Soft foundation reinforcing method of existing railway or highway subgrade construction

A technology for weak foundations and existing railways. It is applied in the direction of infrastructure engineering, soil protection, sheet pile walls, etc. It can solve the problems of large operating space for construction equipment, reduce post-construction settlement and safety and stability coefficients, and avoid traffic interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

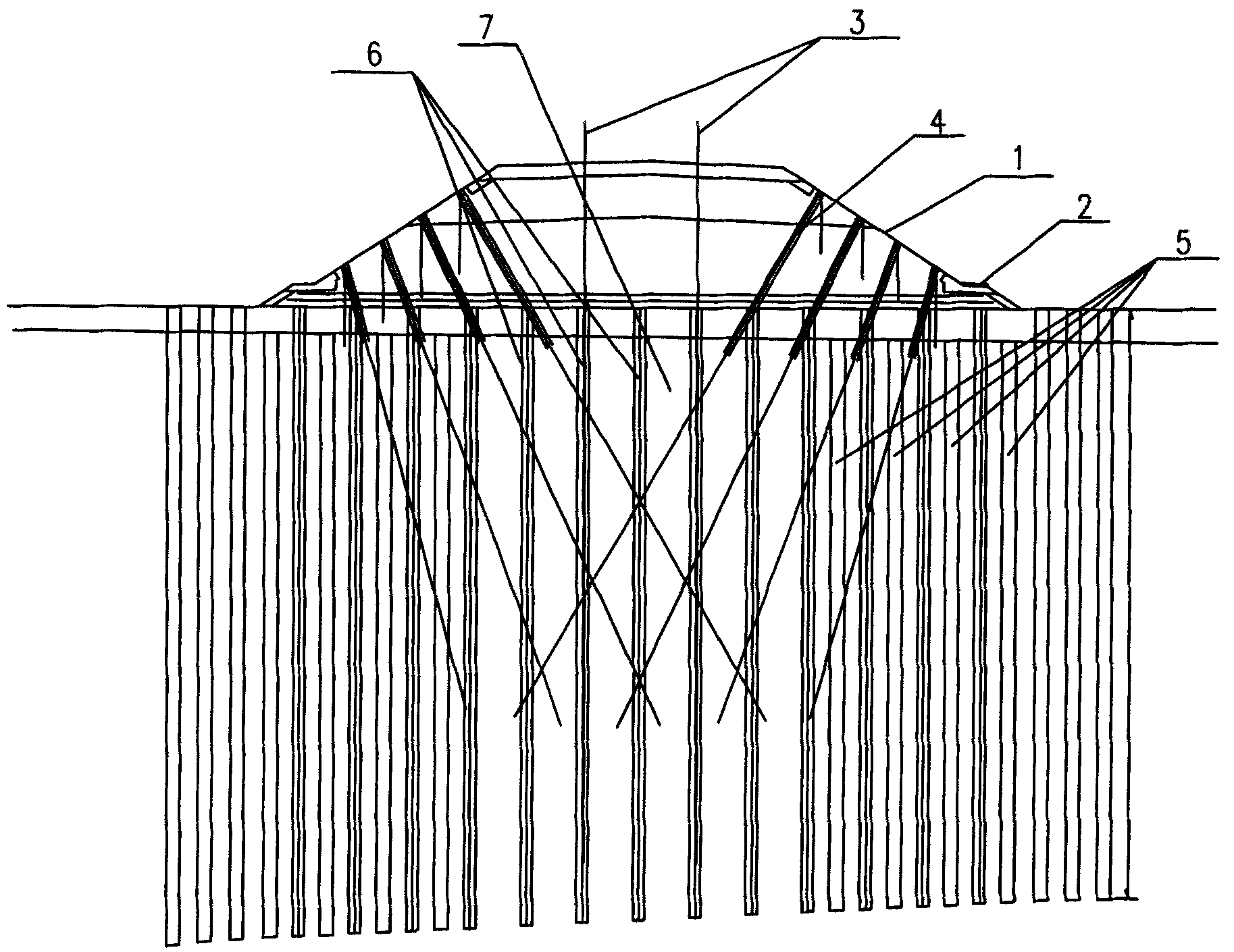

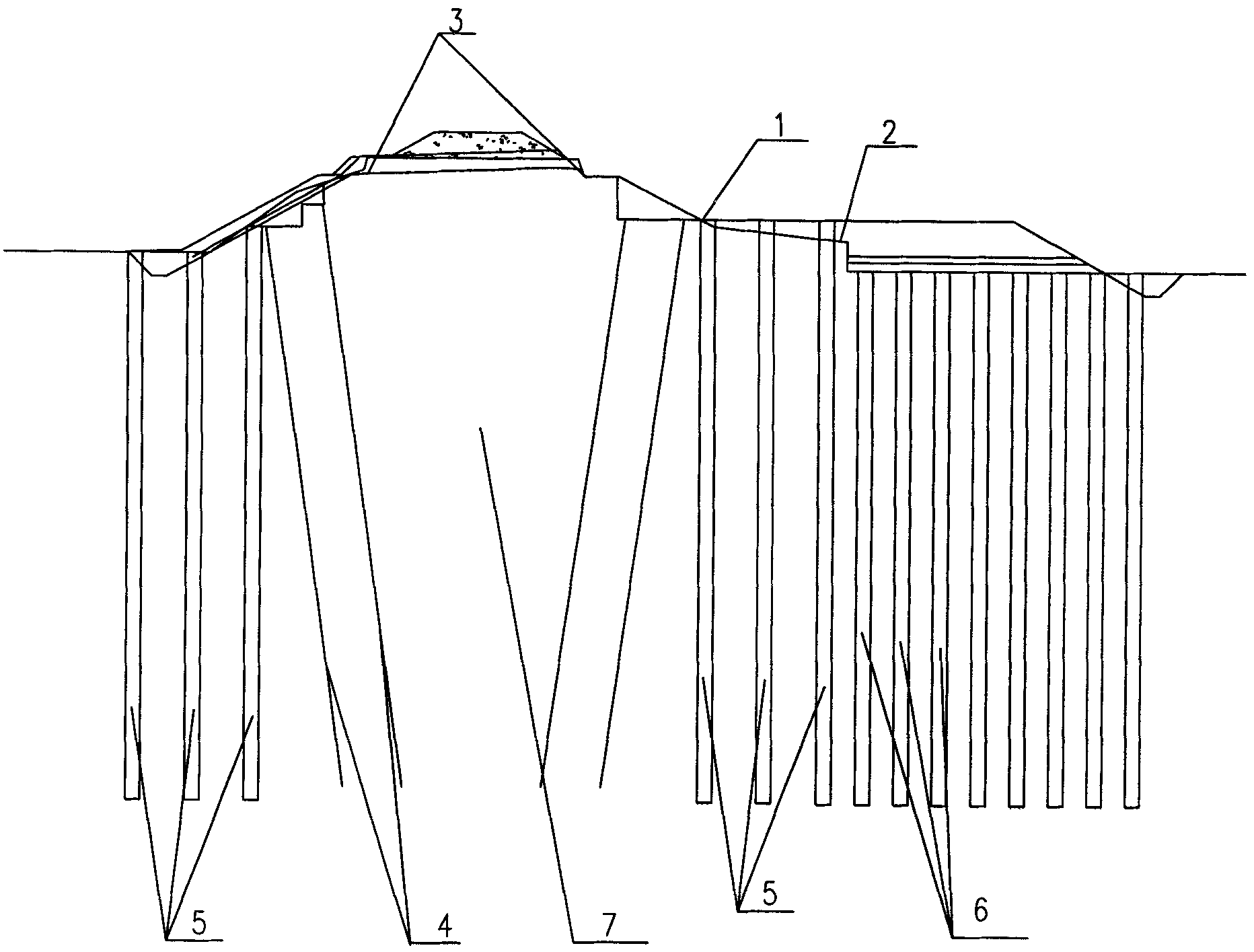

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] A method for reinforcing weak foundations of existing railway and road subgrade engineering, which comprises the following steps:

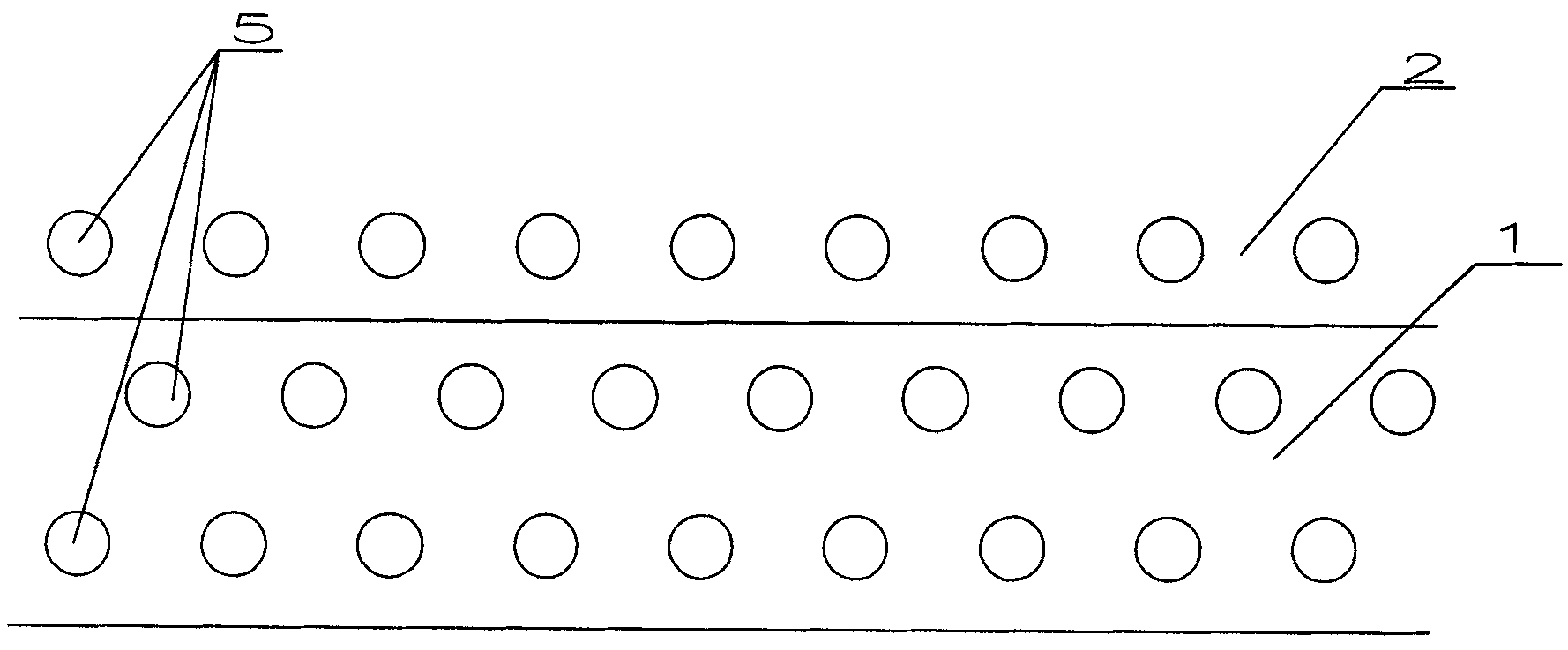

[0029] 1) Set observation piles on the shoulder of the subgrade to be reinforced, and set up a row of observation piles at 2m and 10m outside the slope foot, and the longitudinal spacing of observation piles is 10m.

[0030] 2) Construct vertical jet grouting piles 5 on the side slope 1 and slope toe 2 of the subgrade to be reinforced. A row of vertical jet grouting piles 5, this construction method can reduce the deformation influence of the construction of vertical jet grouting piles 5 on the road base body. The vertical jet grouting piles 5 on the slope 1 are constructed by jumping piles, and the vertical jet grouting piles 5 are constructed at intervals of 3 to 5 piles along the longitudinal direction, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com