Multi-mode operating free piston shock tunnel

A shock tunnel and piston technology, which is applied in the field of hypersonic testing, can solve the problems of error, short operating time of the free piston shock tunnel, affecting the accuracy of test results and test efficiency, and achieves lower operating costs and higher efficiency. , the effect of improving the scope of application and test ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

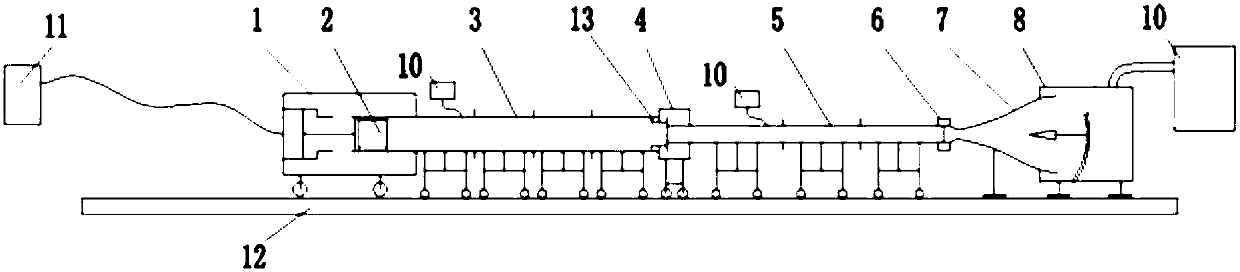

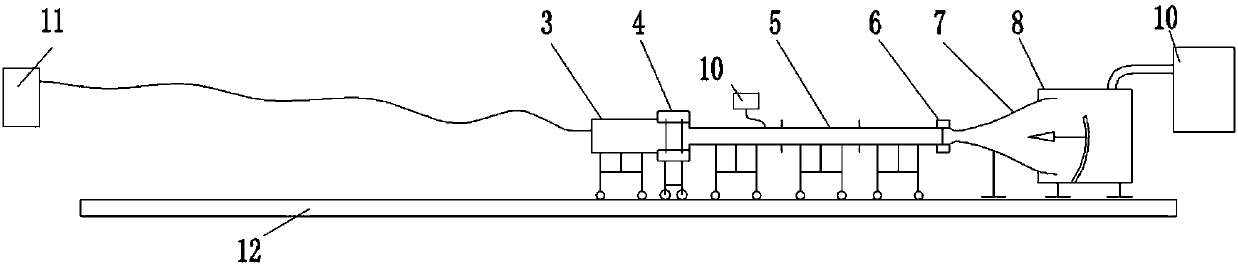

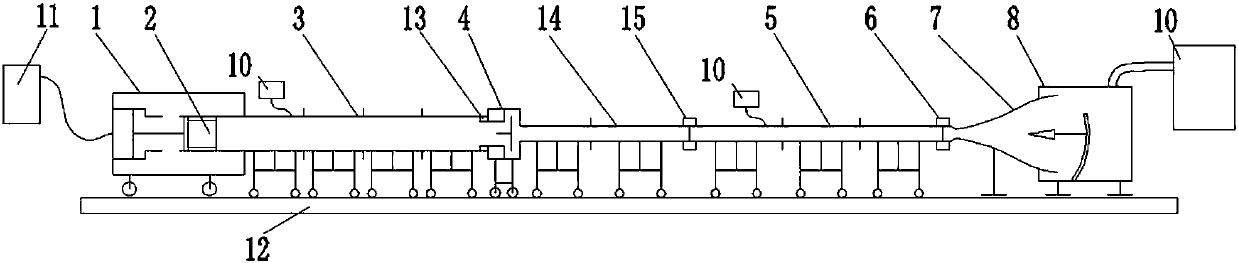

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] A free piston shock wave wind tunnel operating in multiple modes, including a wind tunnel body, a distributed vacuum system 10, an air supply system 11, and a track support system 12,

[0038] The wind tunnel body includes a driving mechanism, a shock wave pipe section 5, a single-membrane clamping mechanism 6, a nozzle pipe 7 and a test pipe section 8,

[0039] The distributed vacuum system evacuates the driving mechanism, the shock tube section 5 and the test tube section 8;

[0040] The gas supply system supplies gas to the drive mechanism and the shock tube section 5;

[0041] The track support system provides support for the drive mechanism, the shock tube section 5, and the single-membrane clamping mechanism 6;

[0042] The wind tunnel body is coaxially sealed with the shock tube section 5, the single-membrane clamping mechanism 6, the nozzle 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com