Patents

Literature

234 results about "Shock tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The shock tube is an instrument used to replicate and direct blast waves at a sensor or a model in order to simulate actual explosions and their effects, usually on a smaller scale. Shock tubes (and related impulse facilities such as shock tunnels, expansion tubes, and expansion tunnels) can also be used to study aerodynamic flow under a wide range of temperatures and pressures that are difficult to obtain in other types of testing facilities. Shock tubes are also used to investigate compressible flow phenomena and gas phase combustion reactions. More recently, shock tubes have been used in biomedical research to study how biological specimens are affected by blast waves.

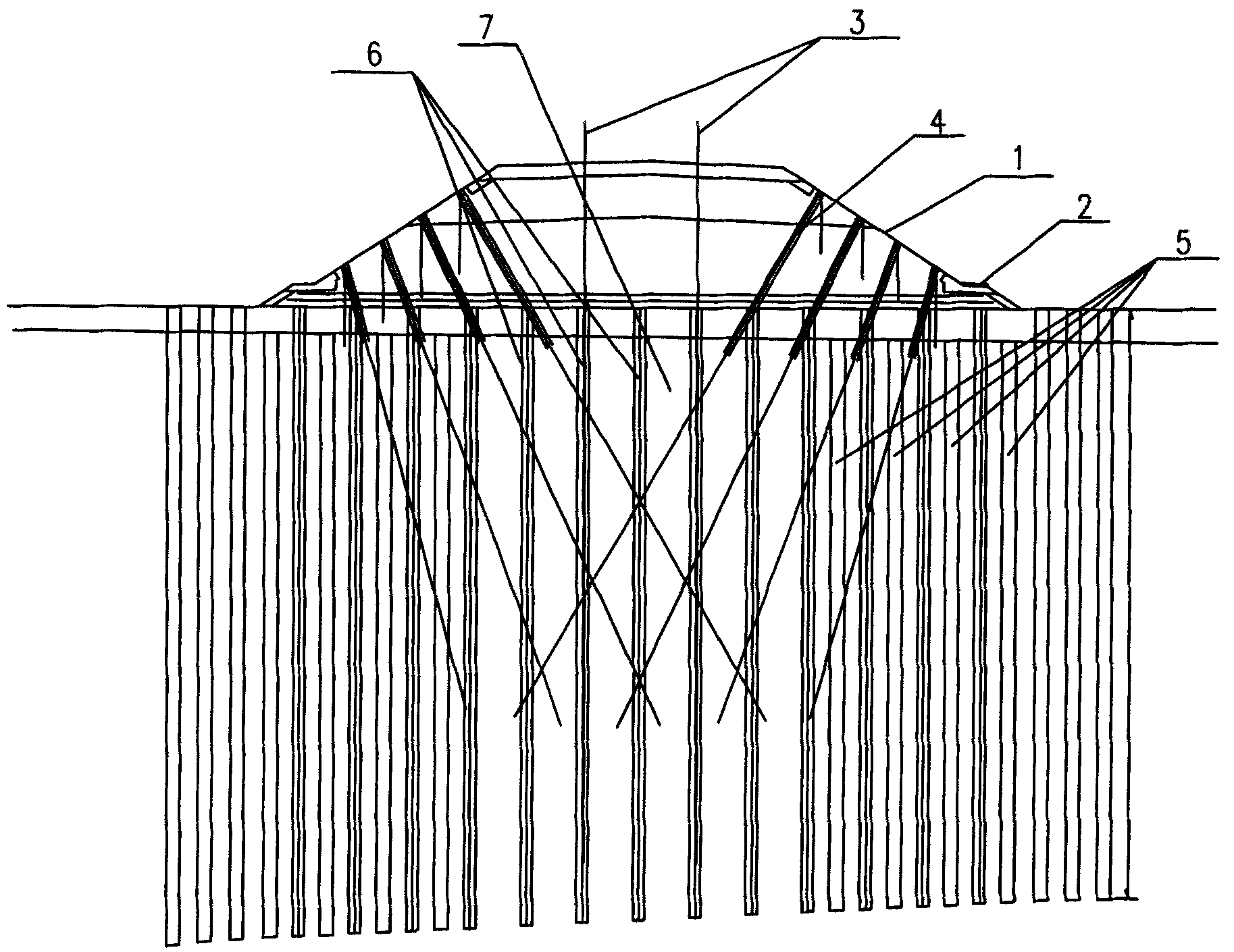

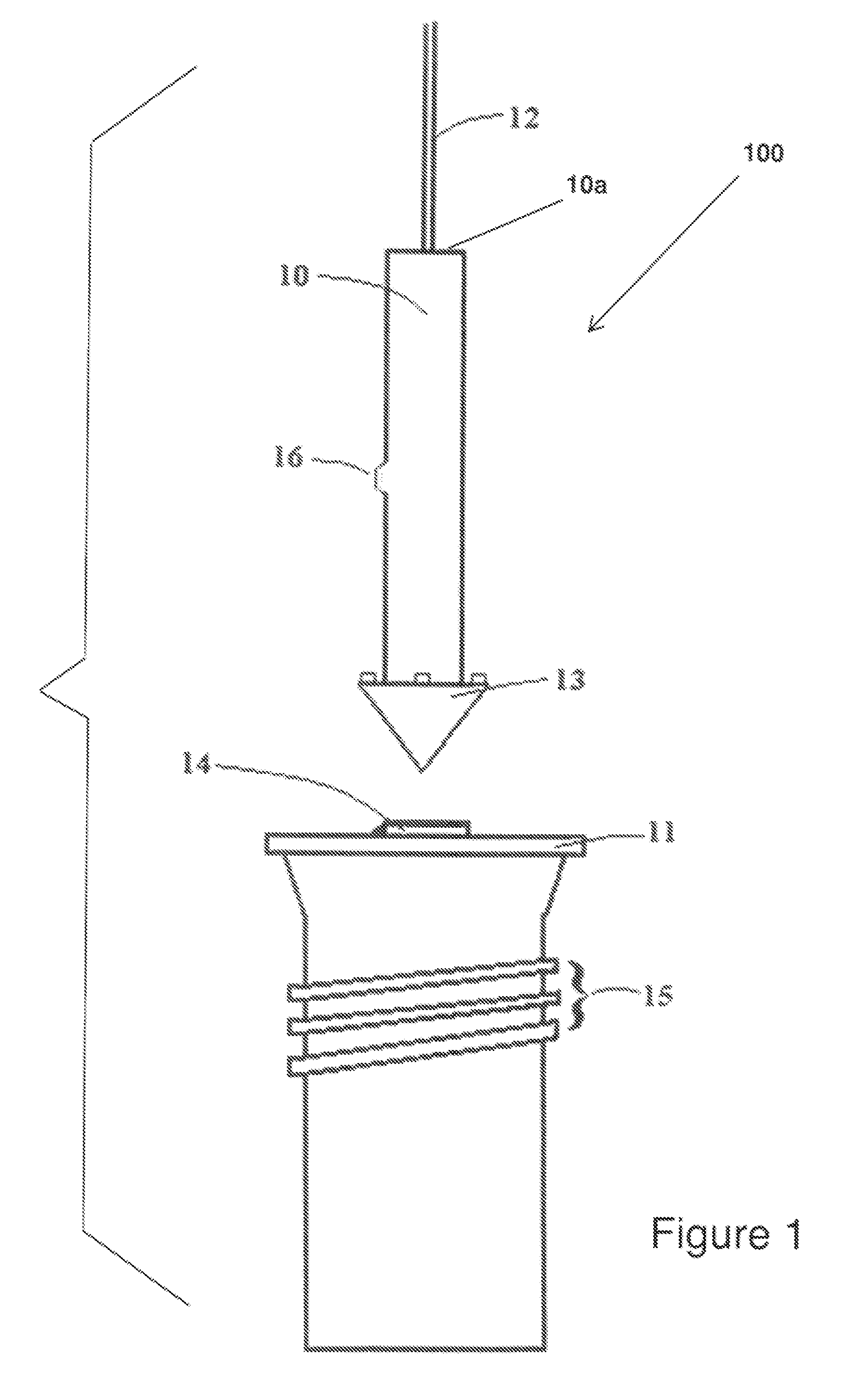

Soft foundation reinforcing method of existing railway or highway subgrade construction

ActiveCN101886382AAvoid traffic disturbanceLess equipmentBulkheads/pilesSoil preservationEngineeringSizing

The invention relates to a soft foundation reinforcing method of the existing railway or highway subgrade construction, which comprises the following steps of: constructing vertical chemical churning piles on the side slope and the slope toe of a subgrade to be reinforced; after the vertical chemical churning piles are cured, drilling a plug hole tilting toward the center line of a track and extending into the soft foundation in the side slope by using a drilling machine; and performing shock tube grouting in the plug hole. A sizing agent in the plug hole permeates towards the periphery of the foundation, the cured sizing agent, the vertical chemical churning piles and the foundation form an integrated reinforcing block, and thus, the reinforcement of the railway or highway subgrade construction is completed. Compared with the traditional single technique, the method has the advantages of no construction transition, no traveling interruption and no reinforcing dead zone by adopting the vertical chemical churning piles together with a shock tube grouting technique. The advantages of both the vertical chemical churning piles and the shock tube grouting technique are fully exerted, and the safety and the quality are controllable.

Owner:广东省铁路规划设计研究院有限公司

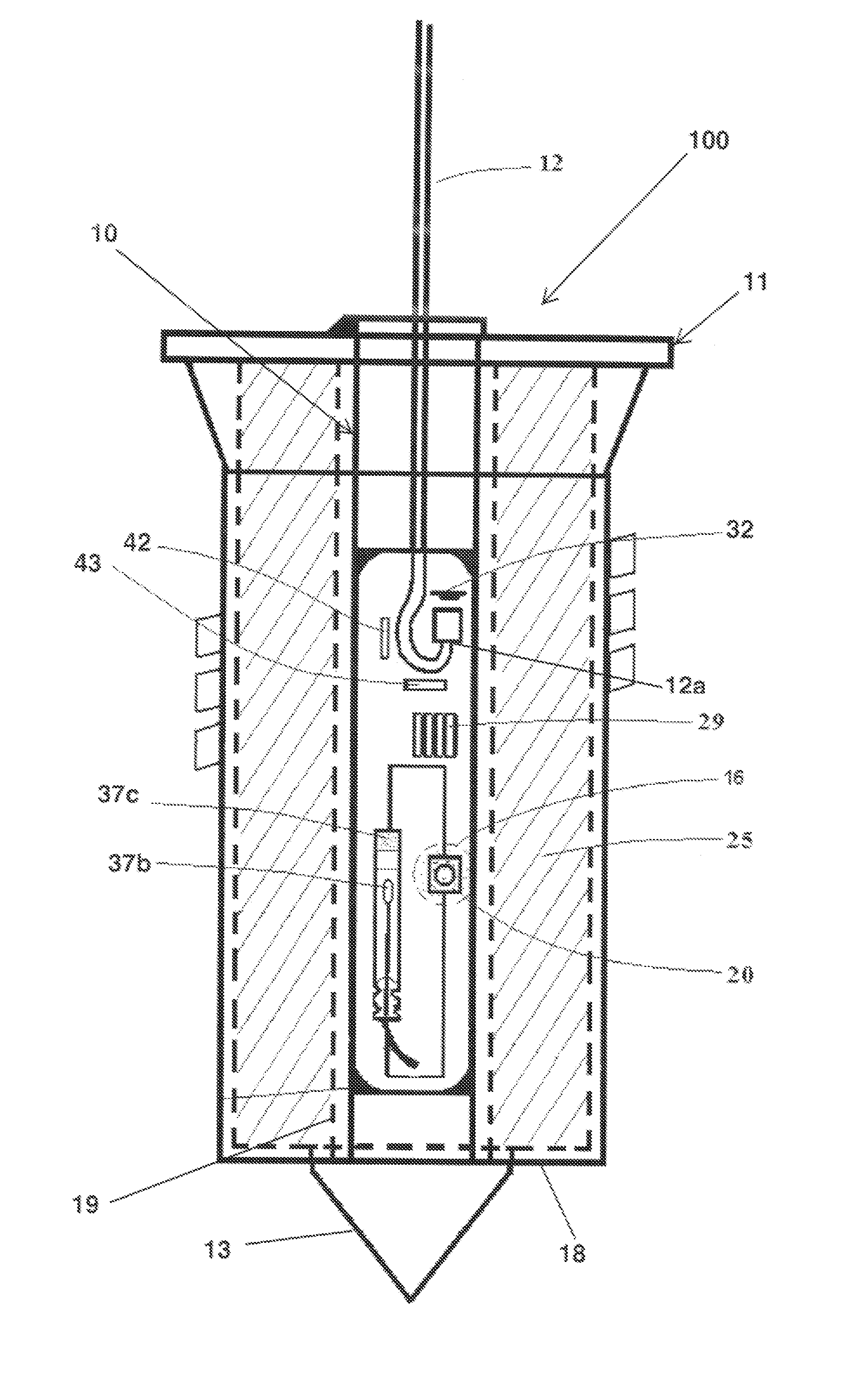

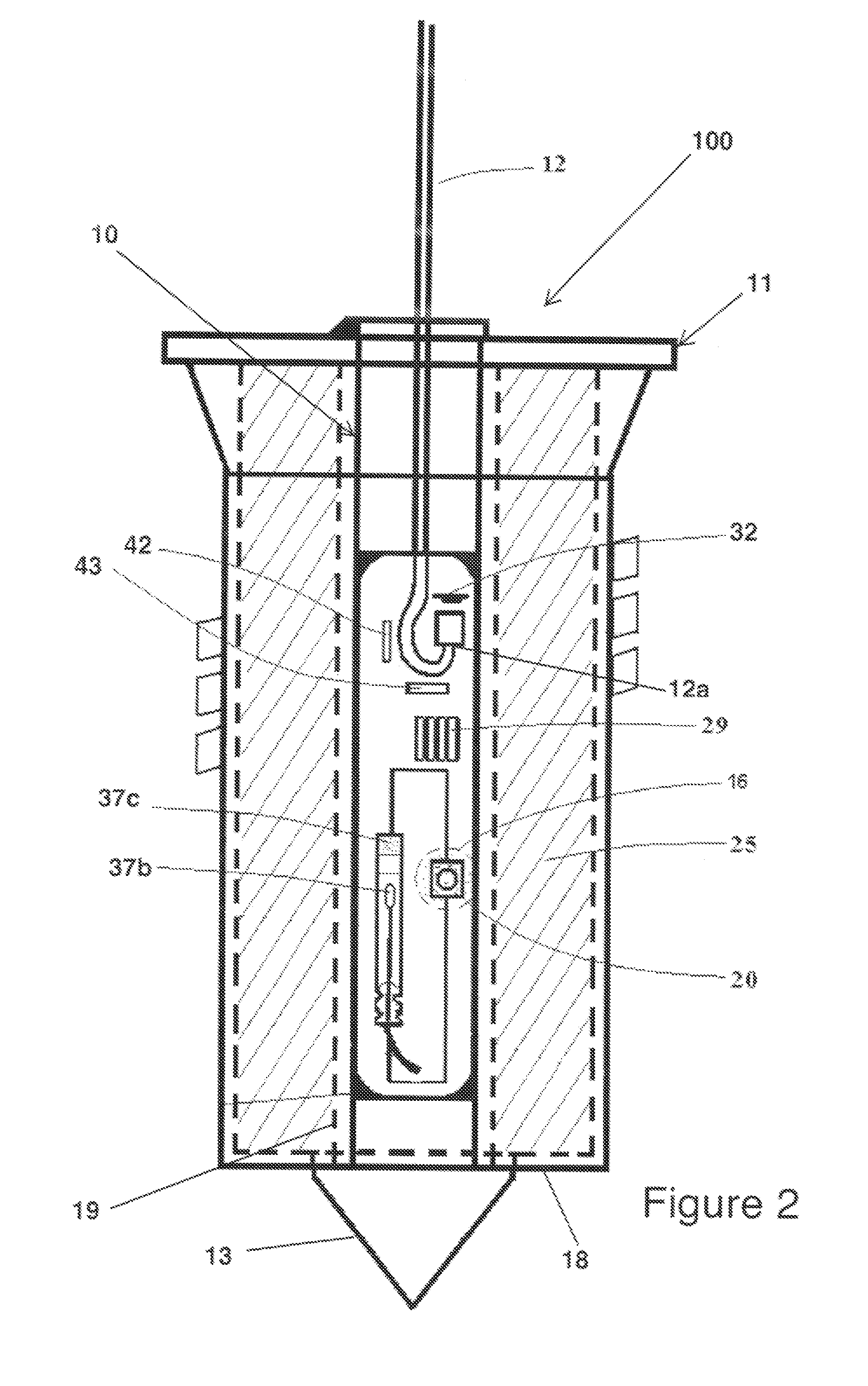

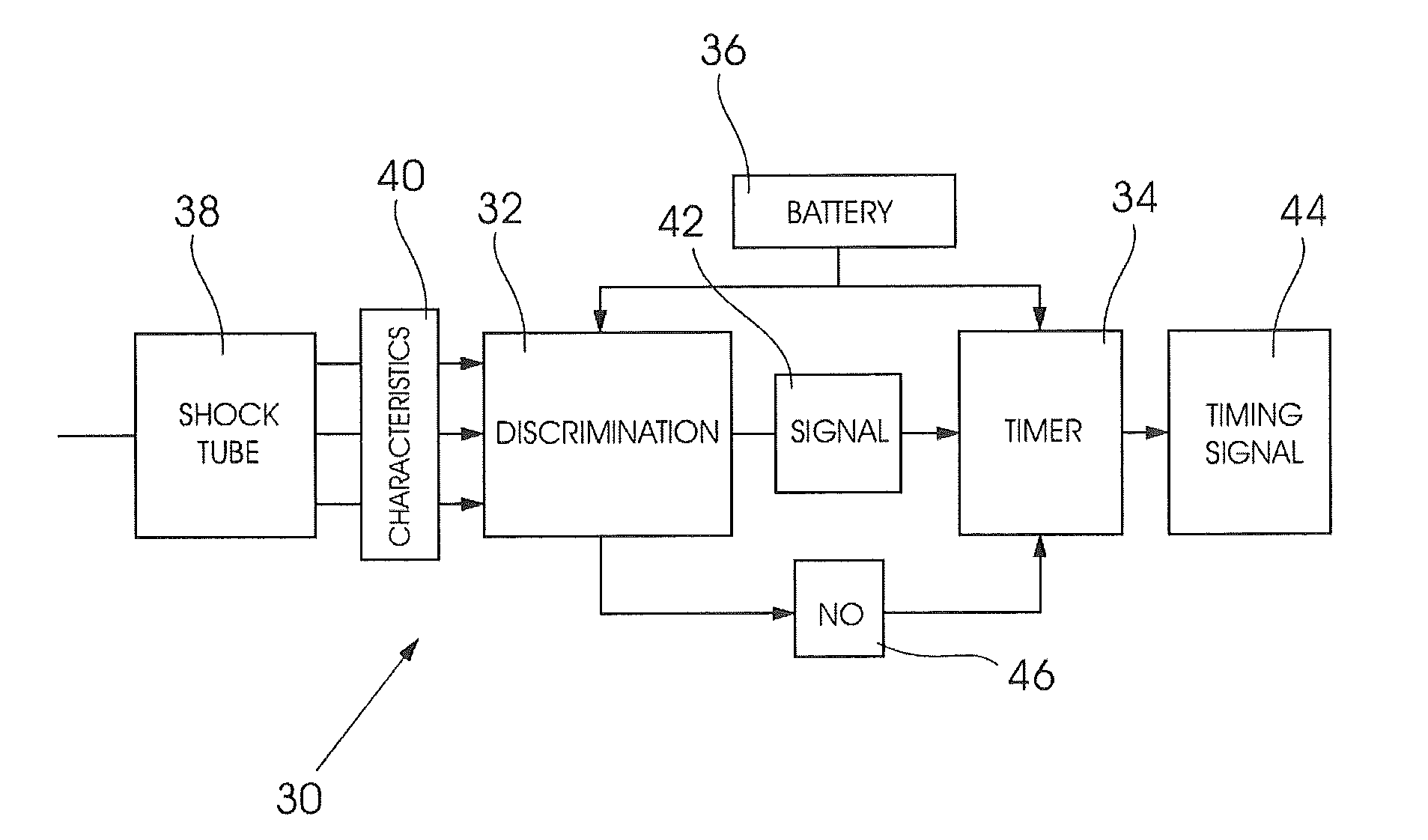

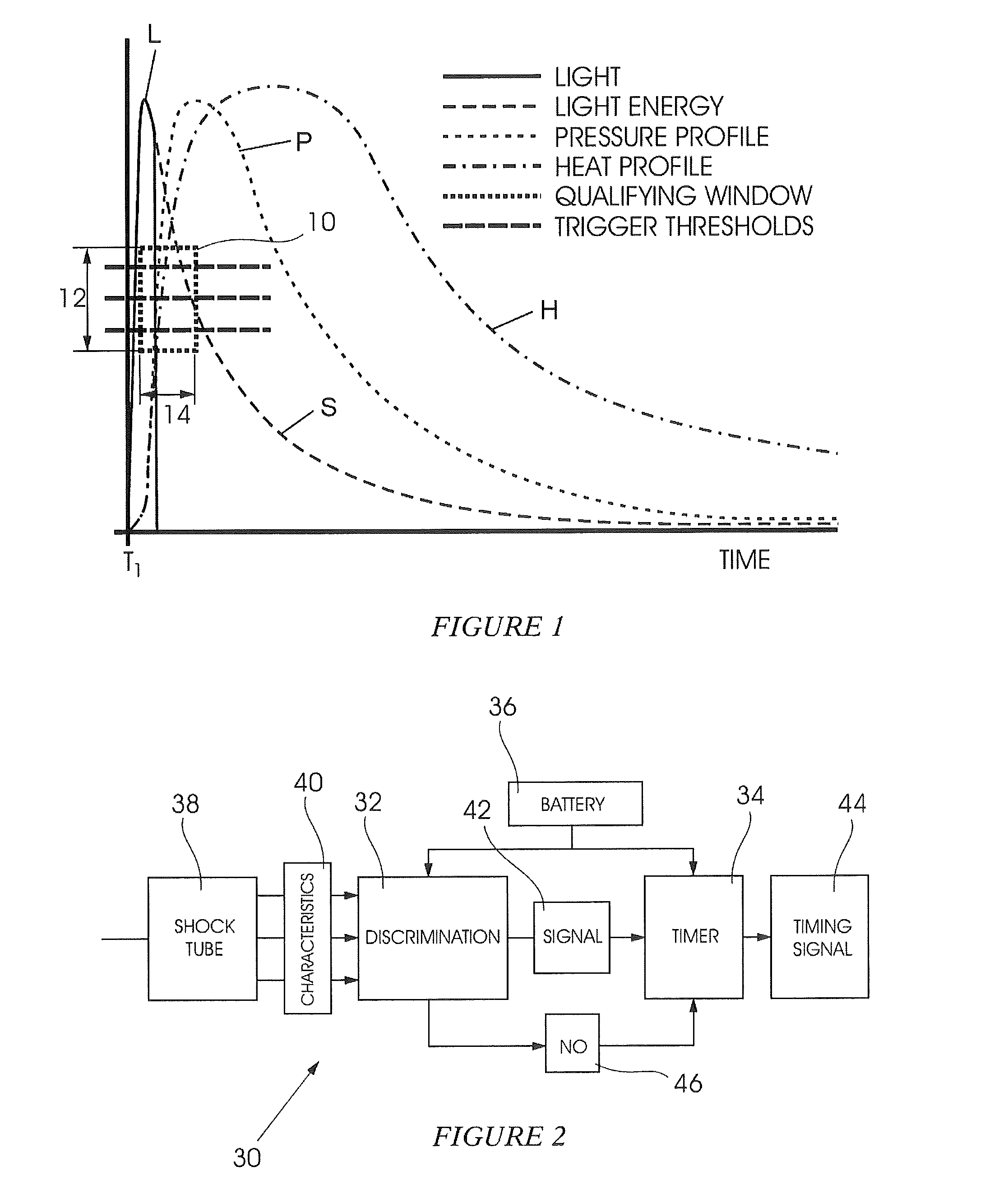

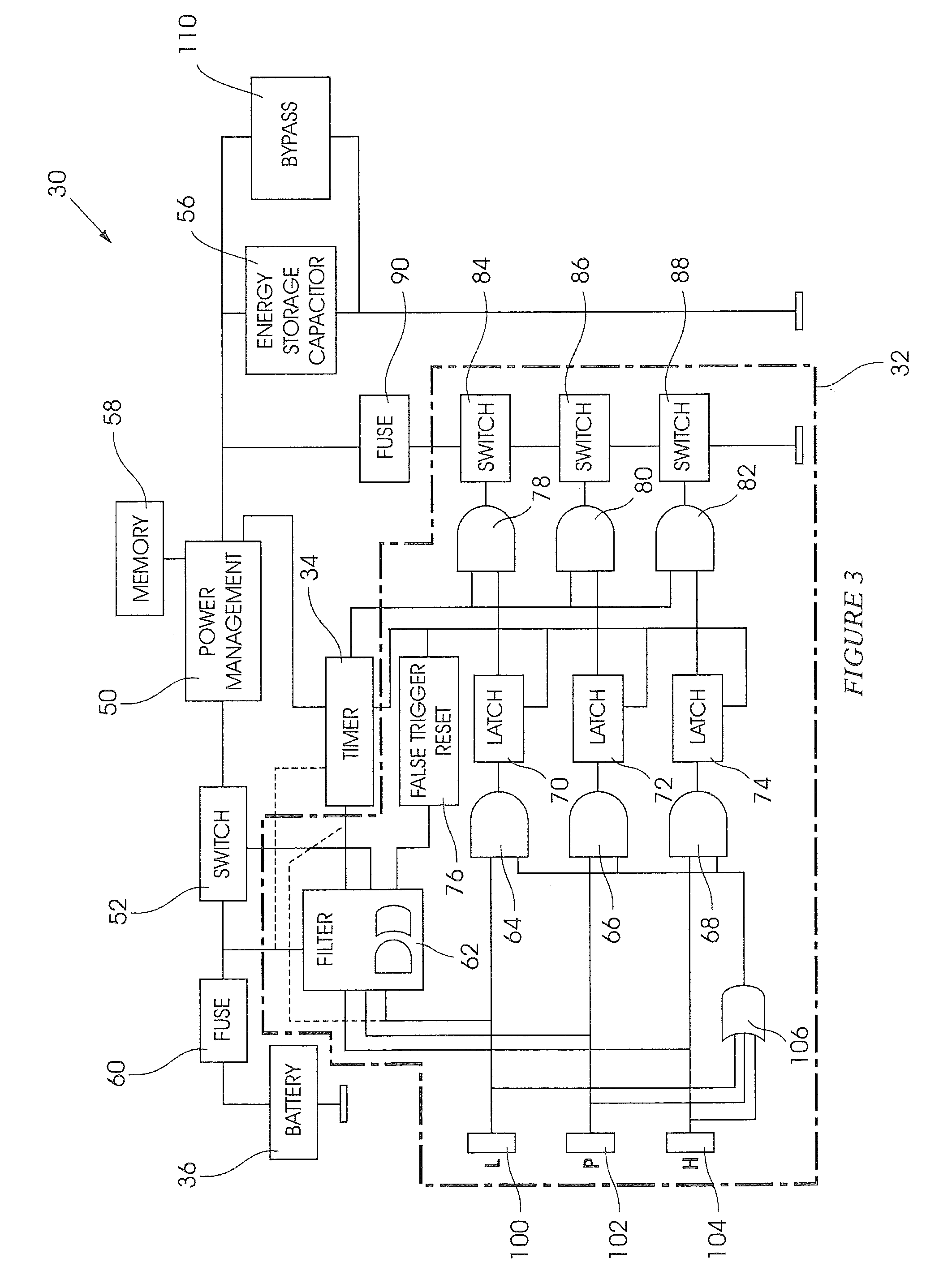

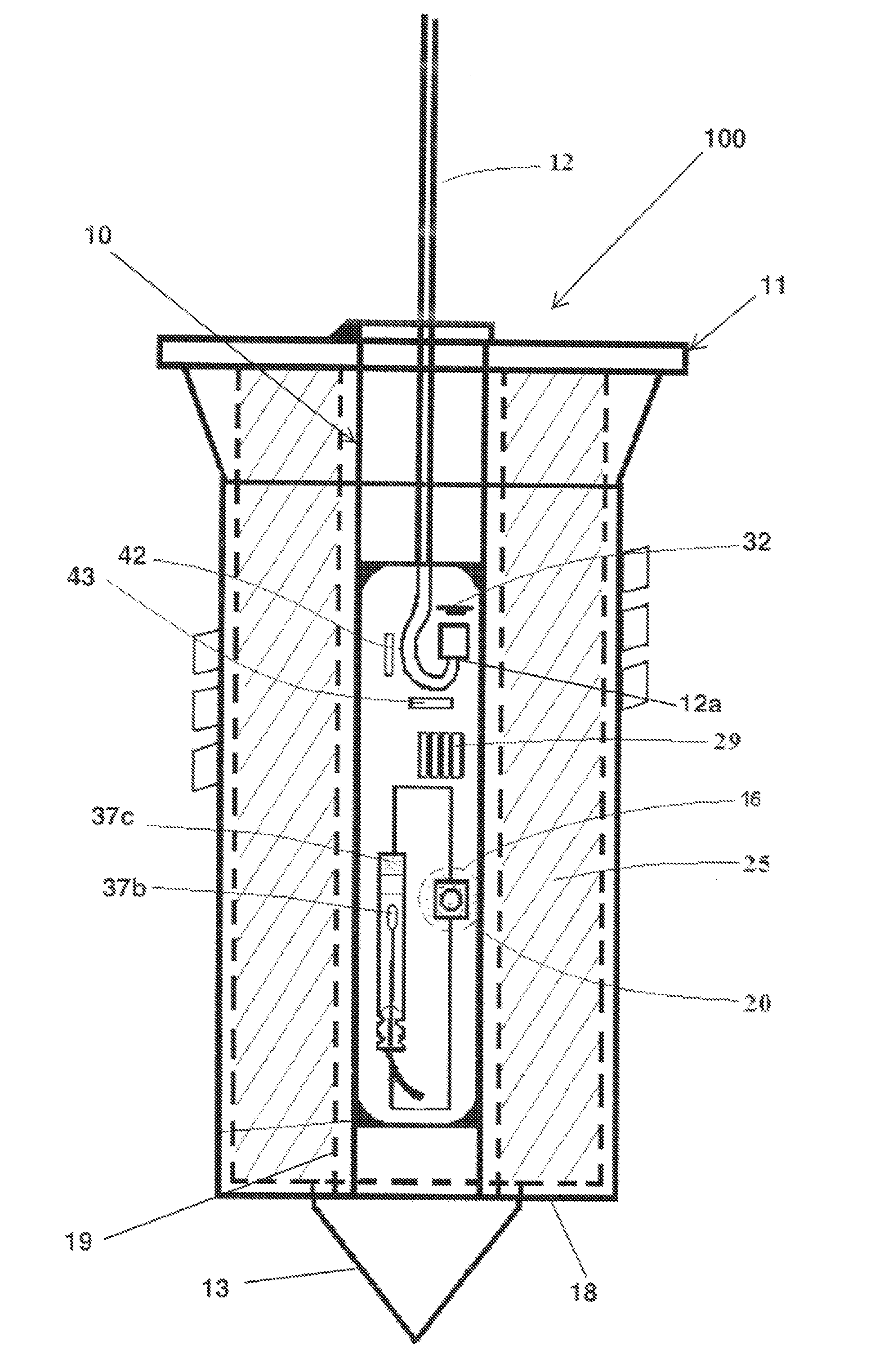

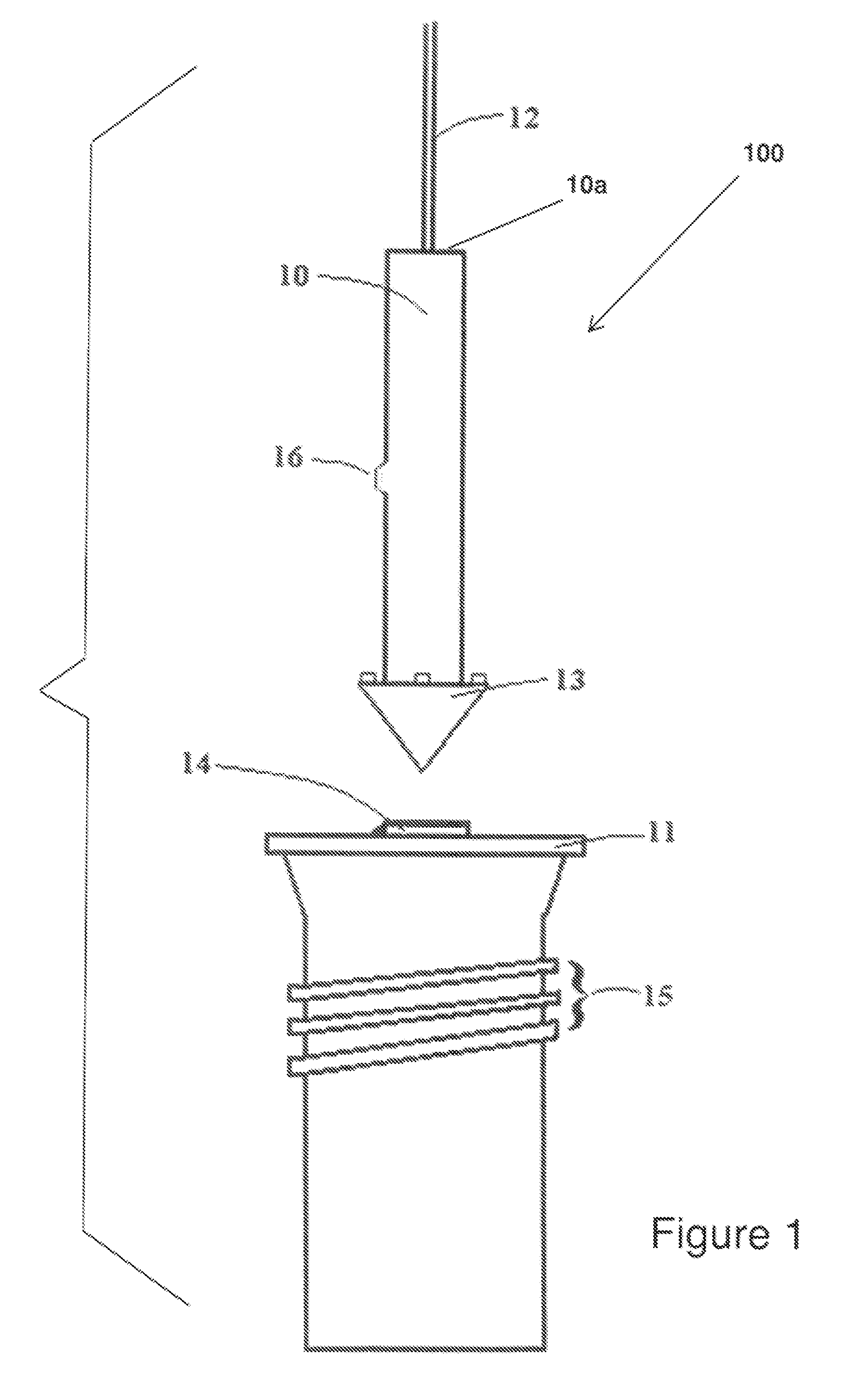

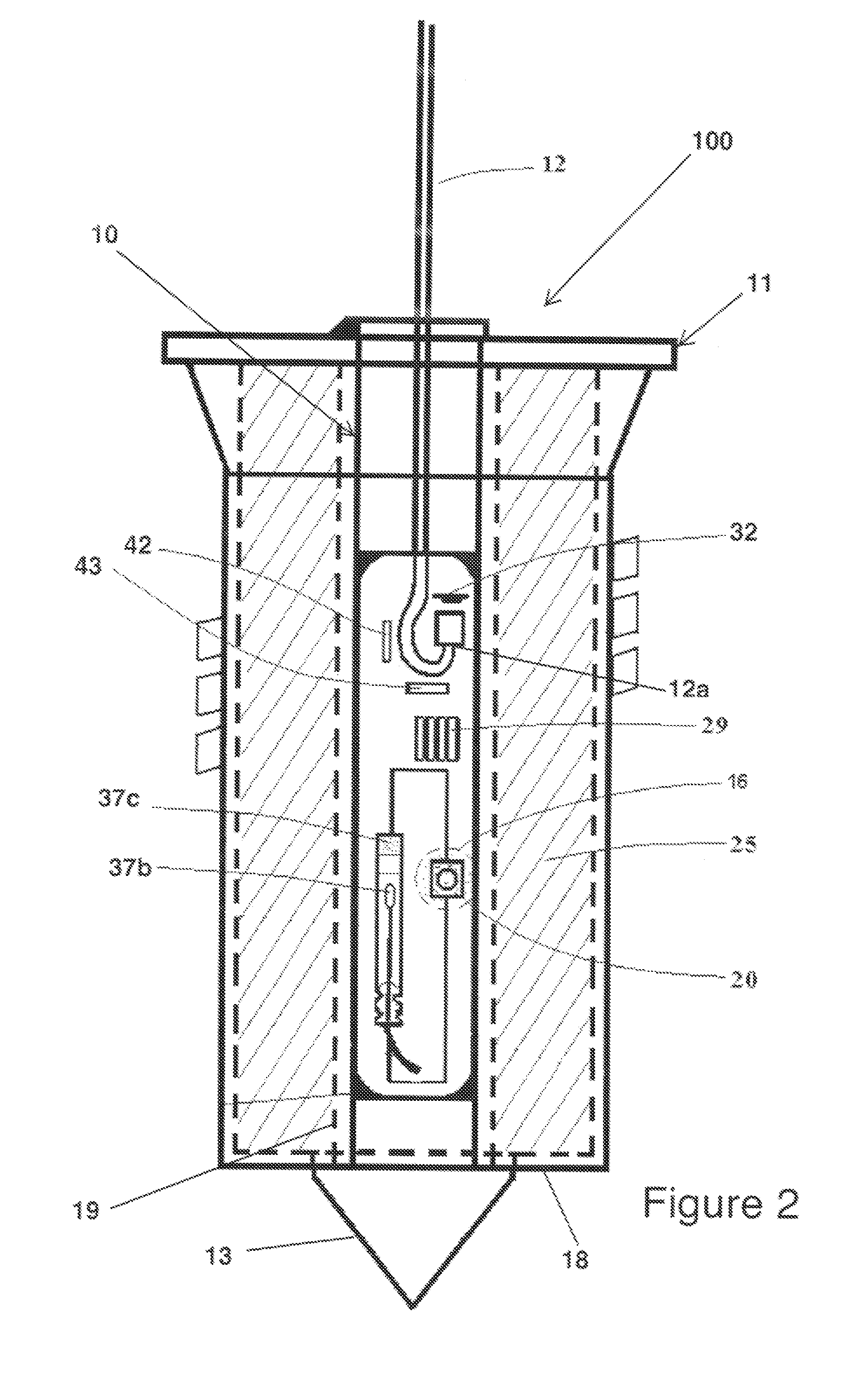

Detonator system with high precision delay

InactiveUS20110155012A1Save energyCheap manufacturingIncandescent ignitionBlasting cartridgesDetonatorElectrical battery

An electrical delay detonator for use in blasting initiation systems energized by a non-electric impulse signal transmitted through a non-electrical conduit, such as a shock tube, with one end inserted inside a detonator housing having redundant sensors for detecting the presence of a non-electric impulse signal and a computerized control circuit for actuating the firing circuit. An elevated voltage is generated, stored in a capacitor assembly, and discharged when fired to an electrically operable igniter. The igniter, when activated, detonates an explosive mass. A battery is also contained within the detonator housing for powering the control circuit and one sensor, in low consumption mode, for several days. Upon detecting the presence of a signal the rest of the circuits are powered up. Periodic time windows generated by the control assembly provide corresponding enabled time periods for the sensors to become operational.

Owner:IND MINCO S A C

Decompression type blocking method for foundation pit dewatering well

ActiveCN103334444AKeep the well closedImprove construction efficiencyFoundation engineeringBasementEmbedment

The invention provides a decompression type blocking method for a foundation pit dewatering well. The method includes the steps of step 1, sleeving a waterproof casing pipe outside a dewatering well pipe and carrying out reinforcement and embedment, step 2, embedding the waterproof casing pipe and pouring the waterproof casing pipe into foundation base plate concrete, step 3, cutting off unnecessary well pipes on the base plate surface after basement base plate concrete reaches a certain strength, inserting one drainage shock tube into the lower portion of the well pipes, and enabling the top end of the drainage shock tube to be communicated with a water conduit, step 4, shutting in the well, lifting a water pump out, then filling well shut-in materials into the dewatering well pipes sequentially, step 5, enabling a cover plate and the waterproof casing pipe to be connected and fixed and enabling a small amount of water to flow out independently from the shock tube, step 6, starting a mud jack pump and compressing curing agents into the dewatering well pipe, and step 7, cutting off the portions, exposed out of the surface of the base plate, of the drainage shock tube, and then using high-intensity concrete to block portions around the well pipe. Thus, blocking of the dewatering well is finished. The decompression type blocking method is wide in application range, high in construction efficiency, convenient to operate, good in water-stop effect and small in later influence.

Owner:CHINA FIRST METALLURGICAL GROUP

Solid particle group accelerating device for shock tube-Laval nozzle

InactiveCN101274710ALong rangeIncreased spray coverageSpray nozzlesFire rescueParticle injectionSolid particle

The invention discloses a shock wave tube-Laval nozzle accelerating device of a solid particle group. A compressed gas source is connected with a high pressure gas chamber of a shock wave tube by a compressed gas check valve, a powder storage chamber is surrounded by tube walls and movable clapboards at the two ends of the powder storage chamber, one of the movable clapboard separates a low pressure air chamber and the powder storage chamber and the other moveable clapboard separates the powder storage chamber and the Laval nozzle; a particle injection hole is cut on the side wall of the powder storage chamber to be connected with a powder supply source; a powder supply switch valve is arranged in the particle injection hole to separate the powder supply source and the powder particle in the powder storage chamber; a control circuit board is respectively connected with a transient switch valve, the powder supply switch valve and the two movable clapboards. As a chemical powder extinguisher, since the shock wave tube and the Laval nozzle function synchronously to accelerate the solid particle group to cause the shooting range of extinguisher to be sufficiently far off and an ejection covering area can be appropriately enlarged by enlarging the expansion angle of the gradual-widening section of the Laval nozzle, the shock wave tube-Laval nozzle accelerating device has high extinguishing efficiency, good effect, long shooting range and energy conservation; as an ultrasonic cool spraying device, the particle adhesive strength and the coating strength are great.

Owner:ZHEJIANG SCI-TECH UNIV

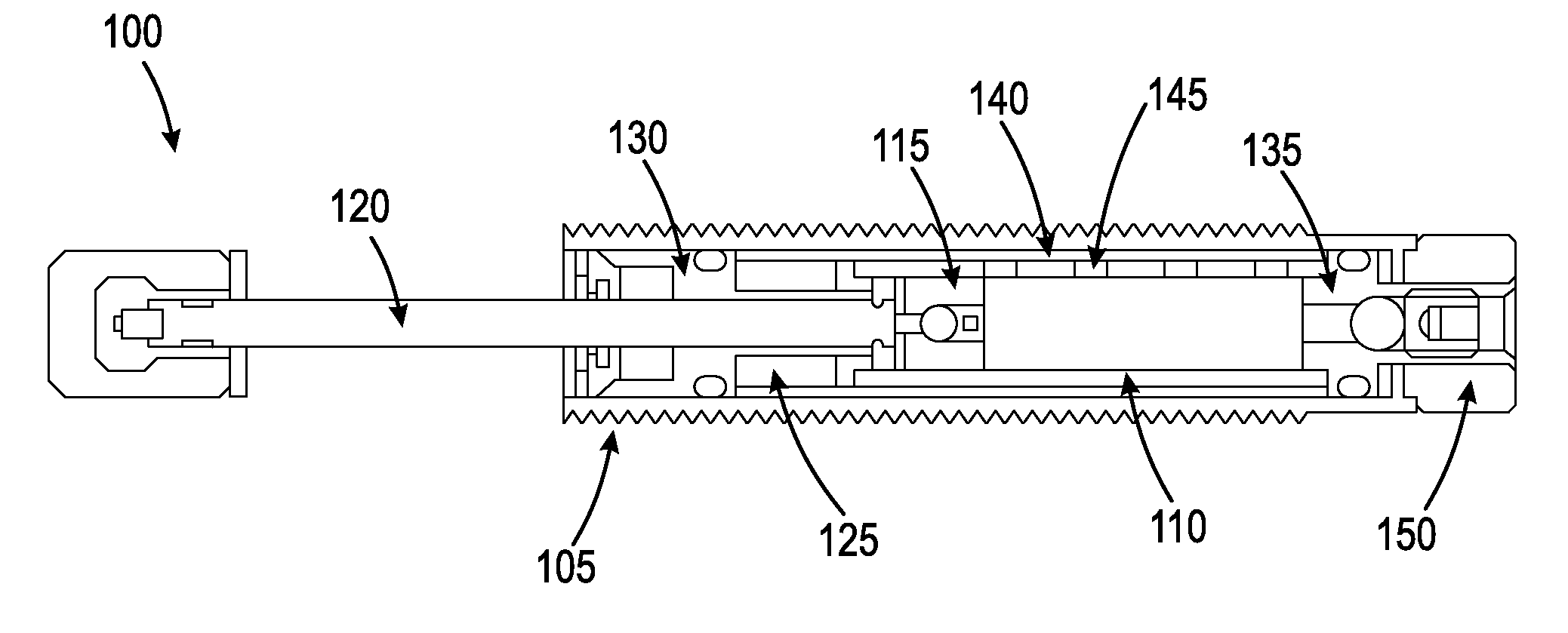

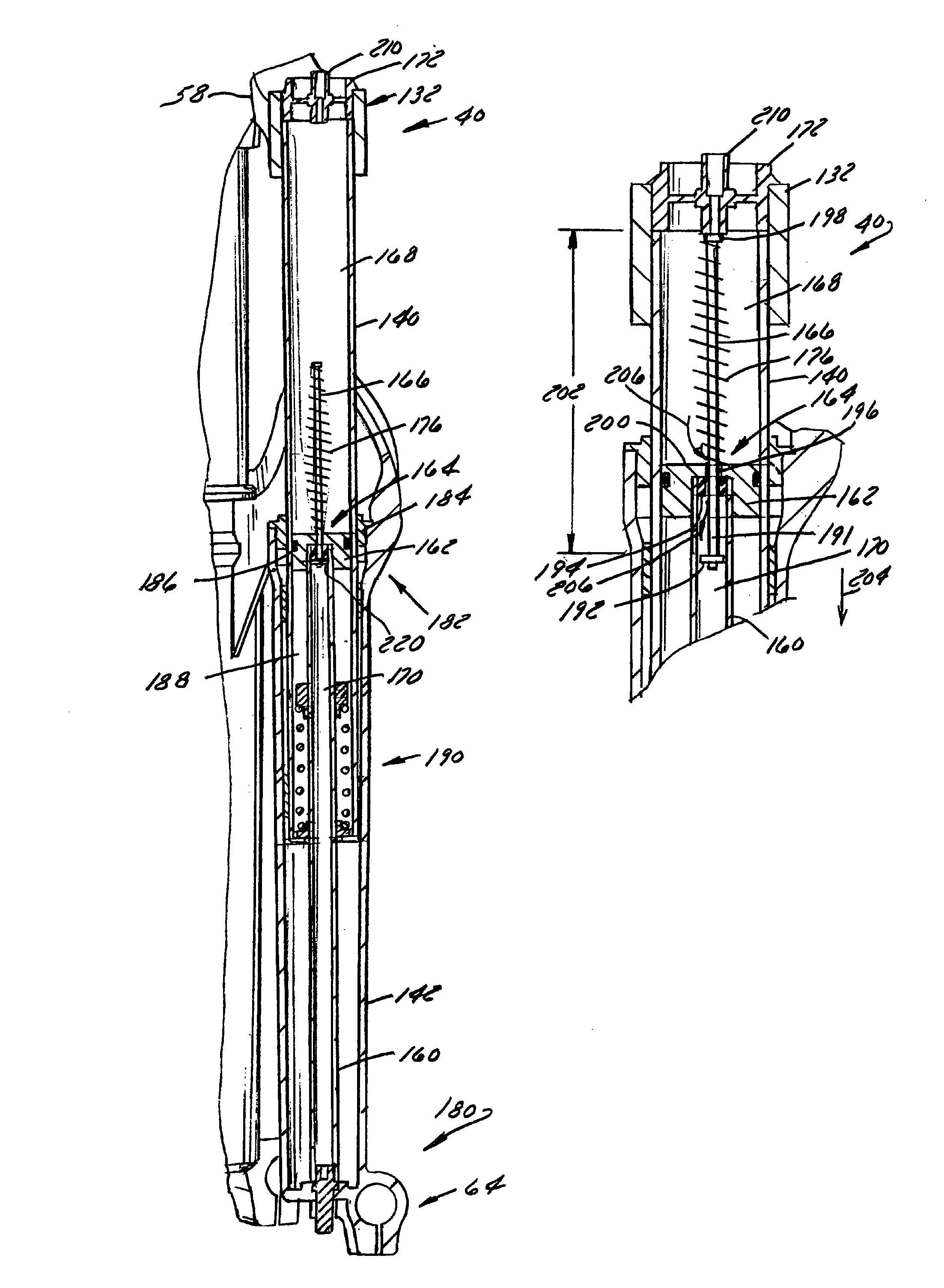

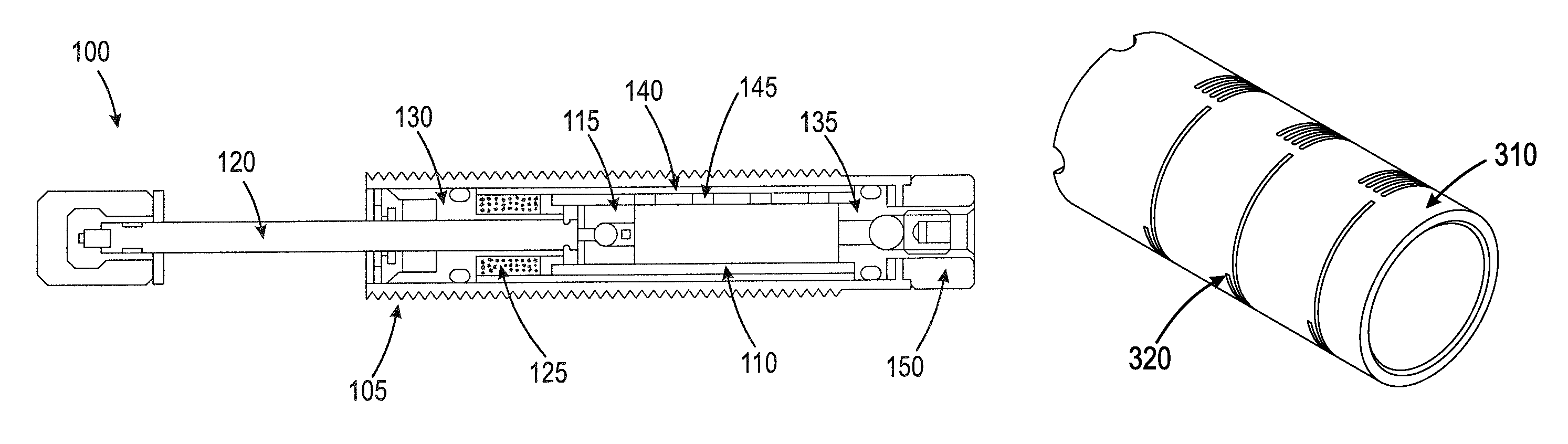

Shock absorber with variable damping profile

Disclosed herein in an energy absorption device that incorporates a diverse range of uses within a single shock absorber. The disclosed energy absorption device is a novel combination of interaction between various components (e.g., piston head, shock tube, cylinder end, external cylinder, and adjustment mechanism) within a single shock absorber. When the components disclosed herein are considered together and designed as an interrelated assembly, the ability to incorporate such a diverse range of uses within a single device emerges. The ability to combine dashpot, square wave, progressive wave, and self-compensating damping in a single device is unprecedented, as is the ability to deliver sublinear damping force vs. input velocity performance in an adjustable device. The disclosed device allows a user to make simpler sizing calculations and decisions, and provides the user with the ability to adjust the shock absorber to a specific application, for example, with the turn of an adjustment knob.

Owner:KYNTEC

Timing module

ActiveUS8967048B2Enhance safety and reliabilityPromote great certaintyIncandescent ignitionBlasting cartridgesComputer moduleEngineering

A timing module for use in a detonating system which includes discriminating and validating arrangements which sense and validate at least one characteristic of at least one parameter produced by at least one shock tube event and an electronic timer which executes a timing interval in response thereto.

Owner:DETNET SOUTH AFRICA (PTY) LTD

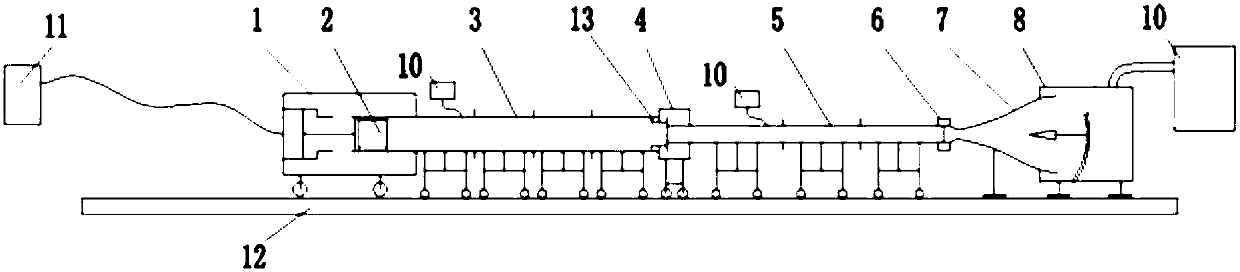

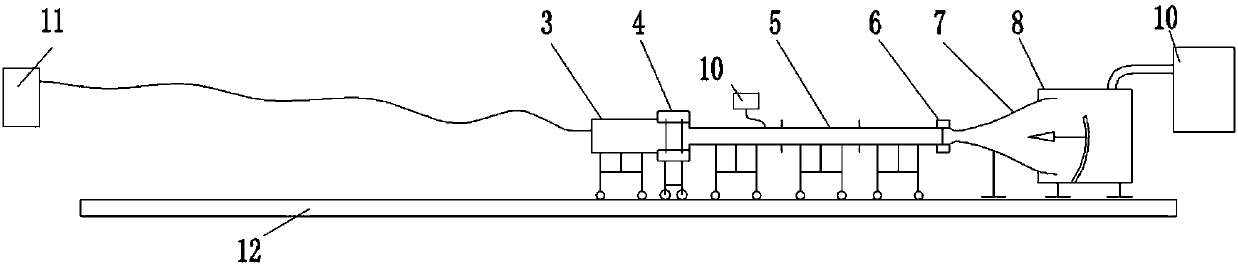

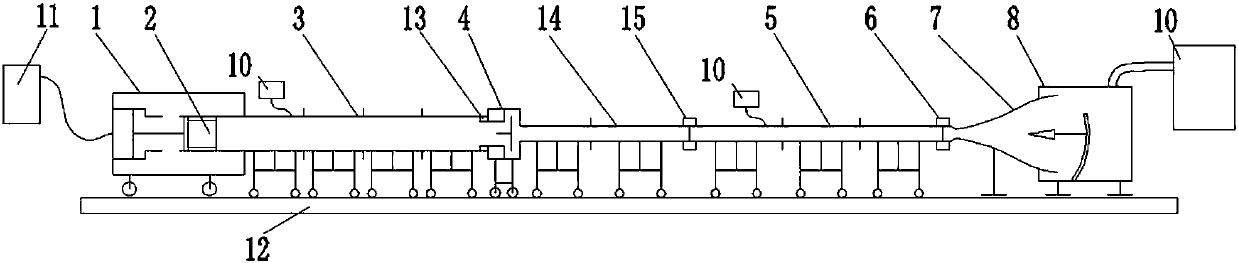

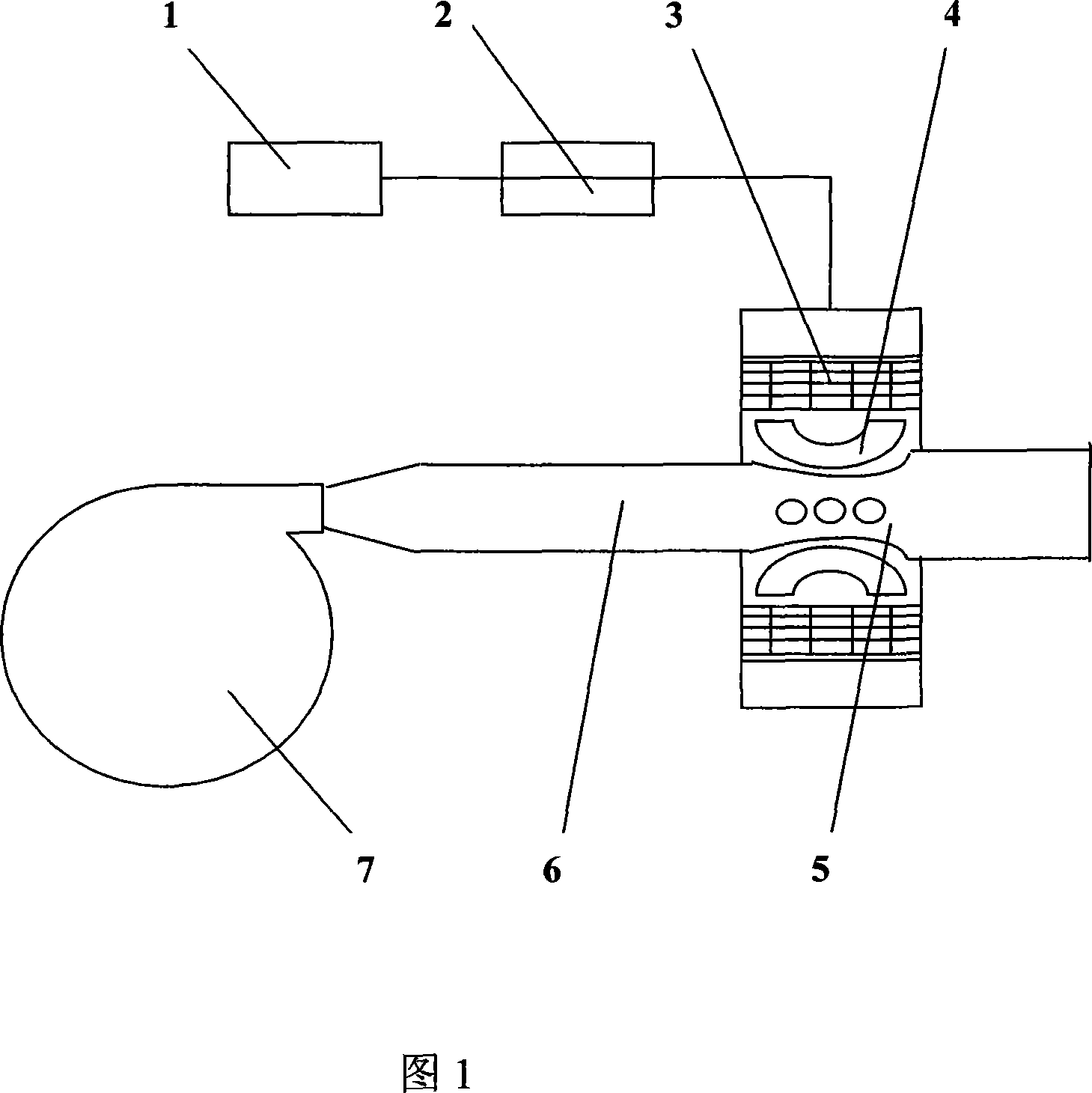

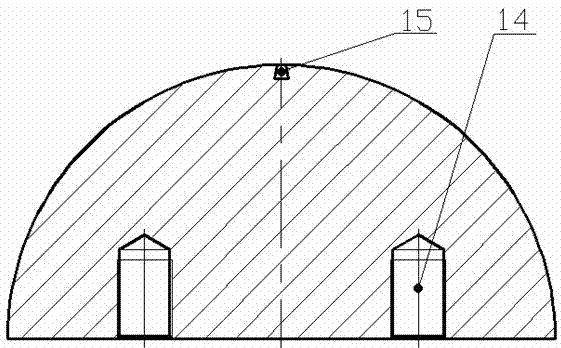

Multi-mode operating free piston shock tunnel

ActiveCN108036918AIncrease the scope of applicationImprove testing capabilitiesAerodynamic testingSupporting systemEngineering

The invention discloses a multi-mode operating free piston shock tunnel which comprises a tunnel body, a distributed vacuum system, an air supply system and a track supporting system, wherein the tunnel body comprises a driving mechanism, a shock tube section, a single-film capsule mechanism, a spray tube and a test tube section; the distributed vacuum system is capable of vacuumizing the drivingmechanism, the shock tube section and the test tube section; the air supply system supplies air to the driving mechanism and a shock tube section; and the tunnel body is sequentially and coaxially connected with the shock tube section, the single-film capsule mechanism, the spray tube and the test tube section in a sealed manner. By taking equipment of free piston high-enthalpy shock tunnel as thebasis, by virtue of rapid replacement, connection of various components and match of a three-use main capsule mechanism, the tunnel has test abilities of two states, namely a conventional a low-enthalpy shock tunnel and a long-term medium-enthalpy shock tunnel, the application range of the tunnel performance and the test ability are improved, and the operating cost is reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

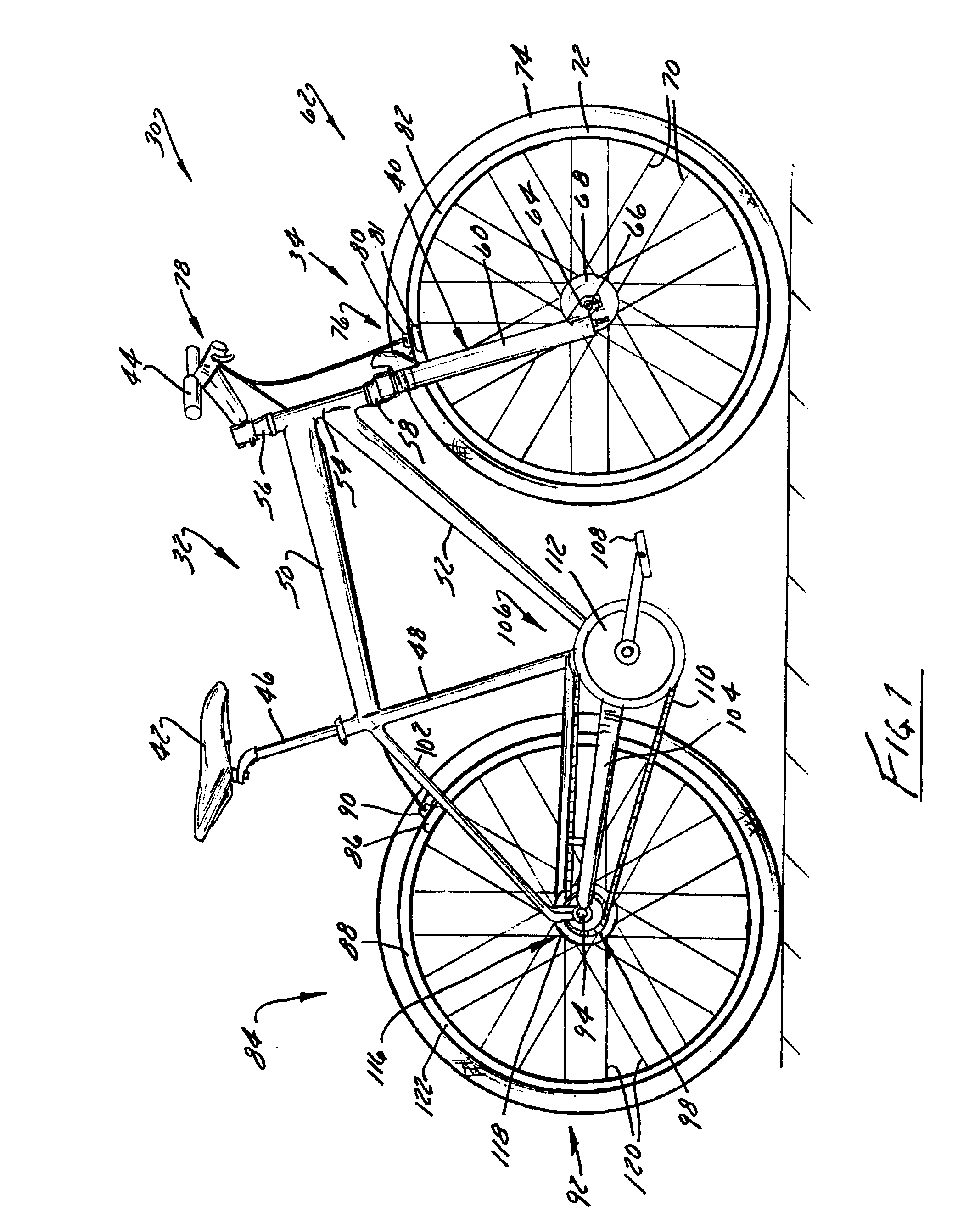

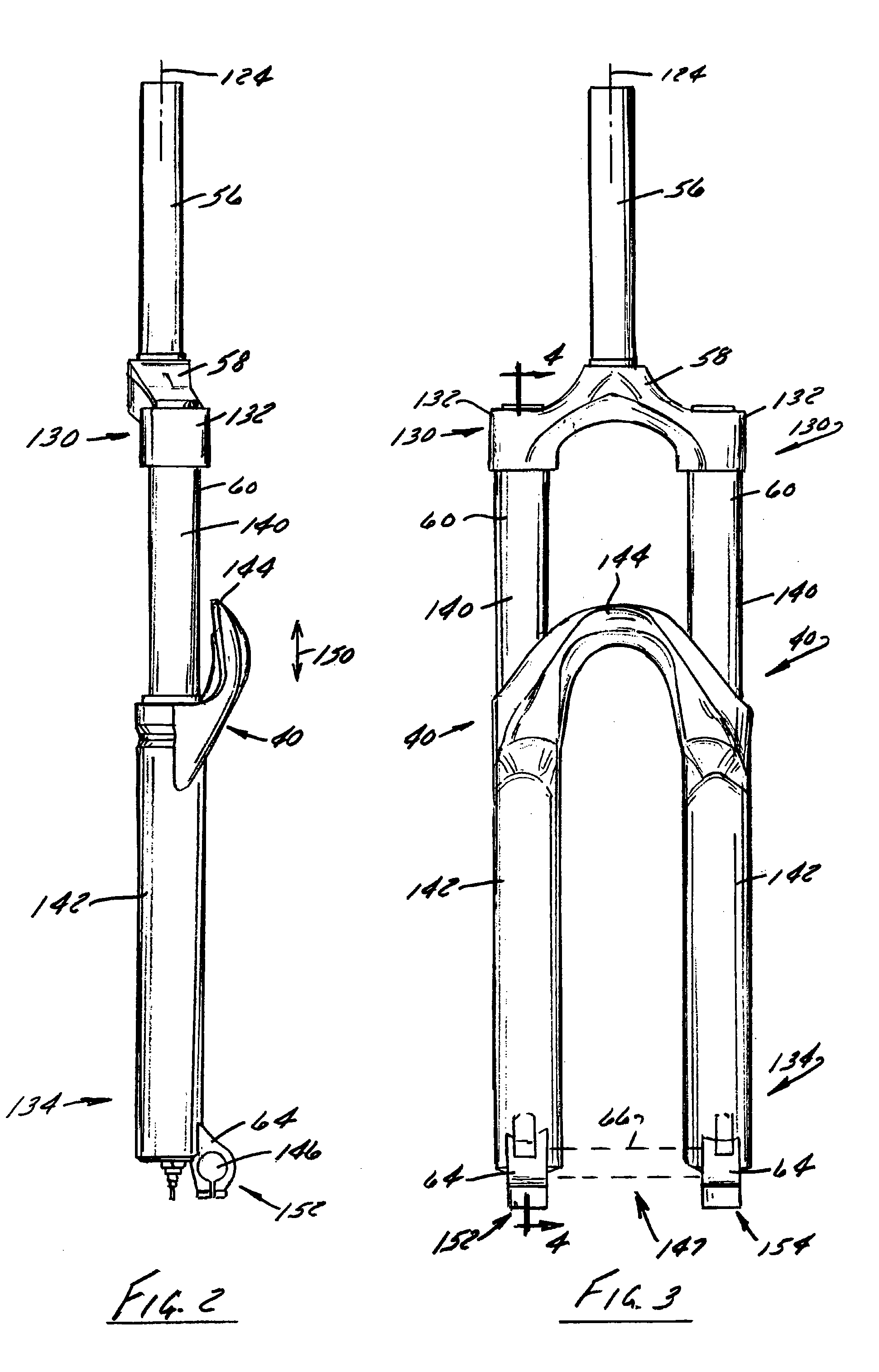

Bicycle shock assemblies with plunger operated valve arrangement

ActiveUS20100314209A1Alter performance of shockOvercomes drawbackWheel based transmissionFrictional rollers based transmissionEngineeringPiston

A shock absorber, which is particularly applicable to bicycles, includes a secondary chamber whose volume selectively contributes to a volume associated with a primary chamber of the shock. A piston is supported by a compression rod and cooperates with a shock tube to define the primary chamber. The secondary chamber is fluidly isolated from the primary chamber by a valve arrangement positioned proximate the piston. A plunger extends along a longitudinal length of the shock and forms or interacts with the valve arrangement such that the secondary chamber is selectively fluidly connected to the primary chamber so the primary and secondary chambers of the shock assembly contribute to the performance of the shock for a selected portion of shock travel.

Owner:TREK BICYCLE CORPORATION

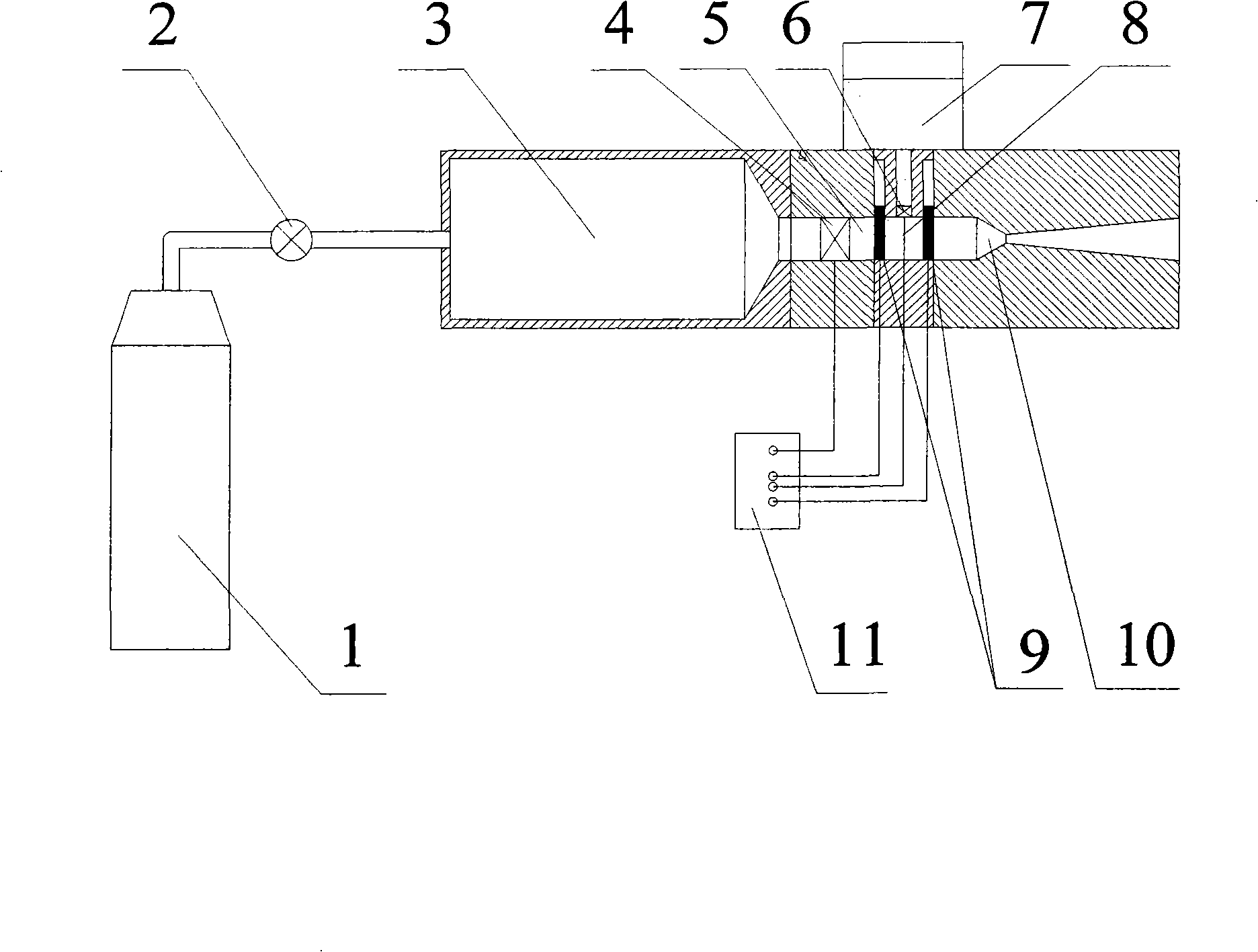

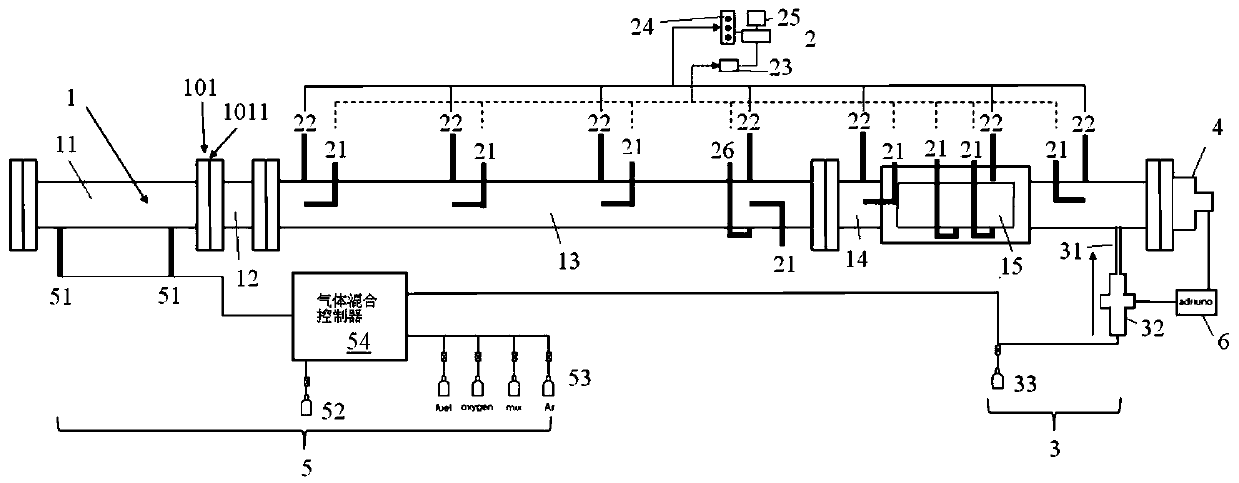

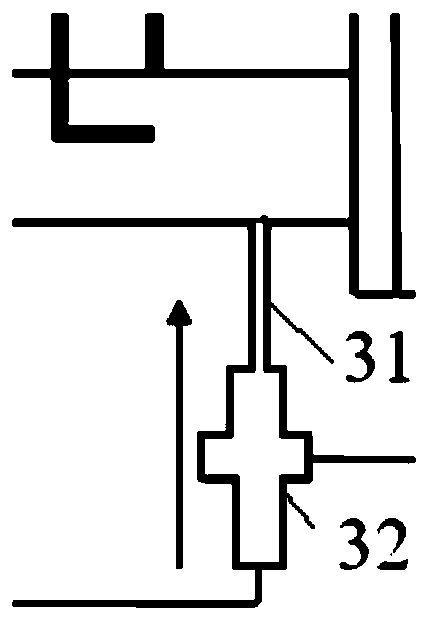

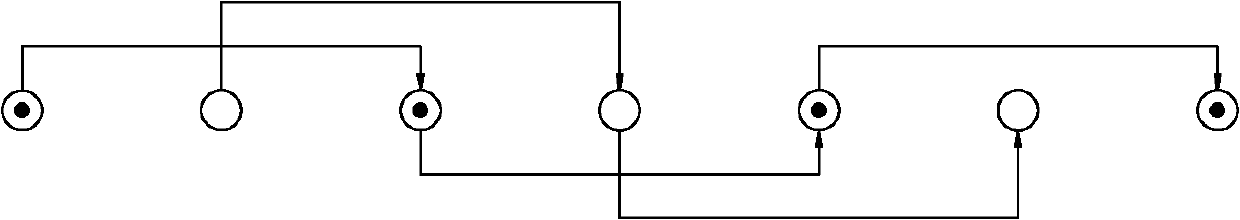

Detonation excitation system and method based on high speed jet

ActiveCN110220942AIncreased turbulenceShorten the distance from combustion to detonationMeasurement of fluid loss/gain rateSubsonic/sonic/ultrasonic wave measurementJet flowControl system

The invention provides a detonation excitation system based on high speed jet. The system comprises a shock tube, wherein a plurality of holes are set on the shock tube, through utilization of the holes; the shock tube is assembled with a test mixed gas system, a data collection system and a jet control system in sequence along a length direction of the shock tube; an ignition system is set at a tail end of the shock tube; the data collection system comprises a plurality of optical fiber sensors and a plurality of shock wave probes which are inserted into the holes of the shock tube at equal intervals, and the jet control system and the ignition system are connected with a control panel. The invention also provides a detonation excitation method. According to the detonation excitation system based on the high speed jet provided by the invention, through mutual effect of the high speed jet and flame, detonation is excited through the high speed jet, so a relatively small blockage ratiocan be achieved, deflagration to detonation distance can be effectively reduced, and total pressure losses in a whole detonation process can be reduced.

Owner:SHANGHAI JIAO TONG UNIV

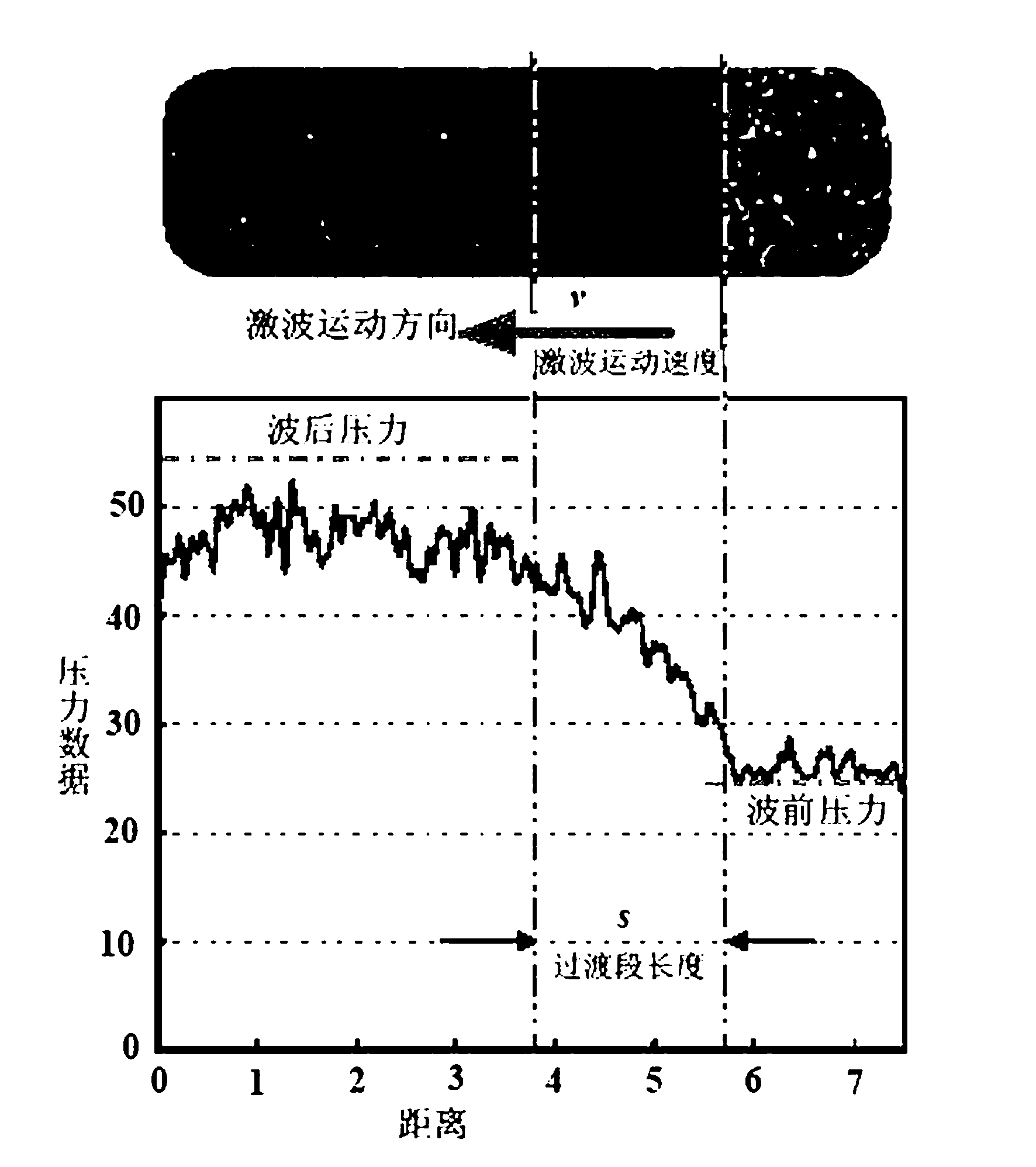

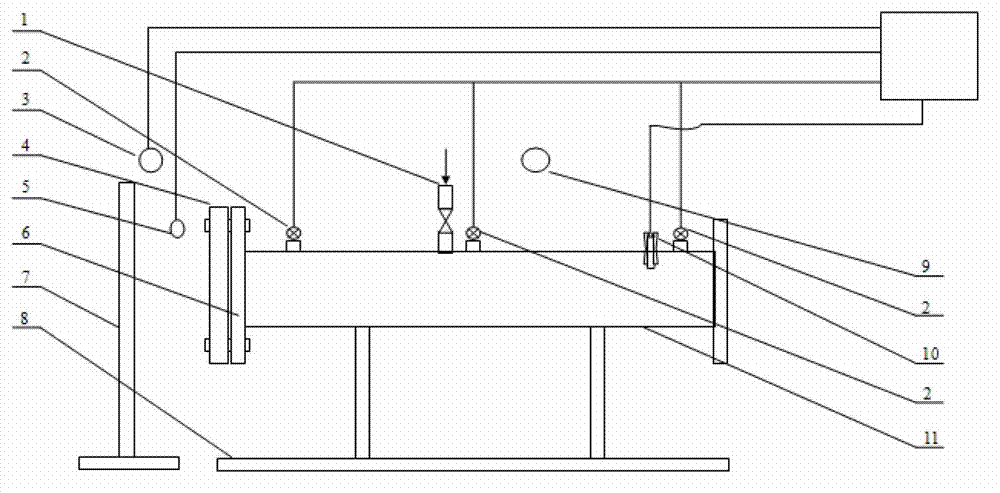

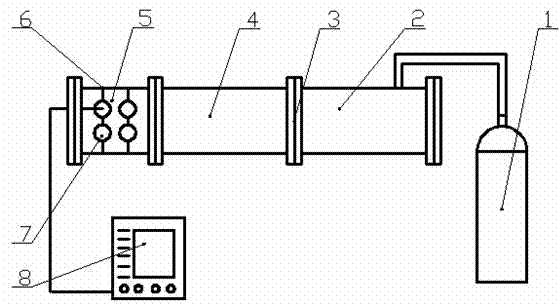

Supersonic gas-solid two-phase flow erosion and wear test device

InactiveCN102288506AAccurately observe the running trackSimple structureInvestigating abrasion/wear resistanceGas cylinderEngineering

The invention discloses a supersonic gas-solid two-phase flow erosive wear test device. The device comprises a high-pressure gas cylinder, a pressure reducing valve, a needle valve, a pressure meter, a shock tube, pressure sensors, an industrial control computer, a high-speed photographic instrument, a gas collecting box and a test piece installation platform, wherein the shock tube is divided into a driving section and a driven section which are separated by using an aluminum film; the driven section is provided with particles for measuring; the test piece installation platform is arranged in the gas collecting box and directly opposite to a location of an outlet of an observation section; the pressure sensors are arranged on the driven section and the observation section and respectively used for measuring a gas flow speed of the film-ruptured aluminum film and speeds of the particles for measuring; and the high-speed photographic instrument is oppositely arranged to a light source arranged in the wall face of the gas collecting box and arranged on the same optical axis with the light source and used for observing movement tracks of solid particles. According to the device provided by the invention, a practical engineering wear failure case of a pipeline system in the field of coal chemical industry can be simulated, and security researches of a pipeline and value on erosivewear mechanism research, optimum design, risk inspection, security evaluation and lifespan prediction and the like are carried out.

Owner:HANGZHOU FURUDE TECH

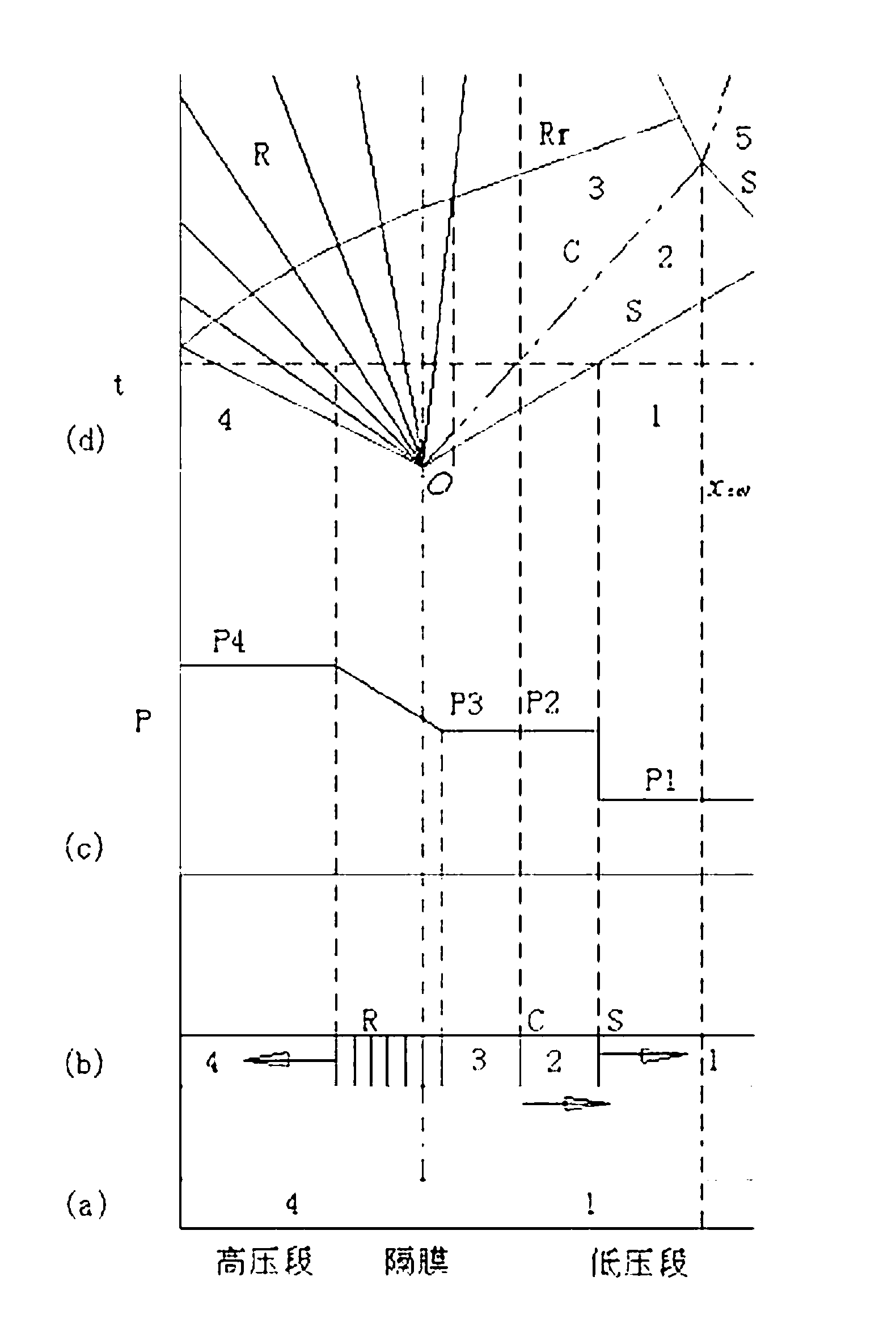

Measuring system for pressure response time of pressure-sensitive paint and temperature response time of temperature-sensitive paint

The invention discloses a measuring system for pressure response time of a pressure-sensitive paint and temperature response time of a temperature-sensitive paint. The measuring device comprises a shock tube, a shock tube test wall plate, a dynamic pressure sensor, an LED (light-emitting diode) light source, a photomultiplier and an optic quartz glass window. The measuring method comprises the following steps: adjusting the LED light source and the photomultiplier, pressurizing the high-pressure section of the shock tube by the photomultiplier to the default pressure; analyzing the time that shock wave S arrives at the test location, which is recorded by the dynamic pressure sensor; analyzing the tested paint fluorescence intensity data curve recorded by the photomultiplier; determining the time that the shock wave S sweeps through the paint fluorescence intensity and achieves 90% of the standing state, and obtaining the pressure / temperature response time of the tested paint. The measuring device is simple and reliable, and can be used for determining the pressure / temperature-sensitive paint response time which is smaller than ms magnitude.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

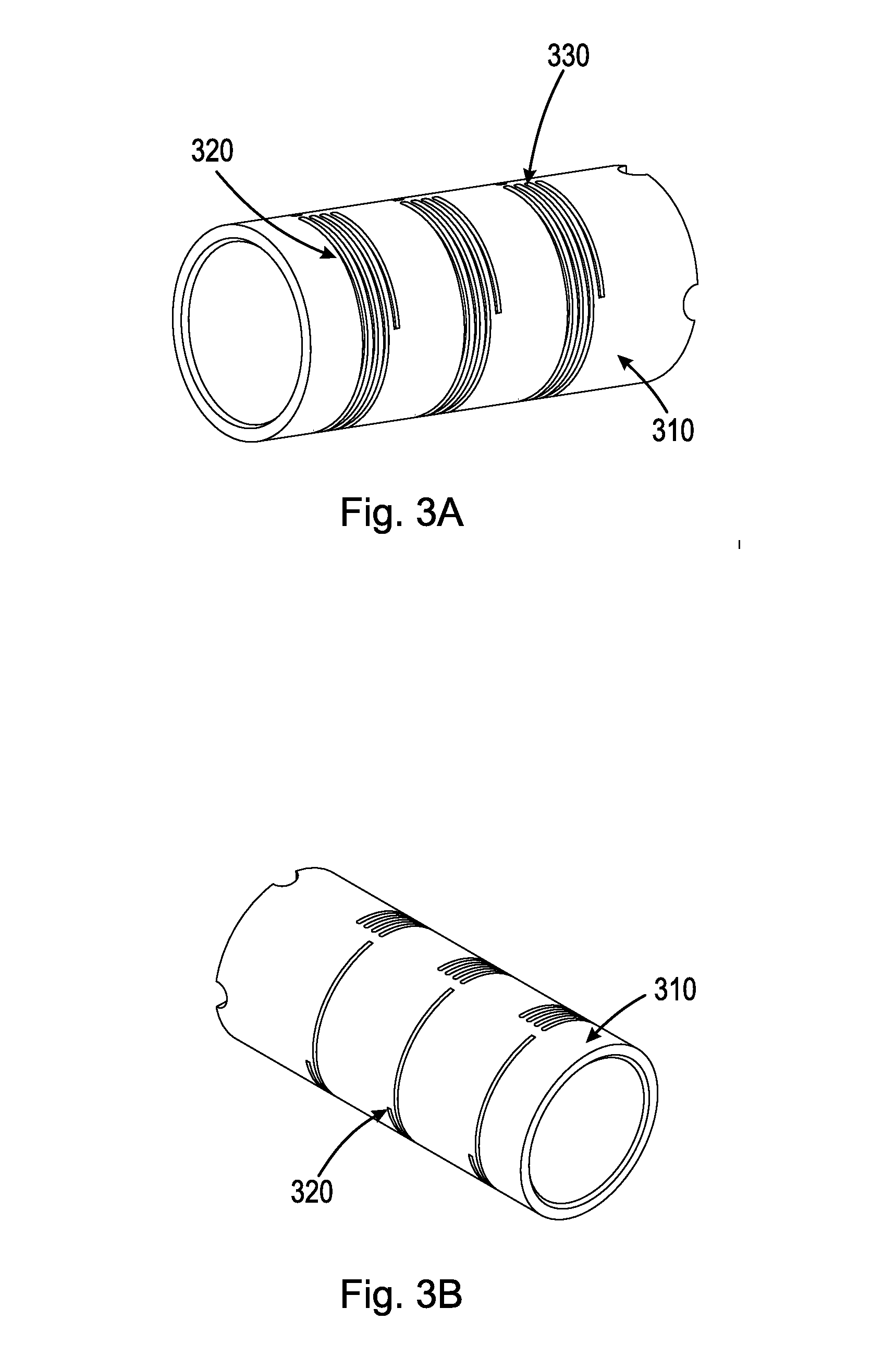

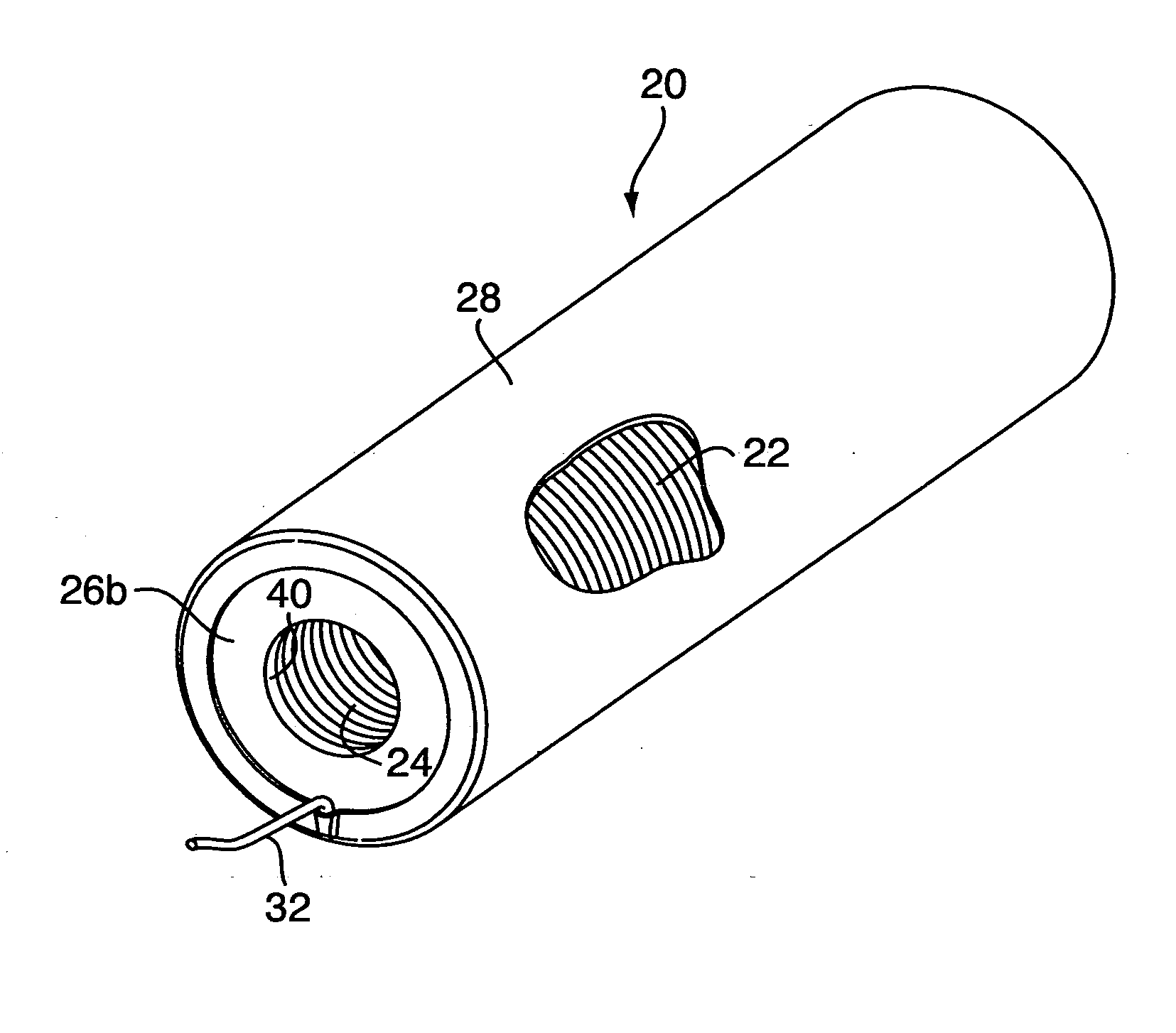

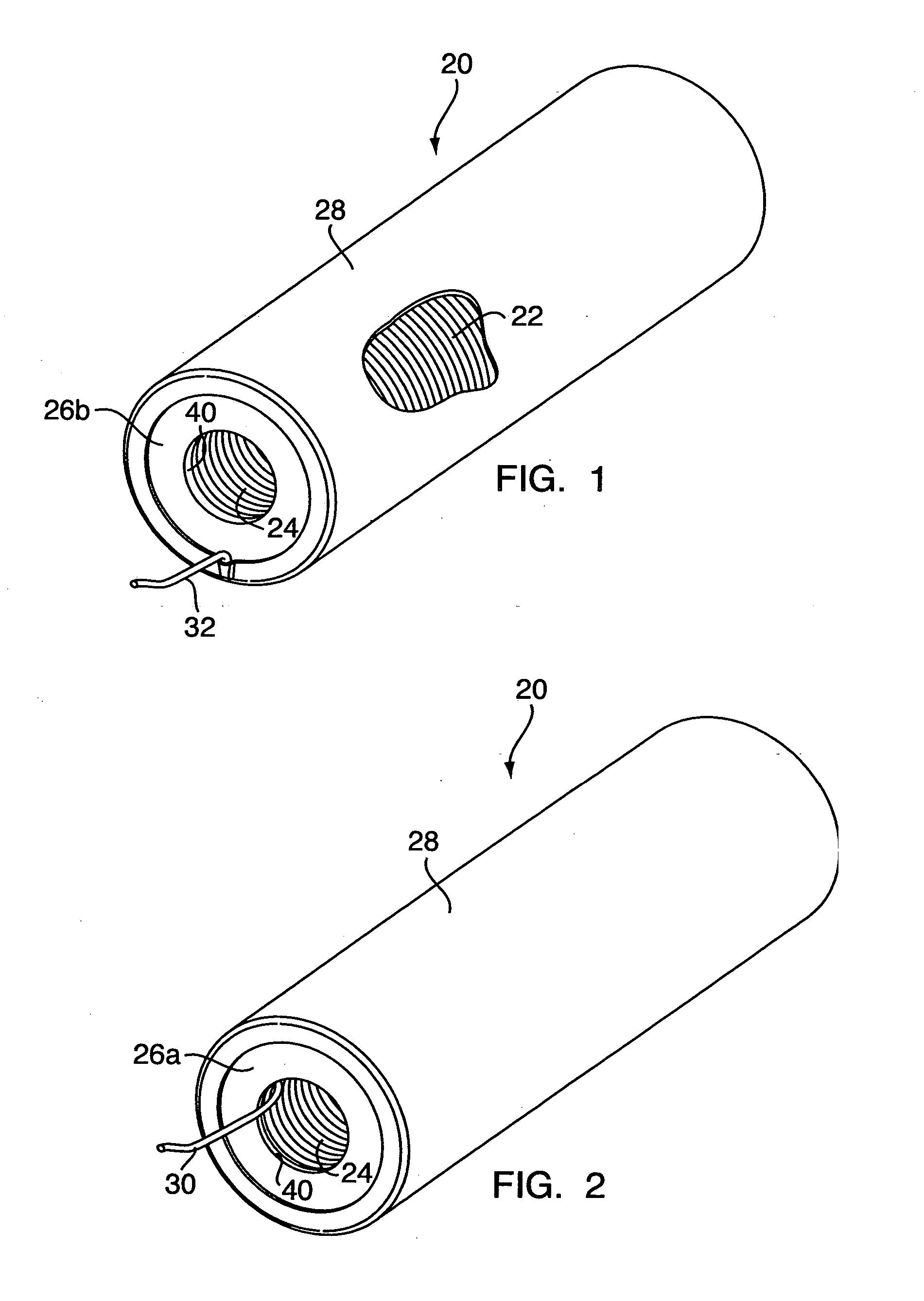

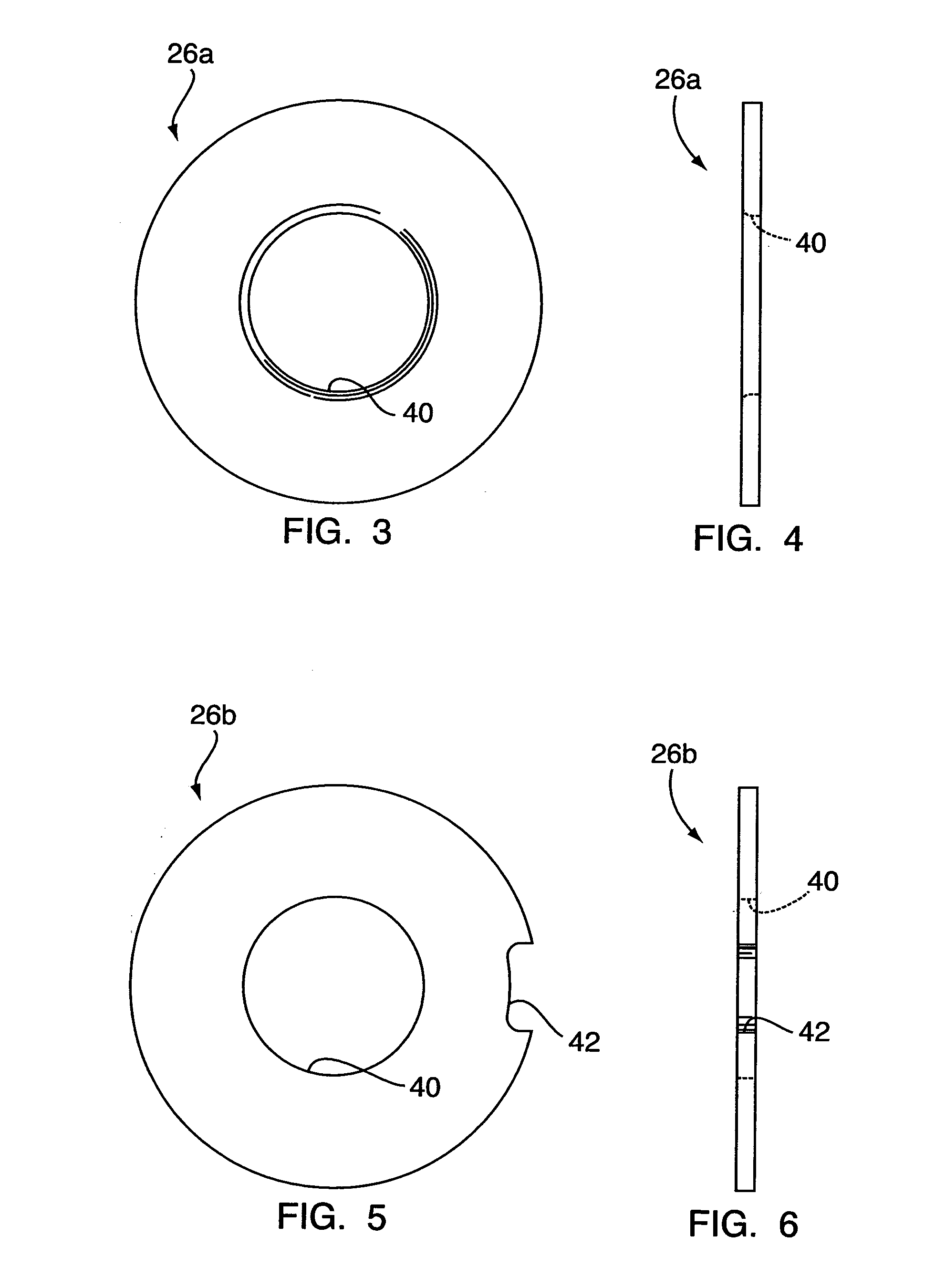

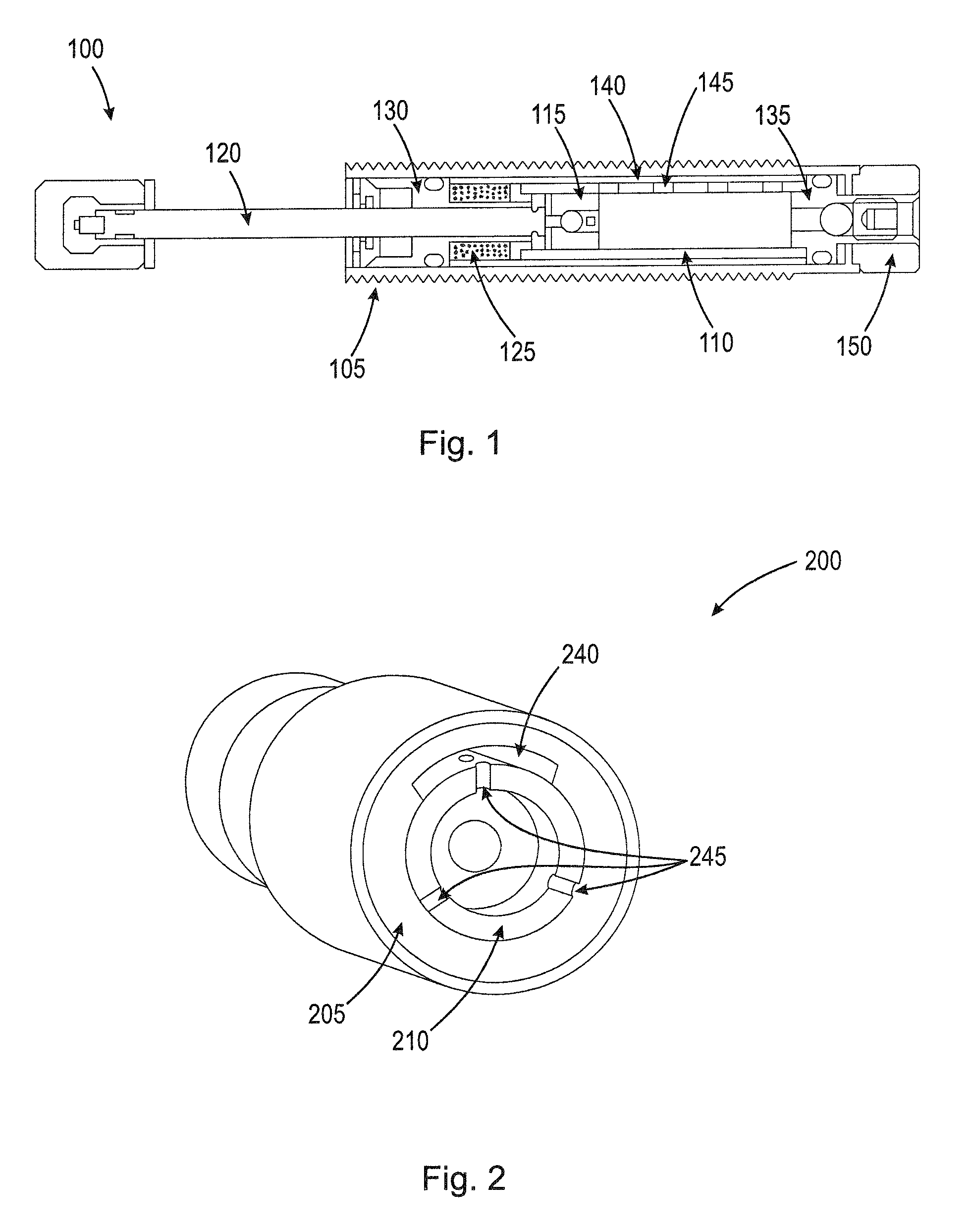

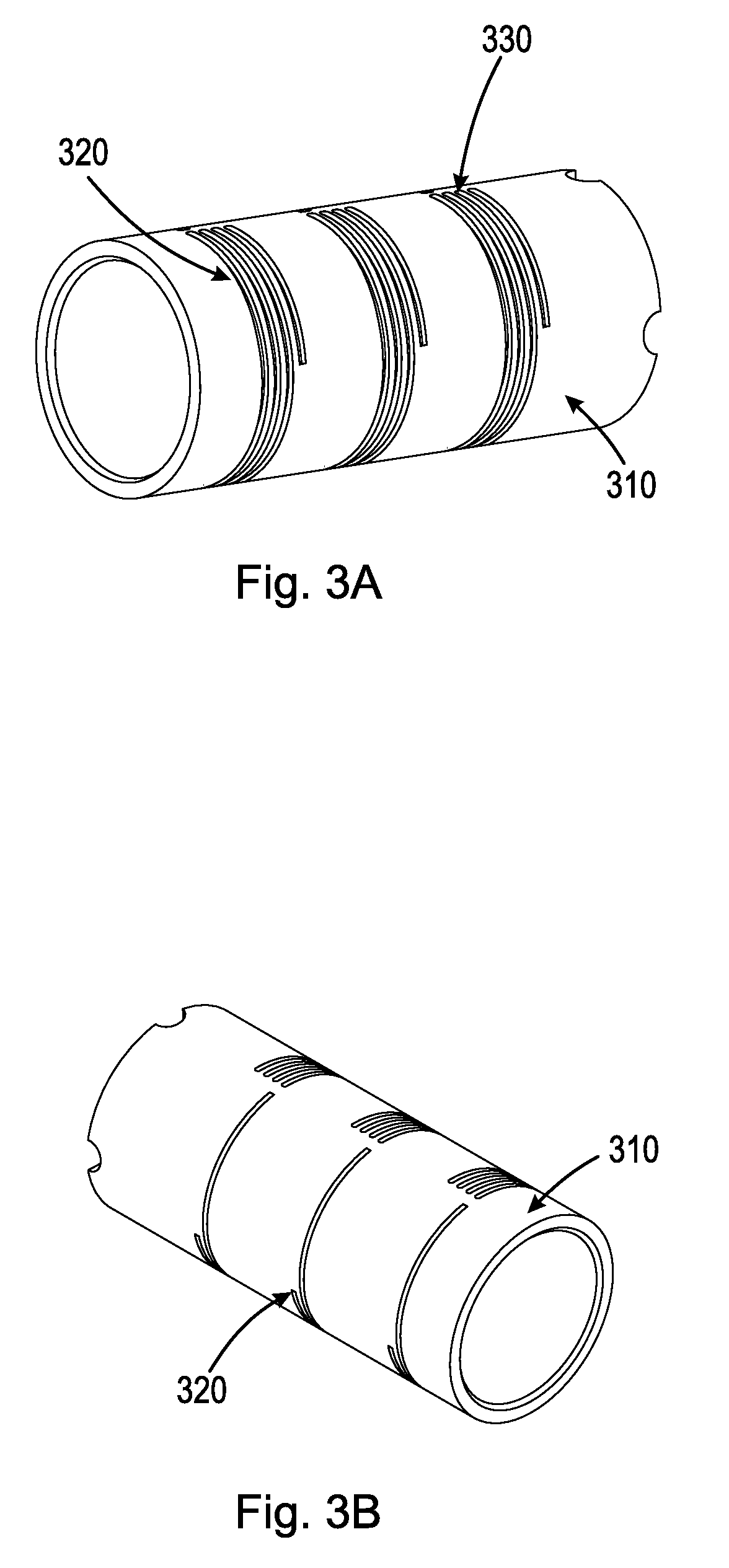

Coreless-coil shock tube package system

ActiveUS20060144279A1Easy to storeEasy to transportFuse ignition meansFilament handlingDetonatorEngineering

A coreless-coil shock tube package system includes a “coreless” bundle of shock tubing, meaning that the tubing is not wrapped around a spool. The bundle may be a generally cylindrical coil of shock tubing. Optionally, two washer-like end plates abut the ends of the tubing coil for axial support. A layer of shrink-wrap or other polymer film partially covers the coil and end plates. A detonator is attached to one end of the tubing and lies tucked into the coil, through an end plate, for storage and transport. An igniter is attached to the tubing's other end. In use, the detonator is removed from the coil and attached to an explosive device. Then, the package is pulled away from the detonator and explosive, thereby uncoiling the tubing through the end plate for deployment. The igniter is actuated for igniting the shock tubing and activating the detonator and explosive.

Owner:ENSIGN BICKFORD AEROSPACE & DEFENSE

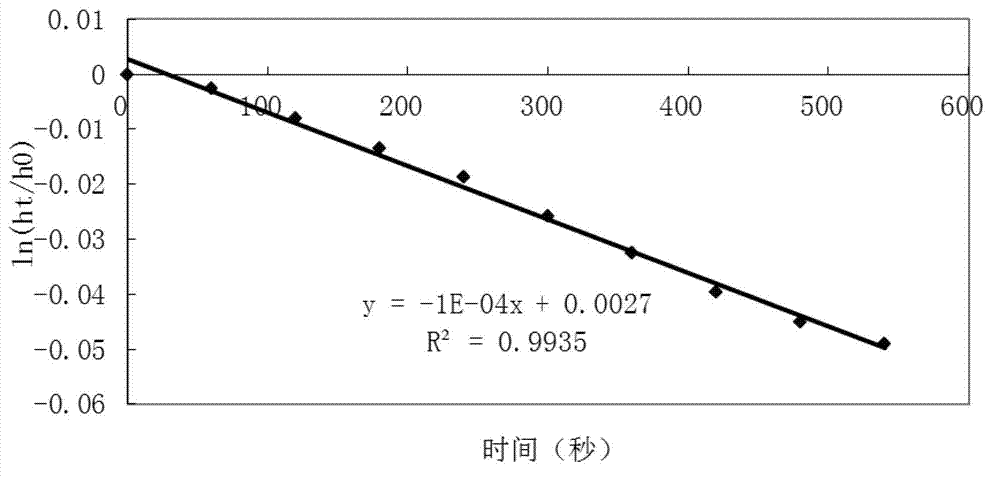

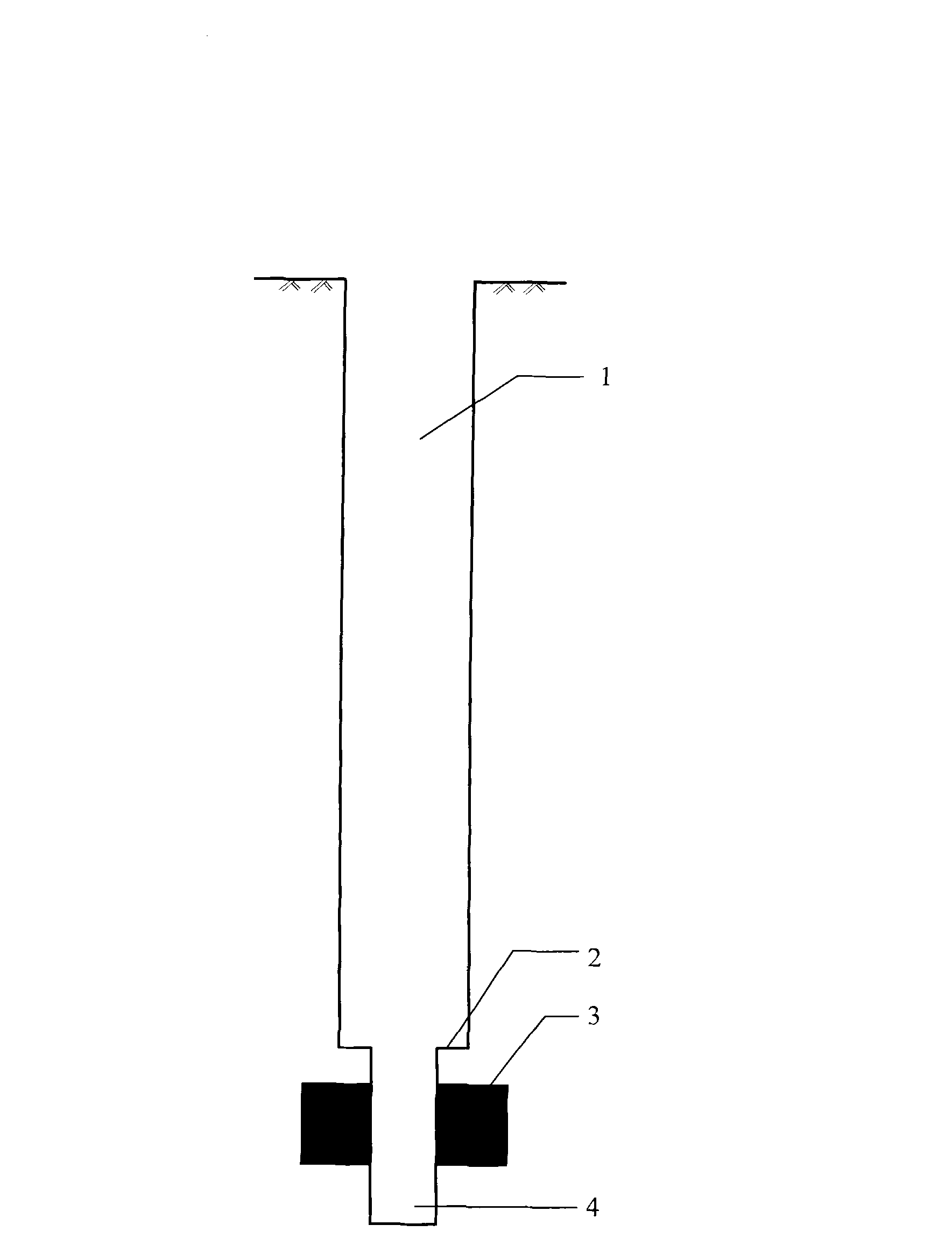

Variable water head sectional permeation coefficient measuring equipment and measuring method

InactiveCN103091229ASimple structureLow costPermeability/surface area analysisWater leakageGraduated cylinder

The invention provides variable water head sectional permeation coefficient measuring equipment which comprises a falling head micro-water testing device, a double-plug blocking device and a probe, wherein the micro-water testing device comprises a measuring cylinder and a water leakage shock tube which are connected though a water guide tube; the double-plug blocking device comprises a high-pressure air cylinder, a one-way valve, a pressure gauge, a first plug and a second plug which are connected through a gas guide tube from top to bottom in sequence; a gas valve is further arranged between the one-way valve and the pressure gauge; and the first plug, the water leakage shock tube and the second plug are arranged inside the probe from top to bottom in sequence. The invention further provides a method for measuring the sectional permeation coefficient by using the equipment. The equipment is simple in structure, low in cost and convenient to use; and the first plug and the second plug are swelled to block and isolate a section of drilling holes by compressing air using the high-pressure air cylinder, the permeation coefficient of a water-bearing layer near the drilling holes at the sealed section can be measured by using the micro-water testing device, and the measurement result is accurate.

Owner:HOHAI UNIV

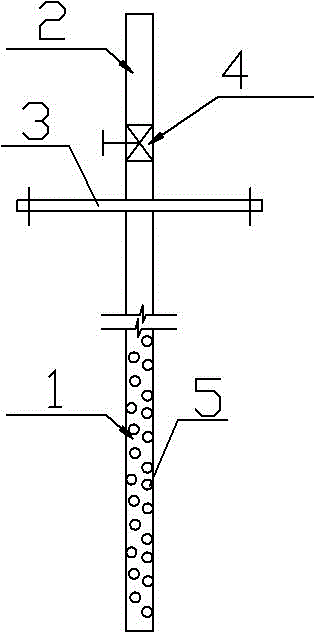

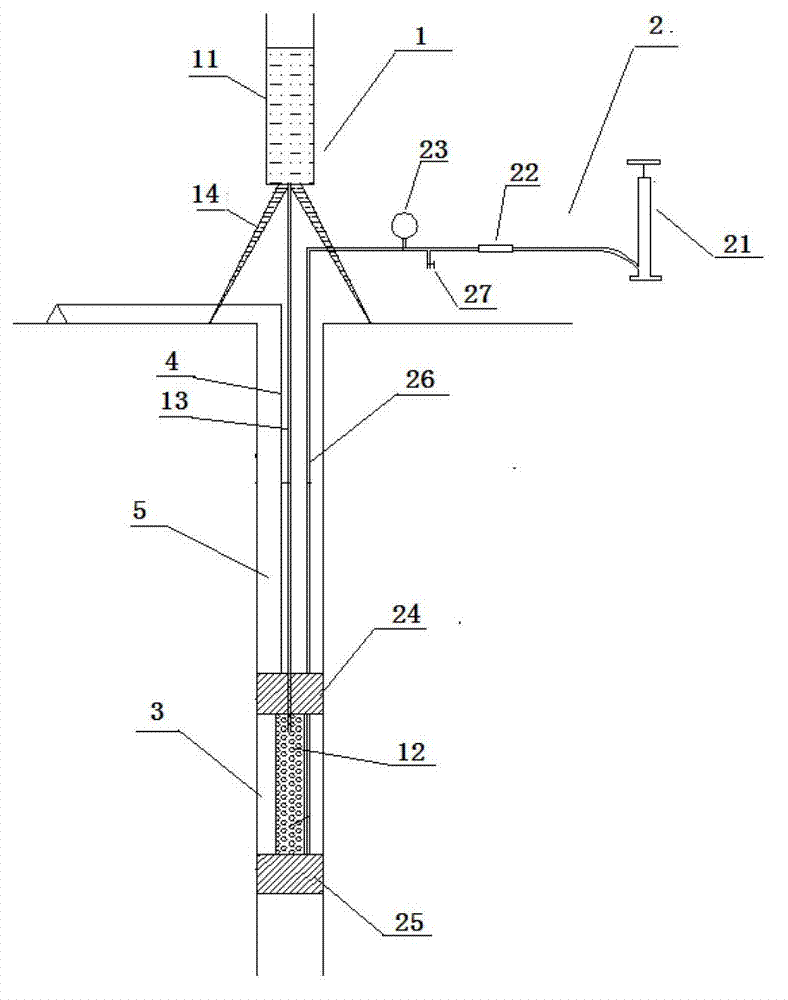

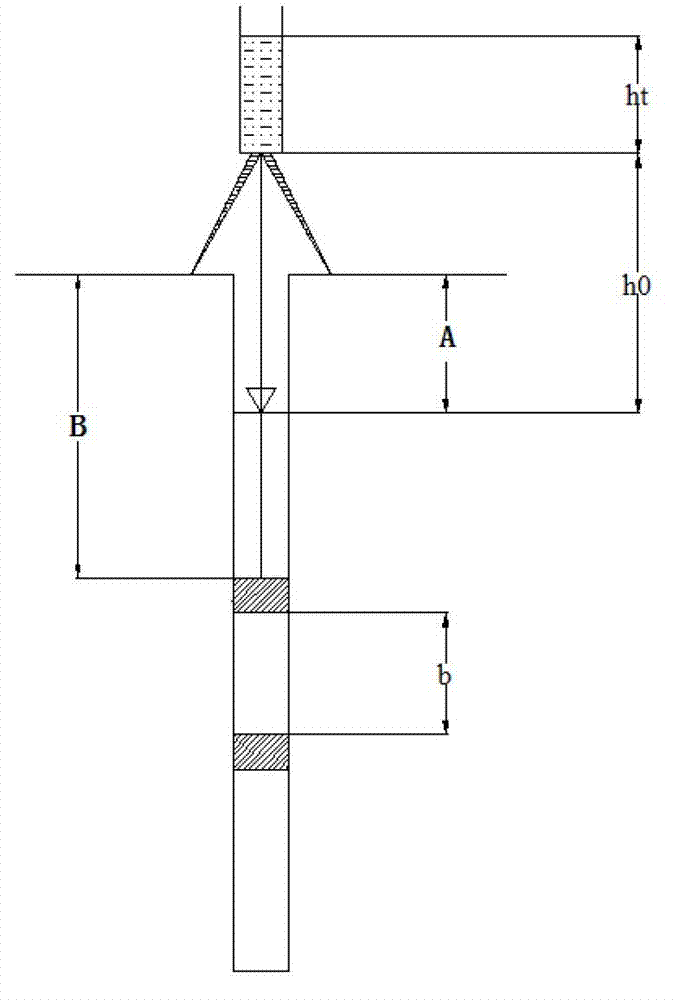

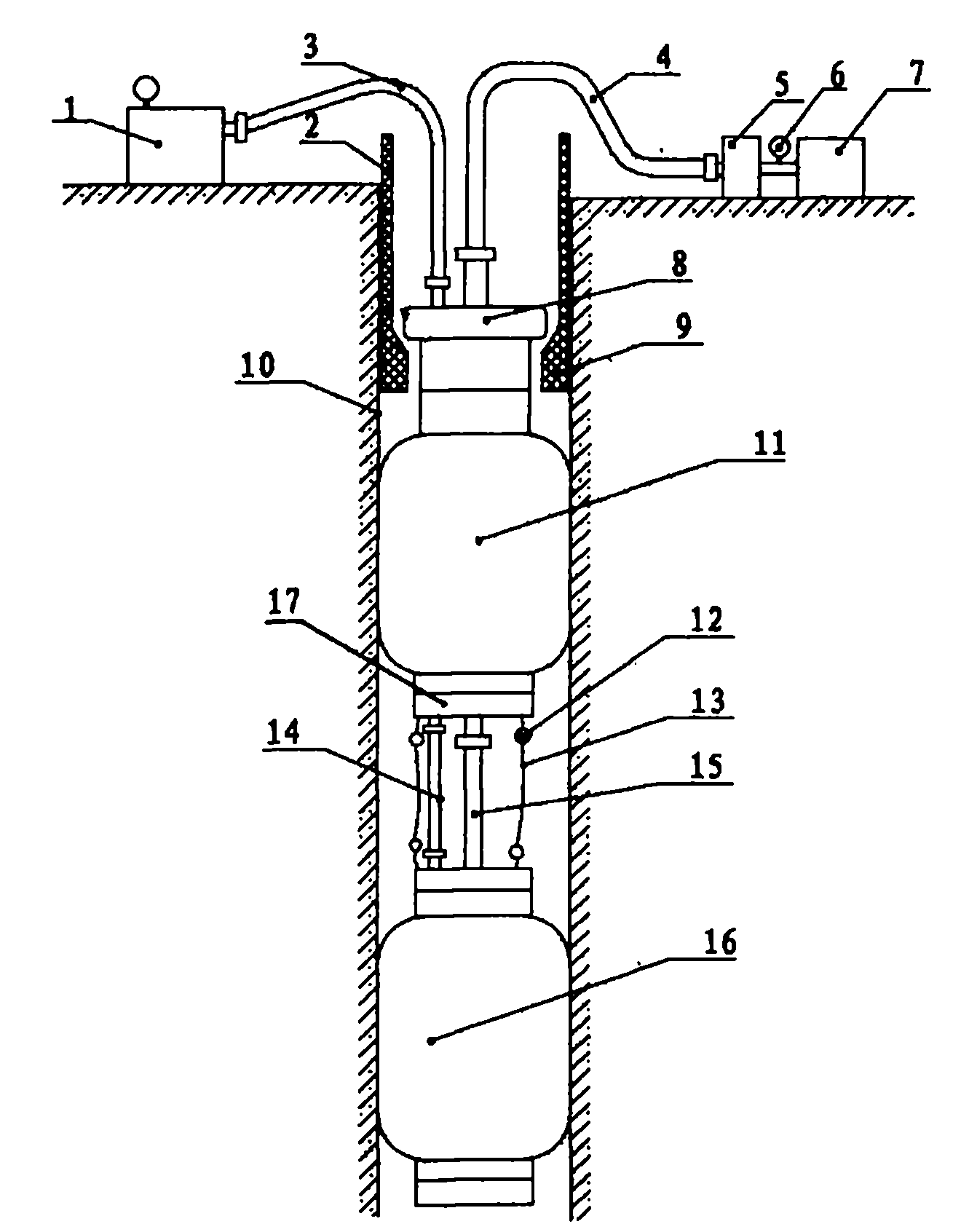

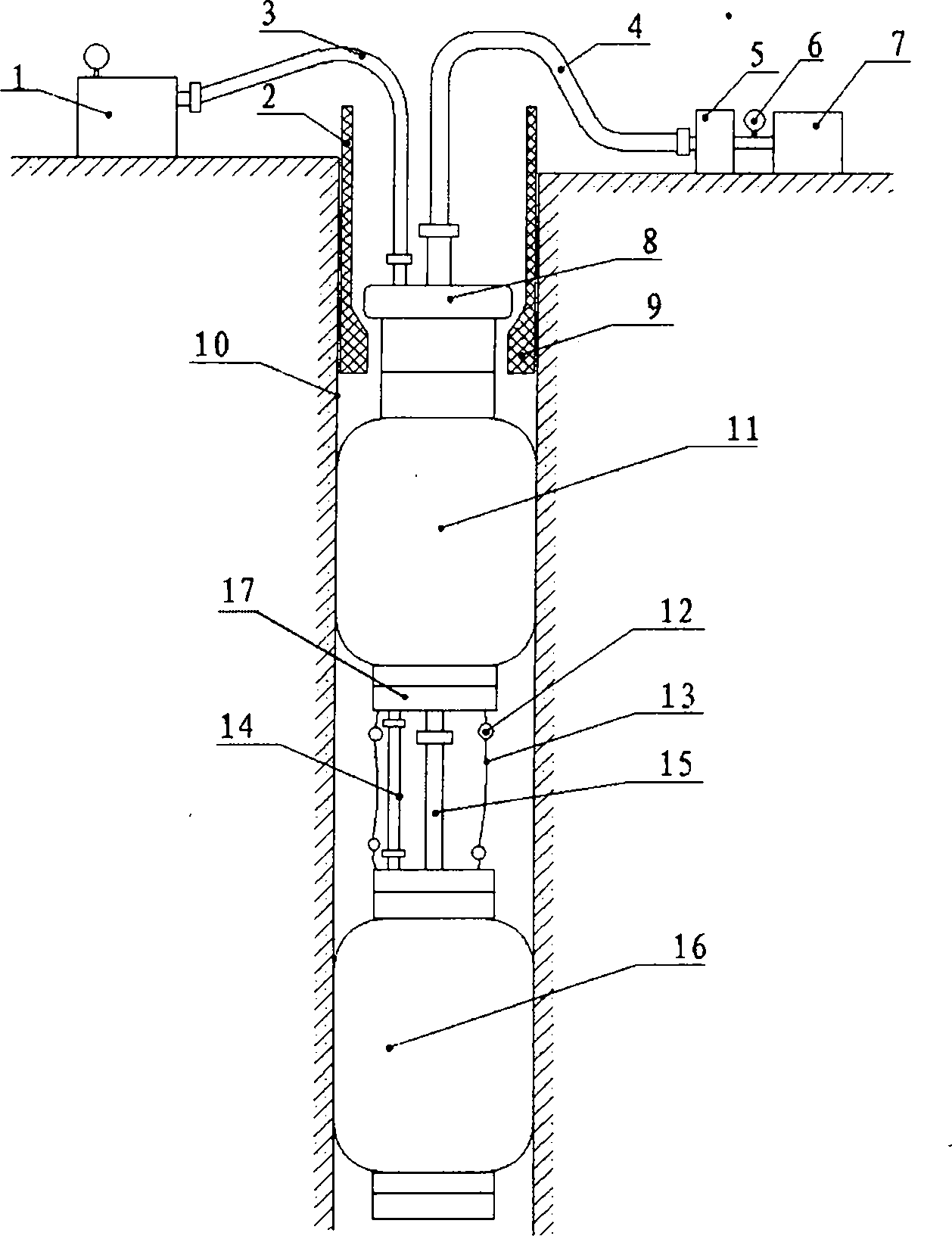

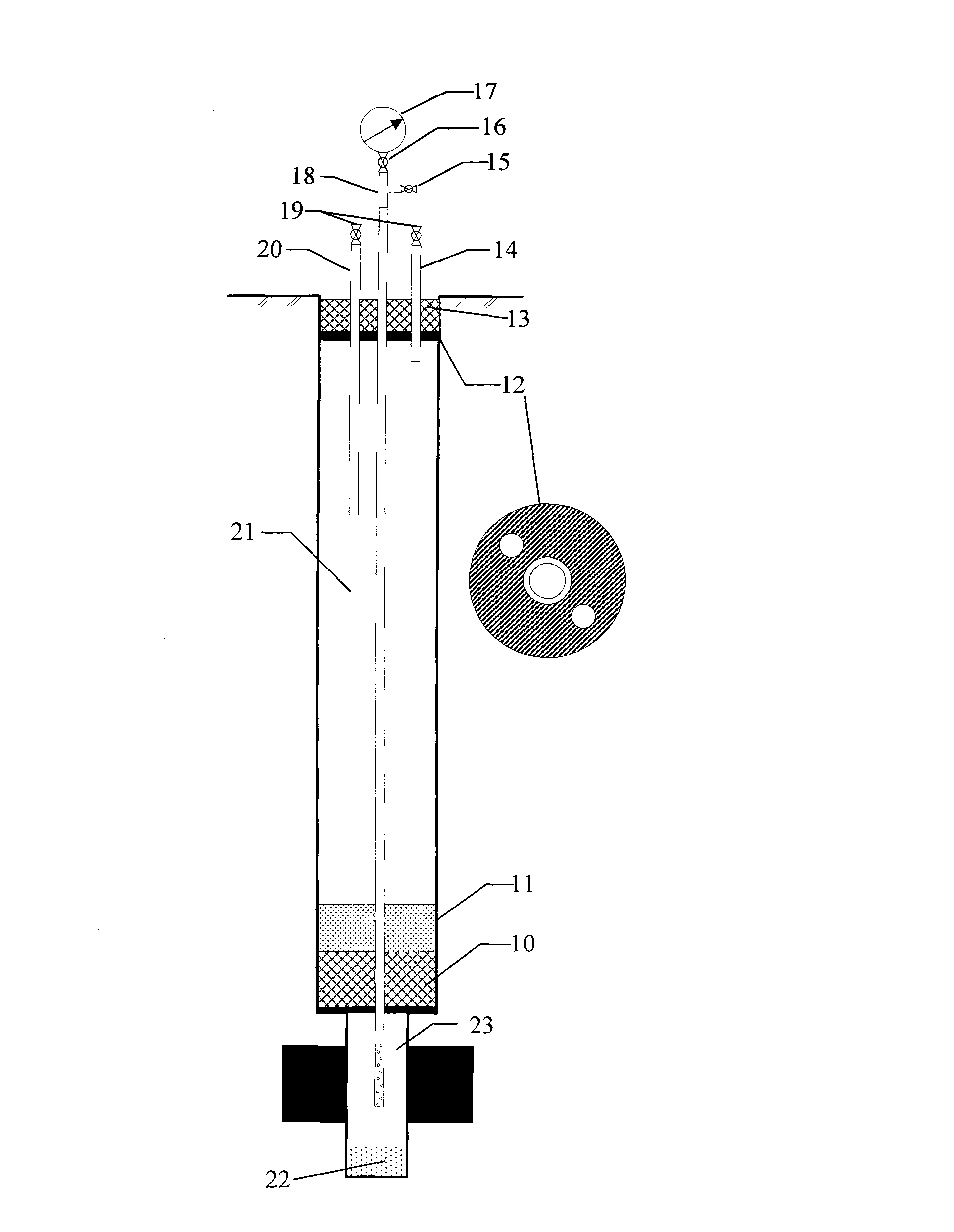

Drilling pressurized-water testing/grouting device

InactiveCN102108697ASimple structureEasy to operateIn situ soil foundationSoil preservationEngineeringAir compressor

The invention relates to a pressurized-water testing and grouting device in geological prospecting. The drilling pressurized-water testing / grouting device in the invention is composed of an air compressor / hand pump (1), an air tube (3), a locating joint (8), an air sac (11), a lower seal head (17), a communicating air tube (14), a shock tube (15), an enclosed air sac (16), a high pressure rubber tube (4) and a water / grout injection pump (7), wherein the locating joint is arranged above the air sac and is fixedly connected with the air sac into a whole, the air compressor / hand pump is communicated with the air sac by penetrating through the locating joint by virtue of the air tube, the lower end of the air sac is fixedly connected with the lower seal head, the water / grout injection pump (7) penetrates through the locating joint, the air sac and the lower seal head by virtue of the high pressure rubber tube (4) to be communicated with the shock tube, the enclosed air sac is arranged below the air sac, the two ends of the air sac are sealed by seal heads, and the communicating air tube penetrates through the lower seal head and the seal head above the enclosed air sac to cause the air sac and the enclosed air sac to be communicated.

Owner:崔开华

Downward hole pressure measuring device and process

The invention provides a downward hole pressure measuring device and a downward hole pressure measuring process. The downward hole pressure measuring device comprises a variable diameter hopper type drill hole, a drilling cuttings settling chamber, a pressure measuring shock tube, a pressure measuring tube, a grouting tube and a return tube, wherein the pressure measuring shock tube is provided with a front baffle and a ventilating hole; the pressure measuring tube sequentially passes through the front baffle, expansion materials, cotton yarns, sand stones and orifice expansion materials; a high-precision pressure gauge is installed at a part of the pressure measuring tube exceeding an orifice; and the grouting tube and the return tube sequentially pass through the orifice expansion materials. According to the downward hole pressure measuring device, as a downward hole is sealed by using the combination mode of a round baffle, the expansion materials, the sand stones, cement mortar, the expansion materials and an orifice sealing baffle, the amount of the cement mortar leaking to a pressure measuring chamber can be effectively reduced, a grouting chamber which is sealed by using double sealing baffles can improve the grouting pressure and play the role of penetration sealing on hole wall cracks. As the drilling cuttings settling chamber is reserved in the pressure measuring chamber, the pressure measuring chamber can be ensured not to be blocked so as to accurately measure the coal bed gas pressures. The downward hole pressure measuring device has the characteristics of simplicity in structure, low cost and convenience for underground operation and is easy to install.

Owner:HENAN POLYTECHNIC UNIV

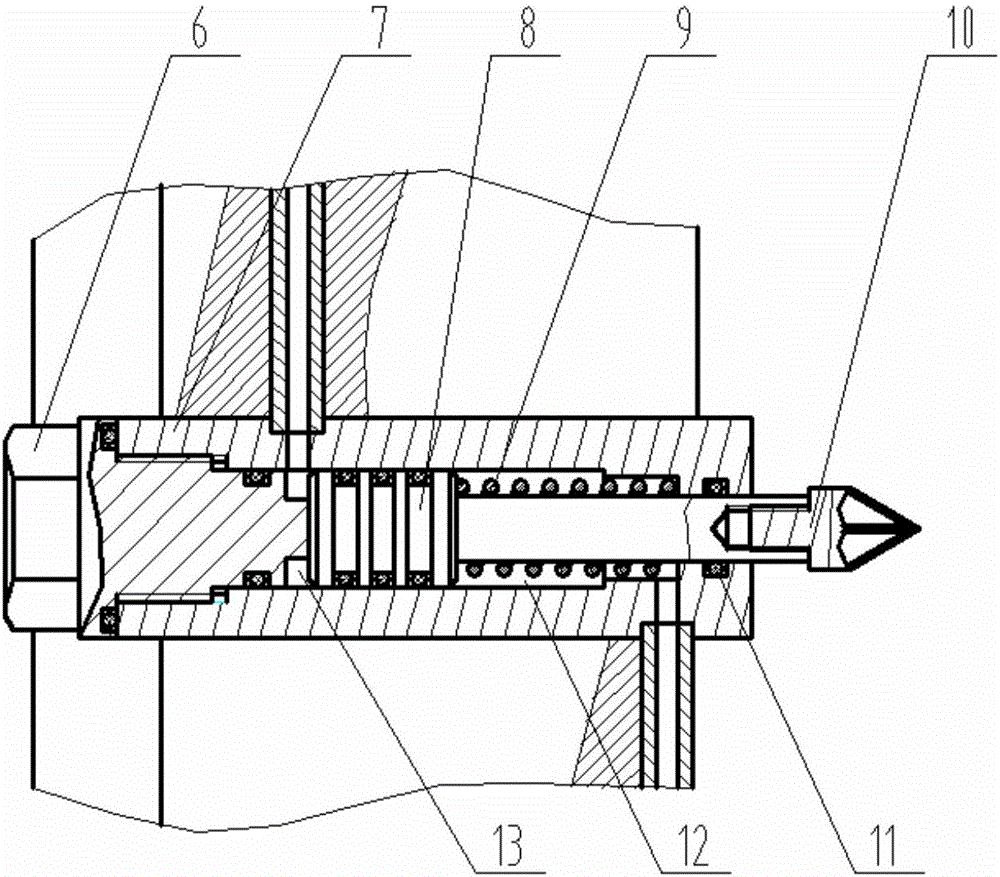

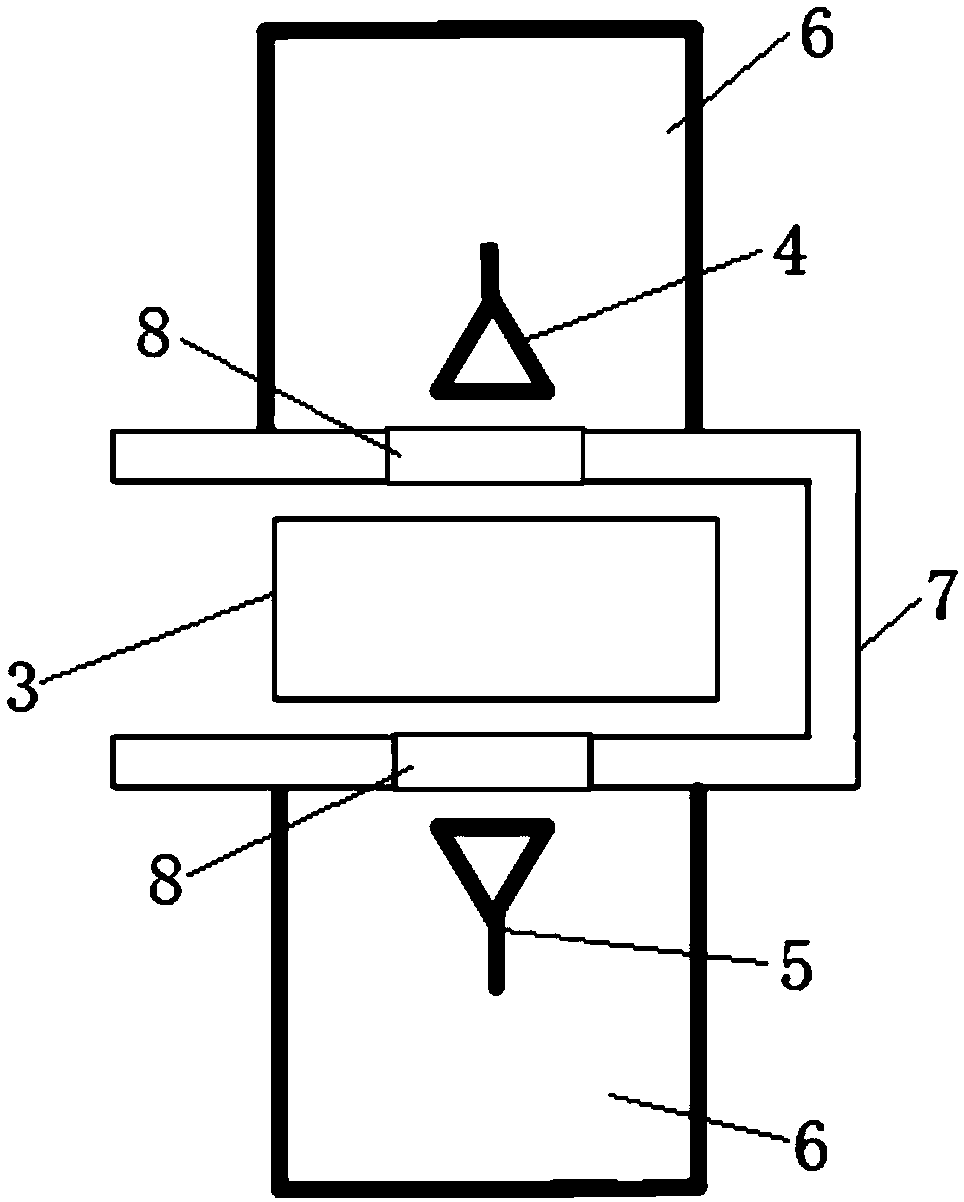

Shock tunnel diaphragm rupture device

ActiveCN106644358ASaving processabilitySave equipment investmentAerodynamic testingDiaphragm ruptureEngineering

The invention relates to a shock tunnel diaphragm rupture device and belongs to the hypersonic shock tunnel engineering field. The shock tunnel diaphragm rupture device includes a gun barrel connection structure, a cone supporting plate, a diaphragm rupture cone, a high-pressure cavity pipeline, a low-pressure cavity pipeline, a shock tube high-pressure section gun barrel, a shock tube low-pressure section gun barrel and a diaphragm; the left side of the gun barrel connection structure is fixedly connected with the shock tube high-pressure section gun barrel; the right side of the gun barrel connection structure is fixedly connected with the shock tube low-pressure section gun barrel; the cone supporting plate is fixedly installed in the gun barrel connection structure; the diaphragm rupture cone is axially and fixedly installed at the axis of the cone supporting plate through the gun barrel connection structure; the high-pressure cavity pipeline and the low-pressure cavity pipeline are arranged at the outer wall of the diaphragm rupture cone along the radial direction of the gun barrel connection structure; and the diaphragm is fixed between the gun barrel connection structure and the shock tube low-pressure section gun barrel. The diaphragm rupture of a shock tunnel can be both realized under high driving pressure or low driving pressure, diaphragm rupture time is significantly shortened, and the controllability of the diaphragm rupture process is high.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Detonator system with high precision delay

InactiveUS8261663B2Save energyCheap manufacturingIncandescent ignitionBlasting cartridgesDetonatorElectrical battery

An electrical delay detonator for use in blasting initiation systems energized by a non-electric impulse signal transmitted through a non-electrical conduit, such as a shock tube, with one end inserted inside a detonator housing having redundant sensors for detecting the presence of a non-electric impulse signal and a computerized control circuit for actuating the firing circuit. An elevated voltage is generated, stored in a capacitor assembly, and discharged when fired to an electrically operable igniter. The igniter, when activated, detonates an explosive mass. A battery is also contained within the detonator housing for powering the control circuit and one sensor, in low consumption mode, for several days. Upon detecting the presence of a signal the rest of the circuits are powered up. Periodic time windows generated by the control assembly provide corresponding enabled time periods for the sensors to become operational.

Owner:IND MINCO S A C

Shock absorber with variable damping profile

Disclosed herein in an energy absorption device that incorporates a diverse range of uses within a single shock absorber. The disclosed energy absorption device is a novel combination of interaction between various components (e.g., piston head, shock tube, cylinder end, external cylinder, and adjustment mechanism) within a single shock absorber. When the components disclosed herein are considered together and designed as an interrelated assembly, the ability to incorporate such a diverse range of uses within a single device emerges. The ability to combine dashpot, square wave, progressive wave, and self-compensating damping in a single device is unprecedented, as is the ability to deliver sublinear damping force vs. input velocity performance in an adjustable device. The disclosed device allows a user to make simpler sizing calculations and decisions, and provides the user with the ability to adjust the shock absorber to a specific application, for example, with the turn of an adjustment knob.

Owner:KYNTEC

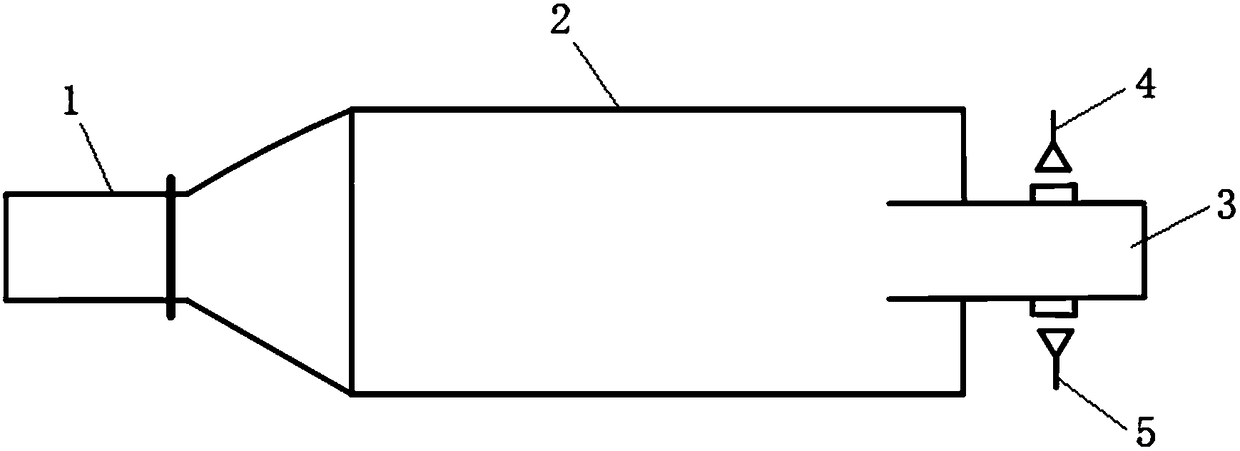

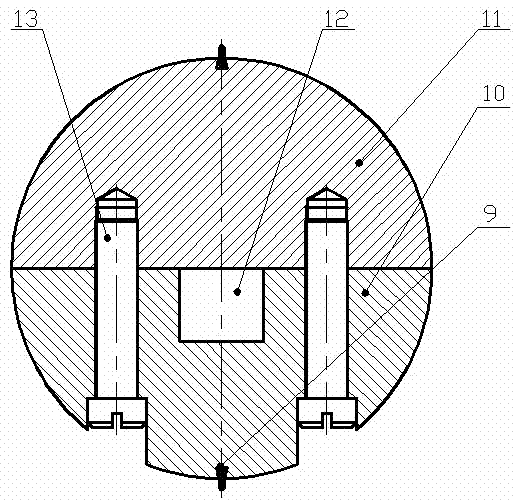

Antenna-shock tube-antenna plasma electromagnetic characteristic simulation method and system

ActiveCN108229067ALow costThe simulation process is reasonableDesign optimisation/simulationSpecial data processing applicationsElectromagnetic simulationShock tube

The invention discloses an antenna-shock tube-antenna plasma electromagnetic characteristic simulation method and system. The method comprises: determining dimensions of a shove tube experimental apparatus, electromagnetic parameters of a material used, structure, and experimental conditions; determining the size and structure of a simulation area; determining electromagnetic parameters of the material, and building a three-dimensional electromagnetic simulation model of the simulation area in a program; performing simulating according to the experimental conditions to obtain flow field distribution in a shock tube experimental segment; coupling simulation data of a flow field to meshes of the three-dimensional electromagnetic simulation model to obtain flow field data on the full-space electromagnetic meshes; coupling flow field mesh parameters to electromagnetic mesh parameters; filling the three-dimensional electromagnetic simulation model with the flow field electromagnetic parameters, and running the simulation program to obtain simulation results. A real simulation process is simulated via the program, flow field simulation and electromagnetic simulation are combined, and therefore, plasma interaction of electromagnetic wave with plasma in a shock tube is more truly simulated.

Owner:XIDIAN UNIV

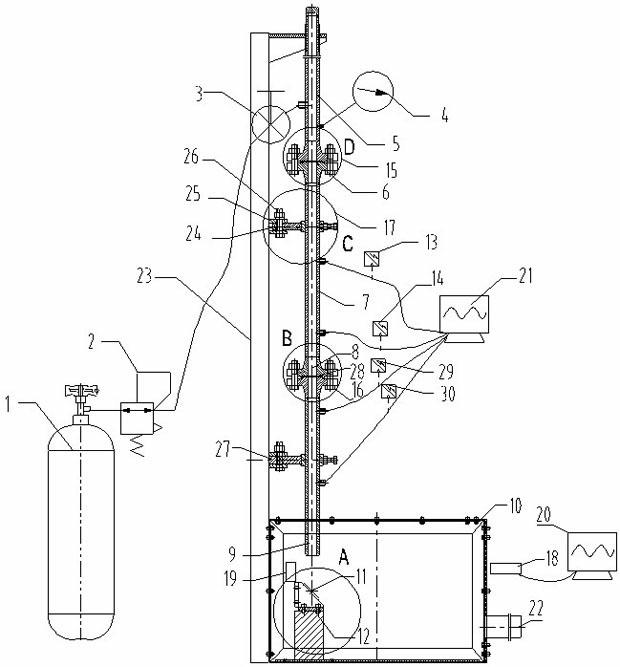

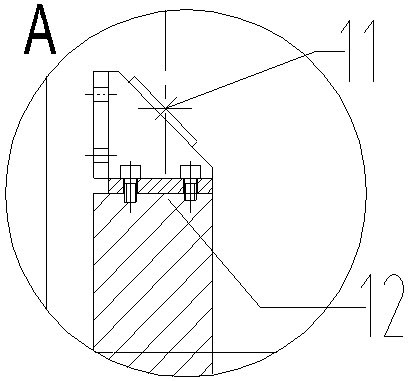

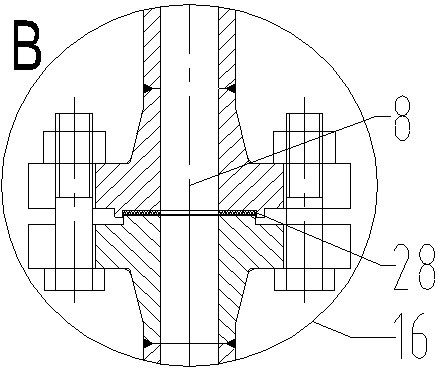

Shock tube type combustible gas explosion experiment device

InactiveCN102930770AEasy to collectEliminate the step of vacuumingEducational modelsCombustible gasEngineering

The invention discloses a shock tube type combustible gas explosion experiment device. The device comprises a tubular explosion test barrel, wherein the explosion test barrel is transversely arranged on a bracket; an opening and an explosion-proof membrane for sealing the opening are arranged at the front end of the explosion test barrel; the explosion test barrel is connected with a gas supply device for injecting normal-temperature normal-pressure combustible gas into an inner cavity of the barrel; the explosion test barrel is provided with a pressure sensor for sensing pressure in the barrel, a monitor for monitoring gas concentration in the barrel and an igniter for igniting gas in the barrel; the pressure sensor is connected with a display module for displaying a pressure value in the barrel; and the rear end of the explosion test barrel is sealed. The device disclosed by the invention is simple to operate and low in cost, and can replay the flame state at the moment of explosion and display the pressure change in the explosion barrel and the explosion sound.

Owner:ZHEJIANG UNIV OF TECH

Shock-wave sand stone extinguishing cannon

InactiveCN101073695AFire extinguishing materials are readily availableImprove fire extinguishing efficiencyFire rescueFiltrationTubes types

The invention is concerned with shock sand-grave fire extinguishing cannon, a fire extinguishing system for forest and grassland with sand-gravel and dust. It relates to compressed gas supply, compressed gas cut-off valve, shock tube, separating valve of shock tube sand-grave cannon, sand-grave cannon, sand-grave, sand-grave transportation framework and sand-grove mining machine. The tube type of shock tube is separated into high press cavity and low press cavity by on-off valve of film. The compressed gas supply is made up of air compressor and gas storage connecting with the tube of shock tube. The separating valve of shock tube sand-grave cannon connects with shock tube and sand-grove cannon. The sand-grave transportation framework is in type of chain or spire, and its front part connects with vibration filtration framework to sand mining machine, and its back part connects with the sand-filling hole to sand-grave cannon. The compressed gas supply connects with shock tube by compressed gas cut-off valve. The material to put out a fire is familiar and the invention has high efficiency and effect, long cannon-shot to save energy sources.

Owner:QINGDAO UNIV

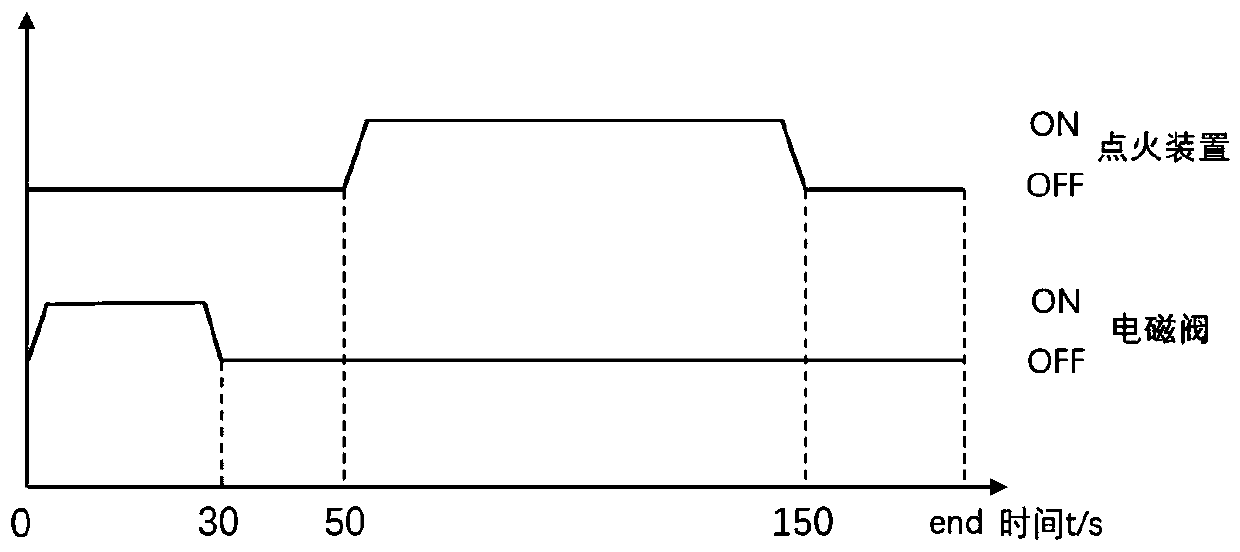

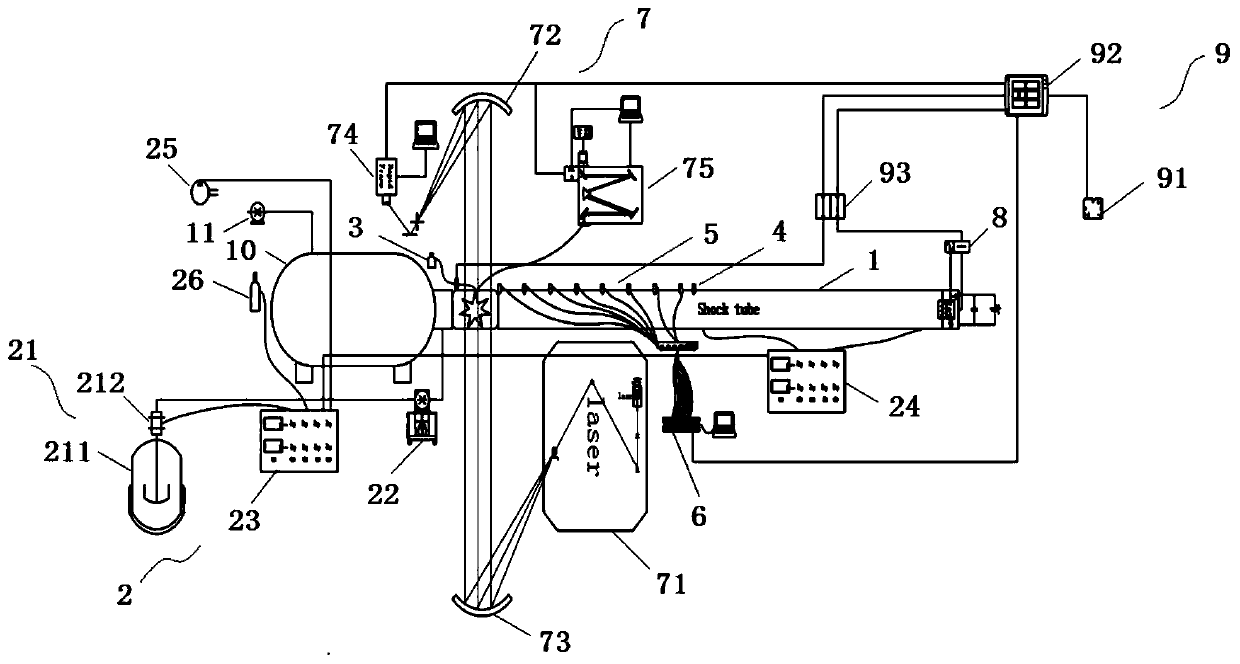

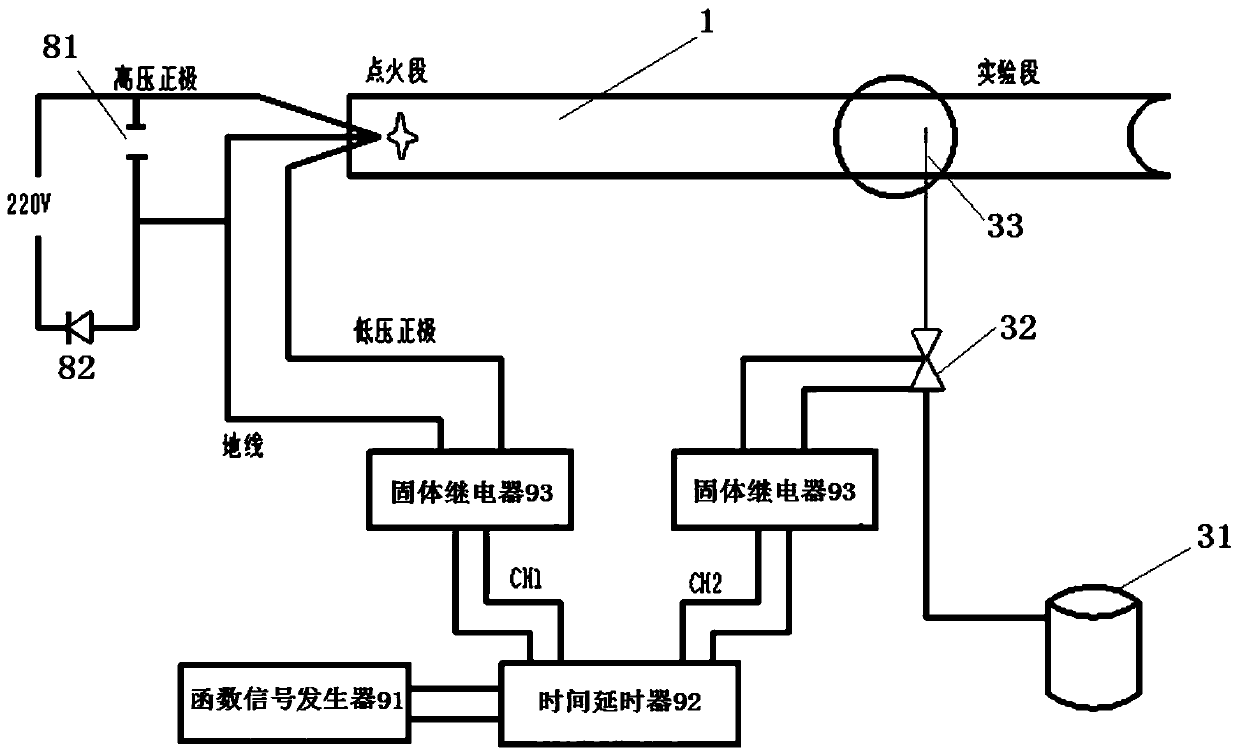

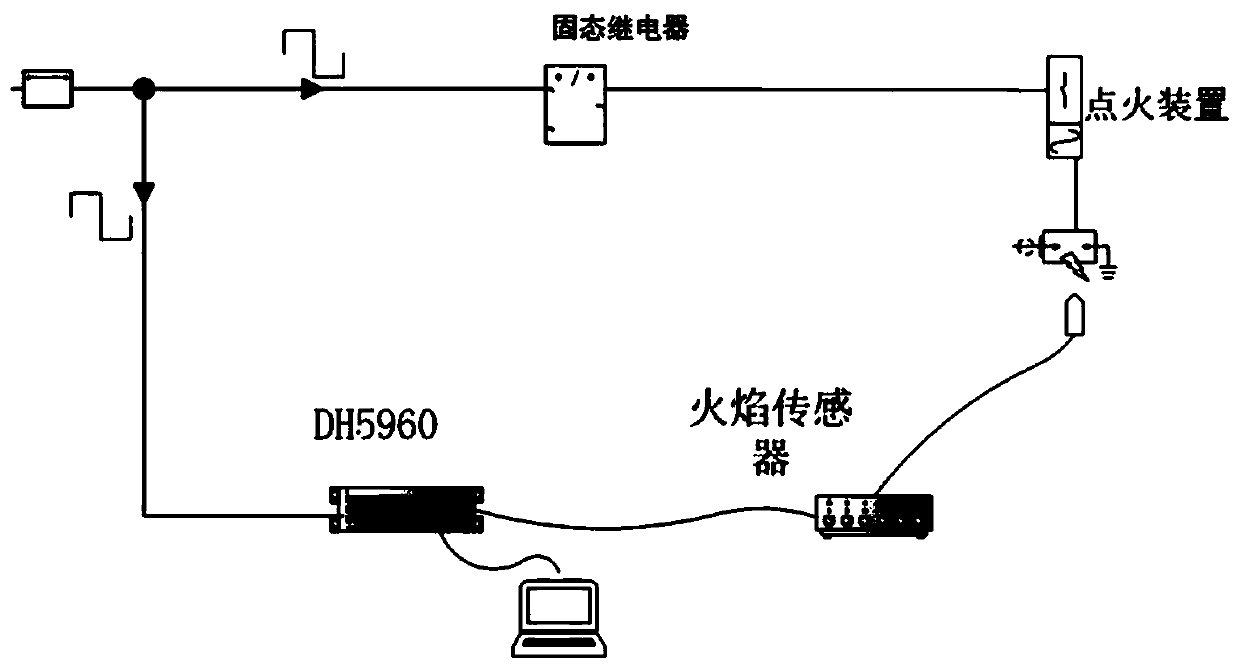

System and method for realizing synchronous control of multiple targets in deflagration experiment test system

PendingCN111122653AGuaranteed vacuumAccurate researchMaterial exposibilityData acquisitionEngineering

The invention relates to a system and a method for realizing synchronous control of multiple targets in a detonation experiment test system. The system comprises a shock tube, a premixed gas supply system, a flame retardant injection system, a flame signal acquisition system, a pressure signal acquisition system, a data acquisition system, a laser schlieren system, a high-pressure ignition systemand a synchronous control system for controlling the systems, the shock tube comprises a plurality of experiment pipelines and a visual observation window experiment section which are connected in sequence; the premixed gas supply system is communicated with the interior of the shock tube to generate premixed gas with a preset equivalence ratio and input the premixed gas into the shock tube; the flame retardant spraying system is connected with the visual observation window experiment section; the flame signal acquisition system and the pressure signal acquisition system are arranged on the side wall of each section of experiment pipeline; the laser schlieren system is used for measuring distribution images of typical free radical concentration and temperature of the deflagration flow field; the high-pressure ignition system is connected with the end of the shock tube and used for ignition. The system and the method can be widely applied to the field of safety science and technology.

Owner:NORTH CHINA INST OF SCI & TECH

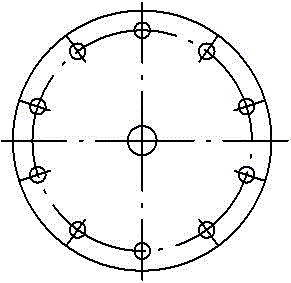

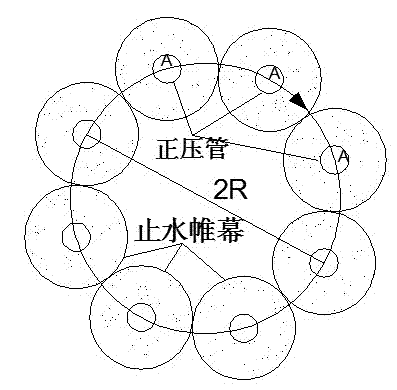

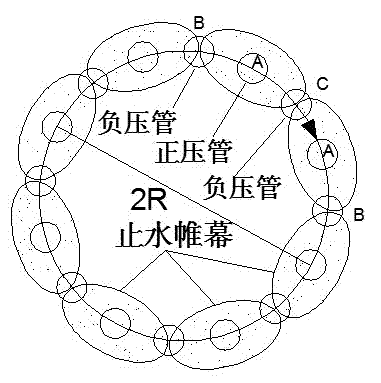

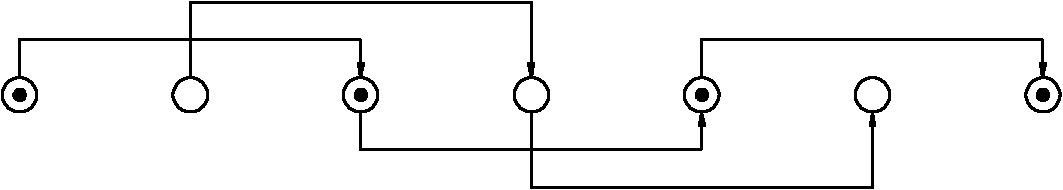

Positive pressure and negative pressure combined grouting method

The invention relates to a positive pressure and negative pressure combined grouting method, belonging to a method for formation of a waterproof curtain and grouting and water plugging of cracking rocks in underground project construction. According to the method, three grouting shock tubes, two negative pressure grouting tubes and one positive pressure grouting tube are adopted, the two negative pressure grouting tubes are connected with a vacuum pump of 1 standard atmospheric pressure, and the one positive pressure grouting tube is connected with a slurry storage tank. Under effects of a pressure gradient formed by positive pressure and negative pressure, slurry flows with smaller resistance and at a higher speed along a cracking channel formed by a positive tube A, a negative tube B and a negative tube C, the tube A and the tube B are moved clockwise into an area adjacent to the tube C when the slurry is diffused to the centers of the negative tube B and the negative tube C, and the steps are repeated until a round closed waterproof curtain is formed. By adopting the method, slurry blockage in the traditional single-tube pressure grouting method can be avoided, the waterproof curtain can be formed easily, slurry can be saved, and significant technical advantages and economic values can be achieved, and the method is particularly suitable for sand layers, silt layers and cracking rocks with good water permeability.

Owner:CHINA UNIV OF MINING & TECH

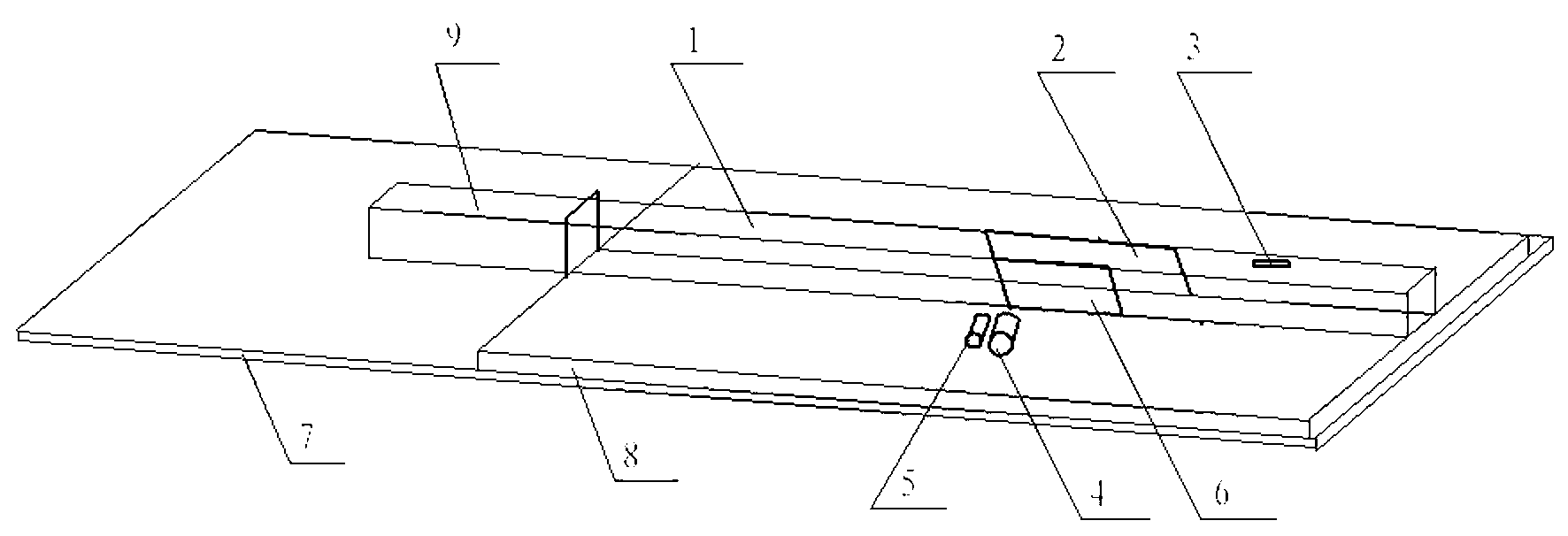

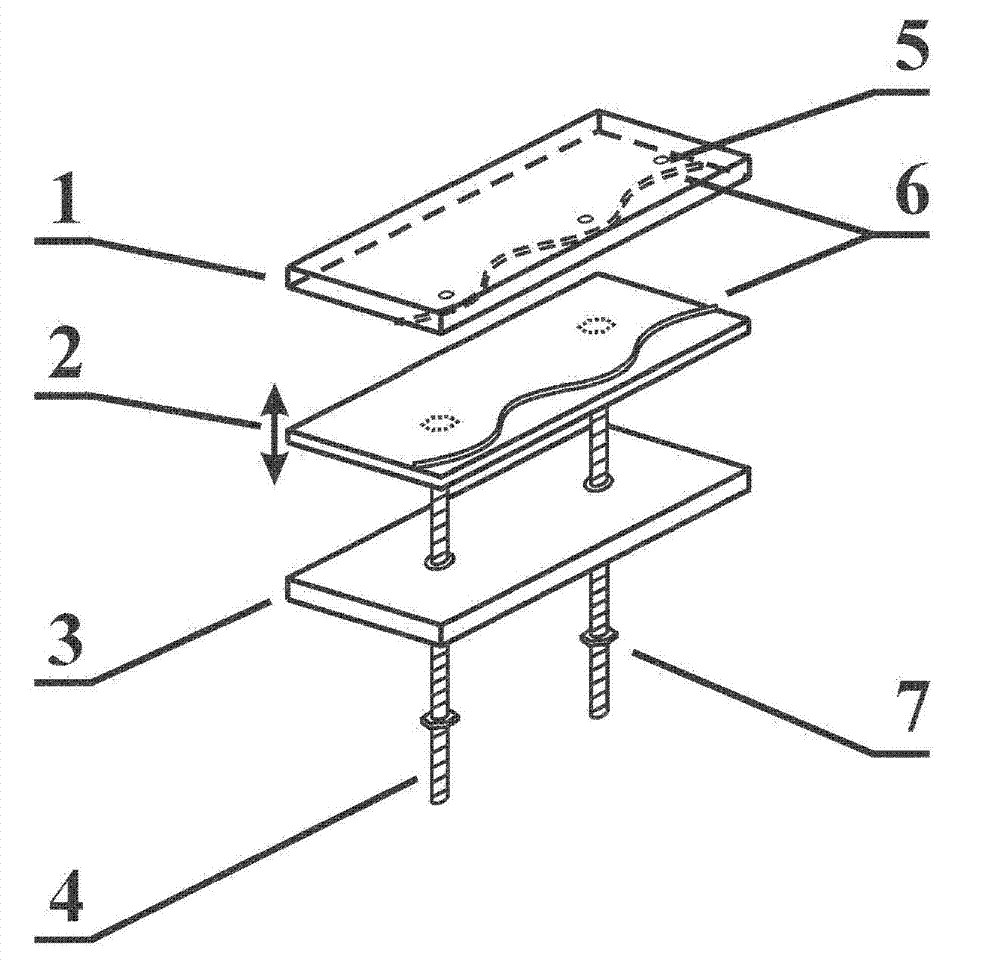

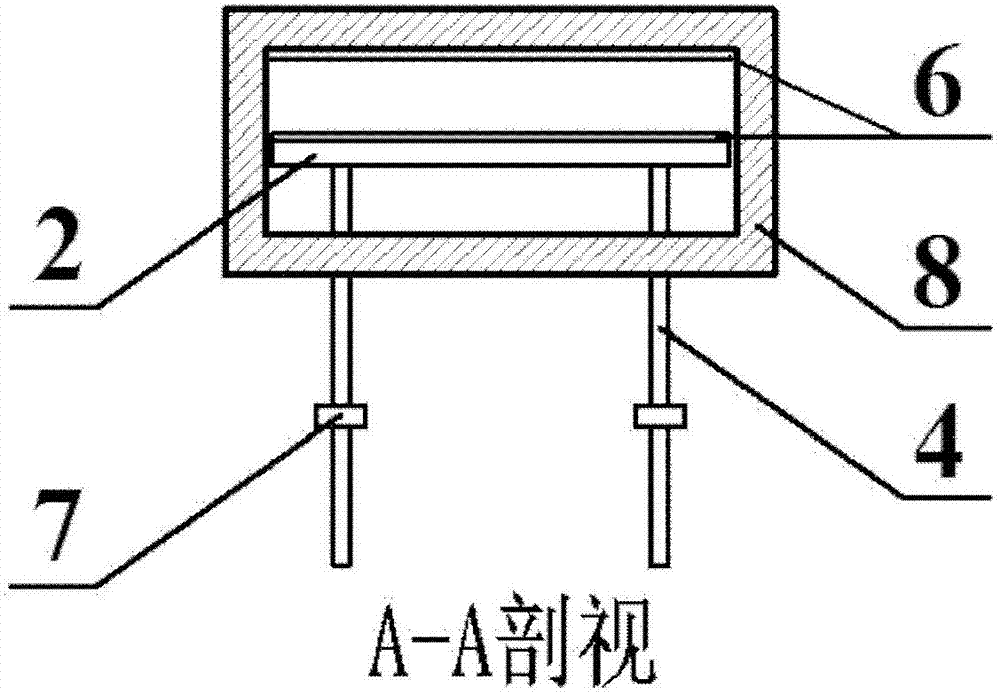

Interface generation device for shock tube experimental study

InactiveCN102759439ASimple structureReasonable settingAerodynamic testingEngineeringMechanical engineering

The invention discloses an interface generation device for a liquid film required by a shock tube generation experiment. The interface generation device comprises a top fixed plate, a bottom fixed plate, a movable plate and interface attachment lines, wherein the top fixed plate and the bottom fixed plate are parallel to each other at a fixed distance and used for fixing the entire device, the movable plate is arranged between the top fixed plate and the bottom fixed plate, the lower surface of the top fixed plate and the upper surface of the movable plate are respectively provided with a slot, the two slots are correspondent in position in a vertical direction and symmetrical in shape relative to a horizontal plane, and are used for fixing the interface attachment lines, the interface attachment lines are used for attaching the liquid film, and the movable plate is used for making the two interface attachment lines contact or separate mutually. The entire interface generation device disclosed by the invention is simple and reasonable in structure and convenient to install, and thus, the experimental efficiency can be increased.

Owner:UNIV OF SCI & TECH OF CHINA

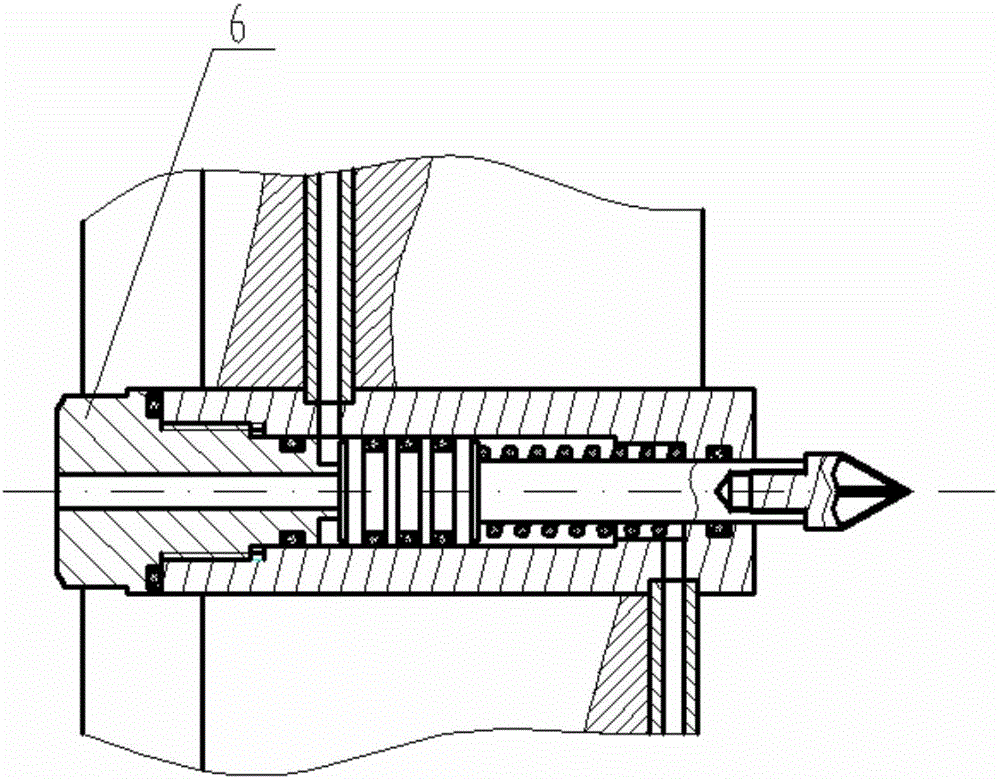

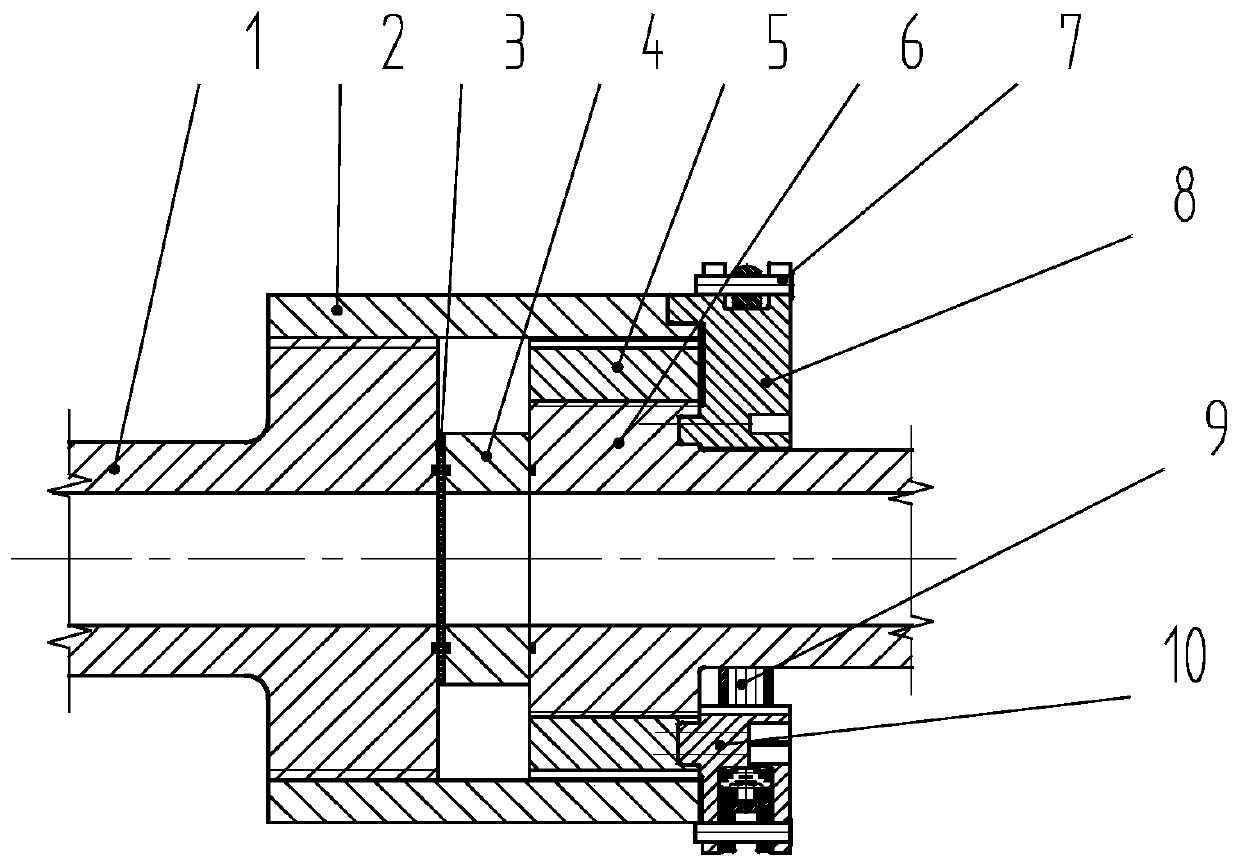

End surface driving film clamping device

The invention discloses an end surface driving film clamping device. A driving section and a rotary nut of the film clamping device are integrated into a whole and serve as a left side section; a filmclamping ring, a transition nut, a driven section, a trunnion, a double-lug support, a single-lug support and an oil cylinder are integrated into a whole and serve as a right side section; a cuttinggroove, with uniform cutting internal threads, of the rotary nut corresponds to a part, in which threads are not removed, of the transition nut with the uniform cutting external threads; and the oil cylinder drives the transition nut to rotate relative to the driven section and the rotary nut, the driven section is driven to move close to the driving section, so that a film and the film clamping ring are clamped. The film clamping ring comprises the trunnion, the double-lug support, the single-lug support and the driving device of the oil cylinder which are all installed in the end surface ofthe rotary nut, and the occupied radial space is reduced. The end surface driving film clamping device can provide enough clamping force for the film of shock tunnel type ground test equipment, and isparticularly suitable for the conditions that the caliber of a shock tube is large, requirement for the clamping force is high, and the space in the circumferential direction is limited.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

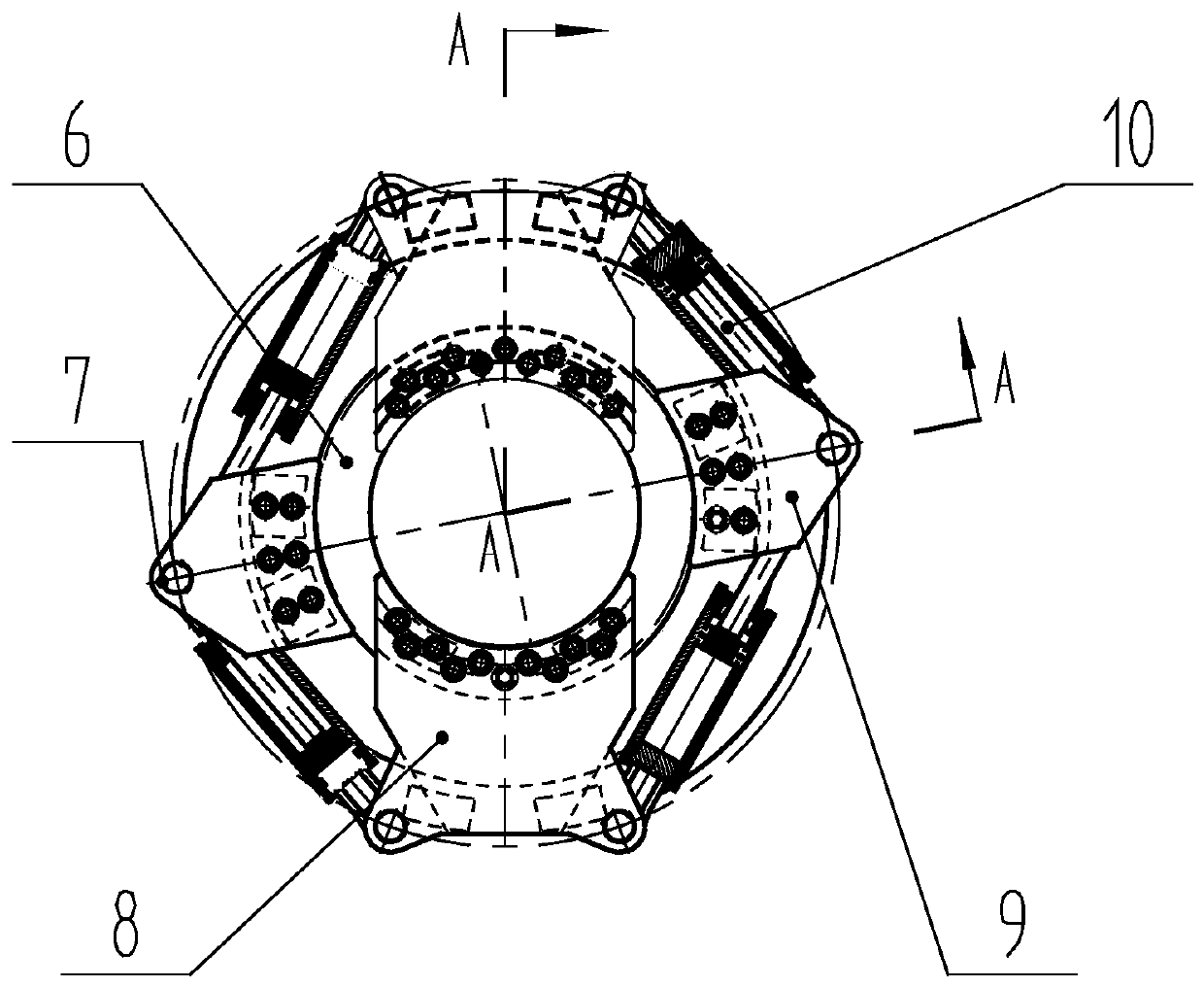

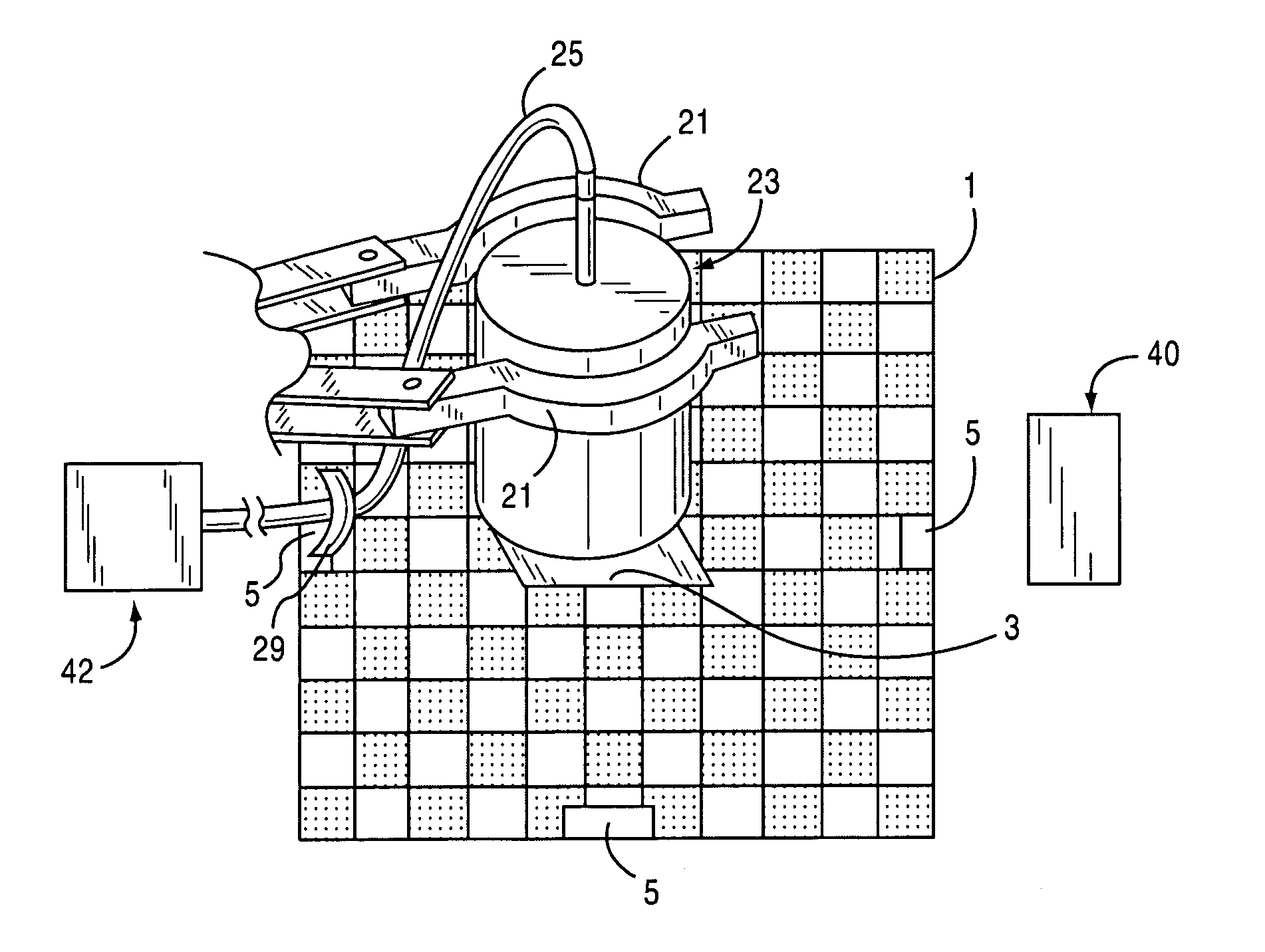

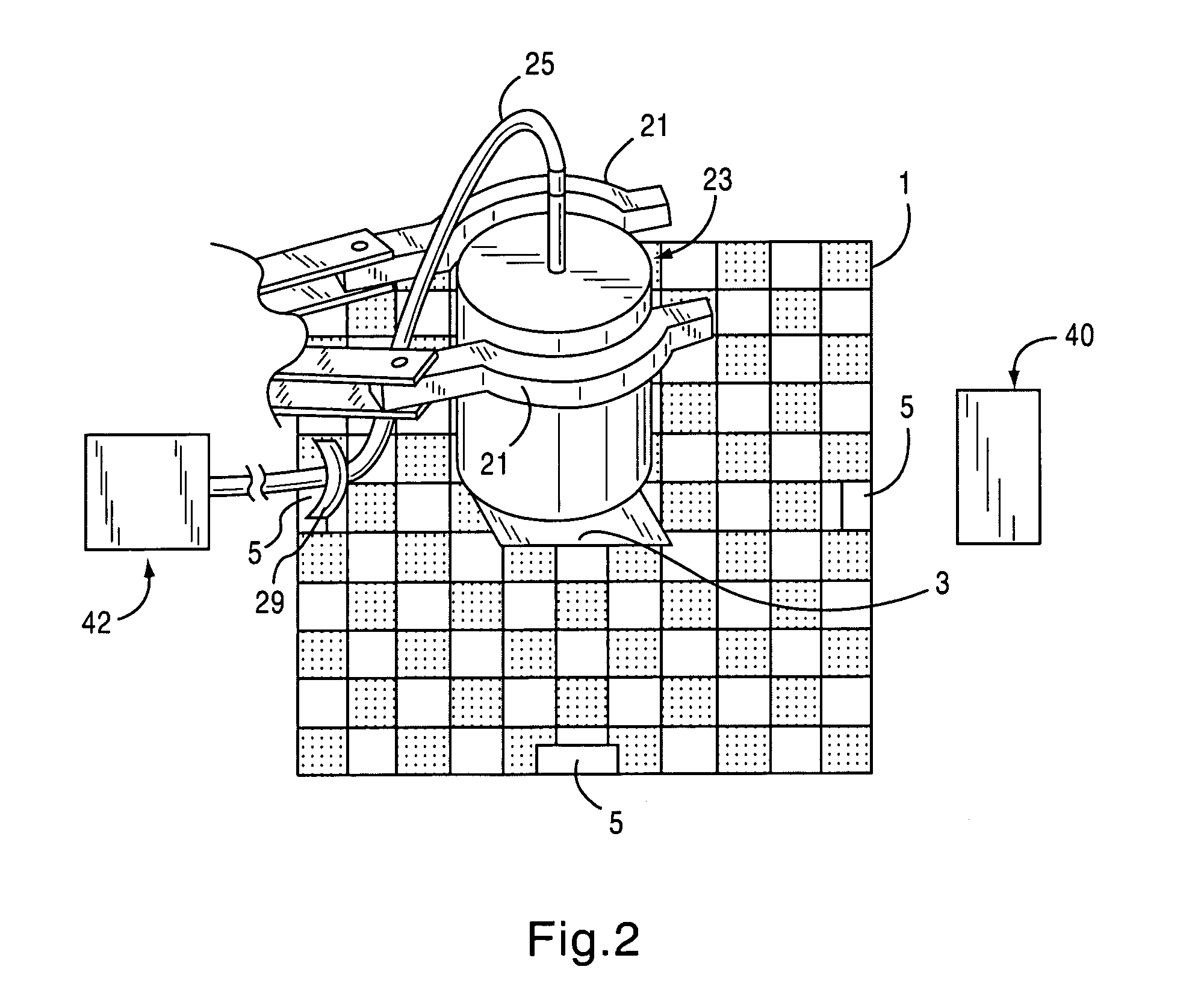

Visual assistance guide system for disrupter placement and method of use

A visual assistance guide system for placement of a disrupter device for explosive ordinance disposal includes a checkerboard base and adhesive containing areas on the base. One of the adhesive containing areas is used to secure a disrupter device on the base. The checkerboard pattern helps position of the disrupter device (preferably done with a robot) at the proper standoff distance from the package targeted for disposal. Other adhesive areas are located so that a detonation line or shock tube emanating from the disrupter device can be secured to the base in the proper position.

Owner:FISH JR JAMES A

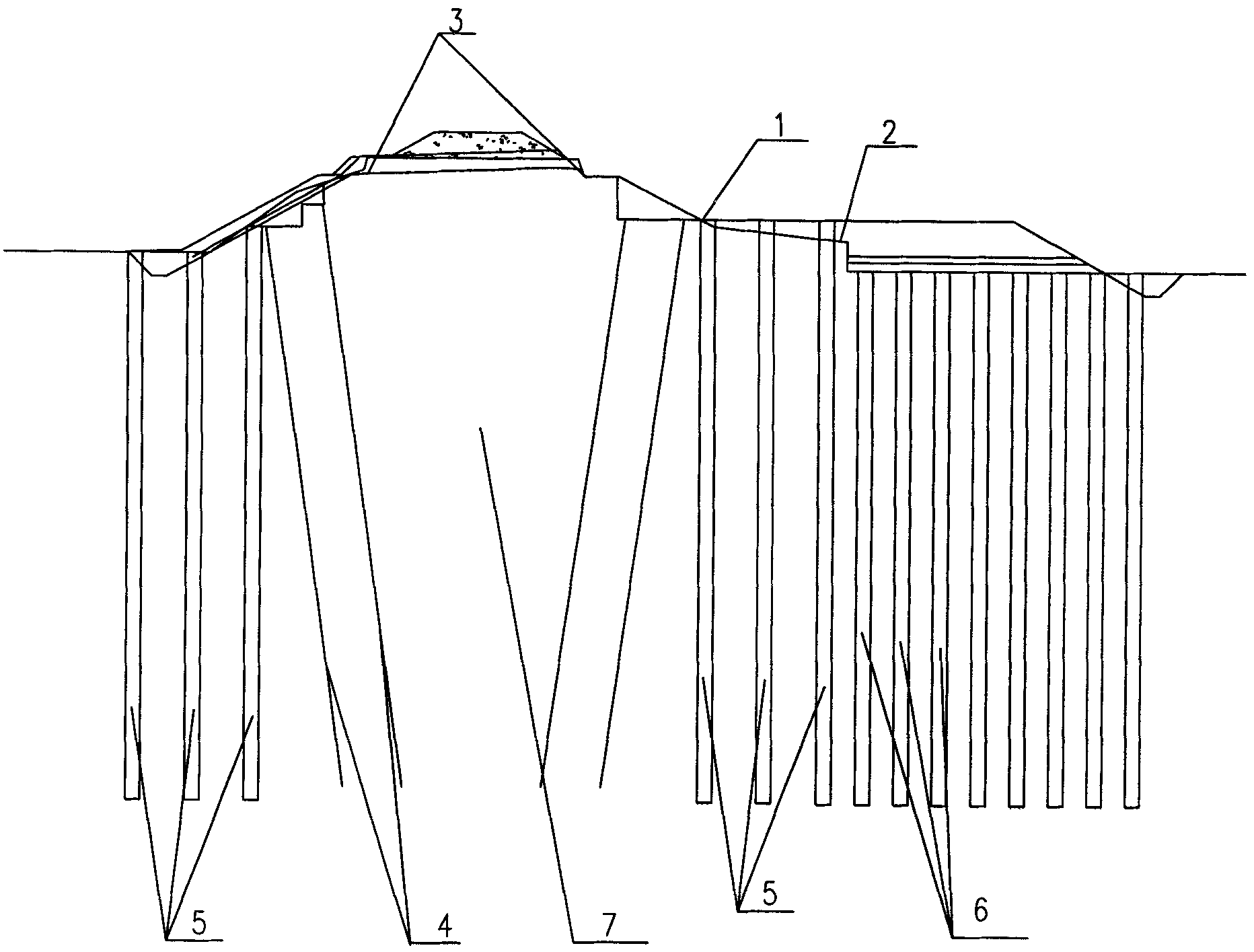

Grouting repairing method of water stopping curtain

InactiveCN102168433AControl the Slurry PhenomenonReduce drainageFoundation repairStructural engineeringShock tube

The invention discloses a grouting repairing method of a water stopping curtain, which comprises the following steps of: (1) measuring and labeling grouting holes, wherein the grouting holes are divided into two sequences, namely a sequence I and a sequence II, the holes of the sequence I and the holes of the sequence II are arranged transversely at equal intervals, and the holes of the sequence I and the holes of the sequence II are arranged longitudinally in rows at equal intervals; (2) grouting the holes of the sequence I: firstly drilling the holes of the sequence I, inserting shock tubes to the holes of the sequence I, then closing the holes of the sequence I and grouting by sections, and finally cleaning the tubes for later use; and (3) grouting the holes of the sequence II: firstly drilling the holes of the sequence II, inserting shock tubes to the holes of the sequence II, then closing the holes of the sequence II and grouting, and finally cleaning the tubes for later use. By the method, grouting is conducted by holes of two sequences according to the principle of grouting at intervals and densifying by sequences; the holes of the sequence I are grouted to fill the holes of the soil layer; the holes of the sequence II are grouted to crack the stratum and form a seepage-proofing curtain in the stratum; and the finally repaired curtain can effectively reduce the displacement of a foundation pit, the underground erosion of the stratum around the foundation pit, and settlement of the foundation and buildings.

Owner:浙江南湖建设有限公司

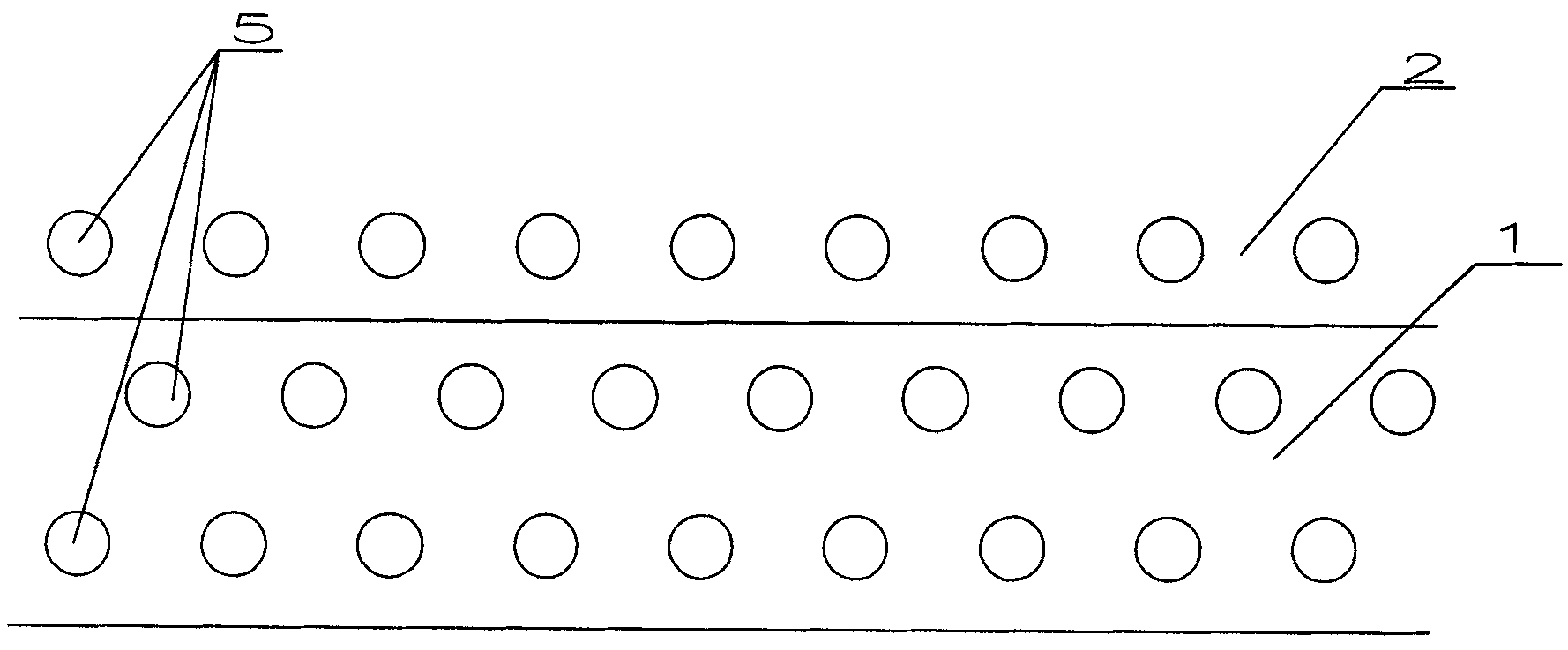

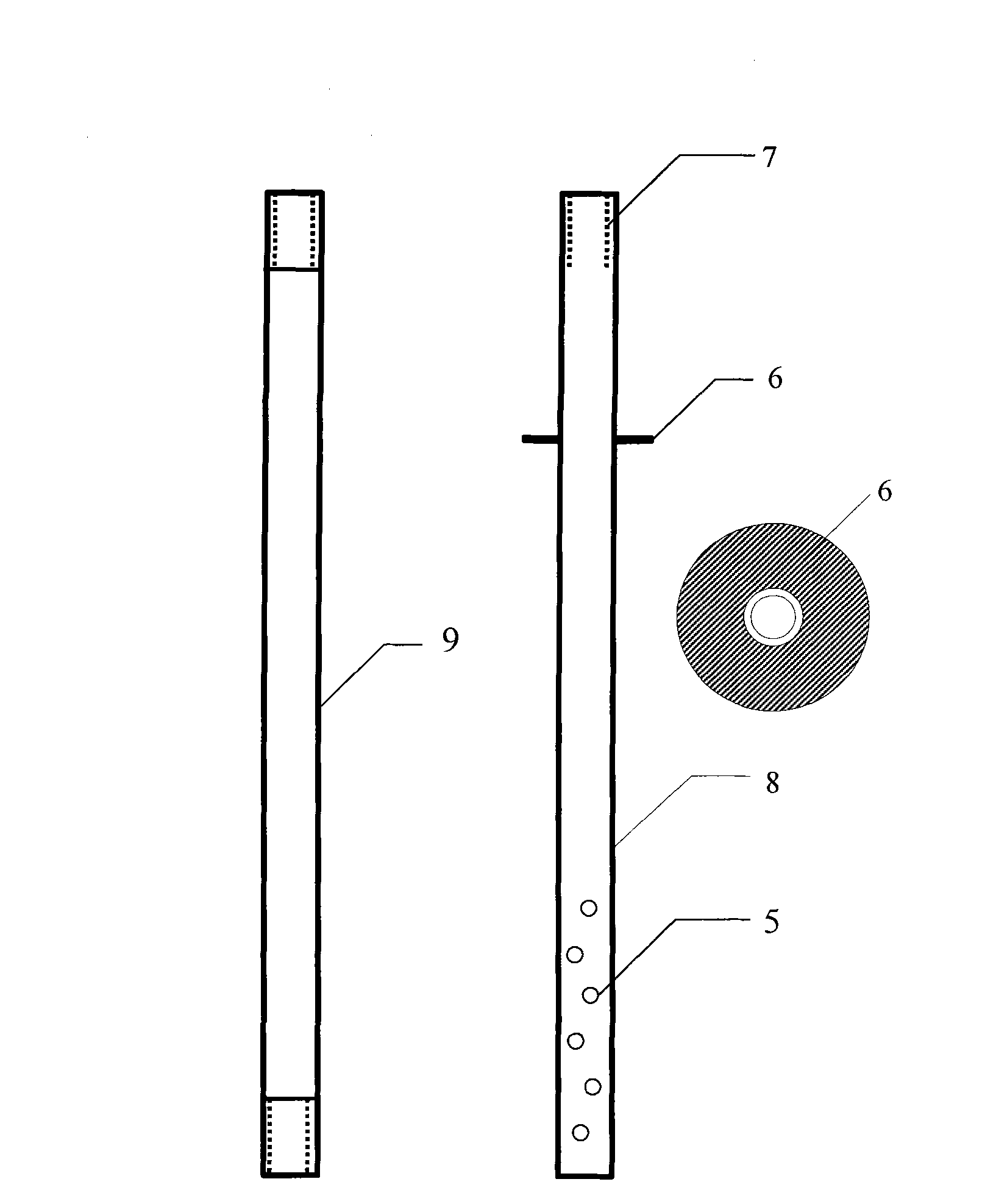

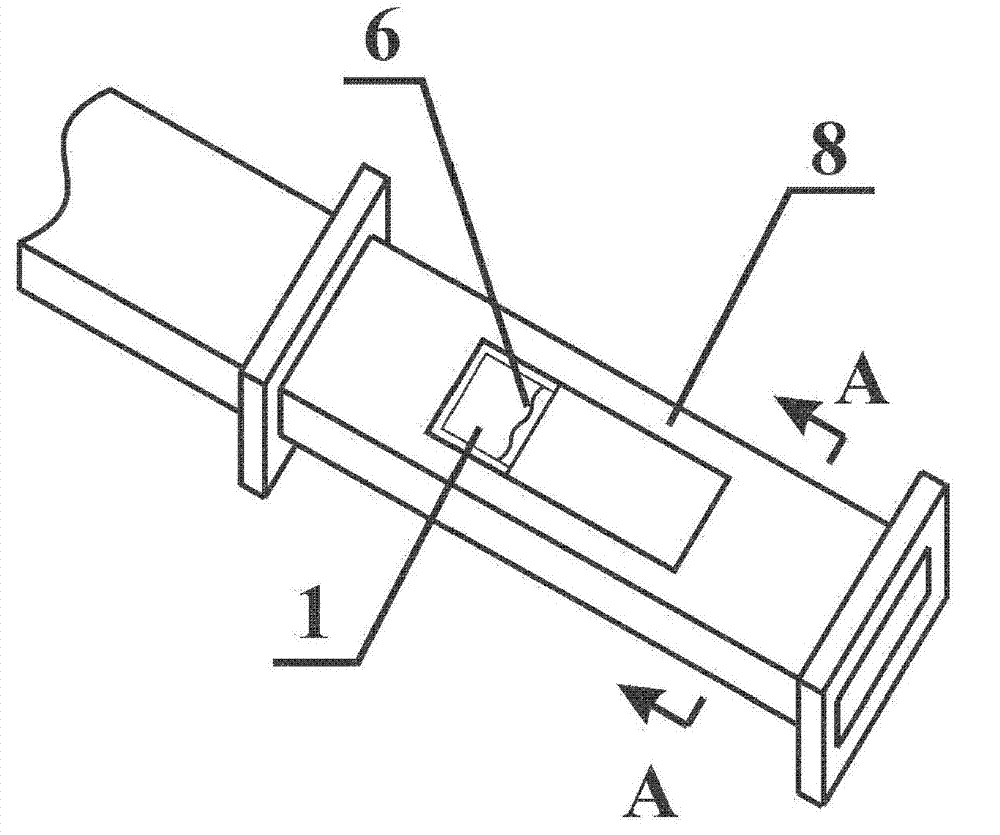

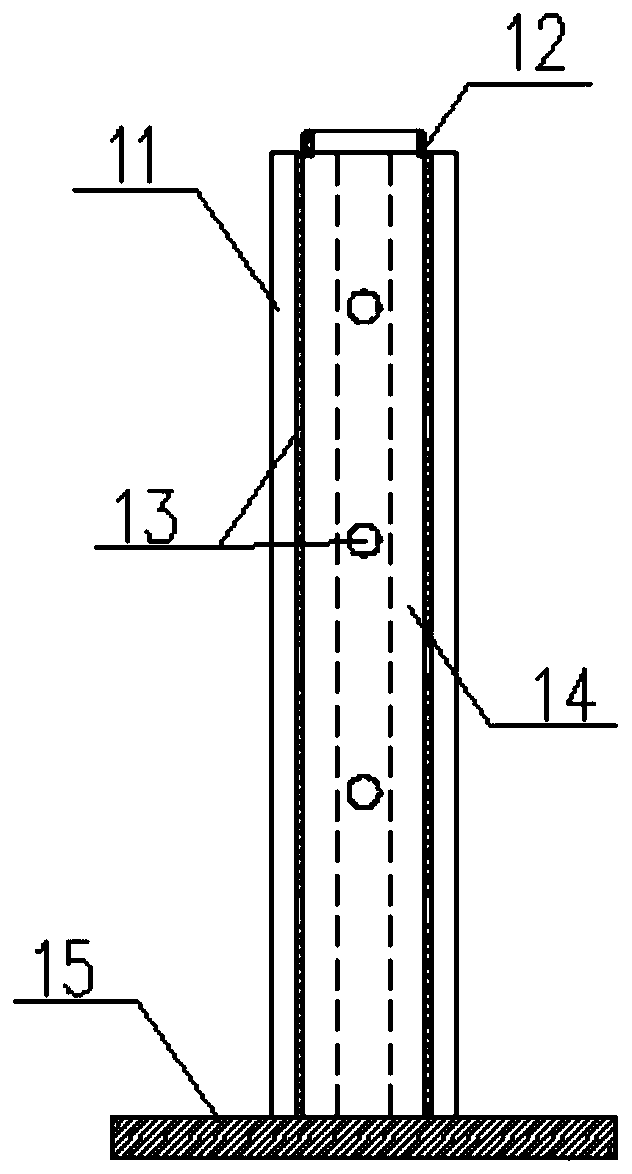

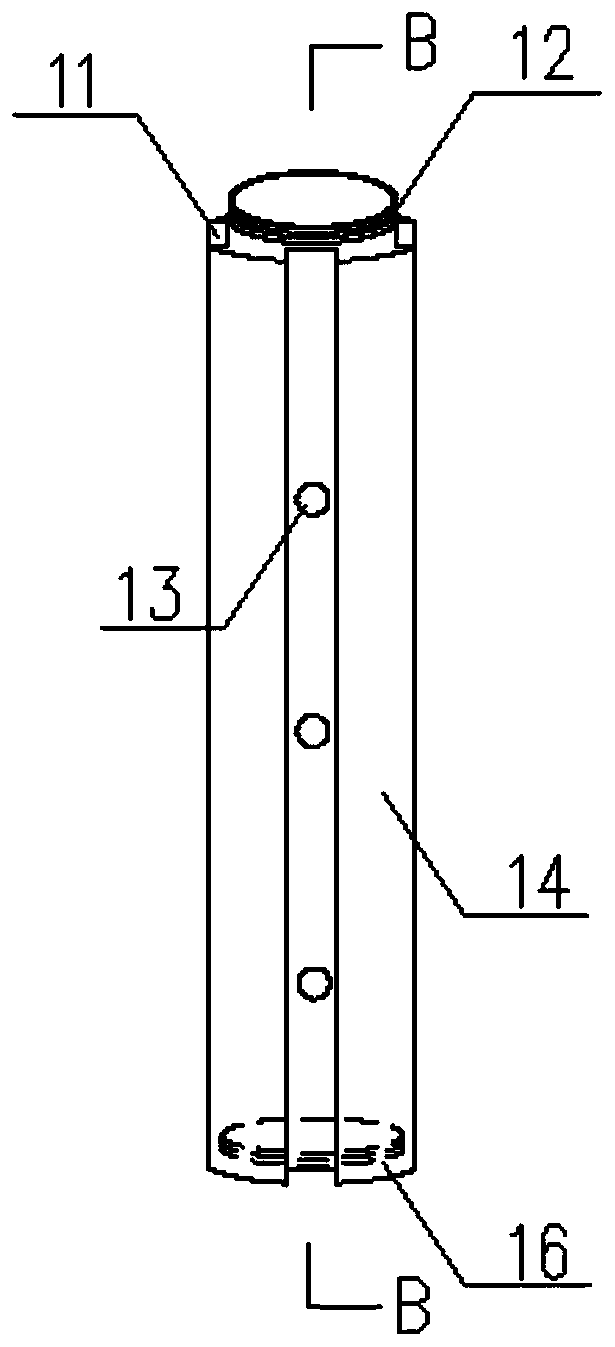

Segmented grouting device and grouting method for grouting steel shock tube

The invention discloses a segmented grouting device and a grouting method for grouting a steel shock tube, wherein the segmented grouting device comprises a grouting pipe; the bottom end of the grouting pipe is provided with a cylindrical mortar stop plug; the grouting pipe is provided with a plurality of grooves extending in the longitudinal direction; the bottom of each groove is provided with aplurality of mortar ejecting holes; the mortar ejecting holes communicate with the inner and outer sides of the grouting pipe; each groove is internally provided with a sliding rod; the surface, clinging to the bottom of the corresponding groove, of each sliding rod is provided with a sealing layer; the grouting pipe is further provided with an annular column mortar stop plug in a sleeving manner; the annular column mortar stop plug is connected with all sliding rods; the cylindrical mortar stop plug and the annular column mortar stop plug are matched with the inner wall of the steel shock tube; the grouting pipe is further provided with a plurality of annular hoops in a sleeving way; and the annular hoops are used for making the sliding rods cling to the bottoms of the grooves. The segmented grouting device can realize flexible regulation of the length of a grouting section according to actual conditions of a ground layer so that the length of the grouting section is preferably matched with the grouting length which is actually required by the ground layer, so that the soil which needs not to be reinforced is prevented from being grouted additionally, and the construction cost isnot increased and resources are not wasted.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

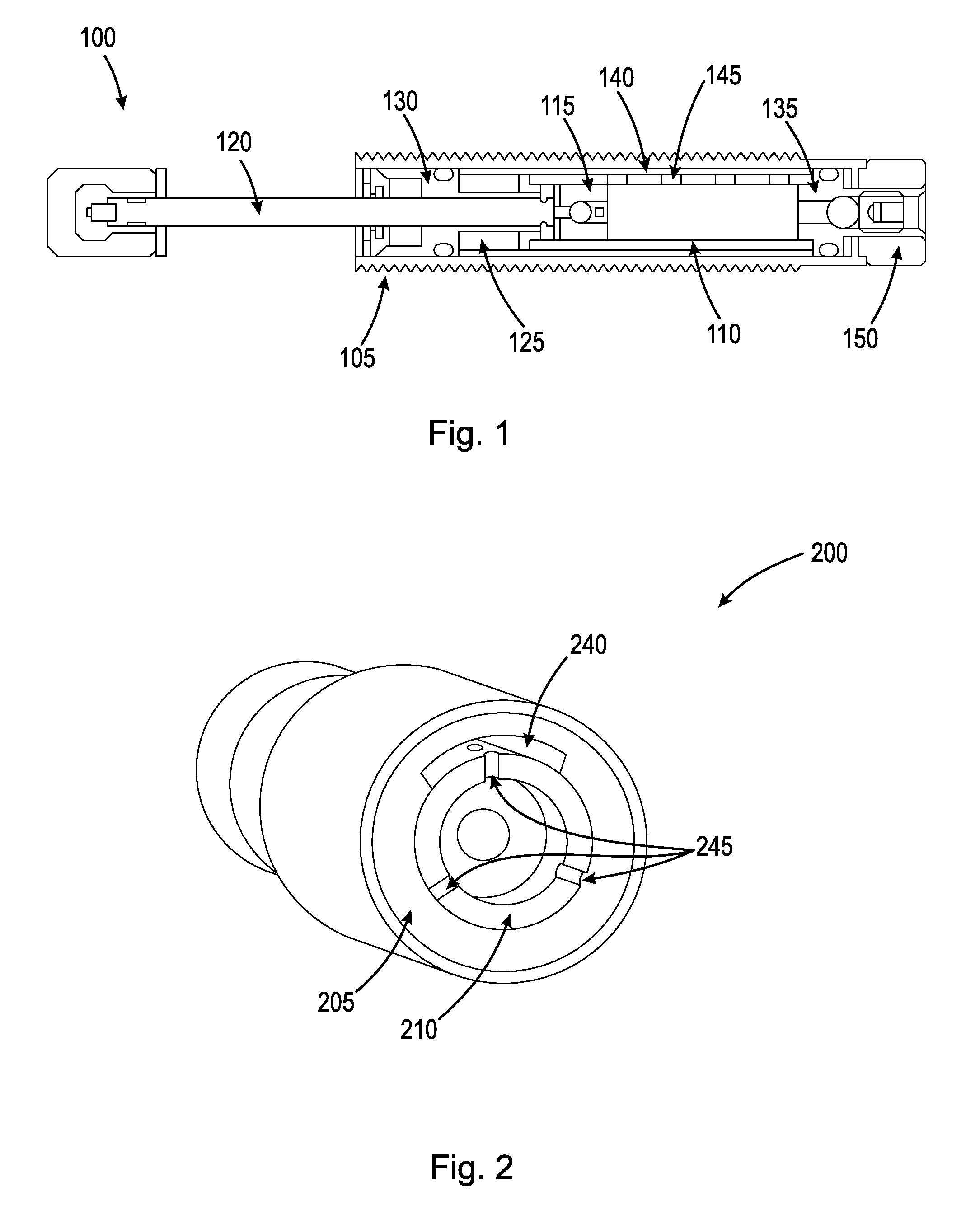

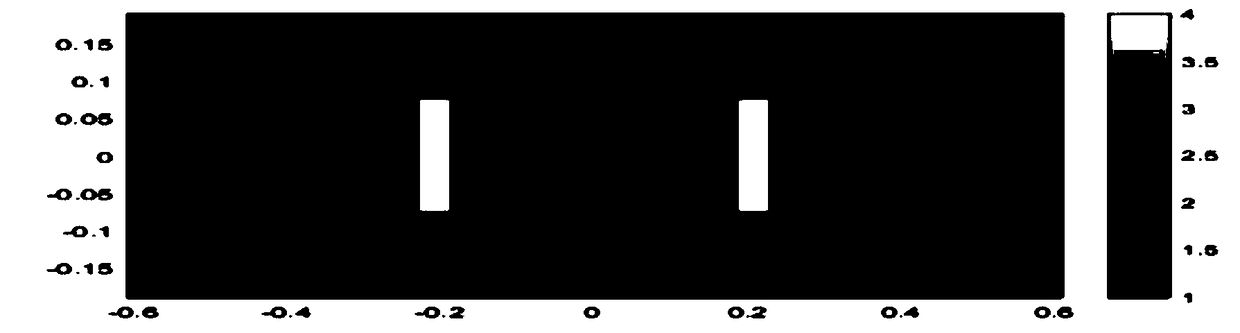

Direct dynamic force measurement device of shock-wave-loaded double-raw model sphere array

InactiveCN103115853APrecisely control the quantityPrecise Control of ArrangementMaterial analysisAccelerometerMeasurement device

The invention discloses a direct dynamic force measurement device of a shock-wave-loaded double-raw model sphere array. The direct dynamic force measurement device comprises a high-pressure air source, a driving section, a diaphragm, a driven section, a tested section, a metal wire, model spheres and a high-speed data acquisition system, wherein one end of the driving section and one end of the driven section are connected by the diaphragm to form a shock tube; the high-pressure air source is connected with the other end of the driving section; one end of the tested section is connected with the other end of the driven section; and lead wires of accelerometer sensors in the model spheres inside the tested section are connected with the high-speed data acquisition system. According to the direct dynamic force measurement device disclosed by the invention, the tested section, which is a transparent organic glass pipe, can be used for carrying out optical measurement; different model sphere arrays needed by experiments can be formed by accurately controlling the number, distribution and spacing of the model spheres because the tested section is provided with double rows of holes and 36 small holes are uniformly distributed in the same radial sections of each row of holes; and the direct measurement on the dynamic force of a shock-wave-loaded granule group is realized by the accelerometer sensors and the high-speed data acquisition system. According to the invention, a good experimental device and testing method are provided for subsequent research.

Owner:ZHEJIANG SCI-TECH UNIV

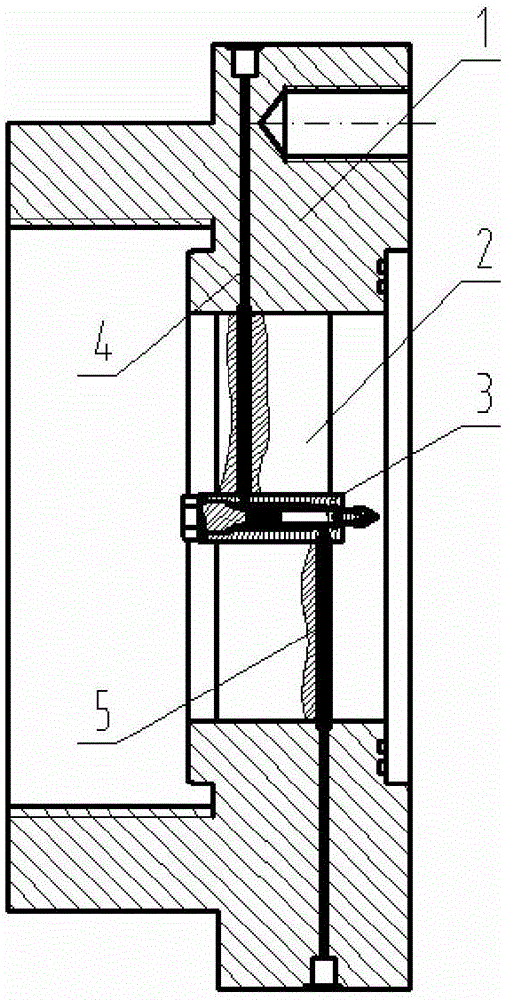

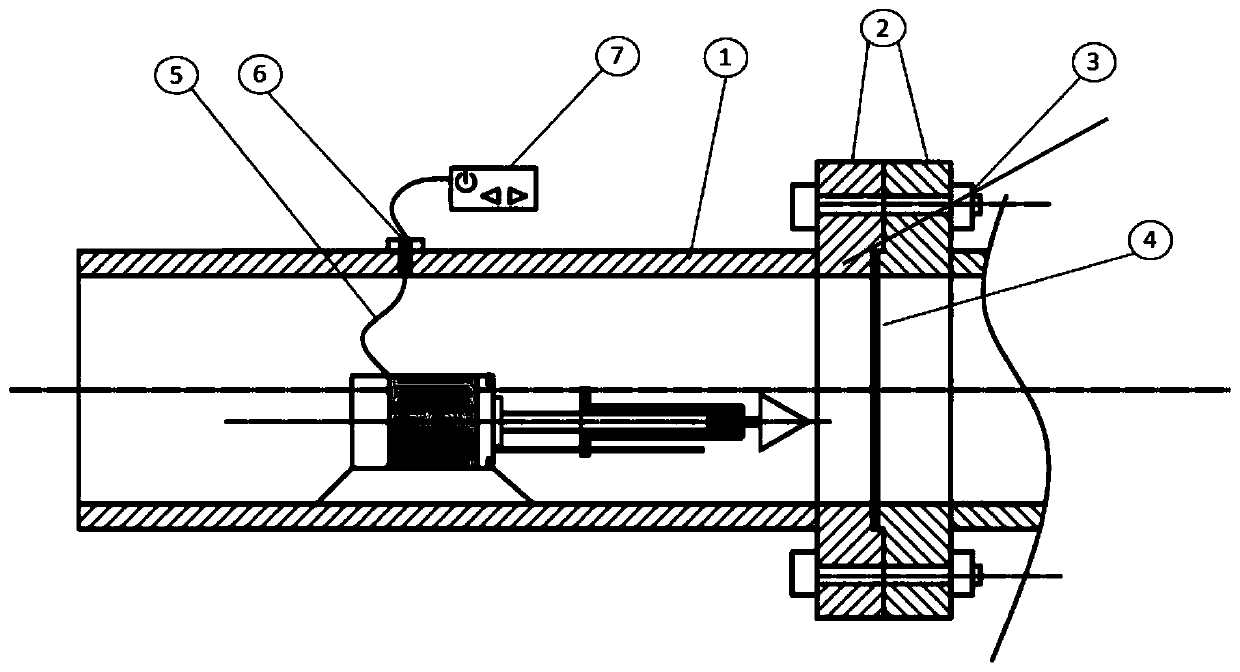

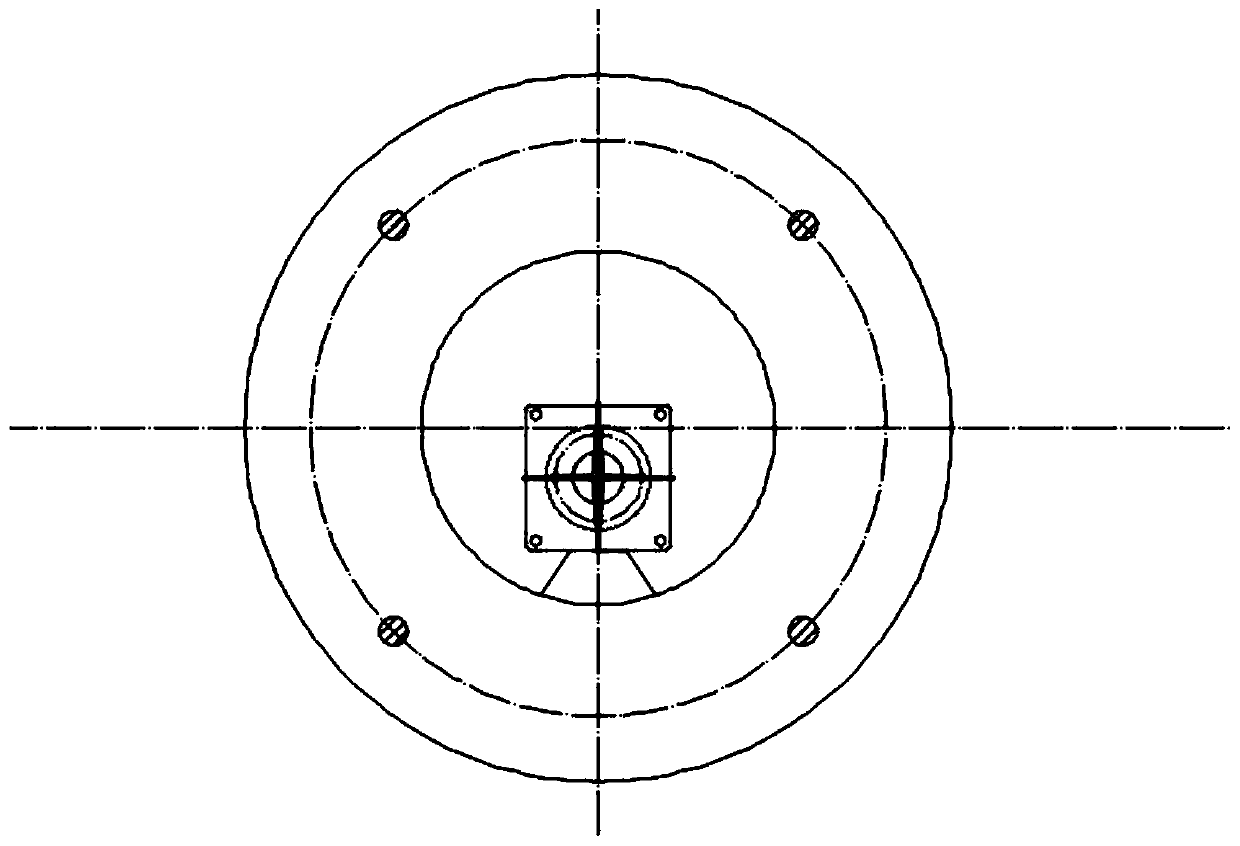

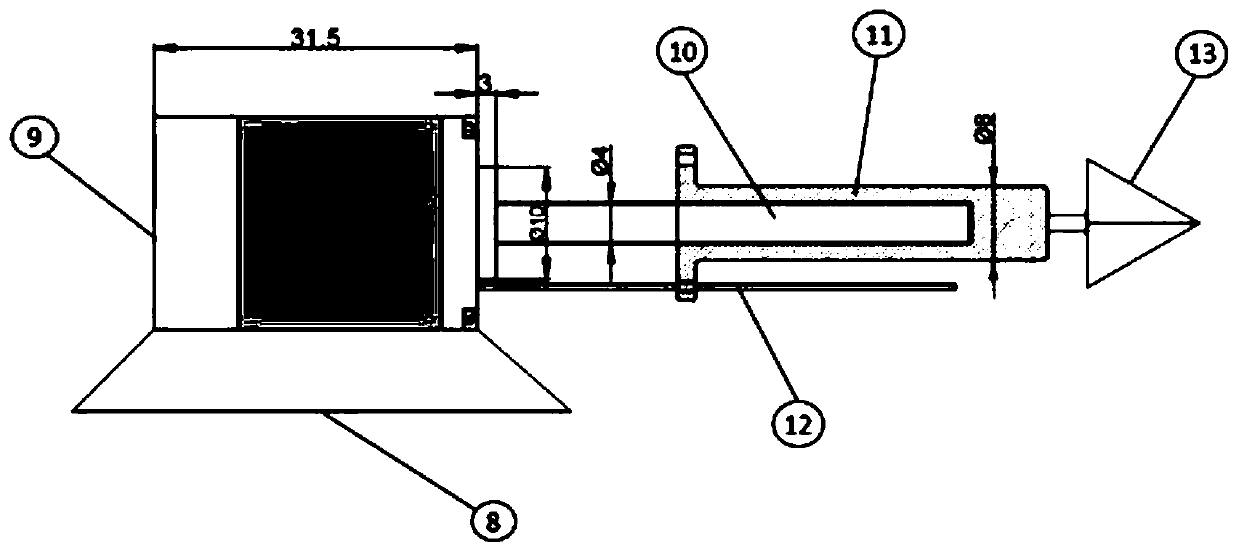

Shock tube electric needle piercing and membrane rupturing device capable of being used under low pressure conditions

PendingCN109975473ANeedle out speed is fast and uniformControl accurate timeChemical analysis using combustionCombustionNeedle puncture

The invention relates to the technical field of combustion experiments, and aims to provide a shock tube electric needle piercing and membrane rupturing device capable of being used under low pressureconditions. The shock tube electric needle piercing and membrane rupturing device comprises a micro motor, wherein the micro motor is fixedly mounted on the inner wall of a shock tube by means of a motor base, a motor screw is parallel to the axis of the shock tube and has threads; a hollow tubular needle piercing sleeve has an opening end and a closed tail end, and a piercing needle is mounted at the tail end; the needle piercing sleeve is internally provided with threads or a rack in the length direction of the needle piercing sleeve, the needle piercing sleeve sleeves the motor screw fromthe opening end and drives the threads or the rack to be engaged with the threads of the motor screw; and the outer side of the needle piercing sleeve is provided with a transverse protruding portionhaving a through hole, a guide rod parallel to the needle piercing sleeve passes through the through hole, and one end of the guide rod is fixed on the micro motor. According to the shock tube electric needle piercing and membrane rupturing device, the needle withdrawing speed of the piercing needle is faster and more uniform than that of an ordinary mechanical needle piercing and membrane rupturing mechanism by adopting electric control, the precise time of membrane rupturing is easier to control, the piercing needle is convenient to replace, easy to seal and high in universal performance, and the shock tube electric needle piercing and membrane rupturing device can be well used under the low pressure conditions, is reliable and efficient and has good repeatability.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com