Two-pole generator

A generator and two-pole technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, magnetic circuit rotating parts, etc., can solve the problem of not fully utilizing the effective area of rotor punching, increasing the pressure ring and buckle Material costs, increased manufacturing and processing costs, etc., to achieve the effect of convenient lamination, convenient rotor winding, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

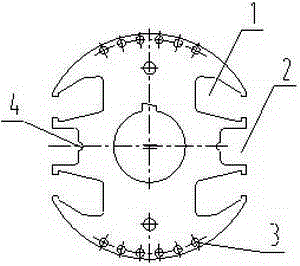

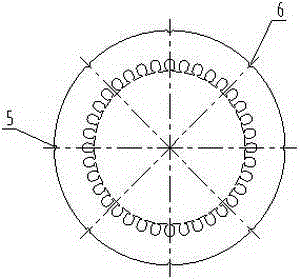

[0022] Such as Figure 1~Figure 5 As shown, the present invention is achieved in this way, a two-pole generator, characterized in that: the rotor punching piece on the generator is an integral punching piece with two-pole special-shaped grooves, the outer circle is an eccentric structure, and the rotor punching piece includes two special-shaped grooves 1. Two square slots 2, 12 damping holes 3 and two semicircular slots 4, two groups of 6 damping holes 3 are symmetrically arranged at the two ends of the rotor punching plate, and special-shaped slots 1 are set beside the 6 damping holes 3. A square groove 2 is arranged in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com