Diaphragm rupture monitoring

A diaphragm and diaphragm pump technology, applied in pump testing, pump control, liquid variable capacity machinery, etc., can solve problems such as incompetence, large structure space, and complex technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

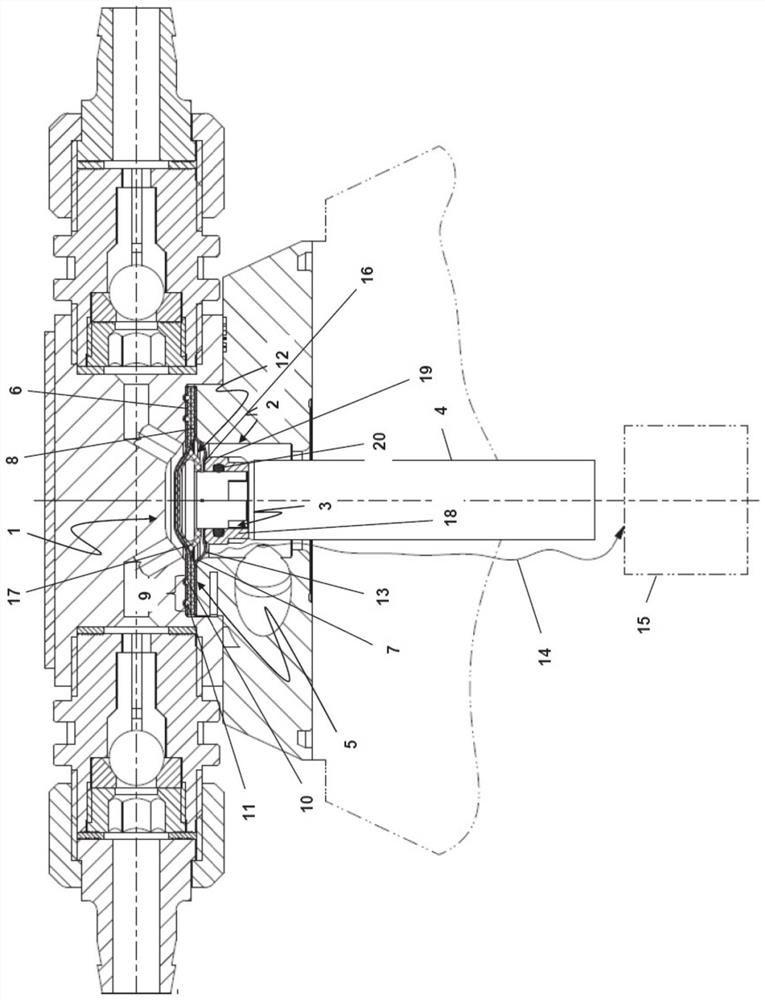

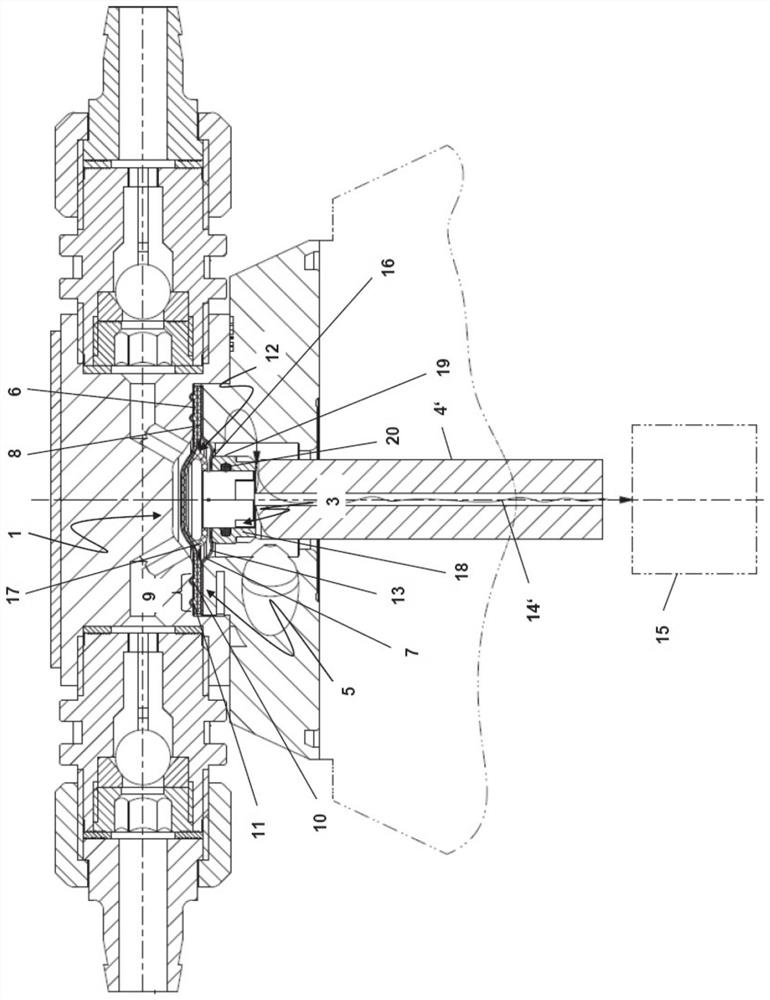

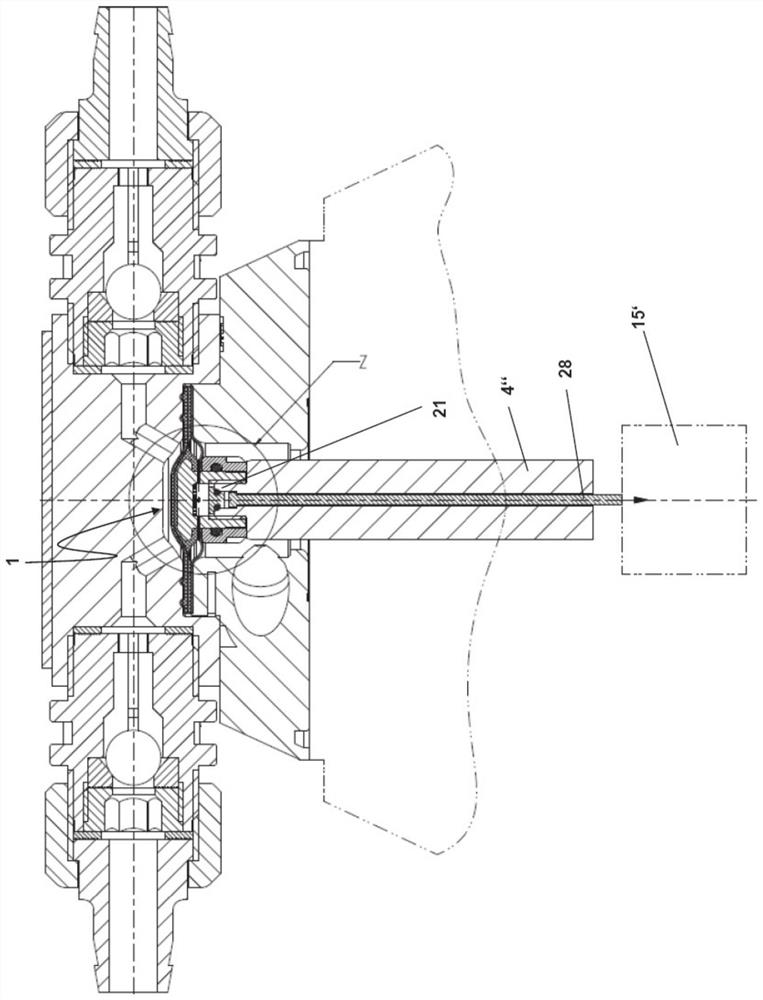

[0056] figure 1 is schematically showing the structure of the diaphragm unit 1 installed in the diaphragm pump.

[0057] The membrane unit 1 has a membrane core 2 which, in the exemplary embodiment shown, is constructed in two parts. The diaphragm core 2 has a threaded hole 3 as a receiving means for a push rod 4 . In the installed state of the diaphragm unit 1 , the diaphragm core 2 is connected to the drive of the diaphragm pump by means of a push rod 4 . According to the present application, the push rod 4 is not an integral part of the diaphragm unit, so that in the event of rupture or other failure of the diaphragm of the diaphragm unit, only the diaphragm unit 1 can be replaced without replacing the push rod 4 .

[0058] Also important for the diaphragm unit is the multilayer pump diaphragm 5 connected to the diaphragm core 2 .

[0059] exist Figure 1 to Figure 3 In the embodiment, the pump diaphragm 5 consists of three layers respectively. A fluid-tight working di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com