Molten carbonate fuel cell set with external manifold tube structure

A fuel cell stack and molten carbonate technology, applied in molten electrolyte fuel cells, fuel cell groups, fuel cells, etc., can solve the problems of increasing the difficulty of material selection, processing and installation of the main pipe, increasing the leakage of the flexible outer main pipe of the seal, The increase of bipolar plate processing workload and other issues achieve the effect of material saving, simple structure and saving assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

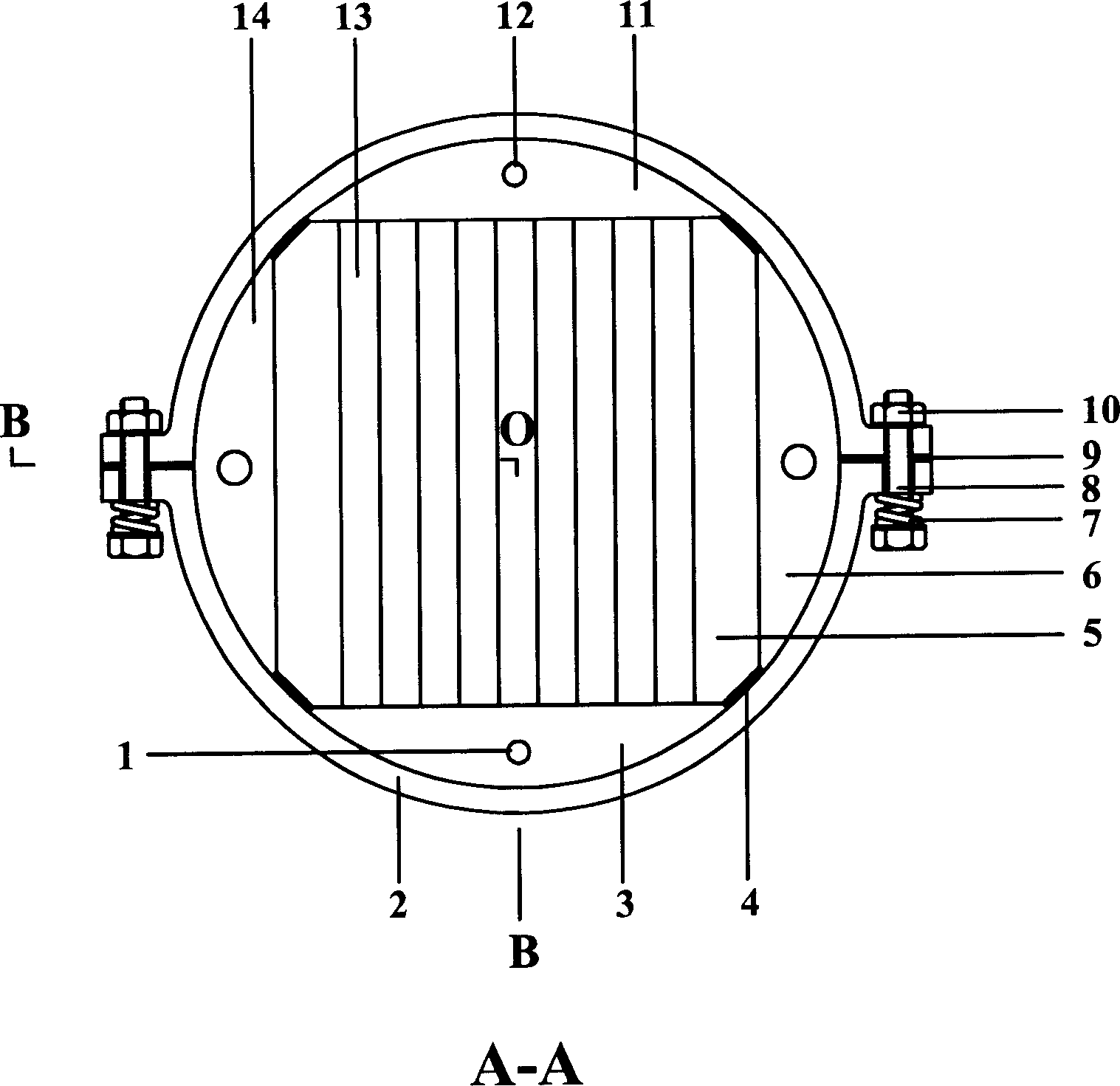

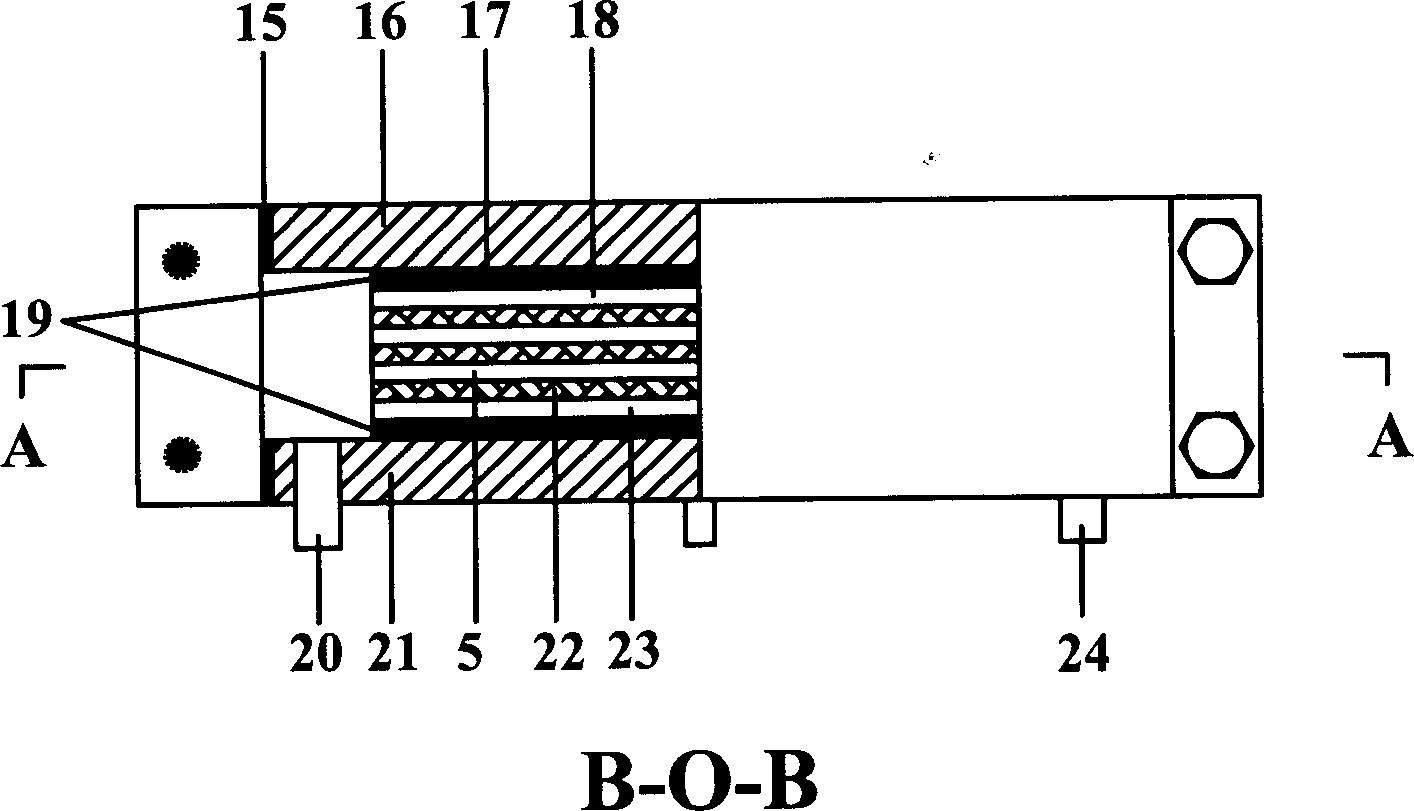

[0017] Such as figure 1 , figure 2 As shown, the present invention comprises: outer main pipe shell 2, molten carbonate fuel cell stack 19, upper cover plate 16 and lower cover plate 21, and the connection relationship is: the upper cover plate 16 is placed in molten carbonate fuel cell stack 19 Above and in contact with the carbonate electrolyte sealing member 17, the lower cover plate 21 is placed under the molten carbonate fuel cell group 19 and is in contact with the carbonate electrolyte sealing member 17; the molten carbonate fuel cell group 19 , The upper cover plate 16 and the lower cover plate 21 are placed in the middle of the two semicircular outer header tube bodies 2, and are pre-tightened connected with the two semicircular outer header tube shells 2 through the header seal 4 and the cover plate seal 15, And constitute the anode air intake main pipe 3, the cathode exhaust main pipe 6, the anode exhaust main pipe 11 and the cathode air intake main pipe 14; two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com