Shock tunnel diaphragm rupture device

A shock-wave wind tunnel and diaphragm technology, which is used in measurement devices, instruments, aerodynamic tests, etc., can solve the problems of long film rupture time, high cost, complex structure, etc., achieving simple rupture device, saving processing costs, The effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

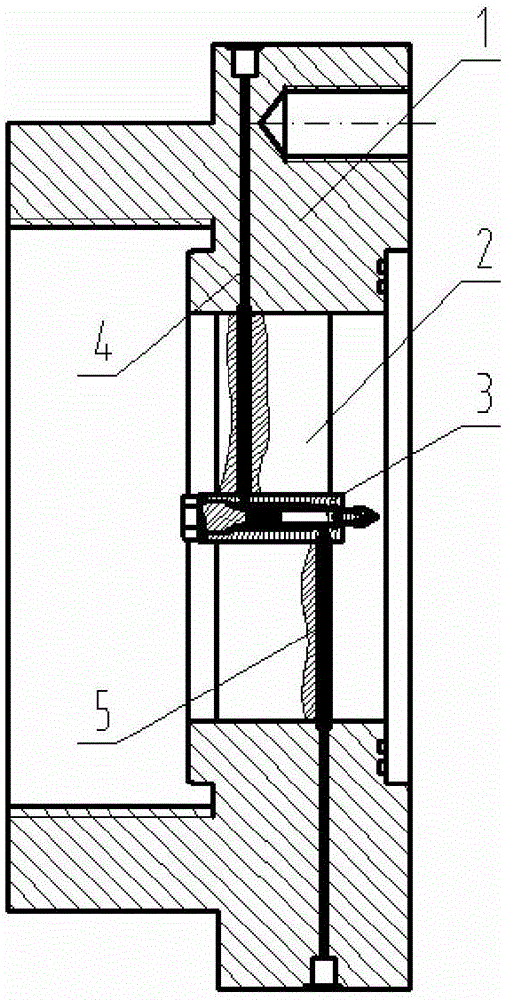

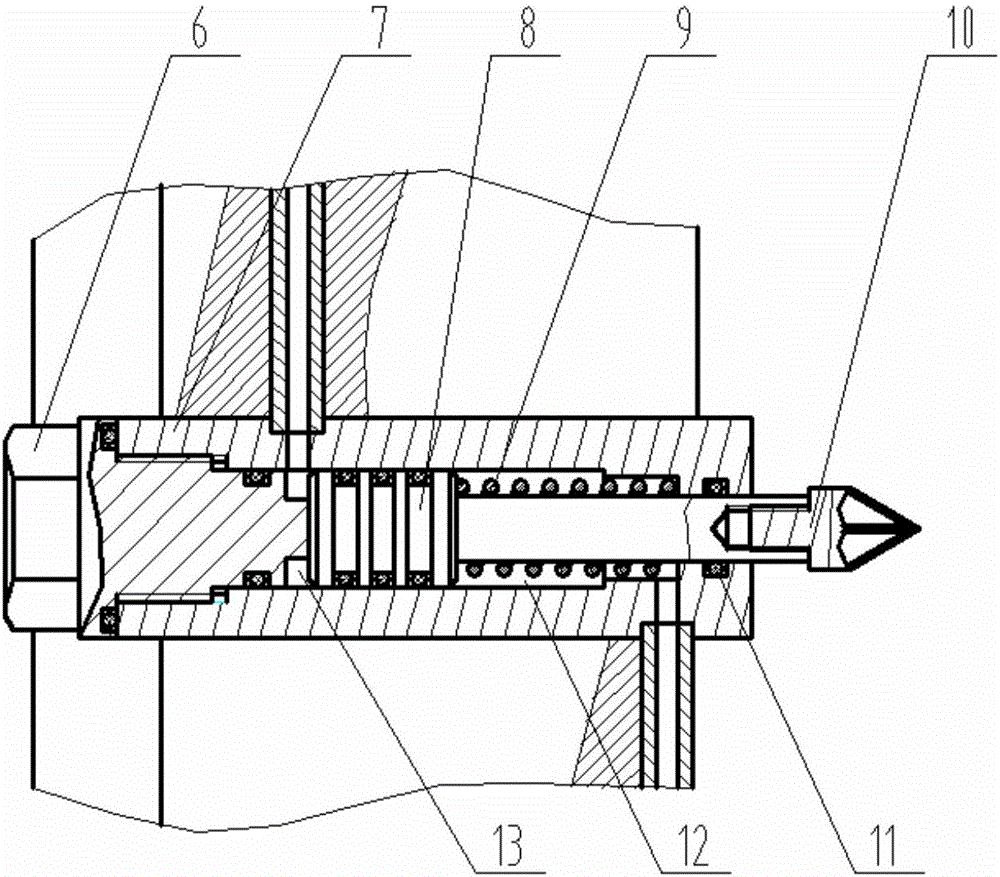

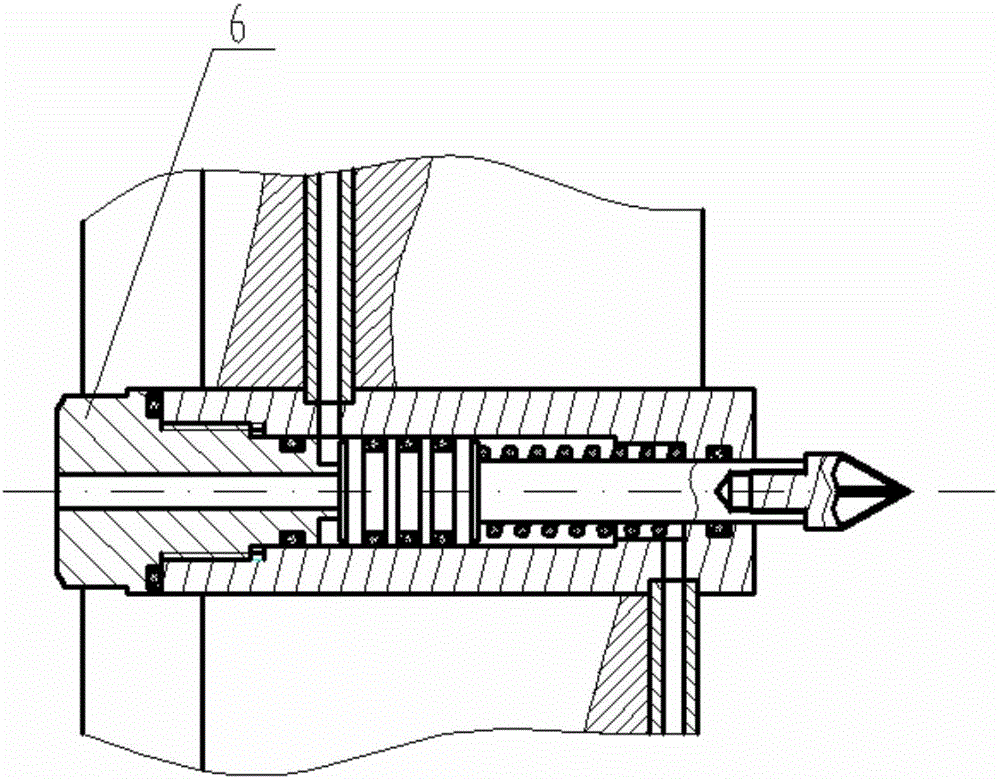

[0025] Such as figure 1 Shown is the structural schematic diagram of the shock tunnel diaphragm rupture device, such as Figure 4 Shown is a schematic diagram of the installation of the shock tunnel diaphragm rupture device in the shock tunnel. It can be seen from the figure that a shock tunnel diaphragm rupture device includes a gun barrel connection structure 1, a vertebral body support plate 2, a ruptured membrane Cone 3, high-pressure chamber pipeline 4, low-pressure chamber pipeline 5, shock tube high-pressure section gun tube 14, shock tube low-pressure section gun tube 15 and diaphragm 16; wherein, the left side of the gun tube connection structure 1 is connected to the shock wave The barrel 14 of the high-pressure section of the tube is fixedly connected, and the right side of the barrel connection structure 1 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com