Segmented grouting device and grouting method for grouting steel shock tube

A segmented grouting and steel flower tube technology, which is applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of inability to adjust the length of the grouting section, waste of resources, and increase in construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

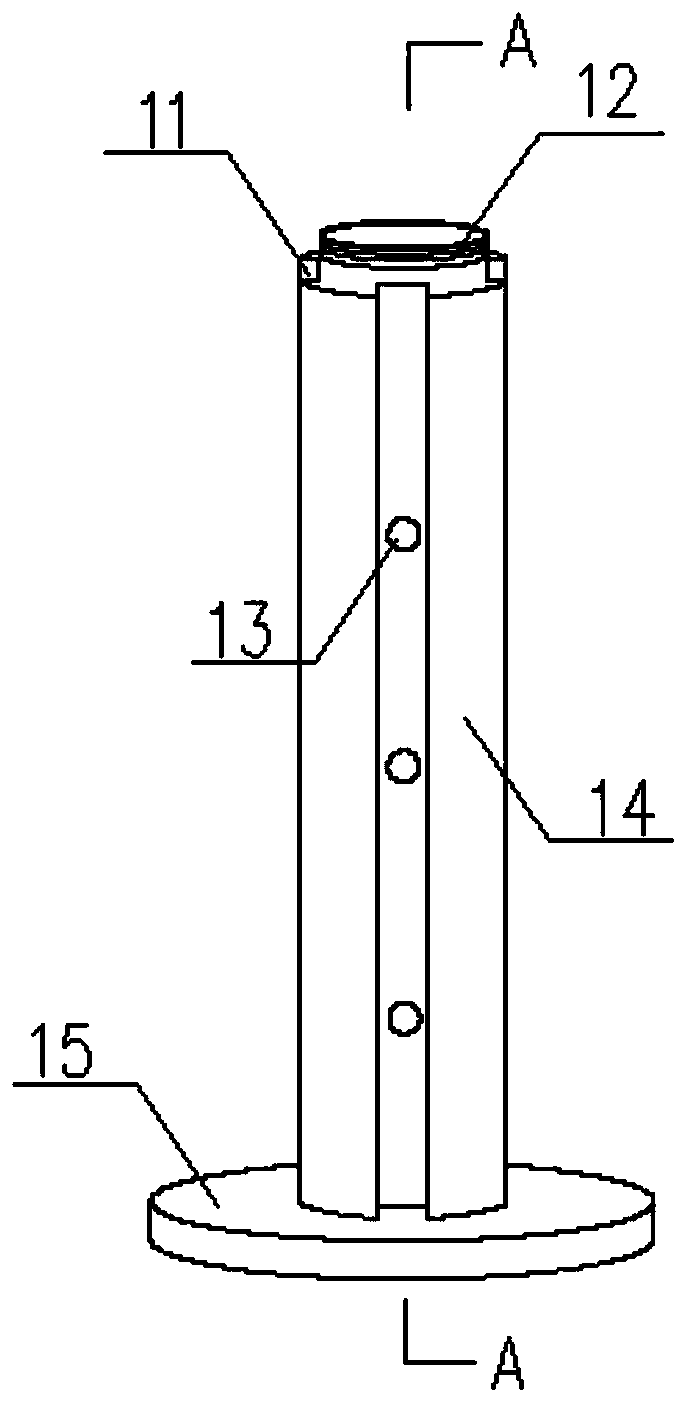

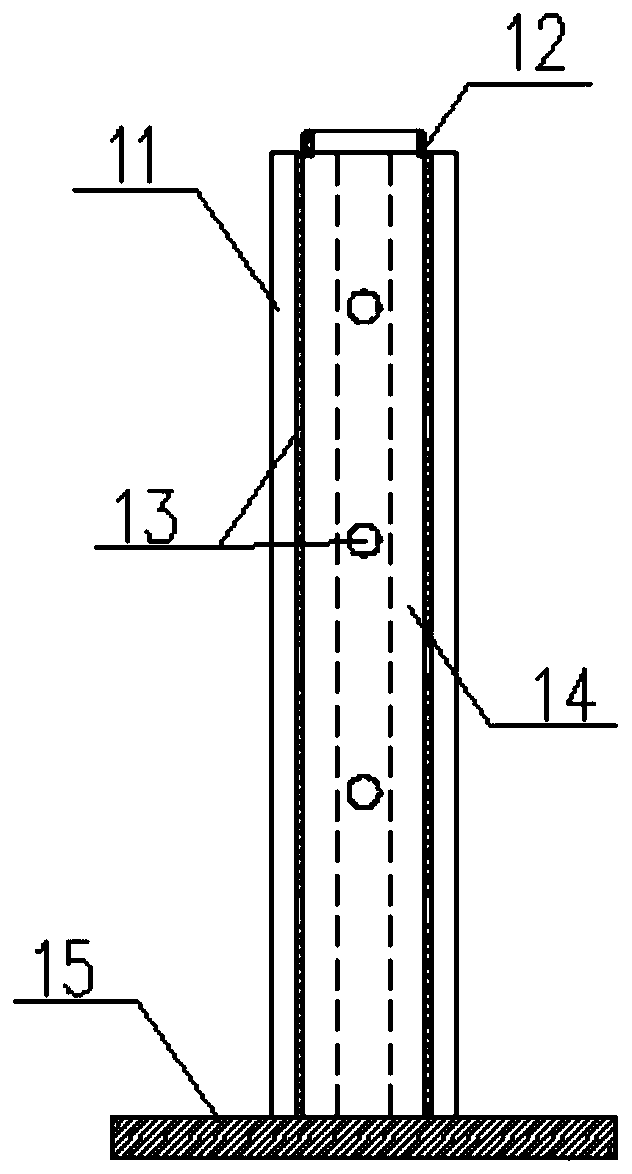

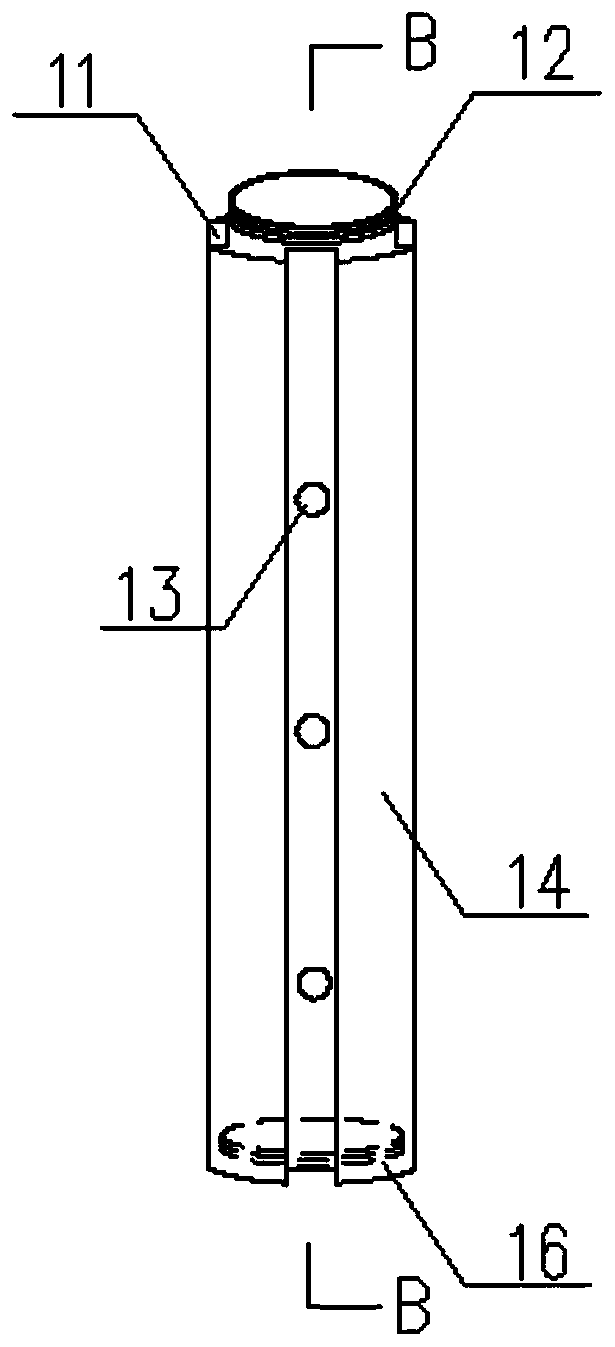

[0045] This embodiment provides a segmented grouting device for grouting steel pipes;

[0046] Such as Figure 1-Figure 14 As shown, the segmented grouting device for grouting steel pipes in this embodiment includes a grouting pipe 14, the bottom of the grouting pipe 14 is provided with a cylindrical grout stopper 15, and the grouting pipe 14 is provided with A plurality of longitudinally extending grooves 11, the bottom of the grooves 11 is provided with a plurality of grouting holes 13, and the grouting holes 13 communicate with the inner and outer sides of the grouting pipe 14, and each groove 11 is equipped with a slide Rod 22, a sealing layer 27 is provided on the surface of the sliding rod 22 that fits with the bottom of the groove 11, and an annular cylinder grout stopper 25 is also sleeved on the grouting pipe 14, and the grout stopper 25 of the annular cylinder The plug 25 is connected to the bottom of all the slide rods 22. The cylindrical grout stopper 15 and the a...

Embodiment 2

[0055] This embodiment provides a grouting method of a segmented grouting device for grouting steel pipes in embodiment 1;

[0056] A grouting method for a segmented grouting device for grouting steel pipes, comprising the following steps:

[0057] Step 1, using a down-the-hole drilling rig to drill holes;

[0058] Step 2. After the drilling is completed, insert the steel floral tube 55, and make the steel floral tube 55 located in the center of the drilled hole as much as possible;

[0059] Step 3: Put the grouting pipe 14 with a cylindrical grout stopper 15 at the bottom into the steel flower pipe 55, and then put the bottom slide bar 22 with an annular cylinder stopper 25 at the bottom, and the bottom slide bar 22 The sealing layer 27 is closely attached to the groove 11, and the ring hoop 44 is installed in sections along the height of the slide bar 22;

[0060] Step 4: Install the second section of the grouting pipe 14 and the sliding rod 22. The grouting pipe is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com