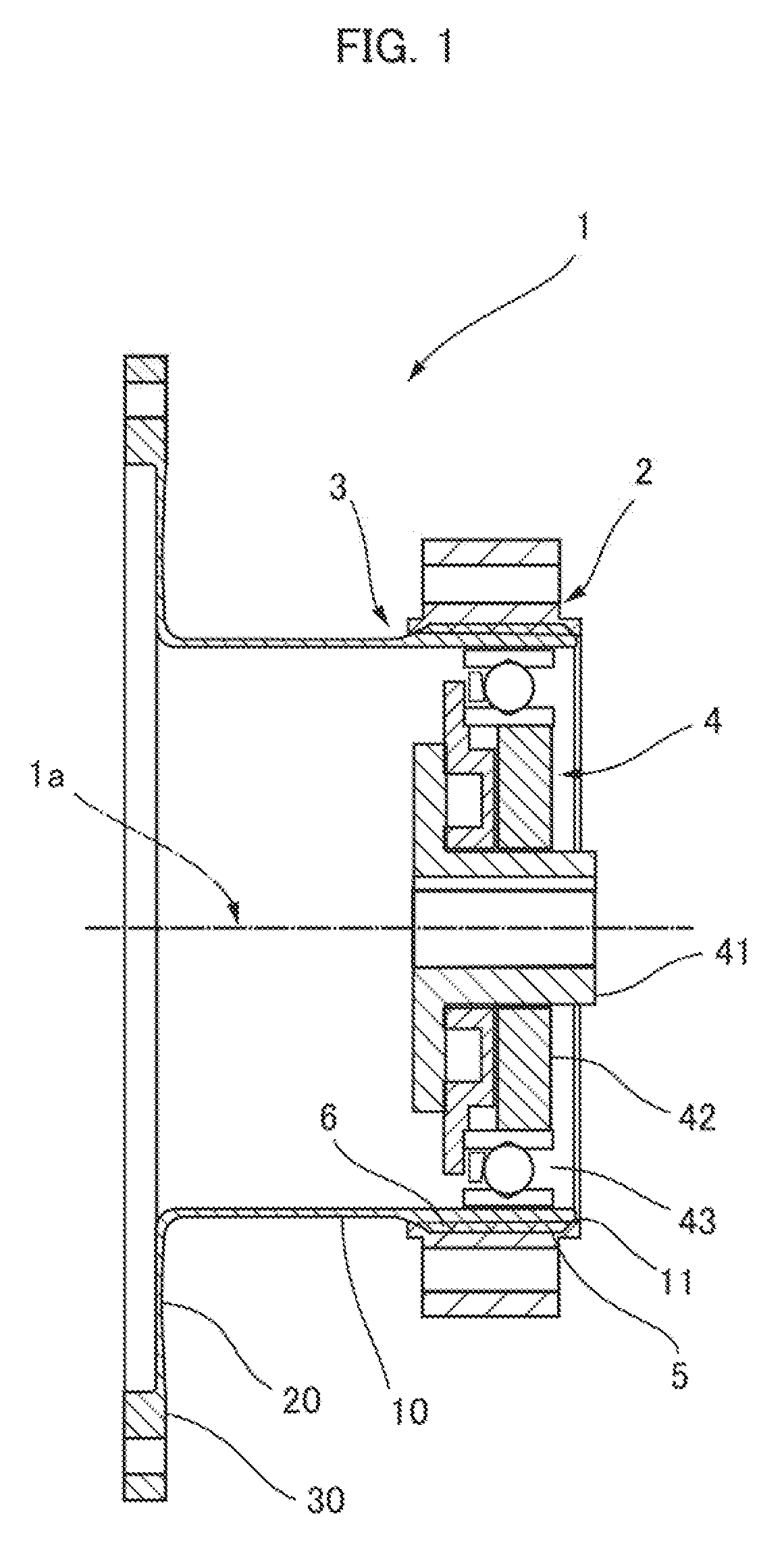

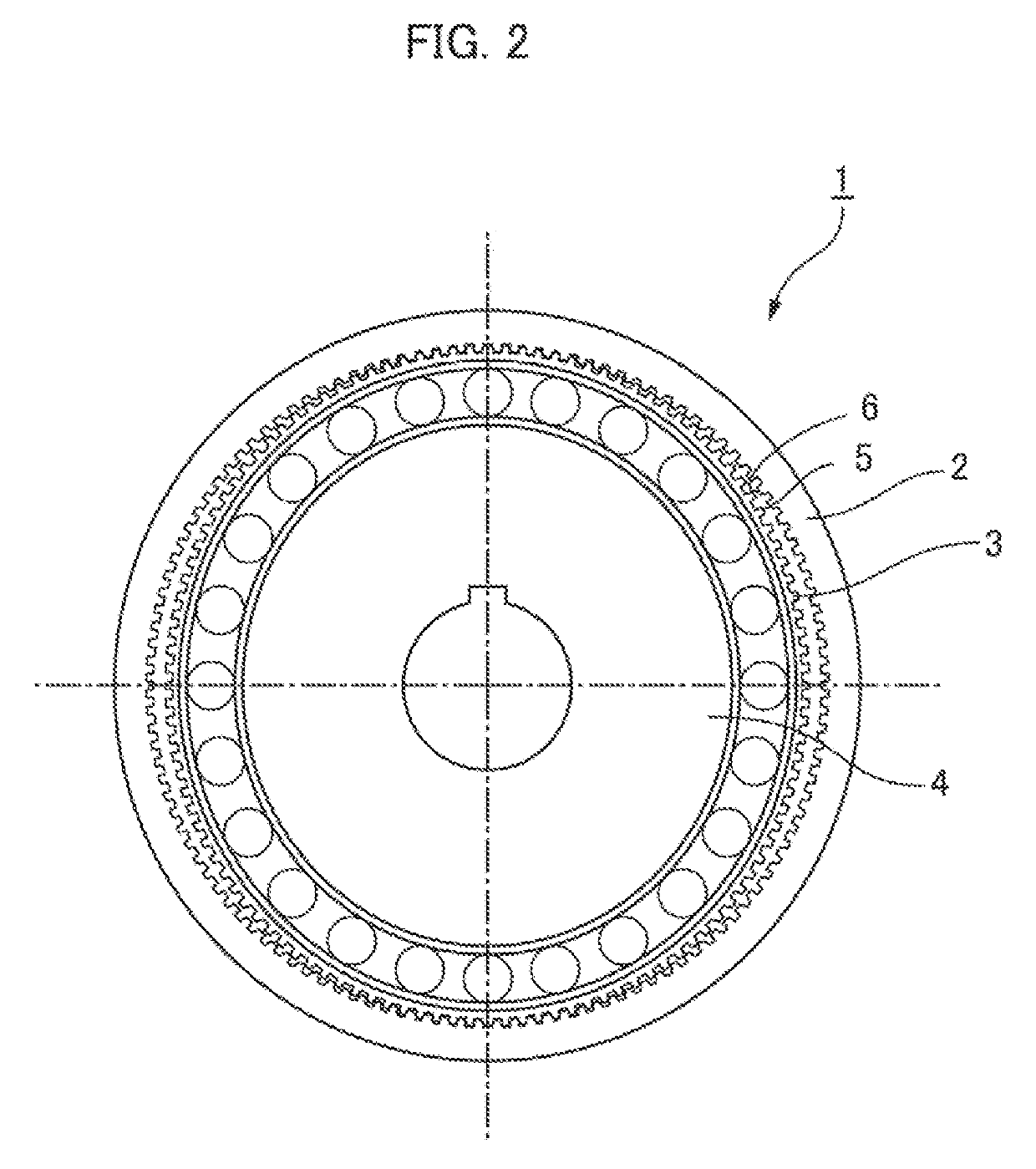

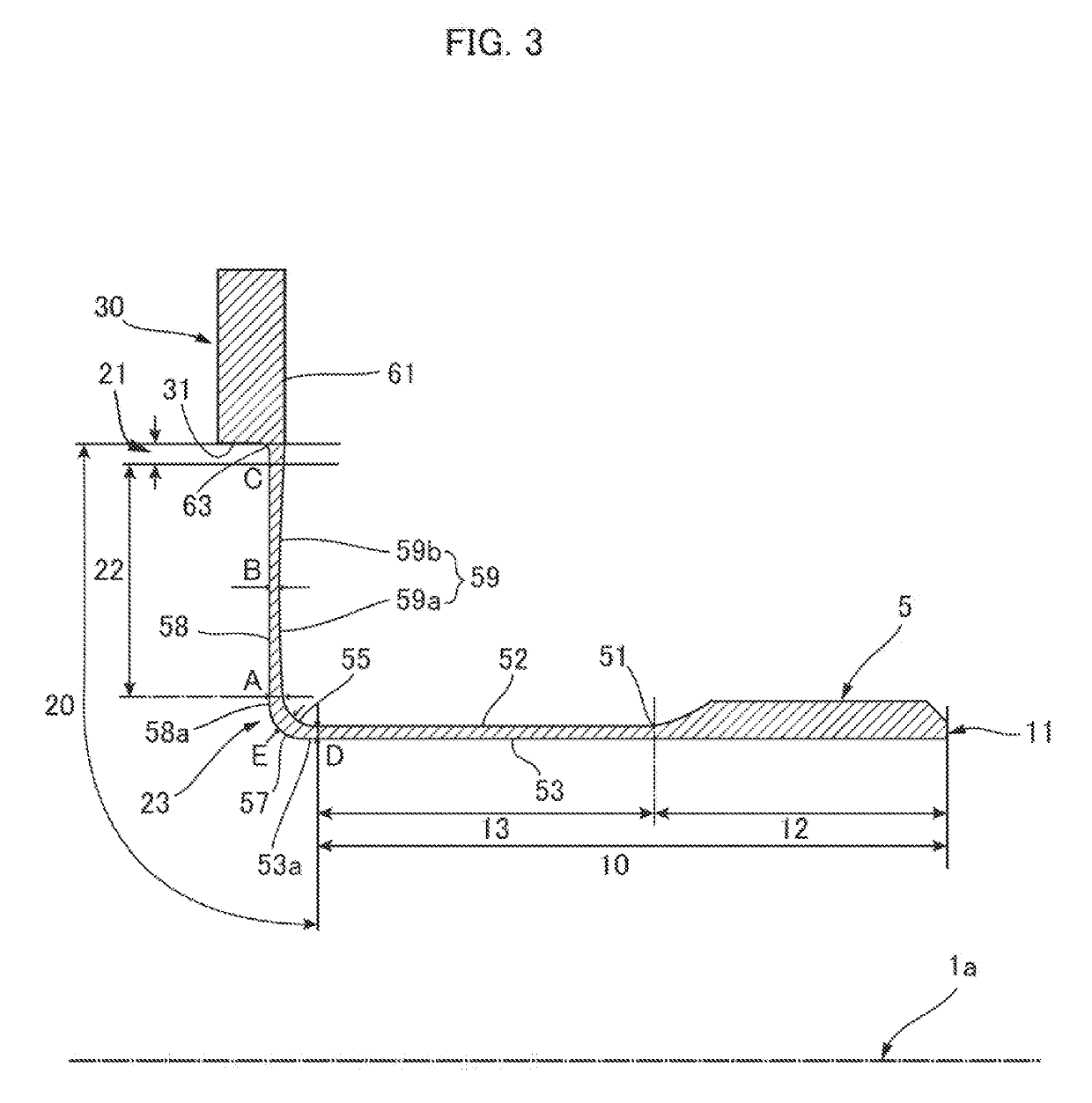

Externally toothed gear for strain wave gearing

ActiveUS10890239B2Breakage can be suppressedIncreased durabilityToothed gearingsDiaphragm ruptureGear wheel

In a silk hat-shaped external gear for a strain wave gearing, t(A)>t(C)>t(D)>t(B) is satisfied, where the thicknesses of the inner circumferential end (A), the middle part (B) and the outer circumferential end (C) of the diaphragm body portion of a diaphragm are t(A), t(B) and t(C), and where the thickness of the barrel-side end part (D) of the curved portion of the diaphragm is t(D). With reference to the thickness of the middle part (B), the thickness of the inner circumferential end (A) of the diaphragm is set so as to be thicker than conventional silk hat-shaped external gears. It is possible to realize an externally toothed gear capable of preventing diaphragm rupture due to thrust force at high load torque and having high fatigue strength.

Owner:HARMONIC DRIVE SYST IND CO LTD

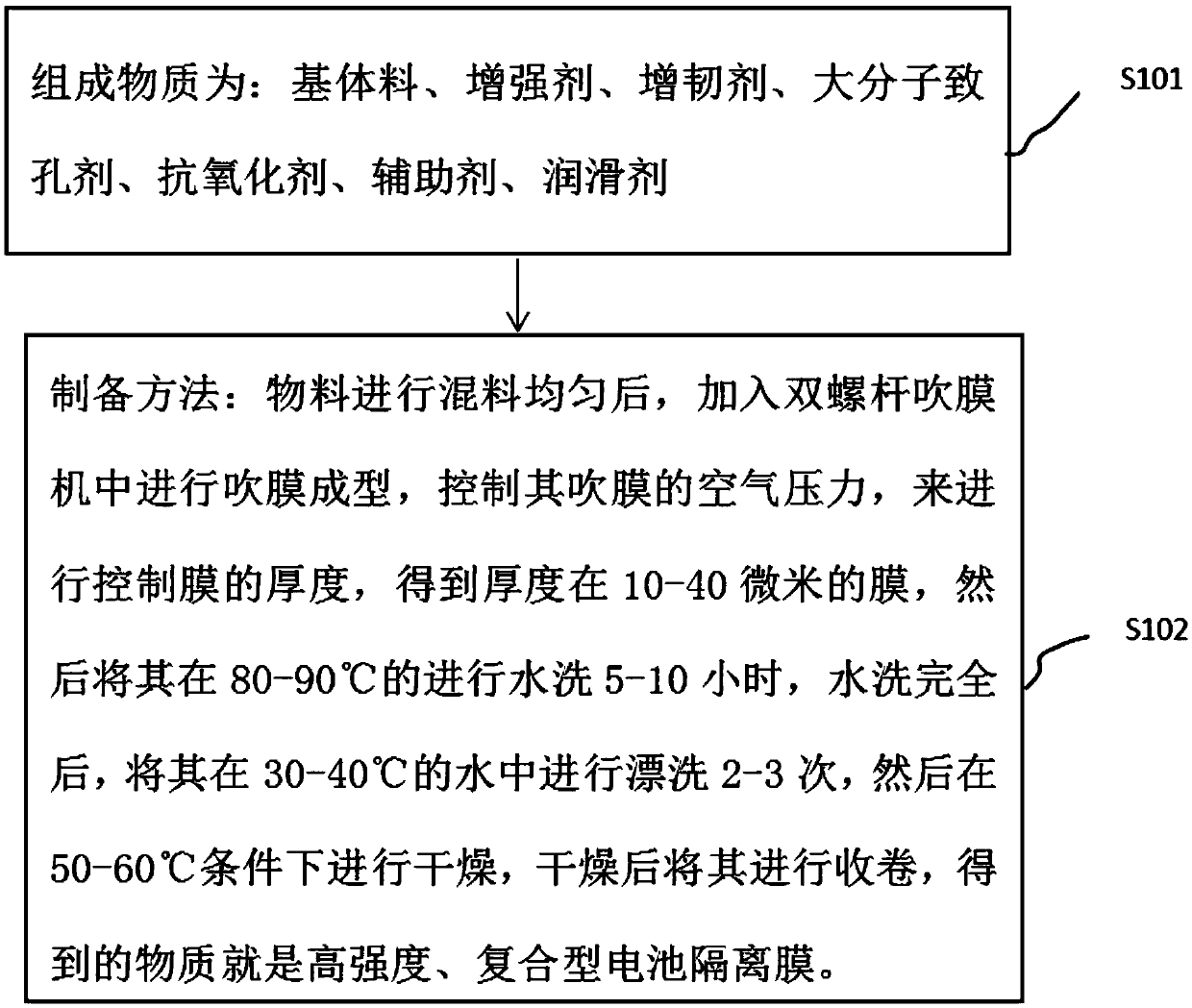

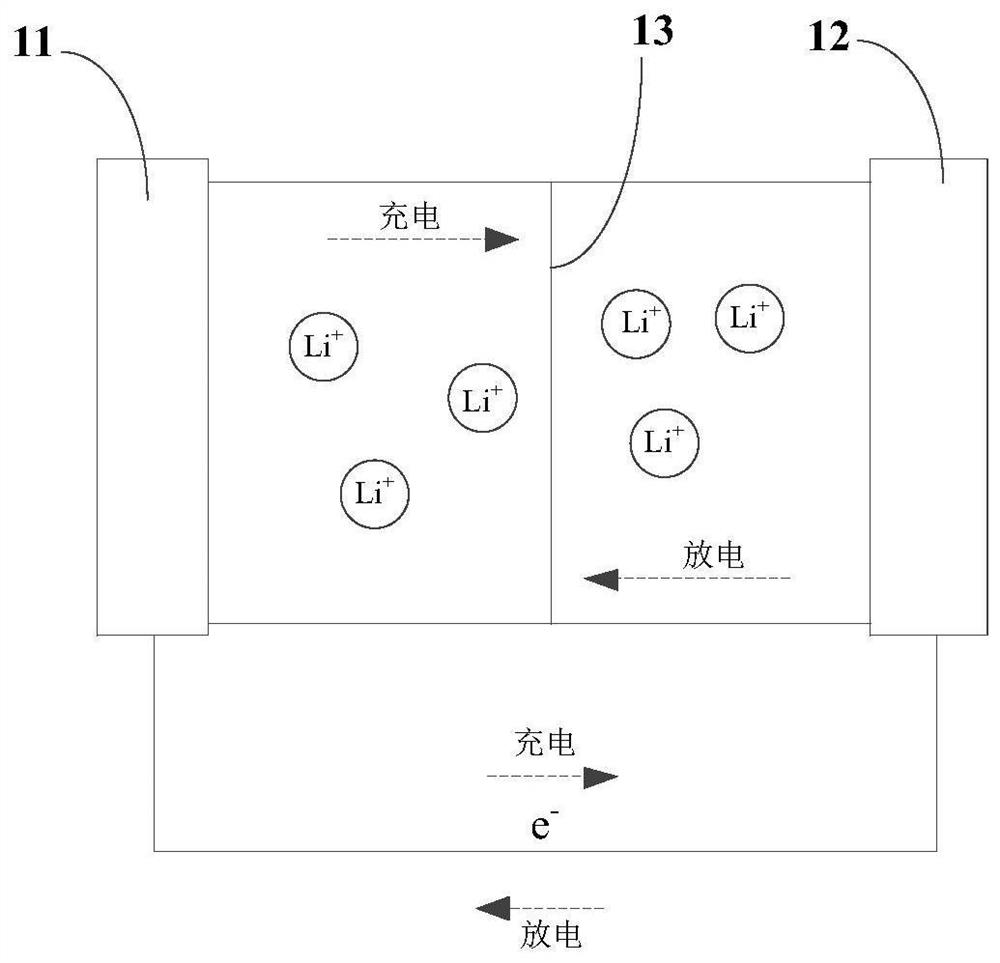

High-strength composite lithium battery diaphragm and preparation method thereof

The invention relates to the technical field of lithium battery diaphragms and in particular to a high-strength composite lithium battery diaphragm and a preparation method thereof. The high-strengthcomposite lithium battery diaphragm comprises components: by weight, 100 to 120 parts of base material, 20 to 30 parts of reinforcing agent, 5 to 10 parts of toughening agent, 10 to 20 parts of macromolecular pore-foaming agent, 2 to 5 parts of antioxidant, 10 to 15 parts of adjuvant, and 2 to 5 parts of lubricant. the lithium battery diaphragm of the invention is prepared by a film-blowing forming and macromolecular pore formation method, and has good high temperature resistance and a relatively high obturator temperature and diaphragm rupture temperature difference. When the working temperature rises during the use of the battery, the migration channel of electrolyte ions can be quickly closed to stop the passage of ions and thus ensure the safety of the battery.

Owner:JILIN UNIV

Diaphragm, preparation method thereof, secondary battery and electric equipment

The invention provides a diaphragm, a preparation method thereof, a secondary battery and electric equipment. The diaphragm comprises a base film, at least one inorganic coating and at least one organic coating, the base film, the inorganic coating and the organic coating are laminated, at least one side surface of the base film is in contact with the inorganic coating, the organic coating contains organic heat-resistant resin, and the lower one of the melting point and the decomposition temperature of the organic heat-resistant resin is greater than or equal to 200 DEG C. The diaphragm with the structure can improve the high-temperature shrinkage performance of the diaphragm while increasing the diaphragm rupture temperature of the diaphragm.

Owner:HUAWEI TECH CO LTD

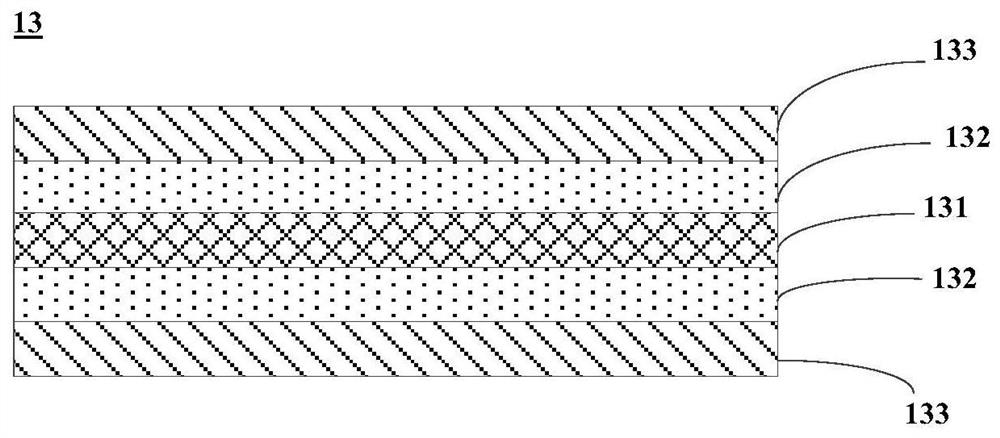

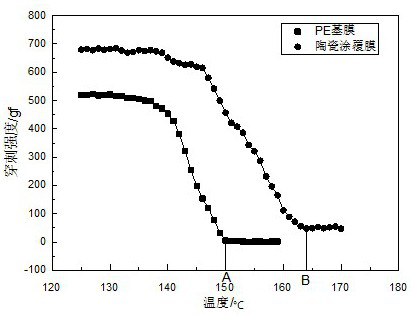

Lithium battery diaphragm hole closure-diaphragm rupture temperature detecting device and test method thereof

PendingCN109916951ASolve the problem of single heating sourceSolve a single problemMaterial heat developmentMaterial resistanceInternal resistanceMeasuring instrument

The invention discloses a lithium battery diaphragm hole closure-diaphragm rupture temperature detecting device and a test method thereof. The device comprises a cylindrical heating main plate, a cylindrical testing bottom plate, a lithium battery diaphragm, a heating controller, an electric heating rod, temperature measuring holes, a thermocouple, a resistance measurement hole, a resistance measuring sensor, a resistance measuring moving block, a heating moving block, a temperature measuring instrument, a resistance measuring instrument, a heating hole, an adjusting bolt, a spring, a circularsealing ring, rectangular heat dissipation holes and a bolt; and the cavity of the cylindrical testing bottom plate is sealed with the diaphragm. According to the use method, the heating rod is inserted into the heating hole, and temperature and internal resistance are displayed in real time on a computer; as the temperature of the heating rod increases, the temperature of the device rises, and when the temperature rises to be a certain value, the micropores of the diaphragm are gradually closed, and a resistance value rises rapidly, and it is judged that the micropores of the diaphragm are closed; and when the temperature continues to rise, the diaphragm ruptures, and the resistance value suddenly drops, and temperature at this moment is rupture temperature. The device and method of theinvention have the advantages of convenient use, real-time display, the synchronous change of internal resistance with temperature, and small error range.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

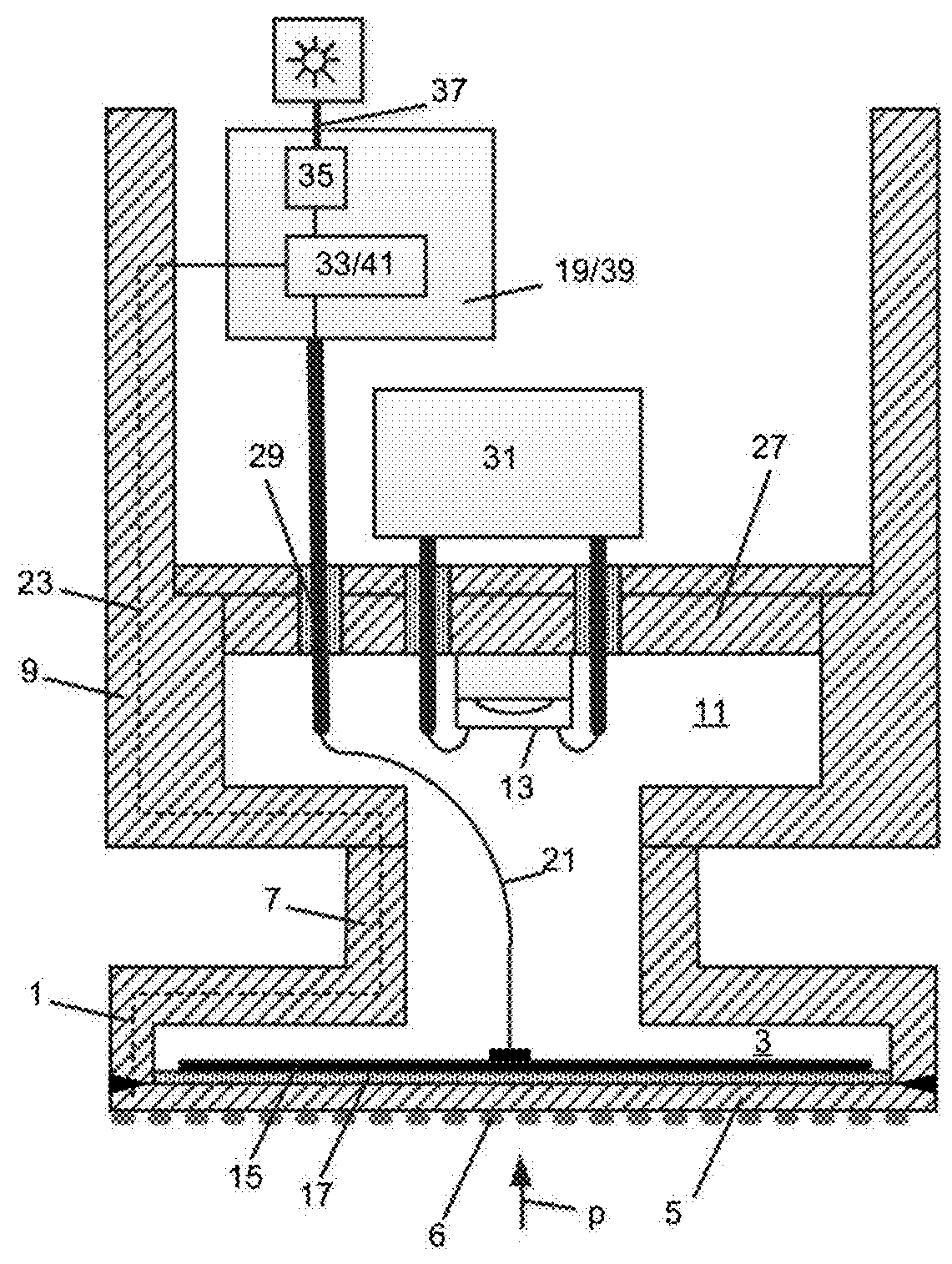

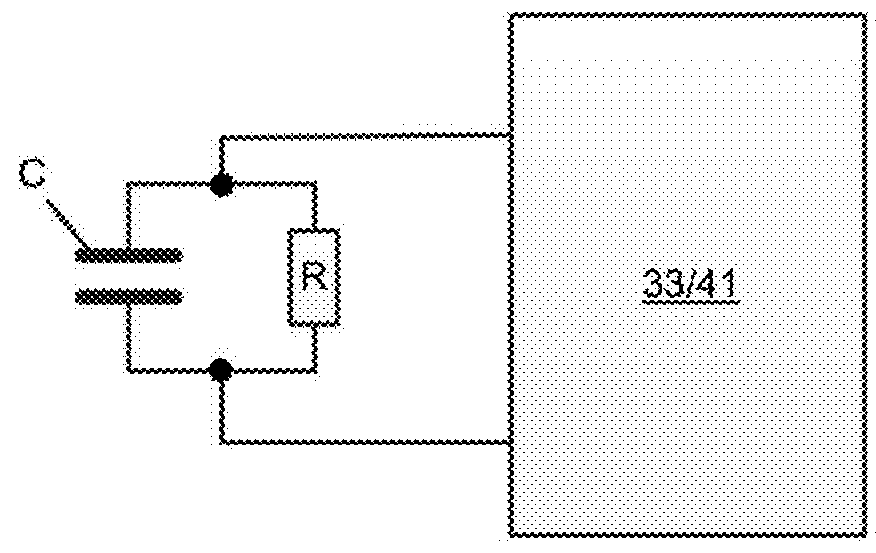

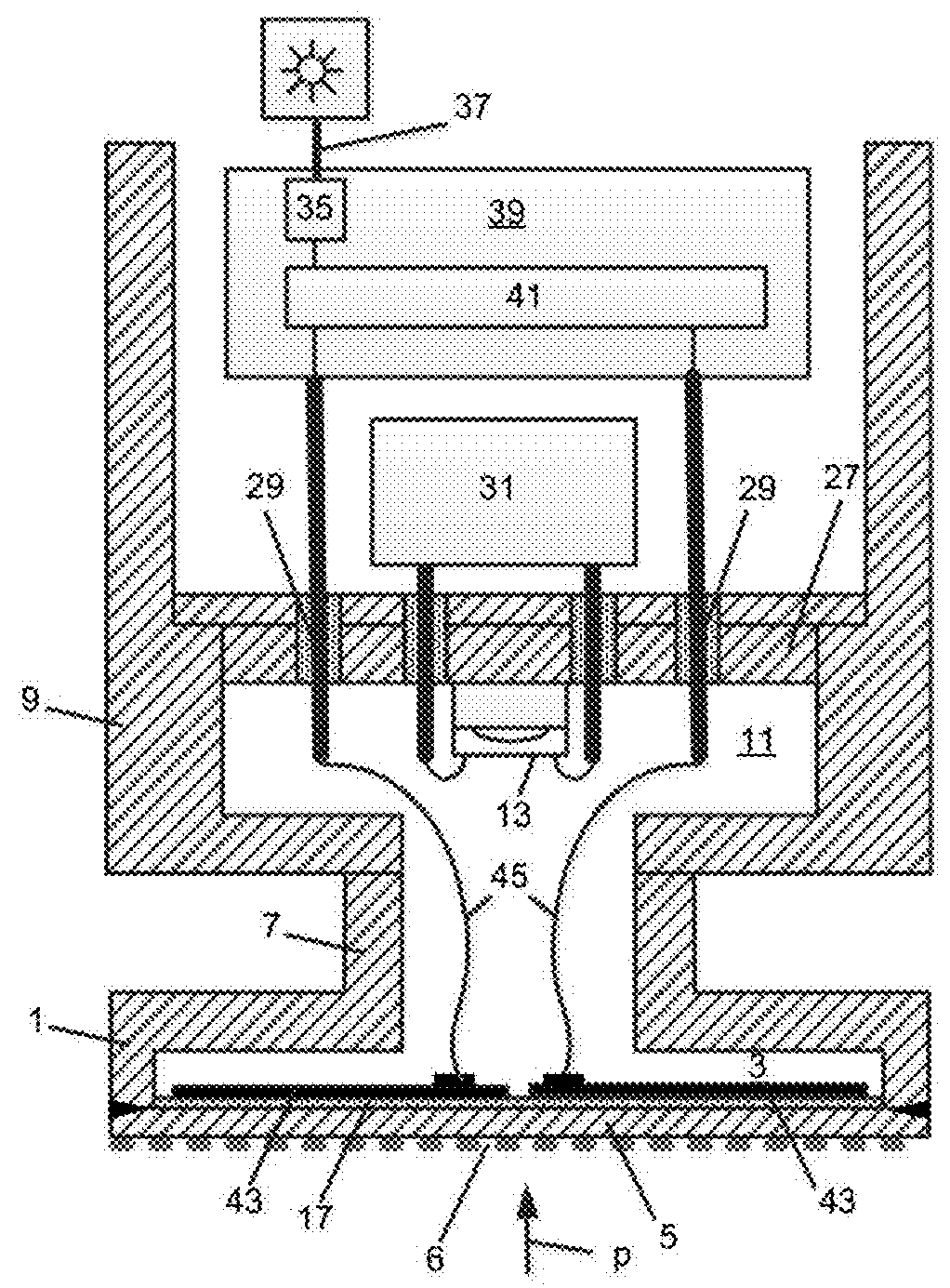

Pressure-measuring sensor

InactiveUS20180180504A1Early detectionFluid pressure measurement by electric/magnetic elementsLiquid mediumDiaphragm rupture

A pressure-measuring sensor having an electrically-conductive separating diaphragm closing off an interior chamber of the pressure-measuring sensor to the outside, to whose exterior surface a liquid medium under pressure can be applied, and having a device for detecting a diaphragm rupture of the separating diaphragm. At least one electrode is arranged on an interior surface of the separating diaphragm which faces the interior chamber, said electrode being electrically insulated from the separating diaphragm by an insulating layer arranged between the electrodes and the separating diaphragm and mechanically connected to the separating diaphragm, a measuring circuit is connected to a capacitor formed by the separating diaphragm and the electrode, said measuring circuit measuring and monitoring a measured variable dependent upon an electrical property of the capacitor, which is changed by a medium penetrating into the area of the capacitor when a diaphragm rupture of the separating diaphragm occurs.

Owner:EHNDRESS KHAUZER GMBKH KO KG

Externally toothed gear for strain wave gearing

ActiveUS20190277383A1Breakage can be suppressedIncreased durabilityToothed gearingsGear wheelDiaphragm rupture

In a silk hat-shaped external gear for a strain wave gearing, t(A)>t(C)>t(D)>t(B) is satisfied, where the thicknesses of the inner circumferential end (A), the middle part (B) and the outer circumferential end (C) of the diaphragm body portion of a diaphragm are t(A), t(B) and t(C), and where the thickness of the barrel-side end part (D) of the curved portion of the diaphragm is t(D). With reference to the thickness of the middle part (B), the thickness of the inner circumferential end (A) of the diaphragm is set so as to be thicker than conventional silk hat-shaped external gears. It is possible to realize an externally toothed gear capable of preventing diaphragm rupture due to thrust force at high load torque and having high fatigue strength.

Owner:HARMONIC DRIVE SYST IND CO LTD

Preparation method of novel diaphragm material for lithium ion battery

ActiveCN105355817AIncrease temperatureImproved resistance to electrolyte solubilityCell seperators/membranes/diaphragms/spacersSecondary cellsPolyesterPolyolefin

The invention provides a preparation method of a novel diaphragm material for a lithium ion battery, comprising the following steps: step 1: blending nylon, polyester and polyolefin to obtain a mixture, putting the mixture into an extruder having an extruding temperature of 260-320 DEG C, cooling the extruded mixture with a cooling temperature of 5-30 DEG C, after cooling, tabletting and stretching to obtain a base diaphragm, wherein the stretching pressure is 1MPa-301MPa, and the thickness of the base diaphragm is 15 mu. m-60mu. m; step 2: performing surface polarity treatment on the base diaphragm; step 3: coating the surface of the base diaphragm with an anticorrosion fluorine-containing coating layer. By adopting a nylon and polyester blended material as the base diaphragm, the pore closing temperature and diaphragm rupture temperature of the diaphragm can be effectively improved; by coating the surface of the base diaphragm with a fluorine coating material, the electrolyte dissolution resistance of the diaphragm can be effectively improved, and the safety of the diaphragm is enhanced; the novel diaphragm material is safe and can be applied by a battery cell.

Owner:浙江锂盾储能材料技术有限公司

MEMS microgenerator cell and microgenerator cell array

A microelectrical mechanical system (MEMS) microgenerator cell and array is disclosed. The MEMS microgenerator cell of the present invention is effective in the conversion of thermal energy to electrical energy. In accordance with the present invention, an explosive material is loaded into a chamber. A diaphragm seals the chamber, containing a plasma material. The explosive material is subsequently heated to its ignition temperature thereby raising the pressure in the chamber until the diaphragm ruptures. The rupture of the diaphragm results in the flow of plasma out of the chamber. Upon exiting the chamber, the plasma is forced to flow between two parallel rectangular electrodes. A magnetic field is applied in a direction orthogonal to both the plasma flow and the electrodes, thereby generating an electromagnetic field sufficient to a power source for MEMS devices.

Owner:UNIV OF SOUTH FLORIDA

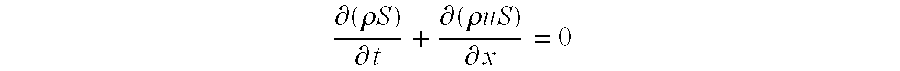

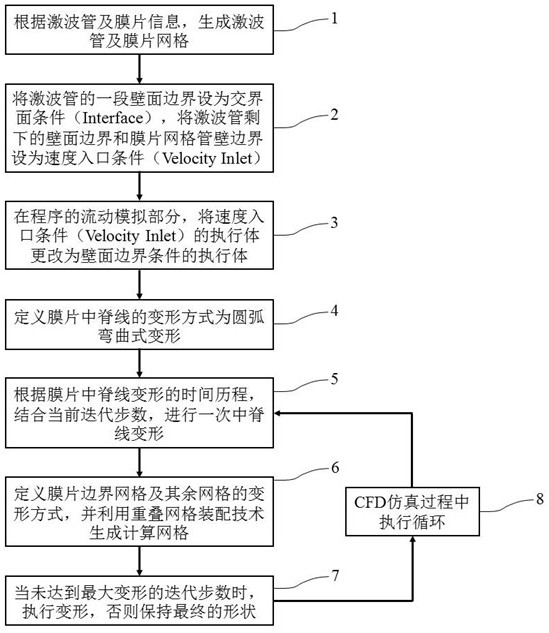

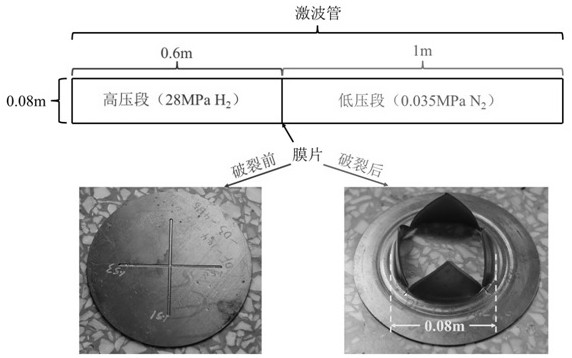

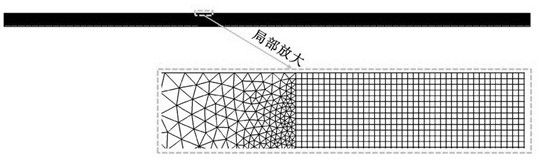

Two-dimensional simulation method for shock tube diaphragm rupture process based on overlapped dynamic grids

ActiveCN113468832AAdjust opening timeThe simulation results are close toSustainable transportationDesign optimisation/simulationDimensional simulationPhysical reality

The invention discloses a two-dimensional simulation method for a shock tube diaphragm rupture process based on overlapped dynamic grids. According to the two-dimensional simulation method for the shock tube diaphragm rupture process based on the overlapped dynamic grids, initial grids are established for a shock tube and a diaphragm respectively, the problem of grid hole breaking under the wall surface crossing condition is solved by setting special boundary conditions, the diaphragm deformation mode is defined as arc bending type deformation, and dynamic grid simulation is carried out on the rupture process of the diaphragm, so that dynamic CFD simulation of the movement process of the diaphragm can be realized. Compared with an existing main ideal diaphragm rupture analysis method, the two-dimensional simulation method for the shock tube diaphragm rupture process based on the overlapped dynamic grids better conforms to physical reality, the obtained simulation result is more accurate and feasible, and the effect of researching the flow problem of a shock tube and a shock tunnel is obvious.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

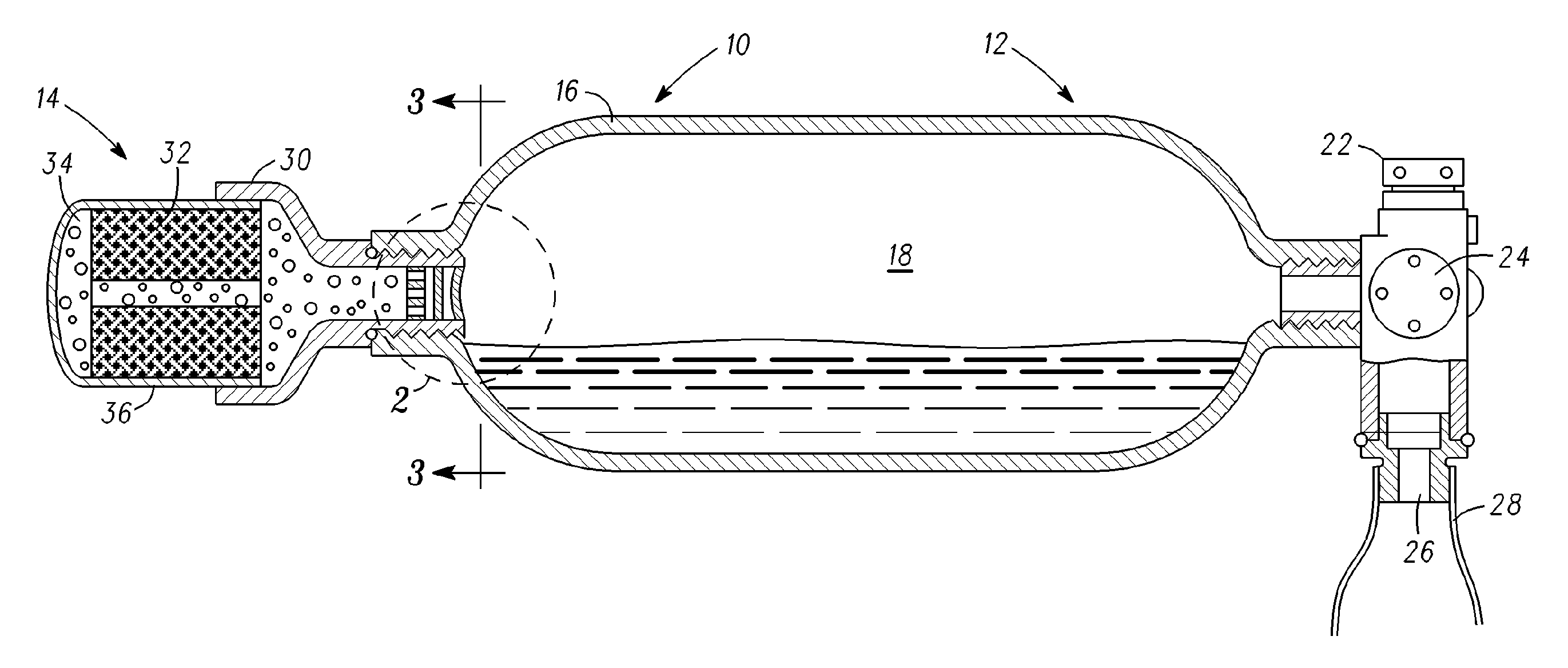

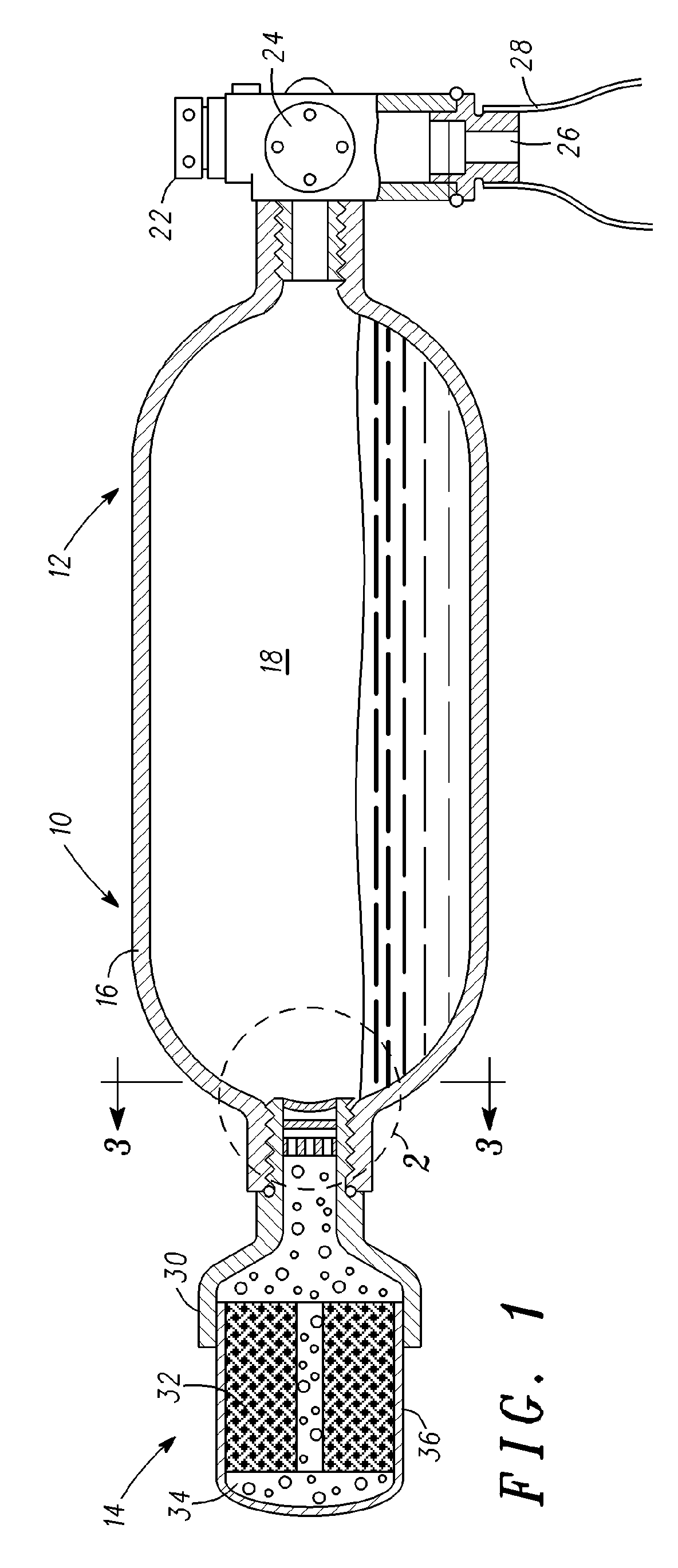

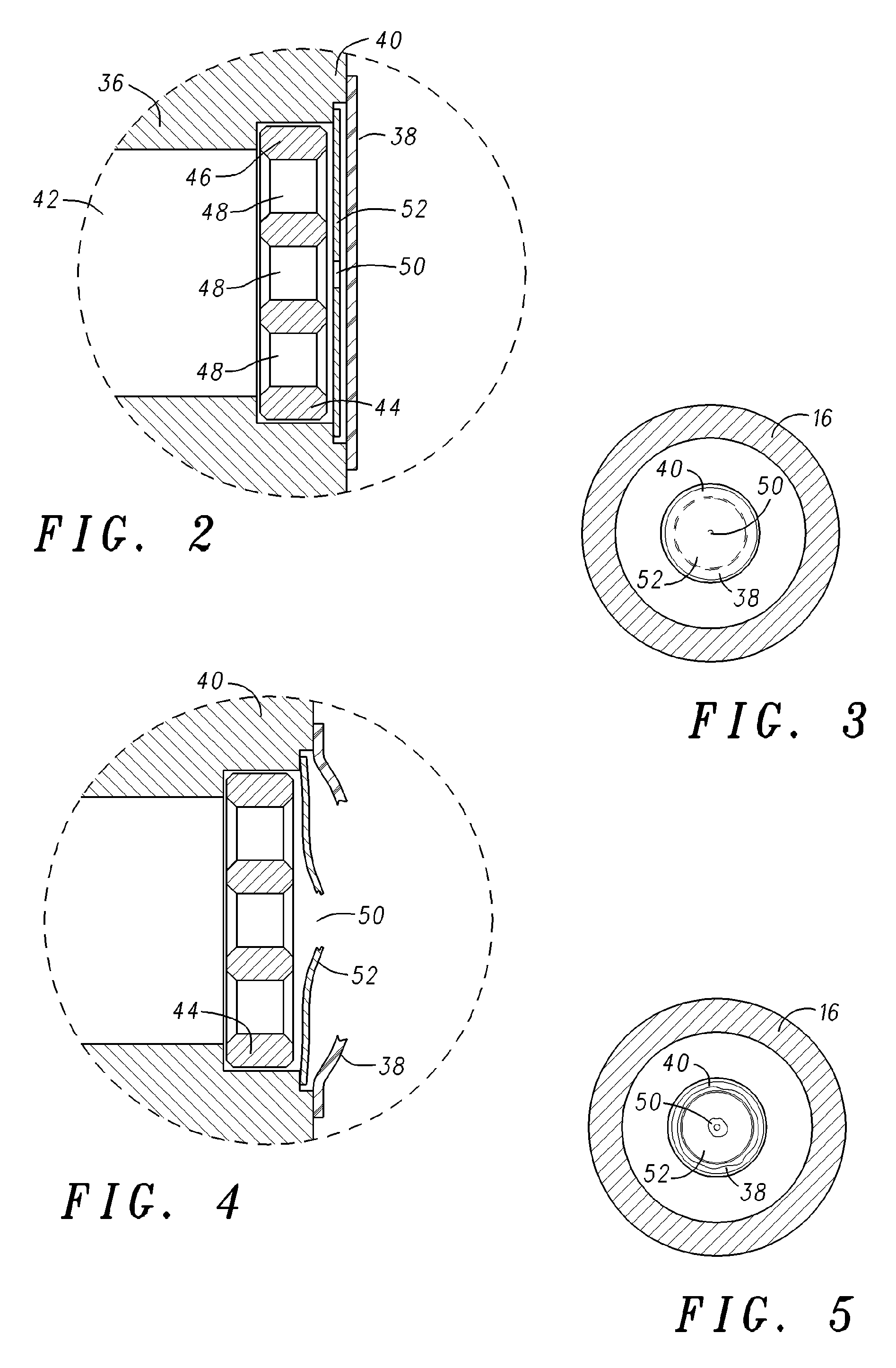

Hybrid inflator with temporary gas generator throttle

ActiveUS7721915B2Maximize heat transfer rateIncrease percentageOpening closed containersBottle/container closureDual stageDiaphragm rupture

A dual stage hybrid inflation device includes a first stage gas source including a liquefied gas stored in a first stage pressure vessel and a second stage gas source including a gas generator having a gas output directed into the first stage pressure vessel. The gas generator is isolated from the first stage pressure vessel by a frangible diaphragm that ruptures when the pressure in the gas generator exceeds the pressure in the first stage pressure vessel by a predetermined amount. The gas generator is also isolated from the first stage pressure vessel by an eroding nozzle that temporarily restricts the flow of gas from the gas generator to the first stage pressure vessel after the frangible diaphragm ruptures. The eroding nozzle initially restricts the flow of gas from the gas generator to the first stage pressure vessel to prevent a sudden pressure drop in the gas generator that would cause the pyrotechnic gas generating material to self extinguish. The nozzle then erodes away to allow an unrestricted flow of combustion products from the gas generator to the first stage pressure vessel.

Owner:THE BF GOODRICH CO

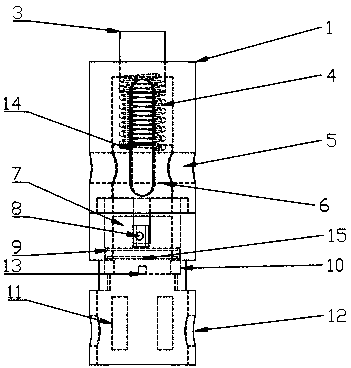

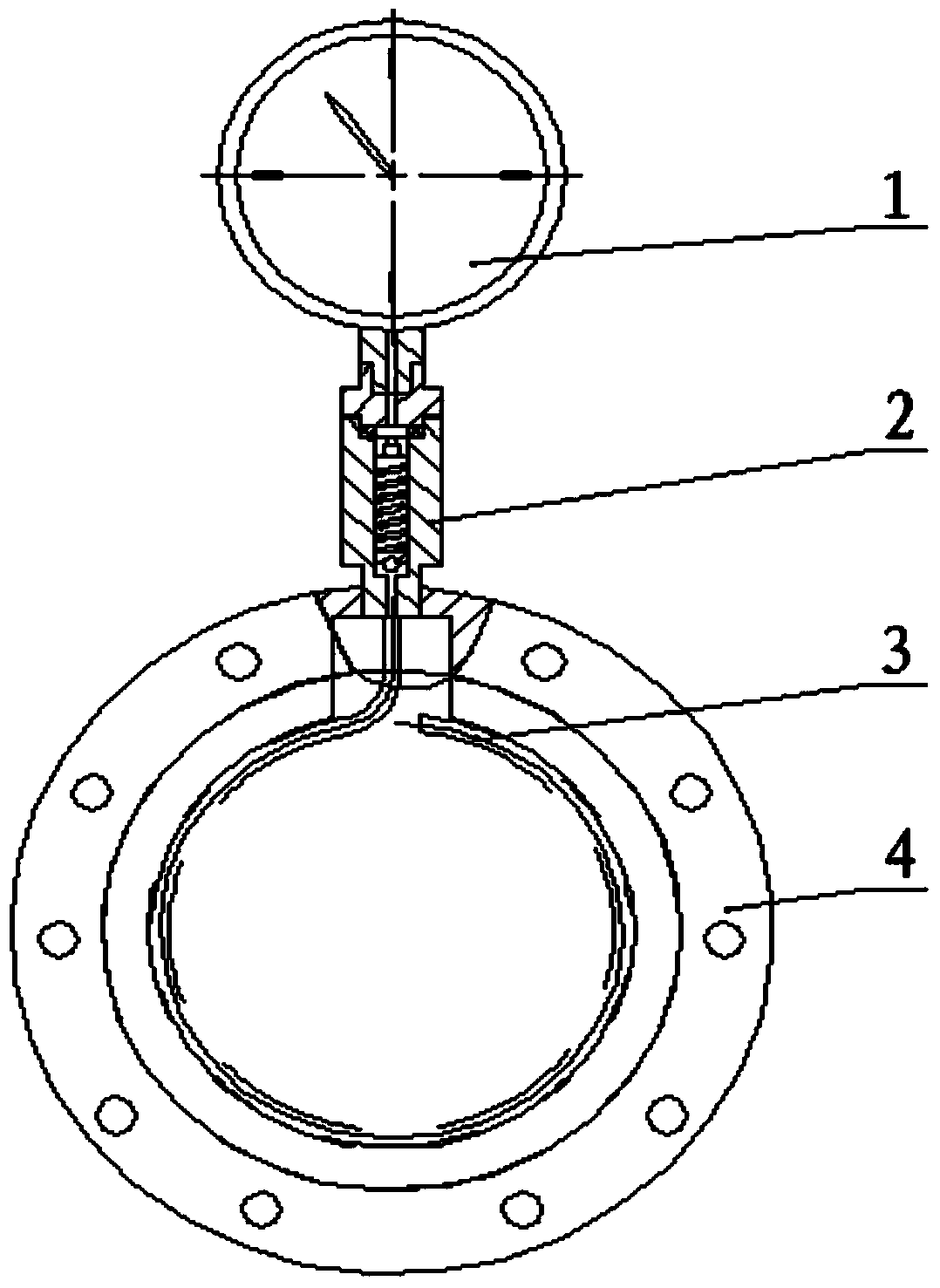

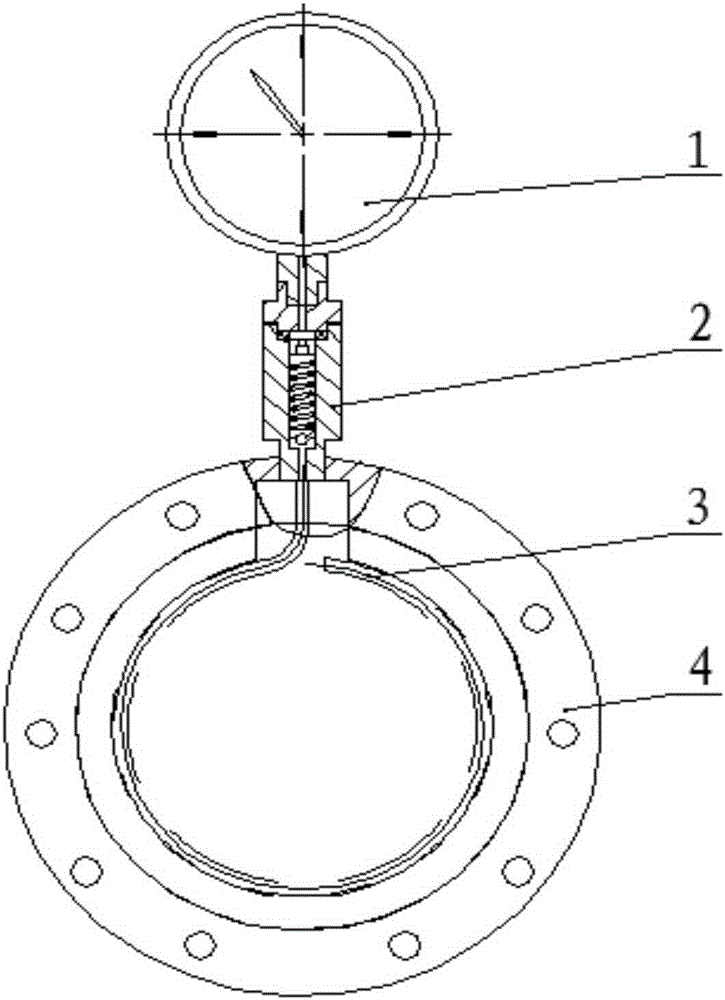

Double-diaphragm rupture warning device of metering pump

InactiveCN103899527AReduce manufacturing costReduce the difficulty of productionFlexible member pumpsPump controlDiaphragm ruptureDiaphragm seal

The invention discloses a double-diaphragm rupture warning device of a metering pump. The double-diaphragm rupture warning device comprises a double-diaphragm sealing ring. The double-diaphragm sealing ring is fixed to a position between a pump head and a pump cylinder of the metering pump by the aid of bolts, mounting fixing positions for a pump-head-side diaphragm and a pump-cylinder-side diaphragm of the metering pump are arranged on the double-diaphragm sealing ring, the top of the double-diaphragm sealing ring is used as a pressure output channel and is connected with an adjustable pressure filter valve, an annular pressure sampling pipe clings to the inner side of the double-diaphragm sealing ring, crossed pressure sampling holes are uniformly formed in a pipe body of the annular pressure sampling pipe, the top of the annular pressure sampling pipe is connected onto the pressure output channel of the double-diaphragm sealing ring, the annular pressure sampling pipe is connected with the adjustable pressure filter valve, and various warning monitoring elements are connected to the top of the adjustable pressure filter valve. The double-diaphragm rupture warning device has the advantages that the problem that media or hydraulic oil are contaminated by fillers of an existing double-diaphragm rupture warning device with the fillers after diaphragms rupture can be solved; problems that mistaken warning signals are easily transmitted by an existing vacuumized double-diaphragm rupture warning device and staffs are misled by the mistaken warning signals can be solved.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION +1

Diaphragm rupture monitoring

The present invention concerns a diaphragm unit for a diaphragm pump comprising a diaphragm core having a receiving means for a thrust rod of a pump drive, and a multi-layer pump diaphragm connected to the diaphragm core, wherein the pump diaphragm has a fluid-impermeable working diaphragm layer which in operation of the diaphragm pump comes into contact with a fluid to be delivered by the diaphragm pump, and a fluid-impermeable safety diaphragm layer, a sealed volume for receiving a fluid passing through the working diaphragm layer, that is arranged between the working diaphragm layer and thesafety diaphragm layer, and a first clamping region with which the pump diaphragm can be received in a receiving means of the diaphragm pump, wherein the first clamping region forms a ring which annularly surrounds the diaphragm core. To provide a diaphragm unit for a diaphragm pump which in a simple fashion permits detection of a rupture of the working diaphragm layer, according to the inventionit is proposed that provided within the ring formed by the first clamping region is at least one element of a sensor for detecting a fluid which penetrates into the sealed volume of the pump diaphragm.

Owner:PROMINENT

Lithium battery diaphragm rupture temperature measurement system and use method

PendingCN111766160AImprove accuracyAvoid influenceMaterial heat developmentThermometers using electric/magnetic elementsThermodynamicsDiaphragm rupture

The invention discloses a lithium battery diaphragm rupture temperature measurement system and a use method. The system comprises a heating device, a puncture device, a diaphragm, a measurement deviceand a control and data acquisition and processing device. The heating device, the puncture device, the measuring device and the control and data acquisition and processing device are connected with one another through electric signals. The relation of the diaphragm puncture strength changing along with the temperature can be measured through monitoring of the dynamic temperature, the diaphragm rupture temperature of the diaphragm can be accurately reflected through the change of the puncture strength, and the diaphragm rupture temperature measurement accuracy is improved.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

A metering pump double diaphragm rupture alarm device

InactiveCN103899527BReduce manufacturing costReduce the difficulty of productionFlexible member pumpsPump controlDiaphragm ruptureDiaphragm seal

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION +1

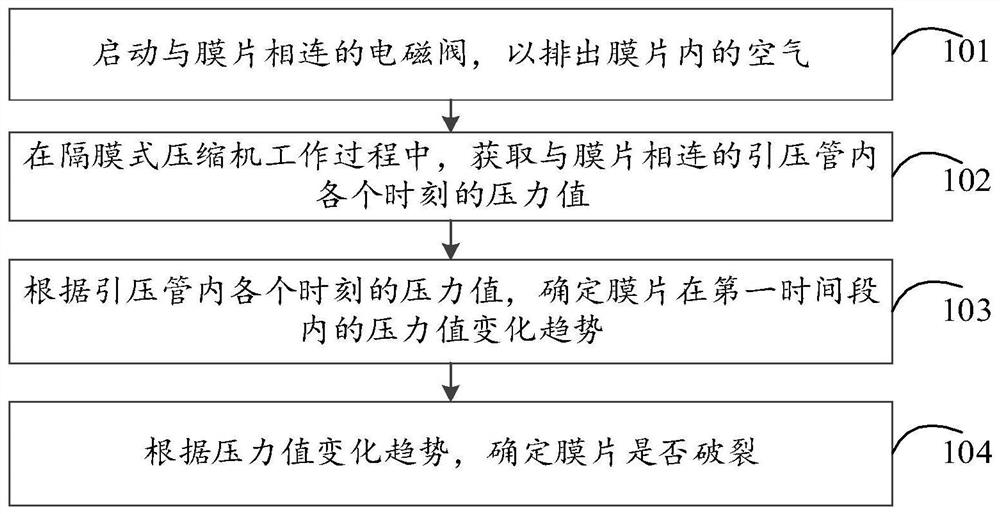

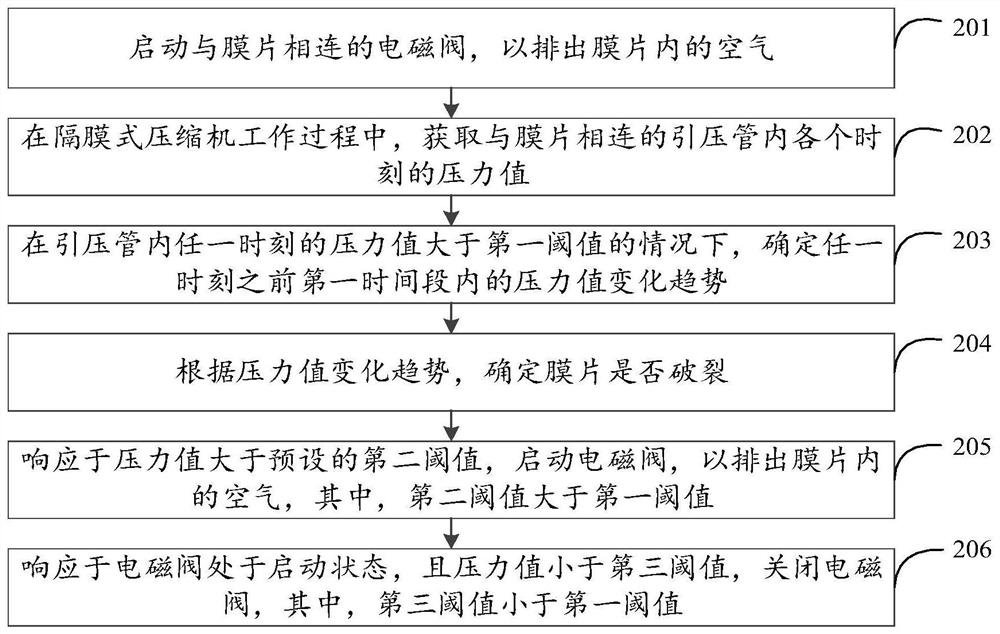

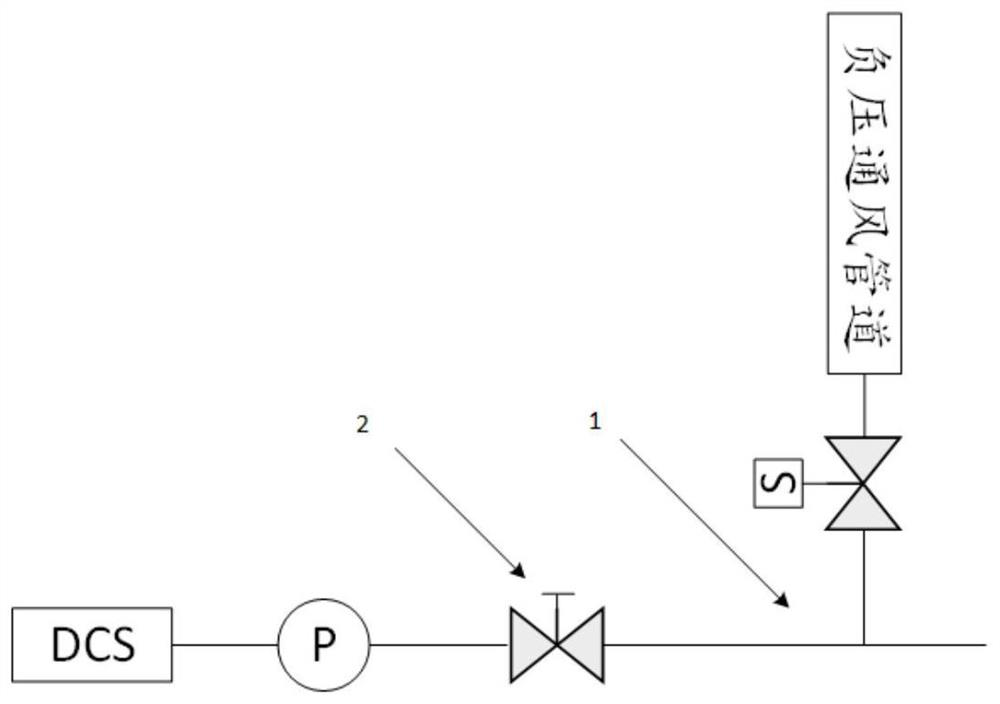

Diaphragm rupture determination method and device of diaphragm compressor and electronic equipment

ActiveCN114263596AAvoid influenceImprove accuracyPump testingFlexible member pumpsDiaphragm ruptureMechanical engineering

The invention provides a diaphragm rupture determination method and device of a diaphragm compressor, electronic equipment and a storage medium, and relates to the technical field of computers. The method comprises the following steps: starting an electromagnetic valve connected with a diaphragm to exhaust air in the diaphragm; in the working process of the diaphragm type compressor, pressure values of all moments in a pressure guide pipe connected with the diaphragm are obtained; determining a pressure value change trend of the diaphragm in a first time period according to the pressure values of all moments in the pressure guide pipe; and according to the change trend of the pressure value, whether the diaphragm is broken or not is determined. Therefore, before the diaphragm compressor works, the air in the diaphragm is discharged firstly, and then whether the diaphragm is broken or not is determined according to the change trend of the pressure value, so that the influence of the air in the diaphragm on the pressure value is avoided, and the accuracy of judging whether the diaphragm is broken or not is improved.

Owner:华能核能技术研究院有限公司 +1

Hybrid inflator with temporary gas generator throttle

ActiveUS20080251348A1Maximize heat transfer rateIncrease percentageOpening closed containersBottle/container closureDual stageDiaphragm rupture

A dual stage hybrid inflation device includes a first stage gas source comprising a liquefied gas stored in a first stage pressure vessel and a second stage gas source comprising a gas generator having a gas output directed into the first stage pressure vessel. The gas generator is isolated from the first stage pressure vessel by a frangible diaphragm that ruptures when the pressure in the gas generator exceeds the pressure in the first stage pressure vessel by a predetermined amount. The gas generator is also isolated from the first stage pressure vessel by an eroding nozzle that temporarily restricts the flow of gas from the gas generator to the first stage pressure vessel after the frangible diaphragm ruptures. The eroding nozzle initially restricts the flow of gas from the gas generator to the first stage pressure vessel to prevent a sudden pressure drop in the gas generator that would cause the pyrotechnic gas generating material to self extinguish. The nozzle then erodes away to allow an unrestricted flow of combustion products from the gas generator to the first stage pressure vessel.

Owner:THE BF GOODRICH CO

A diaphragm frame for diaphragm electrolysis

InactiveCN102268700AImprove corrosion resistanceHigh strengthPhotography auxillary processesDiaphragmsDiaphragm ruptureVinyl ester

The present invention relates to an improvement of a diaphragm holder for diaphragm electrolysis. It is characterized in that the diaphragm frame is made of epoxy methacrylic vinyl ester resin or MFE-3 vinyl ester resin by integral molding. The diaphragm frame used for diaphragm electrolysis of the present invention is formed by a continuous production process and has good corrosion resistance and bidirectional strength, so that the integrally molded FRP diaphragm frame has a long service life, good production and operation effect, and no Due to the collapse and fracture of the diaphragm frame, the liquid level difference between the cathode and anode in the electrolytic cell cannot meet the stable control of process technical conditions and the impact on product quality.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com