Solid particle group accelerating device for shock tube-Laval nozzle

A technology of solid particles and accelerating devices, applied in the directions of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of accelerating solid particle groups, limited, etc., and achieve good effect, large particle adhesion, and increase the spray coverage area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

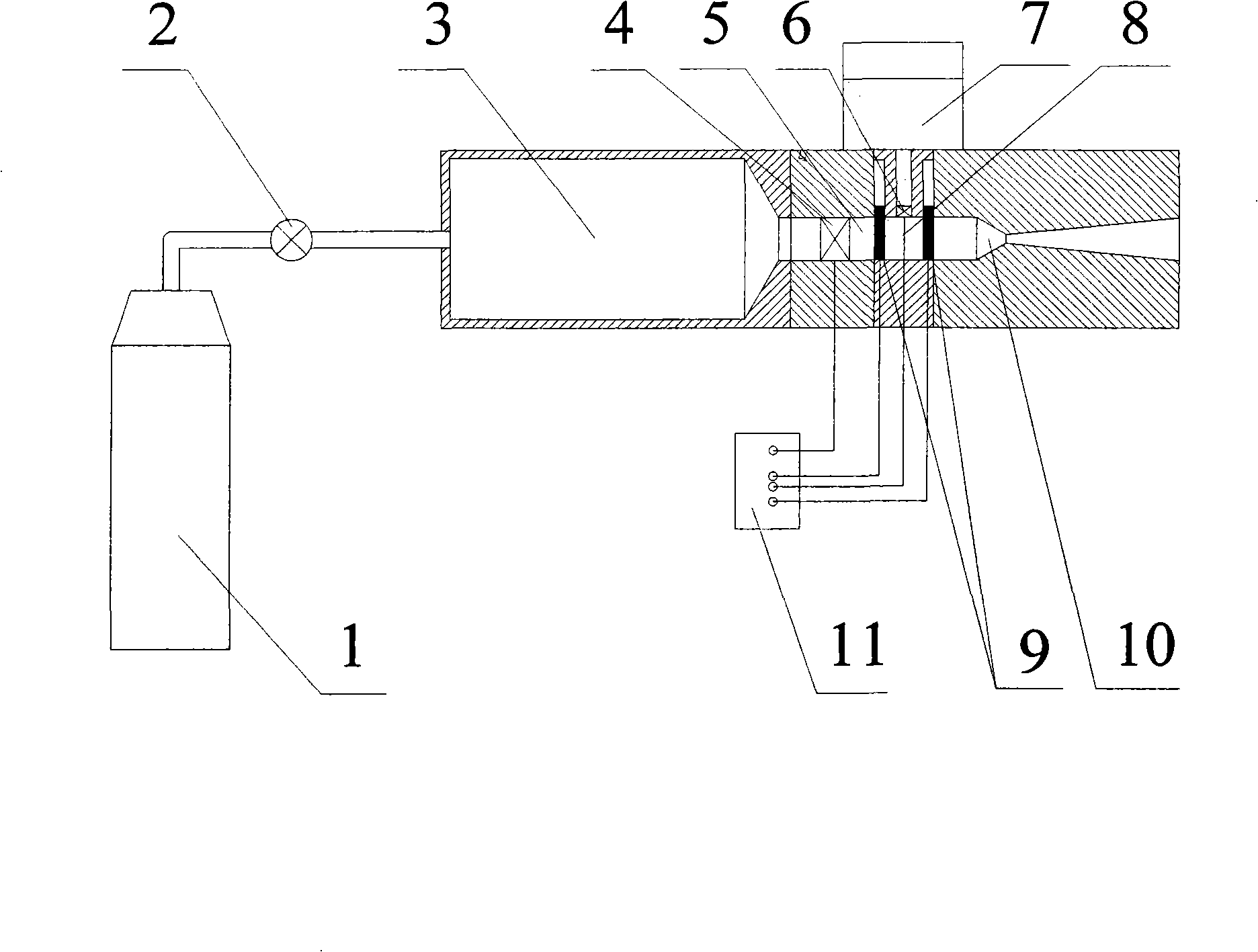

[0014] As shown in the drawings, the present invention includes a high-pressure gas source 1, a compressed gas shut-off valve 2, a shock tube separated by a high-pressure gas chamber 3 and a low-pressure gas chamber 5 by a transient switch valve 4, a powder circuit switch valve 6, Powder supply source 7, powder storage chamber 8, two movable partitions 9 and Laval nozzle 10; compressed gas source 1 is connected with shock tube high-pressure gas chamber 3 through compressed gas shut-off valve 2, and powder storage chamber 8 is composed of The movable partition 9 is surrounded by the pipe wall, one of which separates the low-pressure air chamber 5 from the powder storage chamber 8, and the other separates the powder storage chamber 8 from the Laval nozzle 10; The particle injection hole is connected to the powder supply source 7, and a powder circuit switch valve 6 is set in the particle injection hole to separate the powder supply source 7 from the powder particles in the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com