Patents

Literature

175results about How to "High coating strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

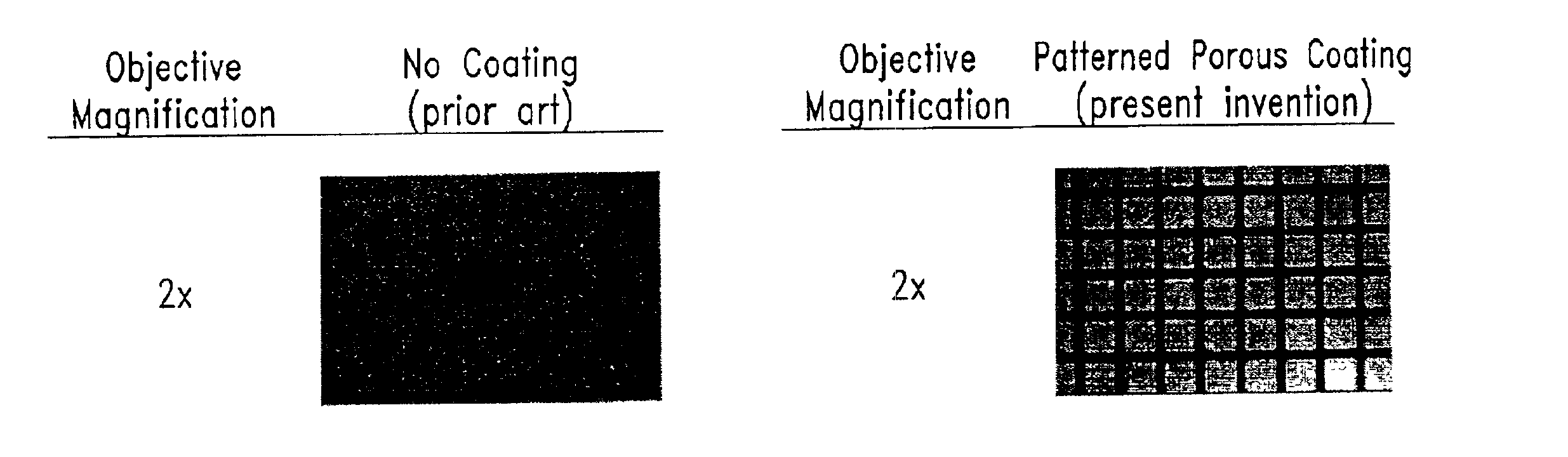

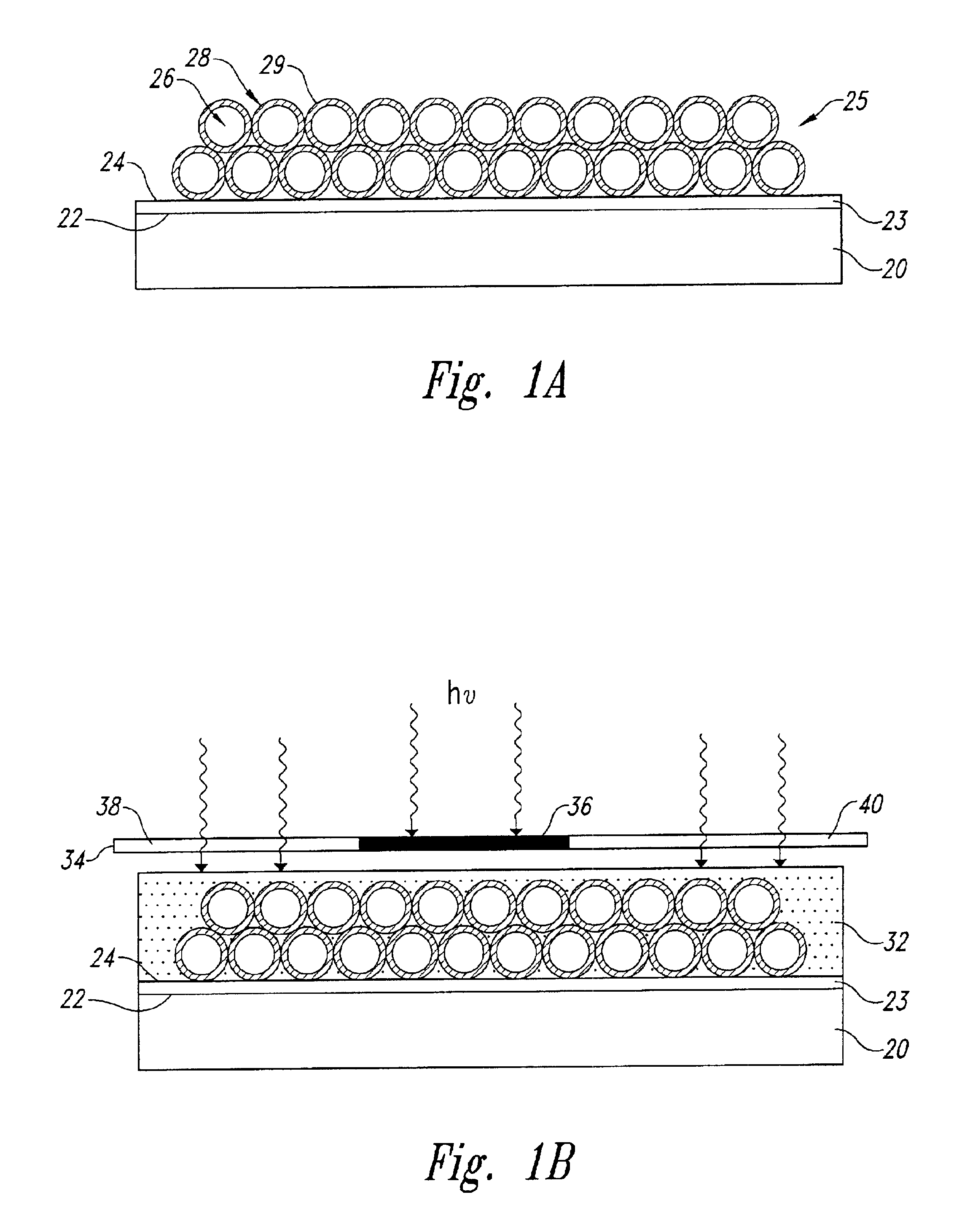

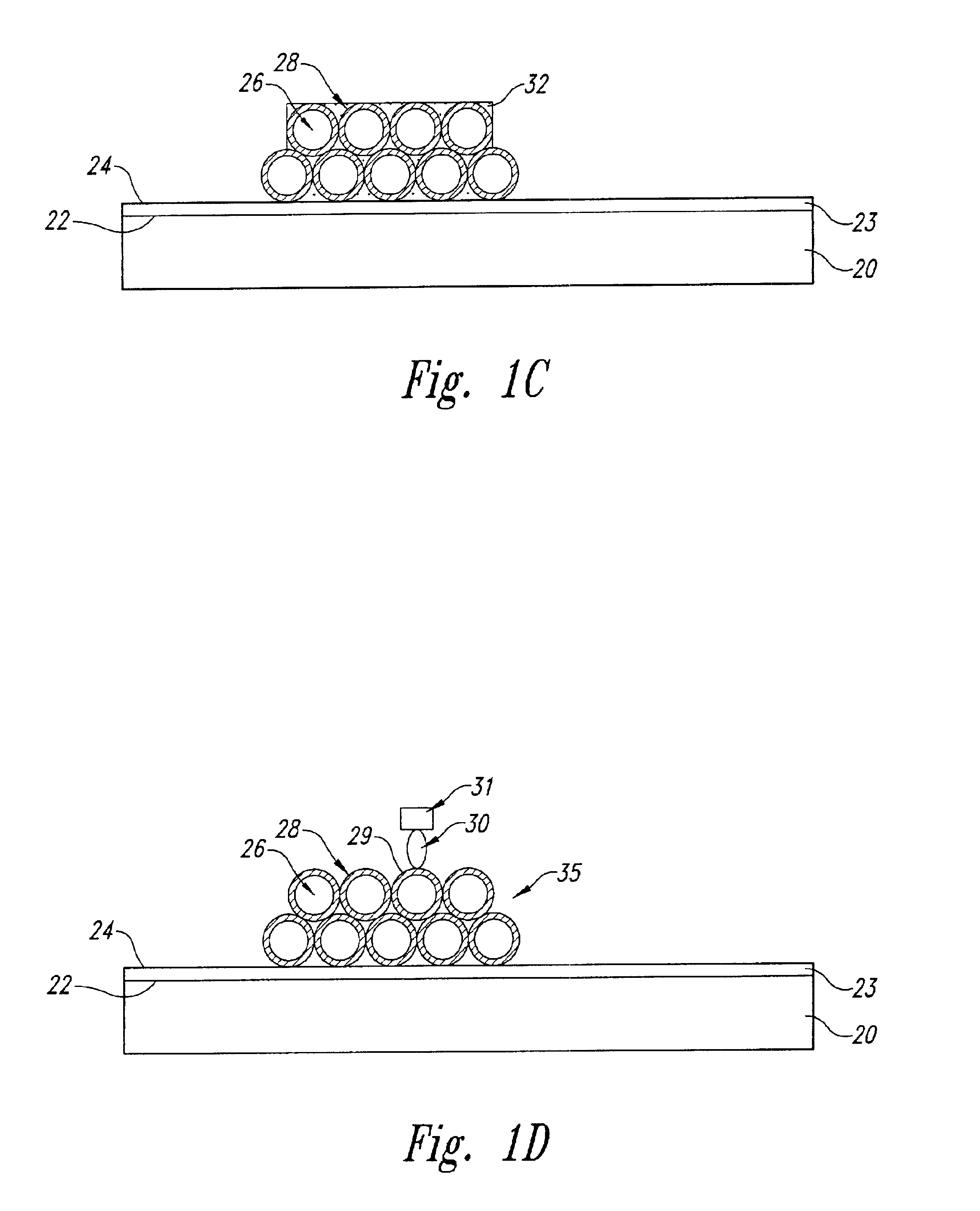

Porous coatings bearing ligand arrays and use thereof

InactiveUS6951682B1Uniform thicknessHigh coating strengthBioreactor/fermenter combinationsMaterial nanotechnologyPorous coatingChemical synthesis

Articles comprising substantially uniform porous coatings, which may be photopatterned, are provided. The use of such porous coatings increases the surface density of attached compounds within, for example, ligand arrays prepared by methods such as regionally selective solid-phase chemical synthesis. Arrays prepared using the porous coatings may be used within a variety of diagnostic and drug discovery assays.

Owner:SYNTRIX BIOSYST

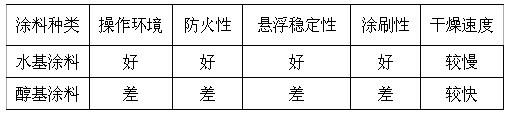

Sintering-strippable red cast iron coating and preparation method thereof

InactiveCN102601300APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresCrack resistancePreservative

The invention relates to a sintering-strippable low-cost red water-based cast iron coating, which is prepared by the following raw materials in percent by mass: 20-45 percent of bauxite powder or powder quartz, 0-25 percent of mullite powder, 1-6 percent of talcum powder, 1-5 percent of iron trioxide powder, 1-3 percent of suspending agent, 1.5-4.5 percent of organic binding agent, 1.5-6 percent of inorganic binding agent, 0.01-0.05 percent of wetting agent, 0.02-0.05 percent of preservative, 0.02-0.1 percent of defoaming agent, 0-0.5 percent of water reducing agent and 30-42 percent of tap water. The sintering-strippable low-cost red water-based cast iron coating has the characteristics that the raw materials are cheap and the source is wide; the product is low-cost, safe, environmental-friendly and convenient to transport; the brushing property, the flowing resistance and the leveling property of the product are good, the suspension percentage, the coating strength and the crack resistance are high and the gas evolution is low; and the sintering-stripping performance is excellent, the most part of the coating can be vastly stripped after castings are taken out of a casting box and are cooled, the defects of sand sticking, sand inclusion, sand drop, voids and the like existing the castings can be effectively avoided, and the castings with excellent surface quality can be obtained.

Owner:湖北省机电研究设计院股份公司

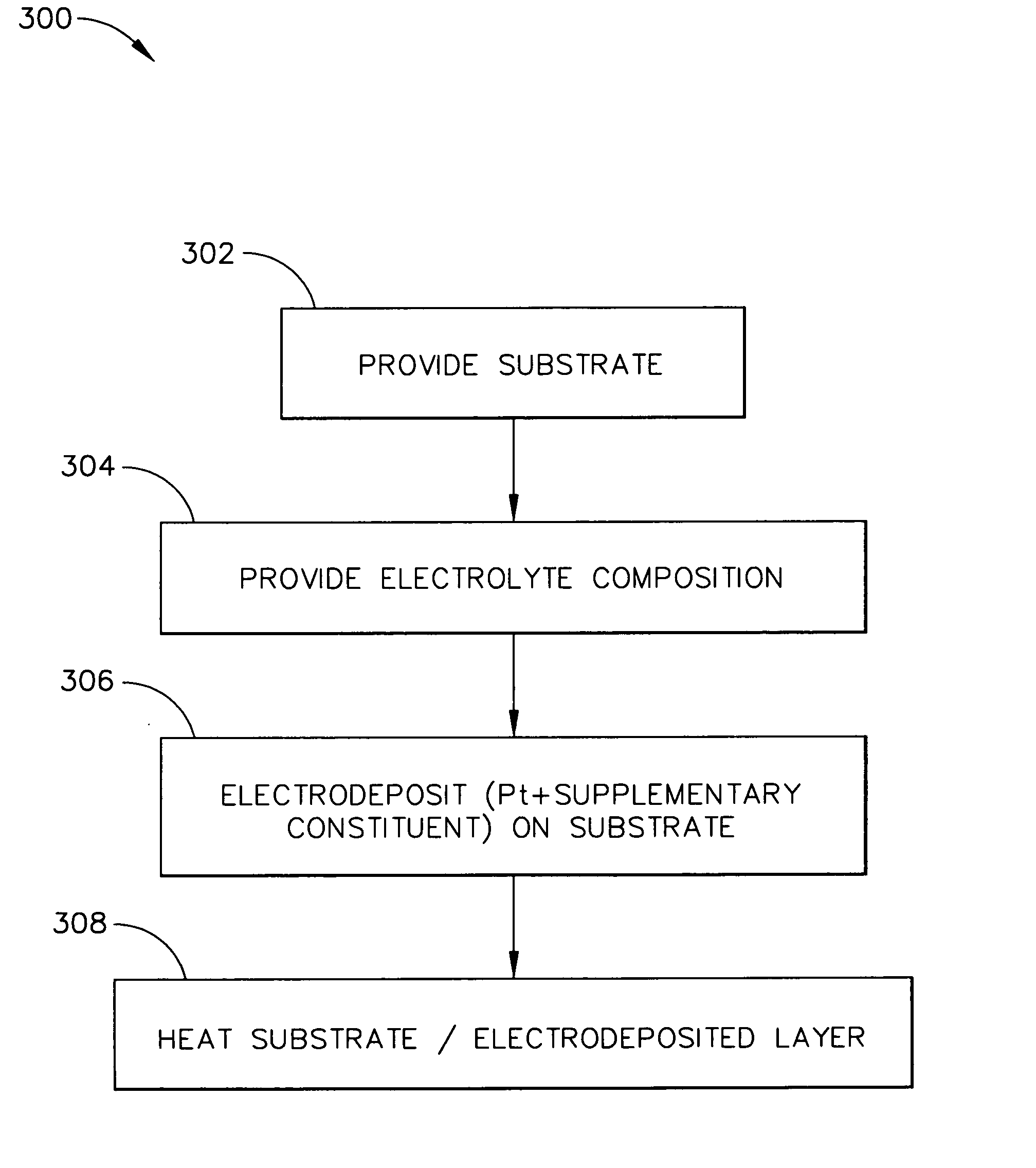

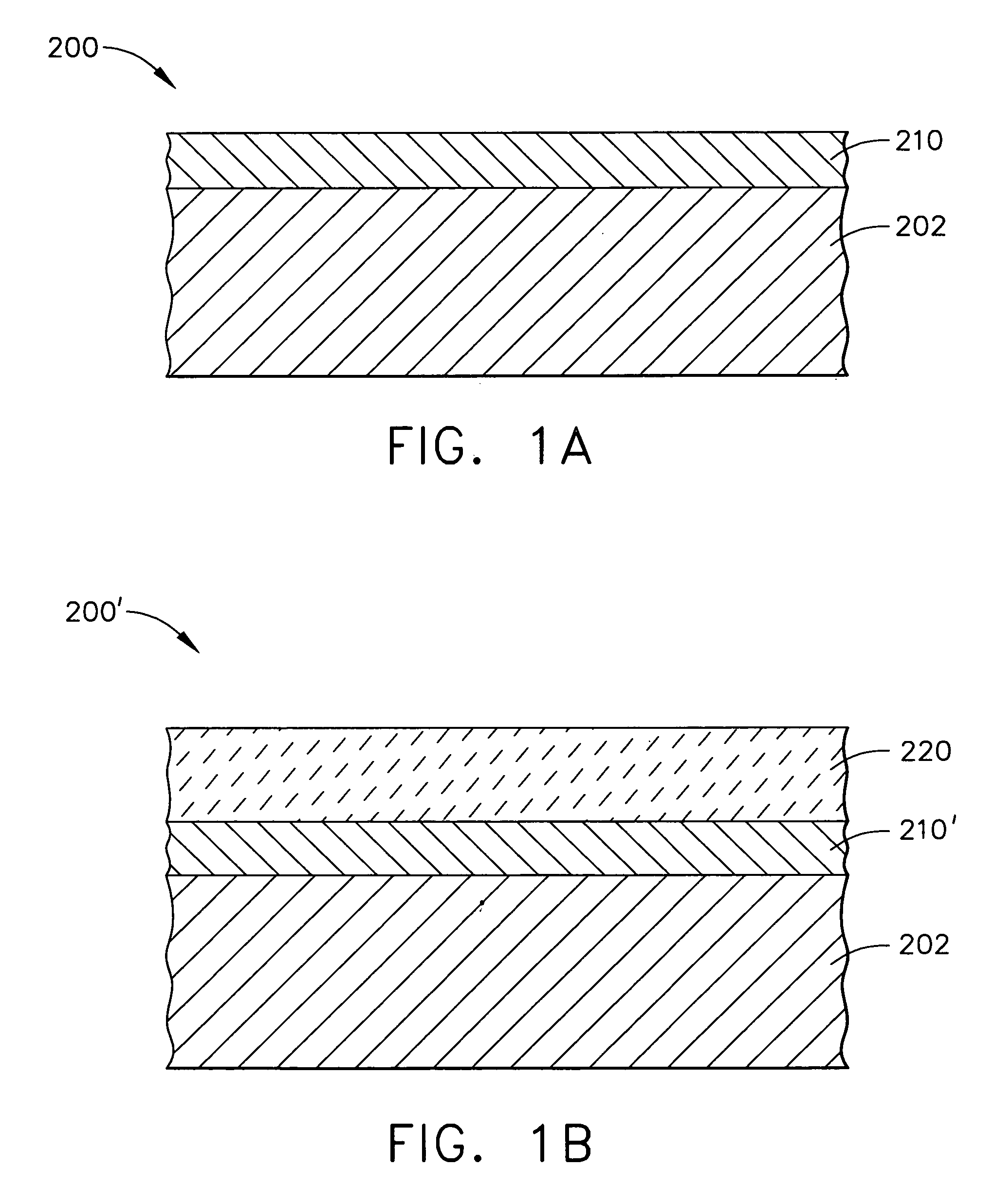

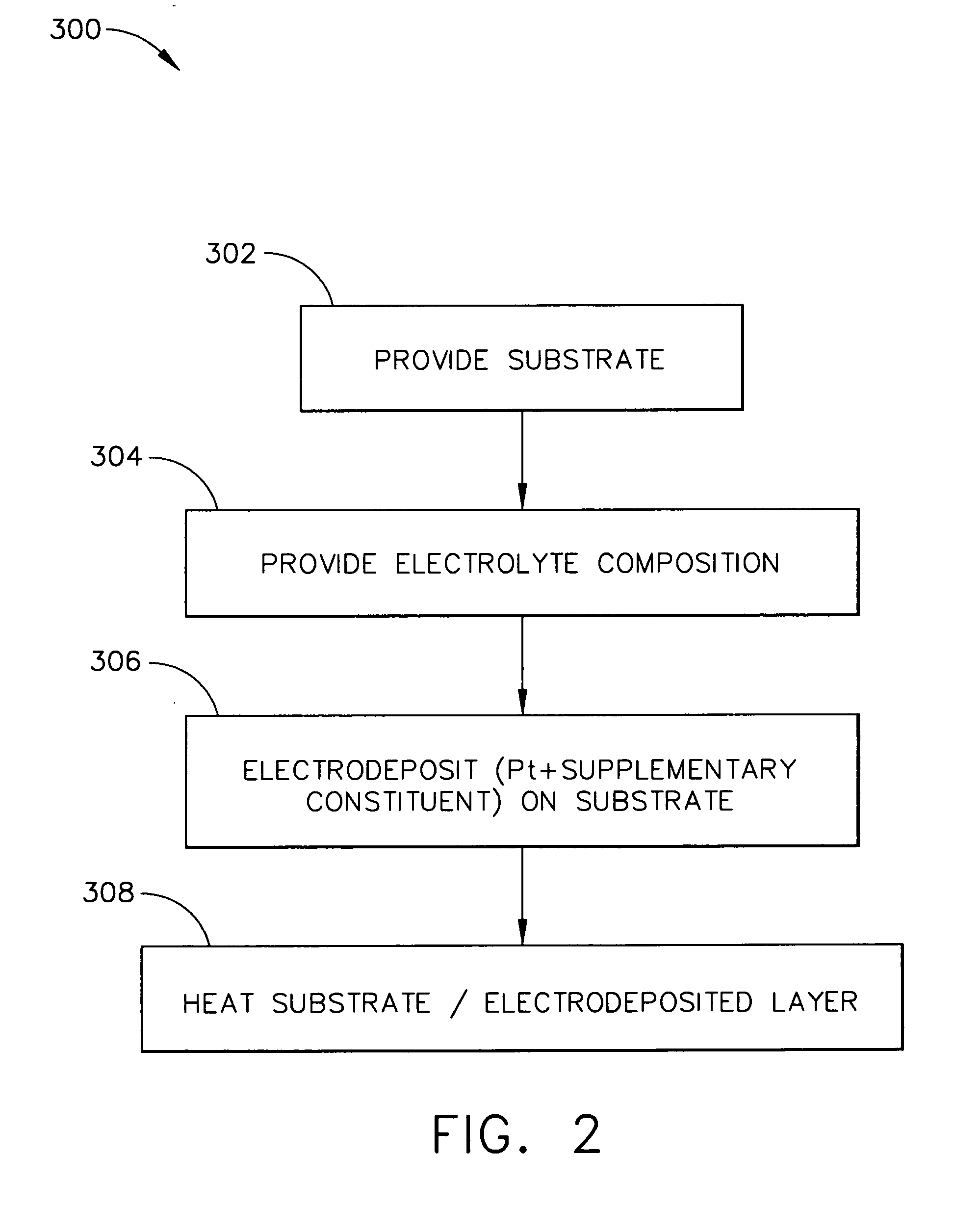

Platinum aluminide coating and method thereof

InactiveUS20050145503A1Improve adhesionReduce diffusional interactionEngine manufactureElectrolytic coatingsPlatinumElectrolyte composition

Platinum containing coatings for corrosion and oxidation protection of a substrate, and platinum electrodeposition methods for coating a substrate. The coating may comprise platinum and at least one supplementary constituent, and the method may involve co-electrodeposition of platinum and the supplementary constituent from a single electrolyte composition. The supplementary constituent may comprise chromium, an oxidation protective reactive element, or an alloy of chromium with a reactive element. Components protected by such coatings are also disclosed.

Owner:HONEYWELL INT INC

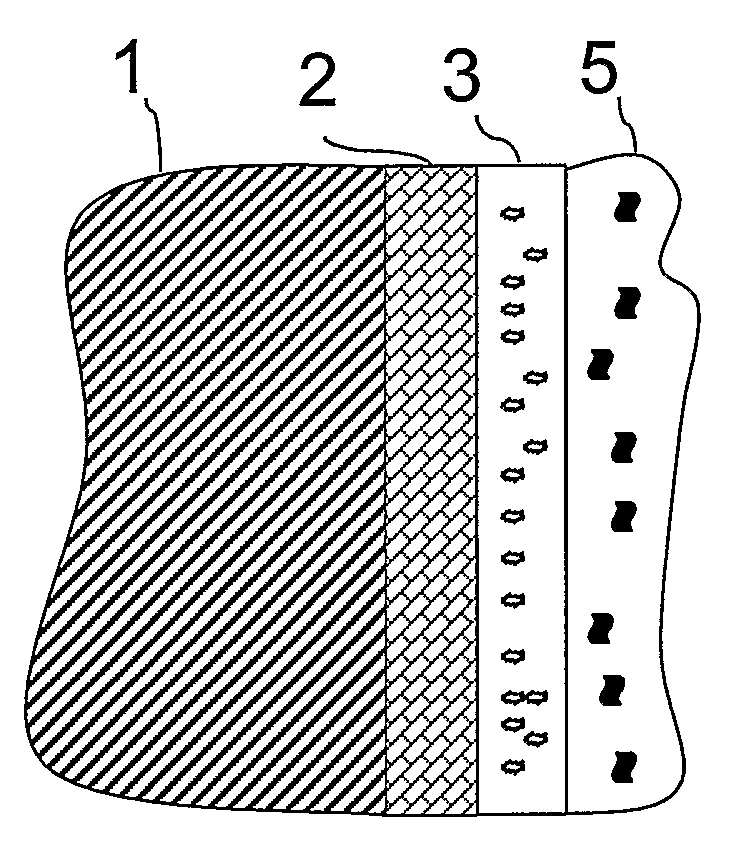

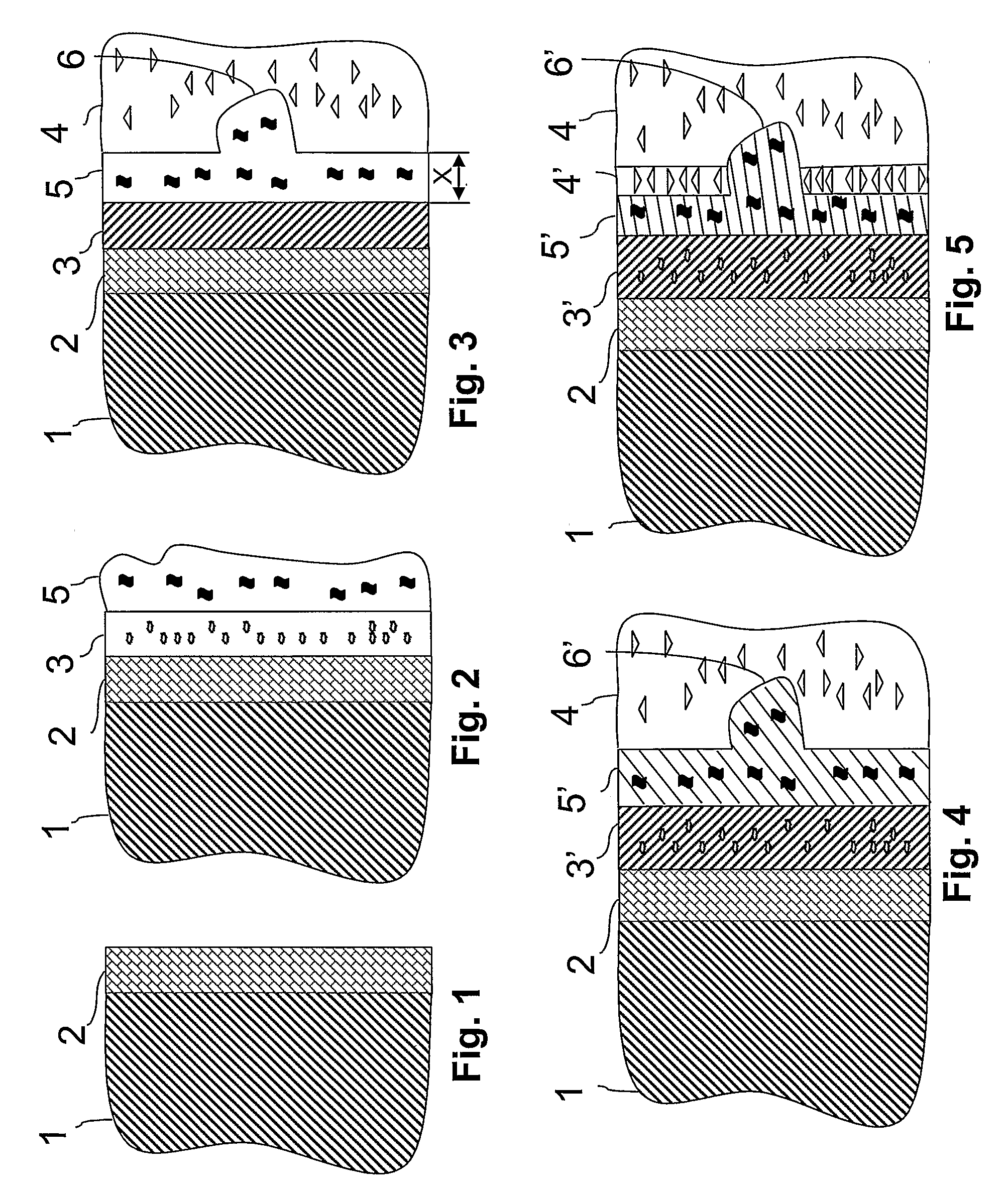

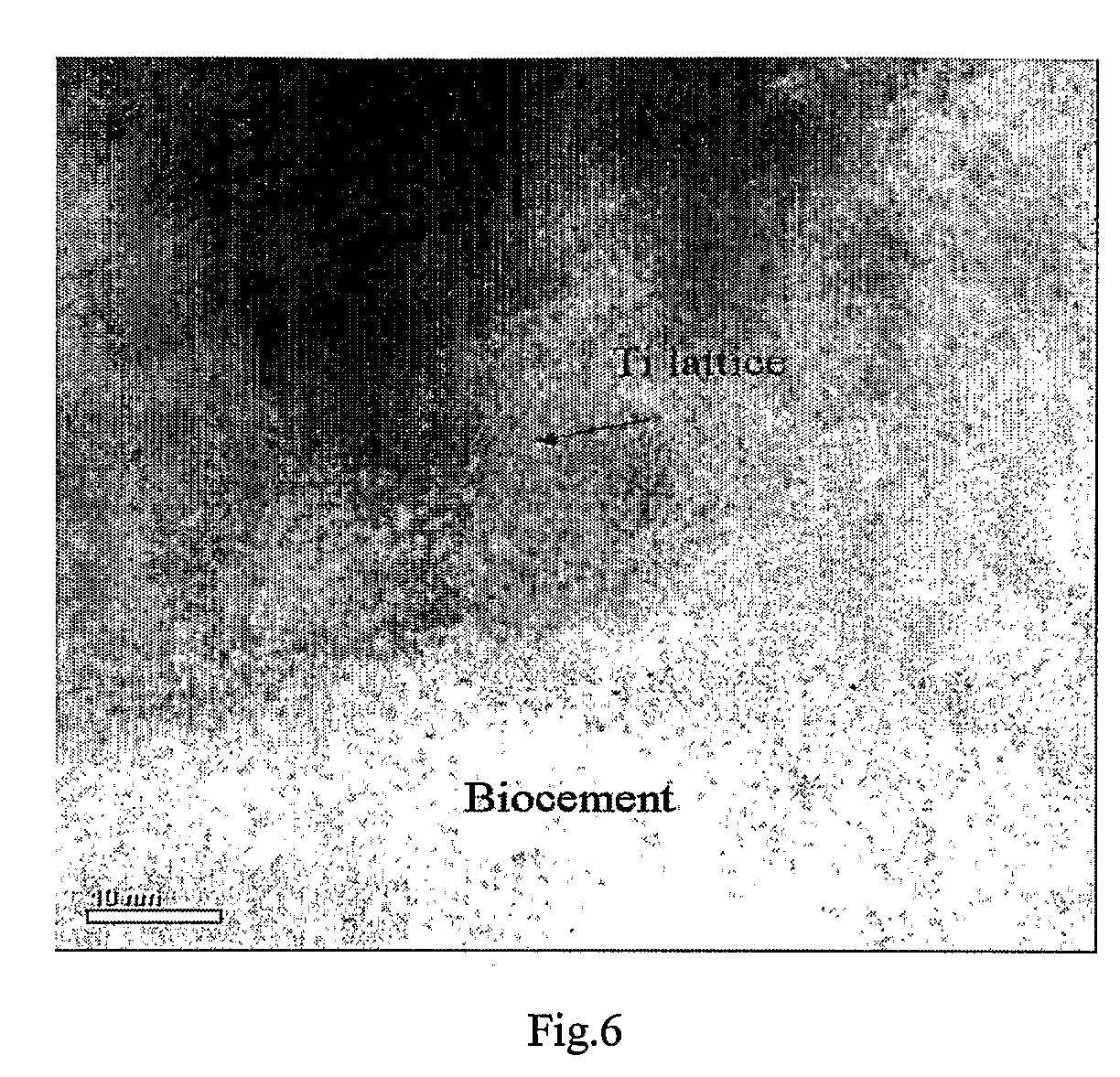

Implant and method of producing the same, and a system for implantation

InactiveUS20070173952A1High strengthPromote regrowthMaterial nanotechnologyImpression capsAluminatePhosphate

The present invention relates to a coated implant for in vivo-anchoring of implants to a biological tissue or another implant, which coated implant comprises an implant having a pre-treated surface and on said pre-treated surface one or more layers of ceramic material chemically and / or mechanically bound to said pre-treated surface. Said one or more layers comprises mainly non-hydrated chemically bonded ceramic material, and each layer independently comprises a first binder phase selected from the group consisting of aluminates, silicates, phosphates, sulphates and combinations thereof. The invention further relates to method of manufacturing said coated implant, a ceramic paste and to a kit comprising said coated implant and ceramic paste. The invention is particularly suitable for dental and orthopaedic implants.

Owner:DOXA AB

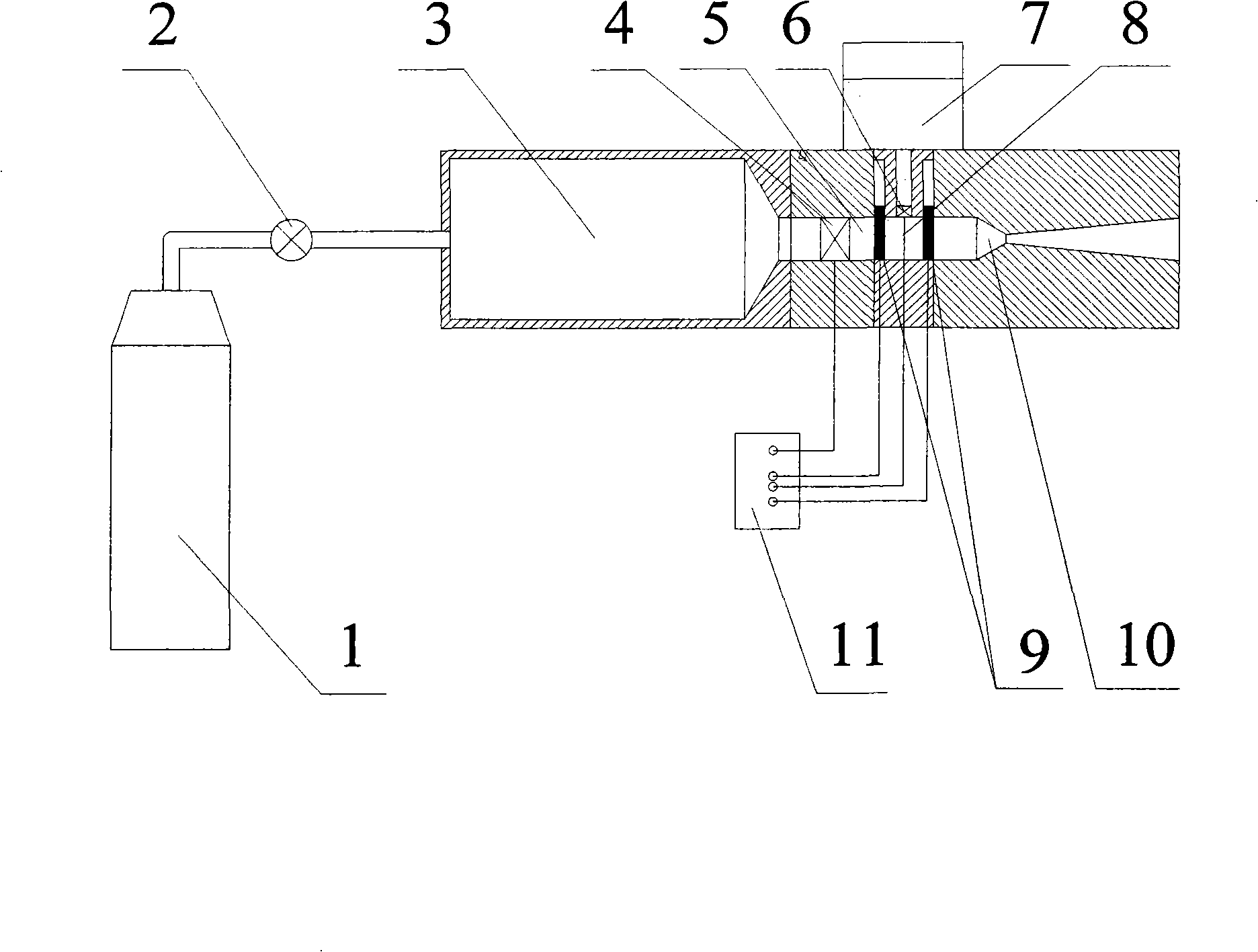

Solid particle group accelerating device for shock tube-Laval nozzle

InactiveCN101274710ALong rangeIncreased spray coverageSpray nozzlesFire rescueParticle injectionSolid particle

The invention discloses a shock wave tube-Laval nozzle accelerating device of a solid particle group. A compressed gas source is connected with a high pressure gas chamber of a shock wave tube by a compressed gas check valve, a powder storage chamber is surrounded by tube walls and movable clapboards at the two ends of the powder storage chamber, one of the movable clapboard separates a low pressure air chamber and the powder storage chamber and the other moveable clapboard separates the powder storage chamber and the Laval nozzle; a particle injection hole is cut on the side wall of the powder storage chamber to be connected with a powder supply source; a powder supply switch valve is arranged in the particle injection hole to separate the powder supply source and the powder particle in the powder storage chamber; a control circuit board is respectively connected with a transient switch valve, the powder supply switch valve and the two movable clapboards. As a chemical powder extinguisher, since the shock wave tube and the Laval nozzle function synchronously to accelerate the solid particle group to cause the shooting range of extinguisher to be sufficiently far off and an ejection covering area can be appropriately enlarged by enlarging the expansion angle of the gradual-widening section of the Laval nozzle, the shock wave tube-Laval nozzle accelerating device has high extinguishing efficiency, good effect, long shooting range and energy conservation; as an ultrasonic cool spraying device, the particle adhesive strength and the coating strength are great.

Owner:ZHEJIANG SCI-TECH UNIV

Porous structural elastic composite material for extracting uranium from seawater and preparation method

InactiveCN108579709AImprove flexibilityImprove mechanical stabilityOther chemical processesSeawater treatmentCross-linkMechanical stability

The invention provides a preparation method of a porous structural elastic composite material for extracting uranium from seawater. The preparation method comprises preparing an amidoximated polyacrylonitrile solution, mixing the amidoximated polyacrylonitrile solution and a strong alkali aqueous solution, maintaining heating and stirring until dissolved, adding the stirred solution into an aqueous solution of a polymer material capable of cross-linking gelation, mixing uniformly the solution, immersing a porous structure elastic material into the mixed solution, carrying out vacuum defoaming,carrying out drying, immersing the dried porous structure elastic material in a cross-linking agent solution, carrying out cross-linking gelation and carrying out rinsing with water. The aqueous solution of the polymer material which can be cross-linked and gelled is cross-linked and gelled so that the coating strength of amidoximated polyacrylonitrile on the porous structure elastic material skeleton is improved, the material flexibility, mechanical stability and hydrophily are improved and the high adsorptive porous structural elastic composite material for extracting uranium ions from seawater is obtained.

Owner:HAINAN UNIVERSITY +1

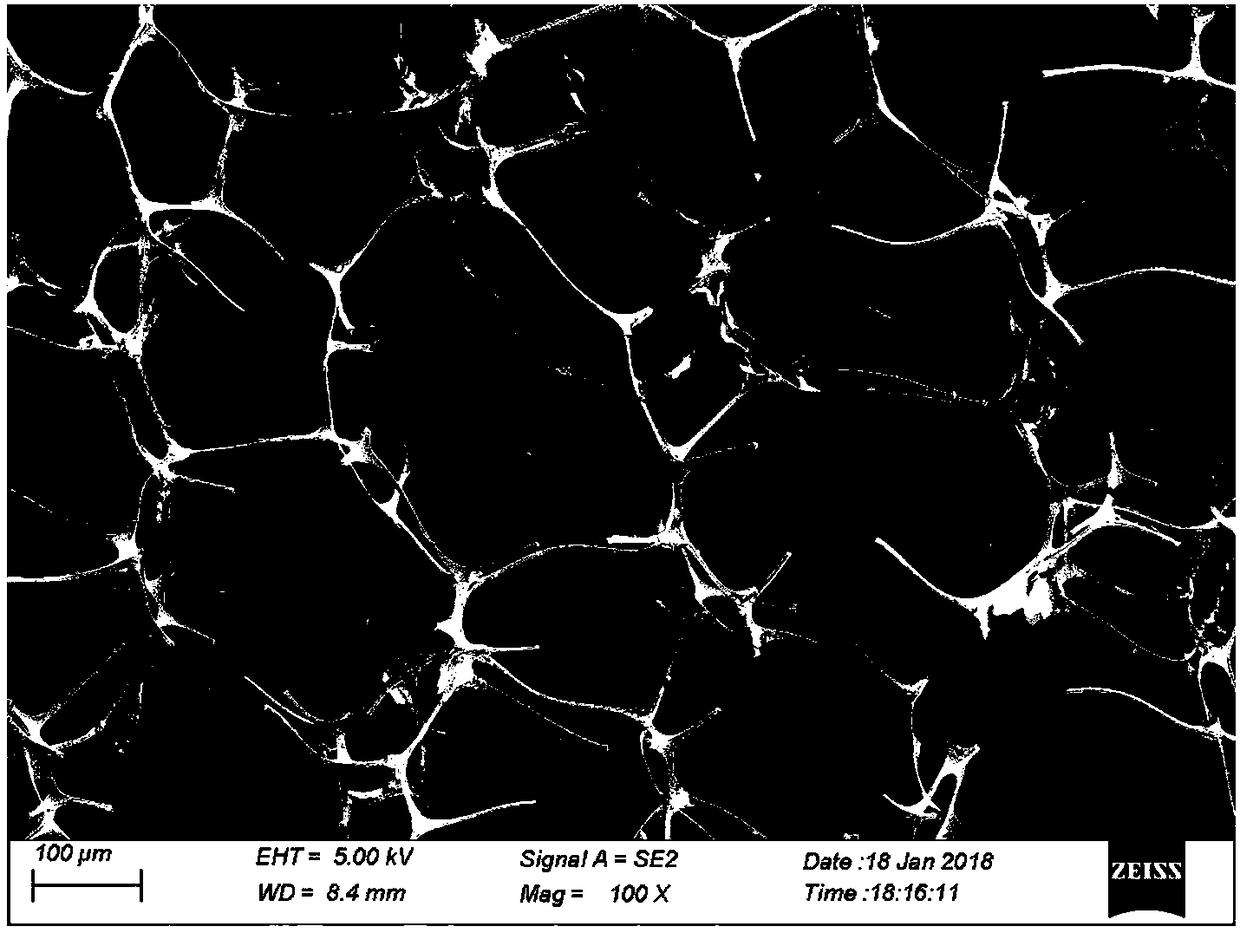

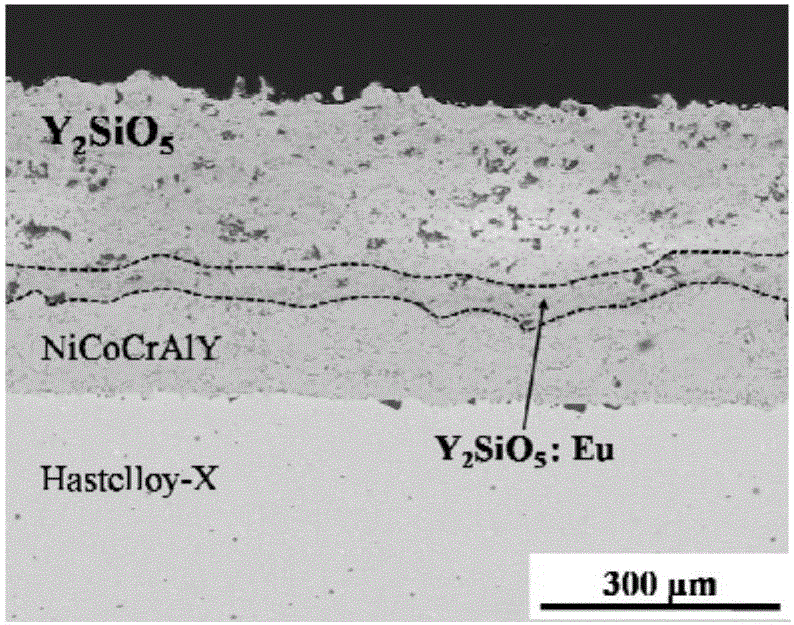

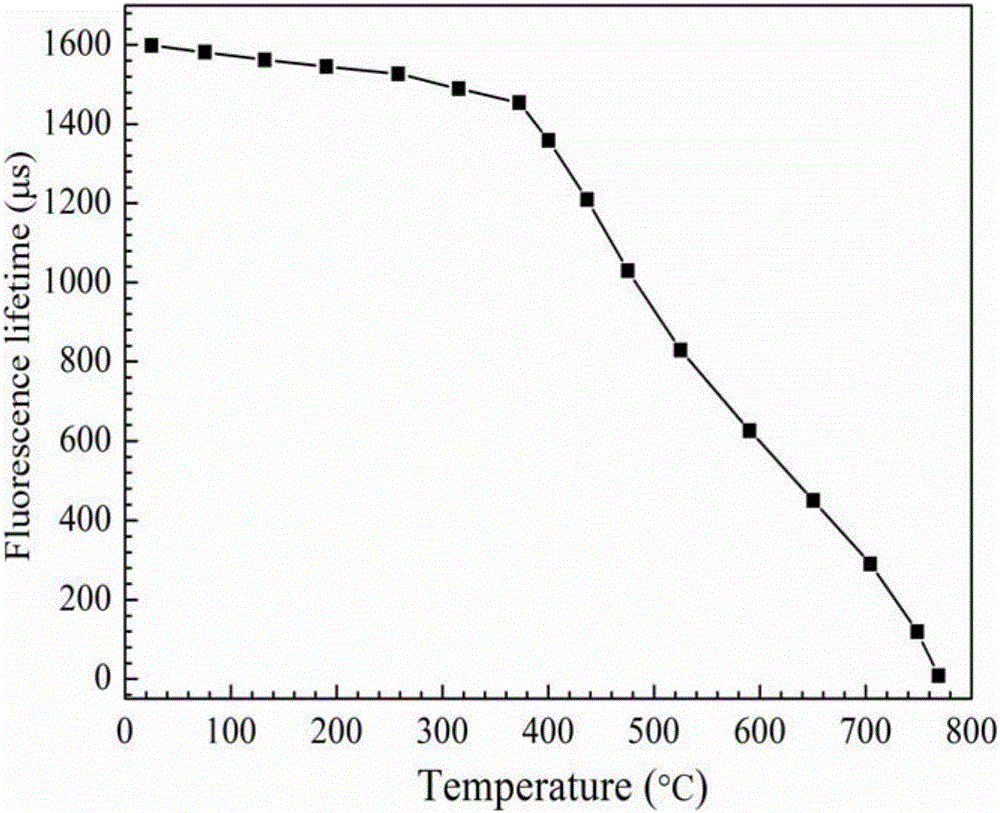

Preparation method and application of temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating

ActiveCN106119765ADoes not affect luminous propertiesFlexible combinationMolten spray coatingThermometers using electric/magnetic elementsFluorescenceMicrosphere

The invention relates to a preparation method and application of a temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating. The preparation method comprises the steps that nanometer yttrium oxide powder, micrometer silicon dioxide powder, nanometer europium oxide powder and LiYO2 powder are subjected to ball-milling and high-temperature sintering to obtain ceramic aggregate powder Y2SiO5:Eu powder which is then dispersed into 1-methyl pyrrolidone; polyving alcohol is added to enable the ceramic aggregate powder Y2SiO5:Eu powder to be dispersed completely and then ultrasonic oscillation is conducted; then a mixed binder is added to conduct L-S phase conversion preparation, and obtained coated Y2SiO5:Eu microballons are sprayed on the surface of a high-temperature alloy sample with a metal bonding layer to form a fluorescent layer with the thickness being 3-50 [mu]m; and then a Y2SiO5 coating is sprayed on the surface of the fluorescent layer according to the same spraying process, so that the temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating is obtained and can be used in coating temperature measurement. The prepared thermal barrier coating has the advantages that the surface is even, no microcrack occurs, the thickness is uniform, no penetrating hole exists, and the bonding force is good. In addition, excellent fluorescent emitting performance and a temperature fluorescent effect are achieved, and the temperature sensitive type Y2SiO5:Eu intelligent thermal barrier coating can be applied to the field of fluorescent temperature measurement of coatings.

Owner:SHANGHAI JIAO TONG UNIV

Sealing corrosion proof protection method of rope-suspension bridge cable system

ActiveCN101457364AGood weather resistanceIncrease elasticityHot-dipping/immersion processesLiquid surface applicatorsShock mountEngineering

The invention discloses a sealing and anti-corrosion protection method of a suspension bridge cable system, and belongs to an anti-corrosion protection method of a bridge cable. The method helps divide the whole cable system into 7 types of surfaces: an outer surface of a main cable of a wire wrapping section; the outer surface of the main cable of a non-wire wrapping section; the outer surface of a main cable saddle exposing a strand; the outer surfaces of a cable strand inside an anchor chamber, a sling wire rope, as well as a railing rope and a side rope of a maintaining roadway; the outer surfaces of a cable clamp, a cable saddle (sleeve) and a saddle, and exposed surfaces of bolts and nuts; the outer surfaces of an anchor cup, a sling clamp, a sling shock mount, and columns and brackets of the maintaining roadway; and gap sealing surfaces of the cable clamp, a cable jacket girth seam, an abutted seam and a top saddle opening. The 7 types of the surfaces are treated by different methods, and the sealing and anti-corrosion method is complete. In the method, novel sealing materials and anti-corrosion paints are used, which has good sealing performance, long anti-corrosion service life and high strength, and ensures the durability of the suspension bridge cable system.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

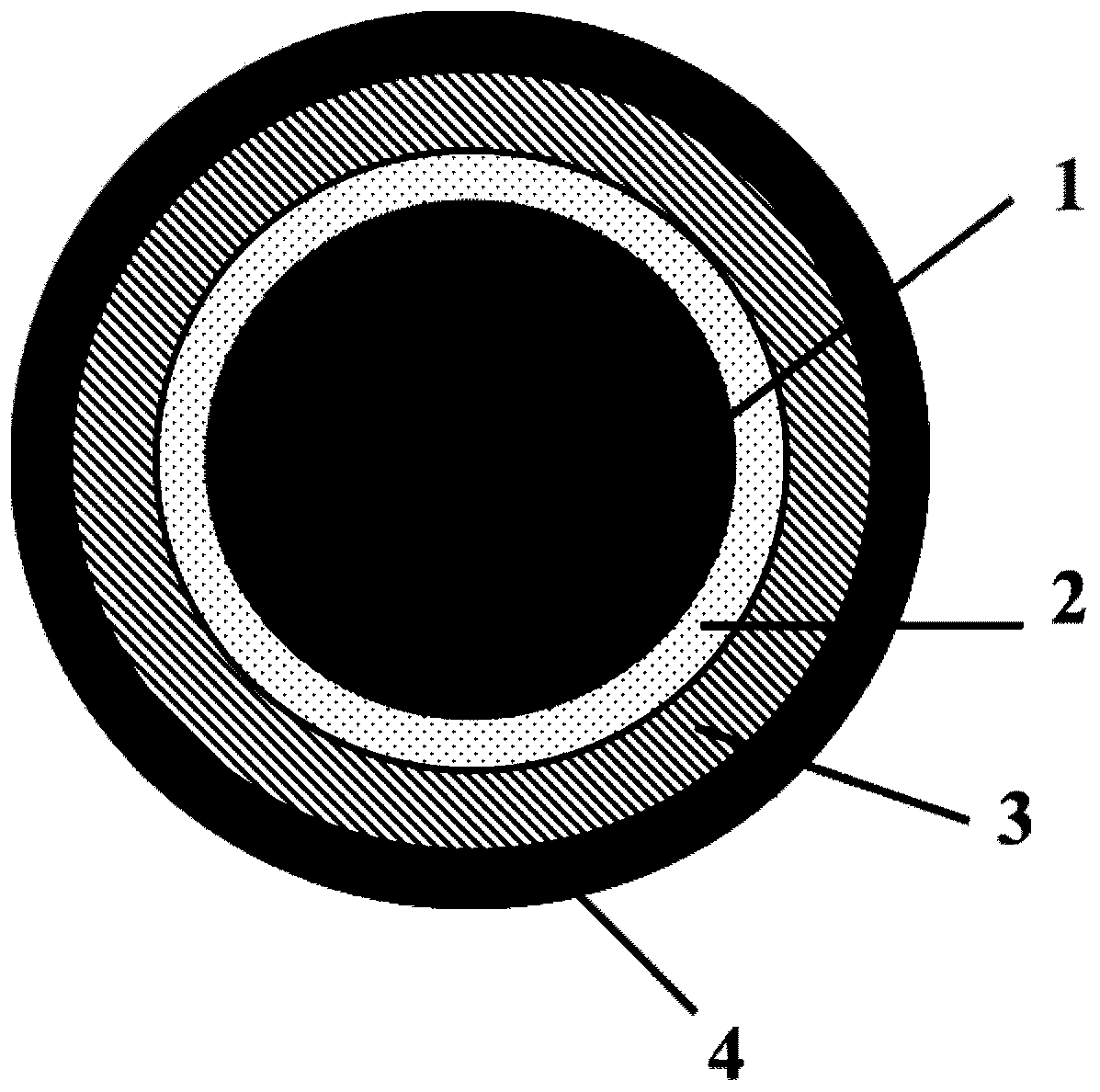

Negative electrode material with multiple coating structures as well as preparation method and application of negative electrode material

ActiveCN110993949ALower pHImprove ionic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon coatingElectrolytic agent

The invention relates to a negative electrode material with a multi-coating structure as well as a preparation method and application of the negative electrode material. The negative electrode material with the multiple coating structures comprises lithium-containing silicon monoxide as well as a lithium salt coating layer, a carbon coating layer and a polymer coating layer which sequentially coatthe surface of the silicon monoxide. The lithium salt coating layer of the negative electrode material effectively inhibits the volume expansion of the material, improves the ionic conductivity of the surface of the material, improves the cycling stability of an electrode, and reduces the alkalinity of the material; the carbon coating layer of the negative electrode material improves the electronic conductivity of the surface of the material and improves the oxidation-reduction reaction rate of the surface of the material; the polymer coating layer of the negative electrode material improvesthe compatibility between the silicon monoxide and the organic electrolyte, limits the volume expansion of the material to a certain extent, avoids the cracking of the material, and more effectively improves the cycling stability of the electrode.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

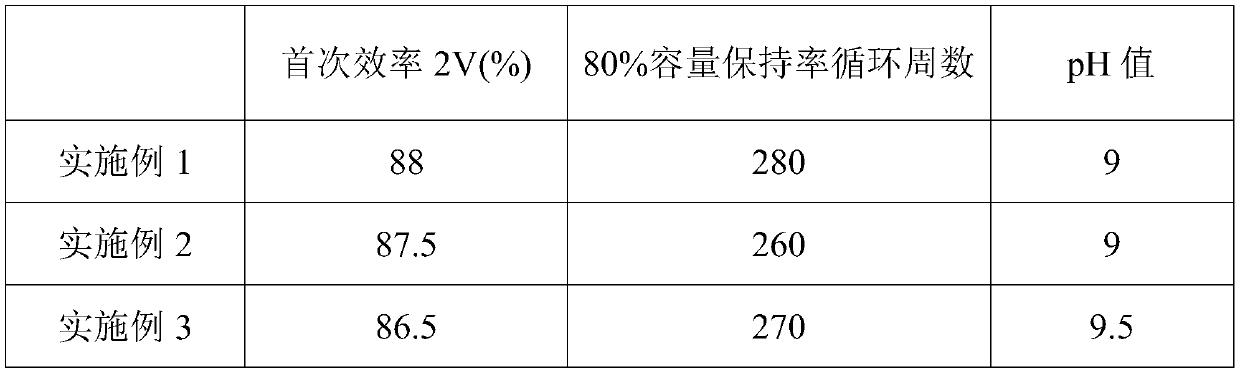

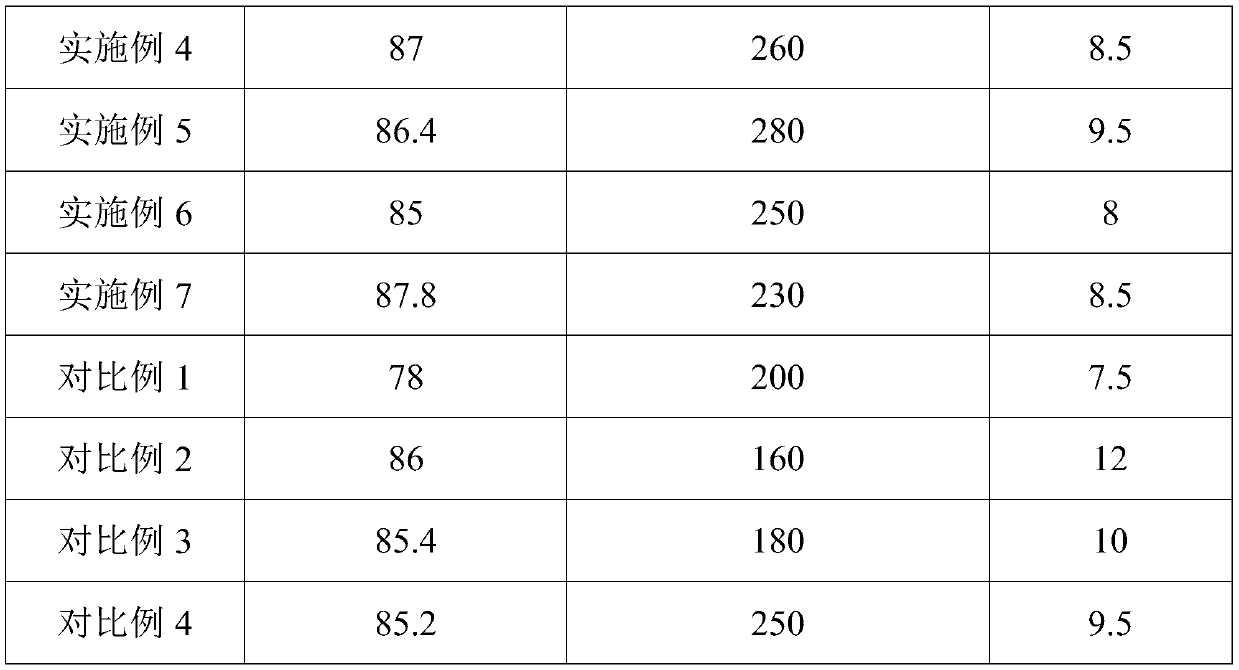

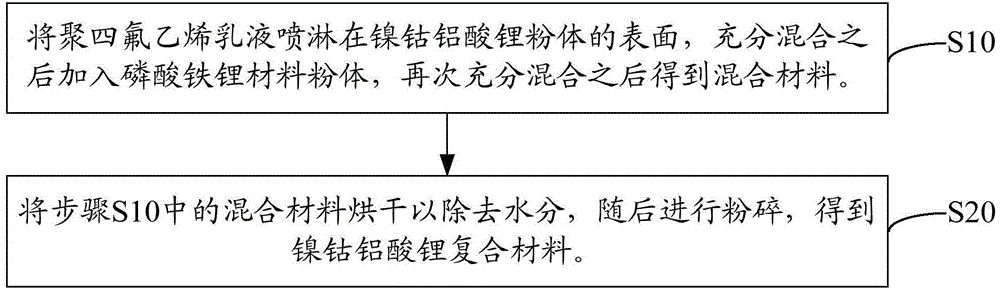

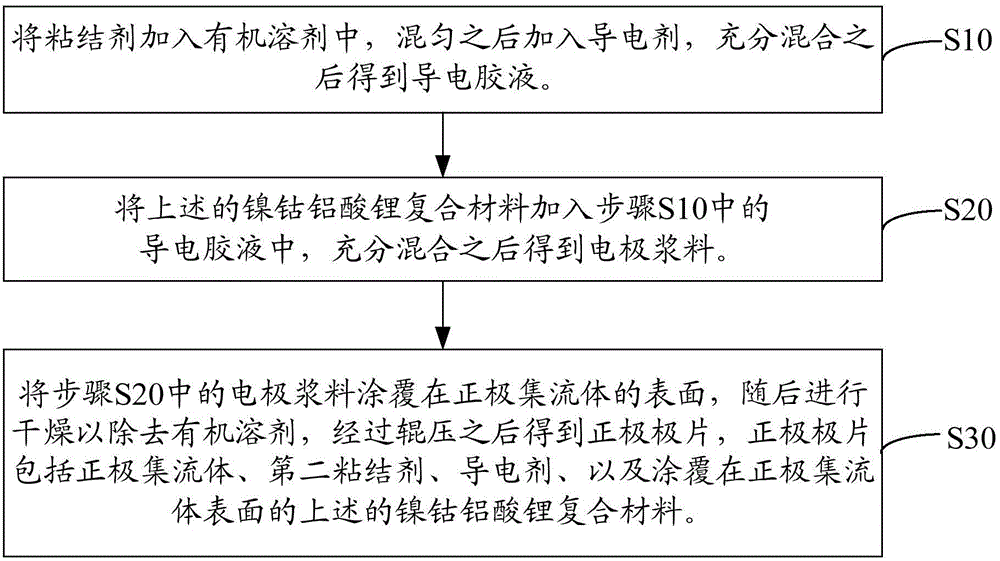

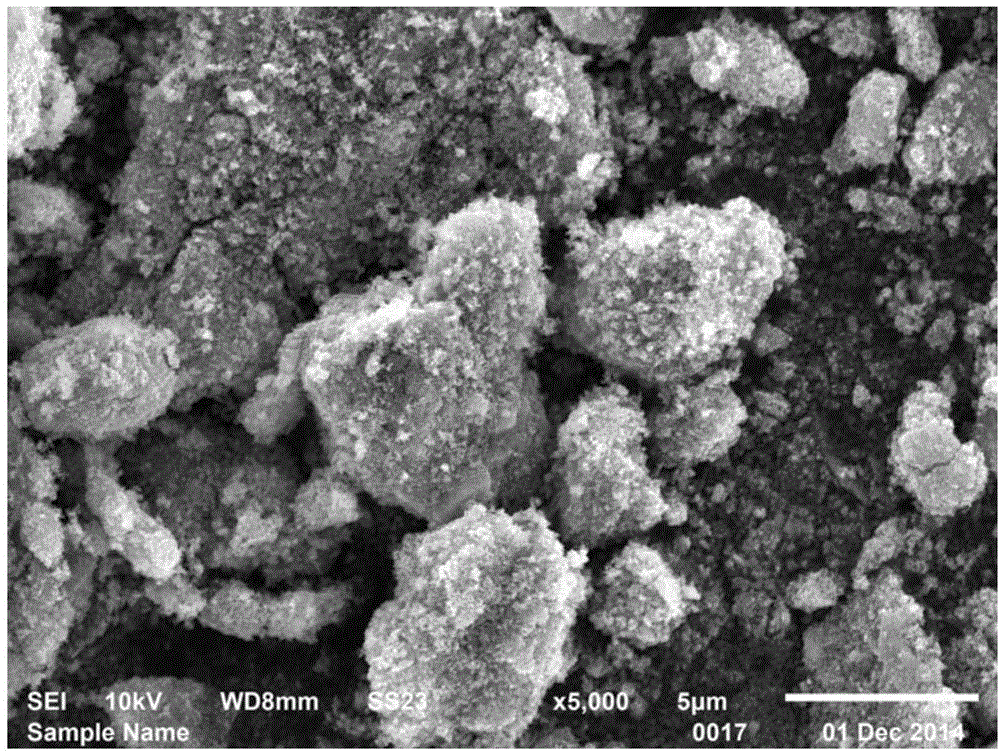

Lithium nickel cobalt aluminate composite material and preparation method and application thereof

InactiveCN106299353AAvoid ability to declineImprove gas problemCell electrodesMixed materialsLithium-ion battery

The invention relates to a lithium nickel cobalt aluminate composite material and a preparation method and application thereof. The lithium nickel cobalt aluminate composite material comprises lithium nickel cobalt aluminate and a lithium iron phosphate material coating the surface of the lithium nickel cobalt aluminate, wherein lithium ferric manganese phosphate and the lithium nickel cobalt aluminate are glued together through polytetrafluoroethylene. By the lithium nickel cobalt aluminate composite material, the problem of battery bulging can be solved. The preparation method of the lithium nickel cobalt aluminate composite material comprises the following steps of spraying a polytetrafluoroethylene emulsion on the surface of lithium nickel cobalt aluminate powder, fully mixing, adding lithium iron phosphate powder and fully mixing again to obtain a mixed material; and drying the mixed material to remove moisture, and then carrying out crushing to obtain the lithium nickel cobalt aluminate composite material. By the method, secondary sintering on the material is not needed, the problem of performance reduction of the lithium nickel cobalt aluminate composite material caused by sintering is solved and application is facilitated. Furthermore, the invention further provides a positive pole piece comprising the composite material and a lithium-ion battery comprising the positive pole piece.

Owner:LONG POWER SYST SUZHOU

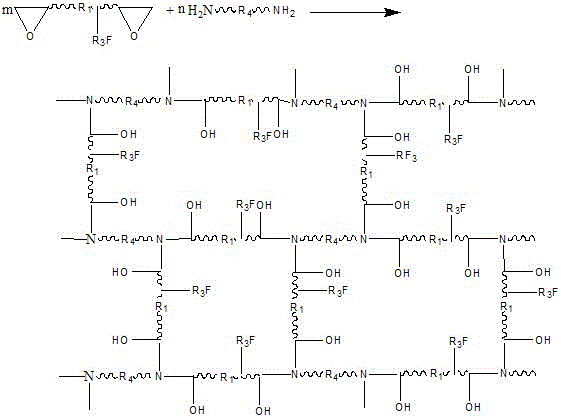

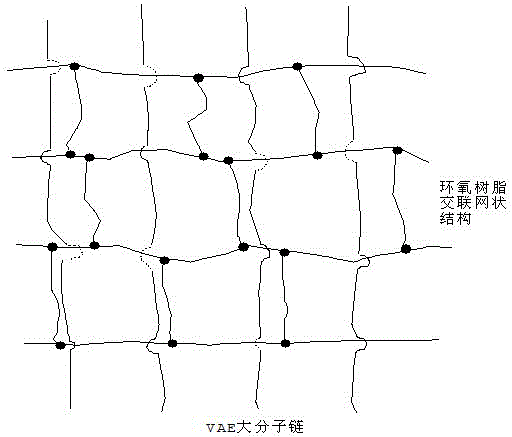

Epoxy resin modified VAE composite waterproof material and preparation method thereof

ActiveCN103555091AImprove water resistanceIncrease crosslink densityFireproof paintsAntifouling/underwater paintsPropanoic acidPhosphoric acid

An epoxy resin modified VAE composite waterproof material and a preparation method thereof. The composite waterproof material is composed of a component A and a component B. A preparation method of the component A is as below: adding a vinyl acetate-ethylene copolymer emulsion into a material canister, then adding an epoxy resin emulsion and a defoaming agent, stirring, then adding aluminum hydroxide, phosphoric acid tris(2-chloroethyl) ester, talcum powder, a polytetrafluoroethylene fine powder, tetra [beta-(3,5-di-t-butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester, 2-(2H-benzo triazoles-2-yl)-6-dodecyl-4-methylphenol and water, and stirring to obtain the component A. A preparation method of the component B is as below: under the protection of nitrogen, adding tetraethylenepentamine into a reactor, dropwise adding ethylene glycol diglycidylether and butyl glycidol ether for a thermal reaction, then adding water to dilute and stirring to obtain the B component. The component A and the component B are stirred according to a part ratio of 100: 5-8 and applied; and after curing, a flame retardant antifouling self-cleaning composite waterproof material with a semi-interpenetrating network macro-molecular structure is obtained.

Owner:太原英可奥笔墨科技有限公司

Calcined quartz powder casting coating and production method thereof

ActiveCN104493076AGood suspensionHigh coating strengthFoundry mouldsFoundry coresSpecific gravitySolvent

The invention discloses a calcined quartz powder casting coating and a production method thereof. The calcined quartz powder casting coating comprises the following components: 80-100 parts of quartz powder, 0-50 parts of corundum powder, 0-100 parts of mullite powder, 0-30 parts of bauxite powder, 0-100 parts of zircon powder, 0-10 parts of flake graphite, 0-20 parts of earthy graphite, 0-5 parts of red iron oxide, 6-8 parts of a suspension, 5-8 parts of resin and an appropriate amount of a solvent. The production method comprises the following steps: adding the suspension, the resin and the appropriate amount of solvent in a blender to be stirred for 10-30 minutes, then adding quartz powder, alumina powder, mullite powder, bauxite powder, zircon powder, flake graphite, earthy graphite, and red iron oxide to be stirred for 30-60 minutes, adding the appropriate amount of solvent to be adjusted to an appropriate proportion to obtain the casting coating. According to the calcined quartz powder casting coating and the production method thereof provided by the invention, the calcined quartz powder is used as a refractory material to produce the coating, and the resource of quartz powder is rich, so that the problem of lack of resources is solved; the cost is greatly reduced, the product quality is improved, the market competitiveness is strong and the popularization and application value is high.

Owner:昌乐恒昌化工有限公司

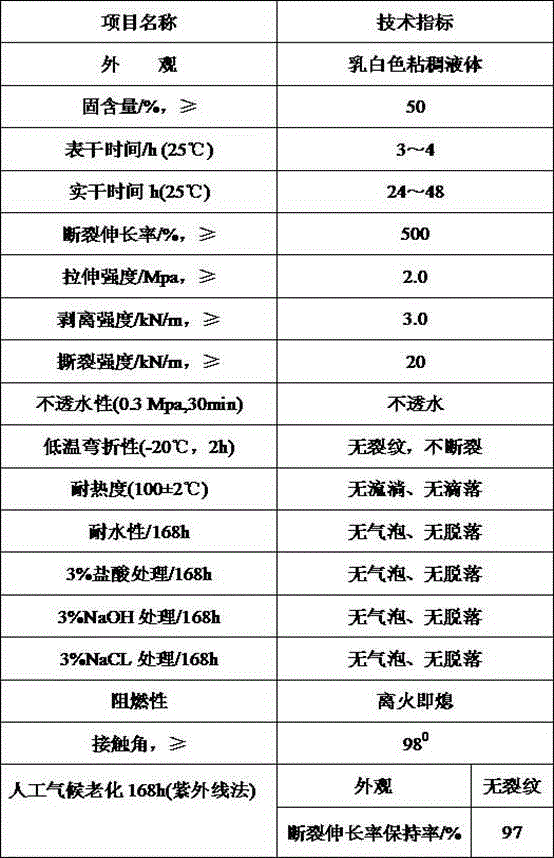

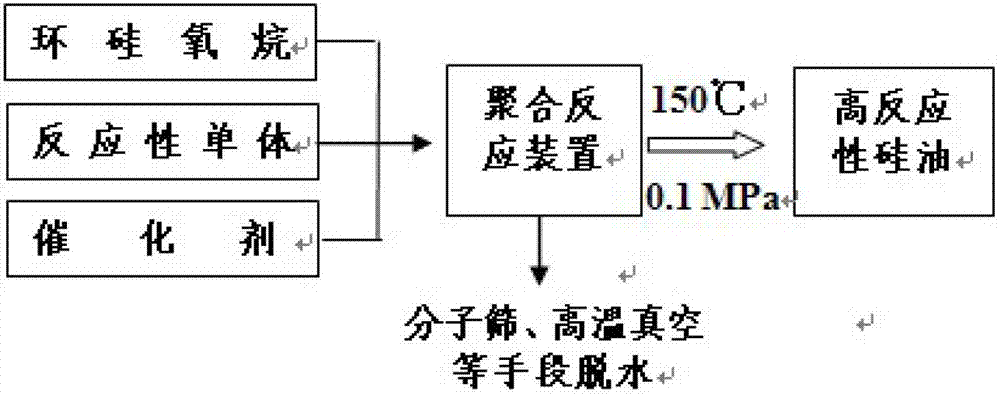

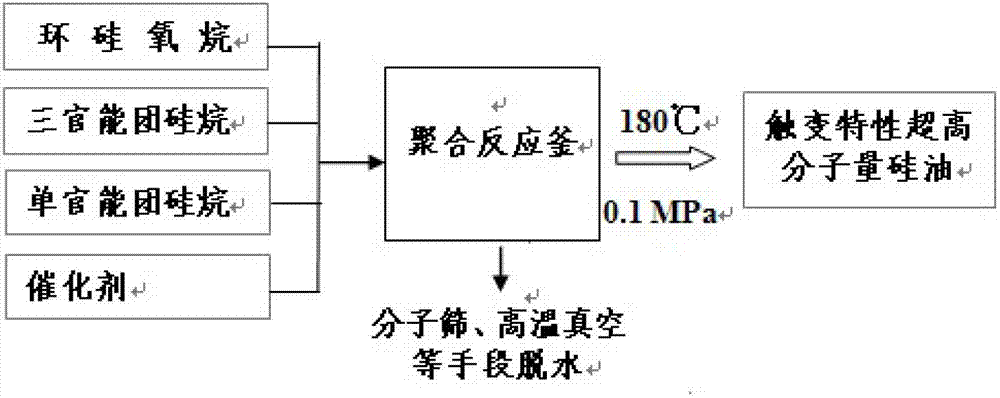

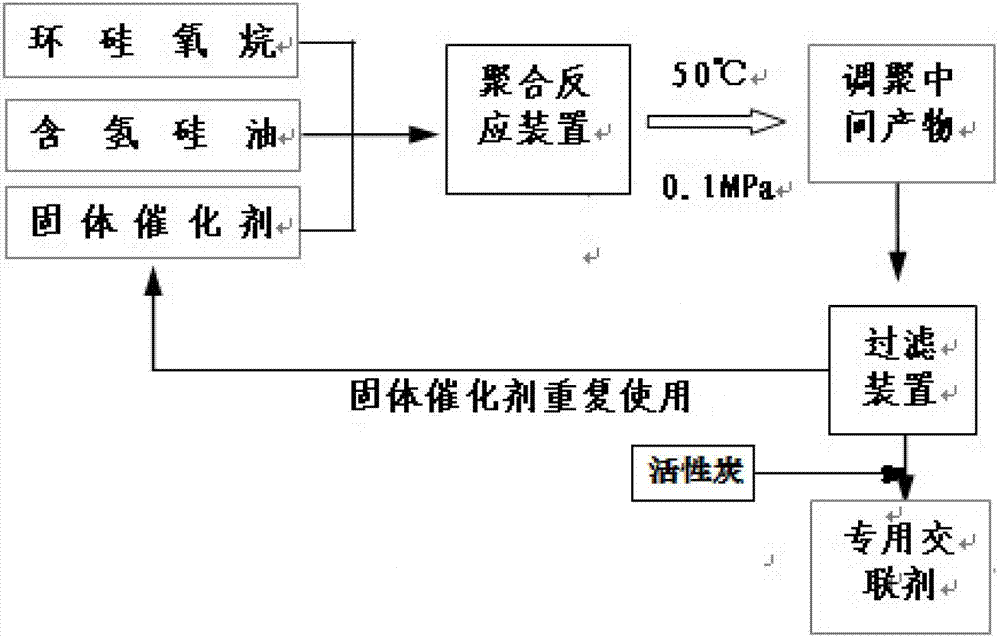

Organic/inorganic nanometer function particle modified organosilicon fabric coating agent preparation method

ActiveCN102898652ADoes not affect softness and comfortHigh strengthVegetal fibresChemical industryPolymer science

The present invention belongs to the technical field of chemical industry, and specifically relates to an organic / inorganic nanometer function particle modified organosilicon fabric coating agent preparation method. The preparation method comprises: adopting an anion ring opening polymerization process to synthesize hyperreactivity silicone oil, a special cross-linking agent, and silicone oil having thixotropy and ultra-high molecule weight; carrying out molecule penetration melting of the hyperreactivity silicone oil, the special cross-linking agent, and the silicone oil having thixotropy and ultra-high molecule weight to synthesize an organosilicon coating agent base gum; and finally adopting a high energy dispersing device to uniformly wrapping nanometer hollow silica microspheres and polymer hollow microspheres into the organosilicon coating agent base gum under a strong shear condition to obtain the organic / inorganic nanometer function particle modified organicsilicon fabric coating agent. With the organic / inorganic nanometer function particle modified organicsilicon fabric coating agent, good crisp hand feeling and slick feeling can be provided for the coated fabric coating, and strength, hydrostatic pressure resistance and waterproof moisture permeation performance of the fabric coating can be significantly improved without influence on softening and comfort of the fabric.

Owner:ZHEJIANG CHANGE ORGANIC SILICON MATERIAL

Magnetic recording medium

InactiveUS20050282040A1Low surface electrical resistivityLight transmittance be reduceBase layers for recording layersRecord information storageMagnetic layerRadiation

Provided is a magnetic recording medium having excellent surface smoothness and coating durability. The magnetic recording medium comprises an undercoating layer comprising a radiation-curing resin as a main component and a magnetic layer comprising a ferromagnetic powder and a binder in this order on a nonmagnetic support. The undercoating layer comprises no particulate matter, and the magnetic layer comprises a diamond powder.

Owner:FUJIFILM CORP +1

Metal coated fiber and electroconductive composition comprising the same and method for production thereof and use thereof

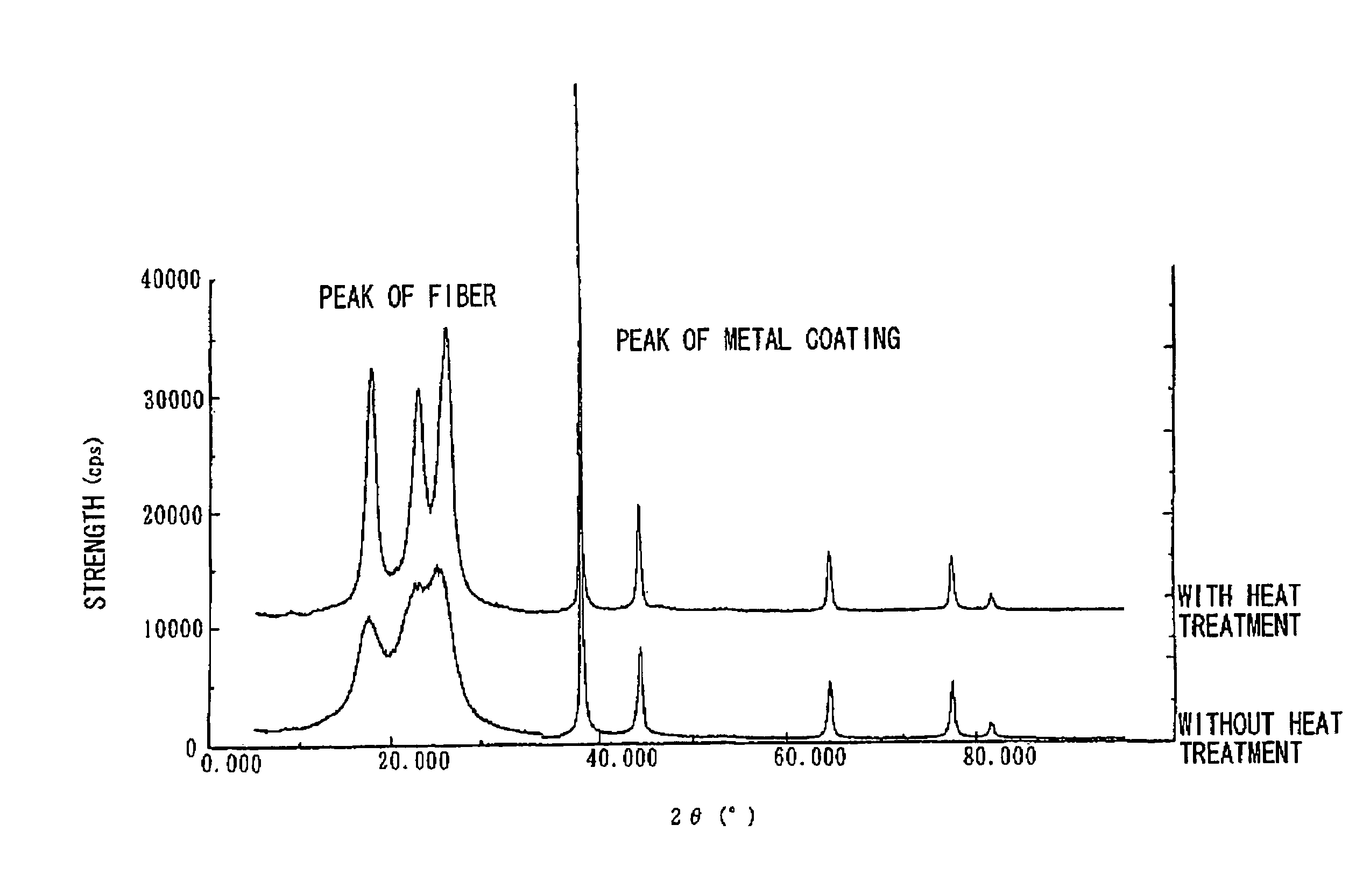

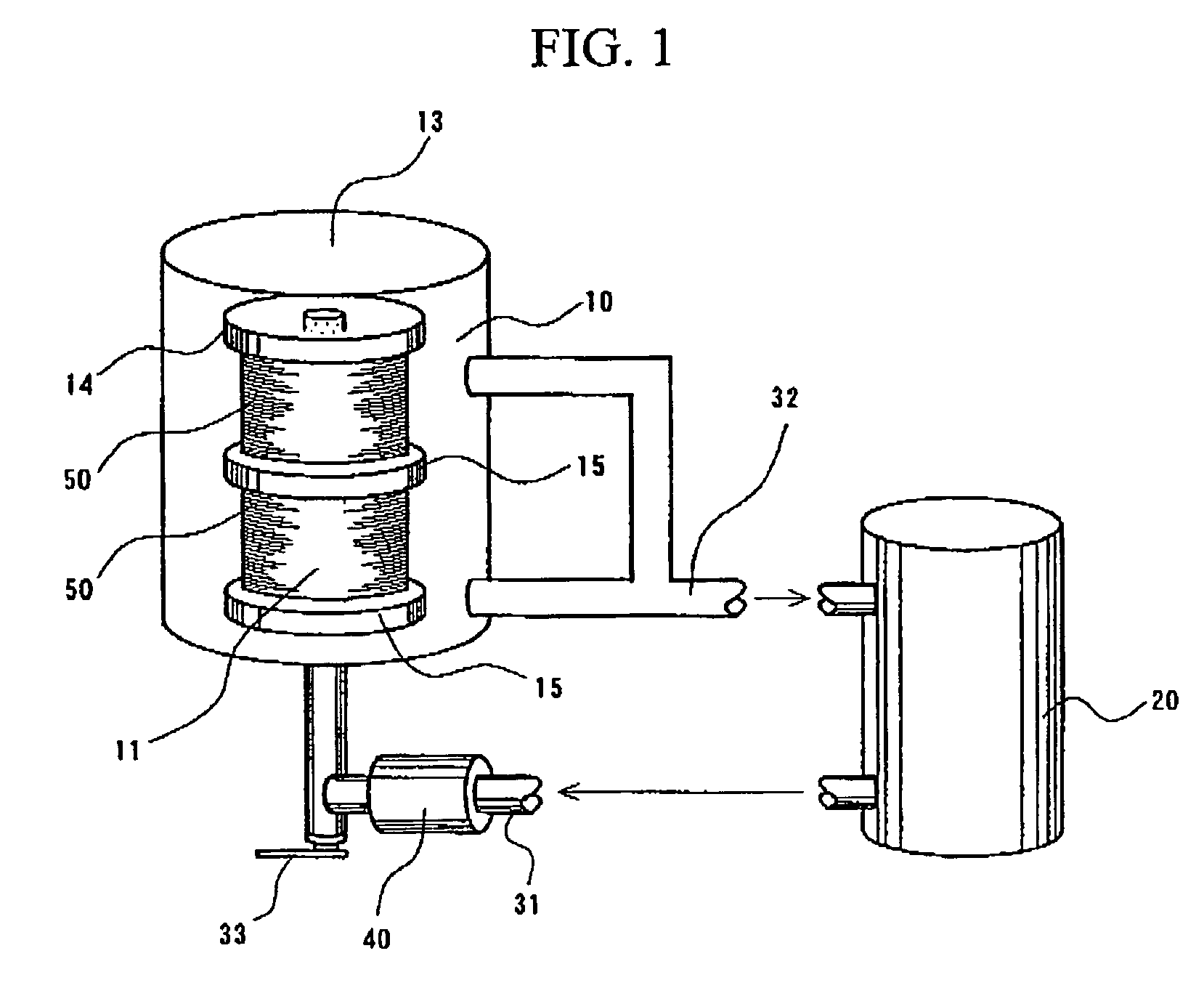

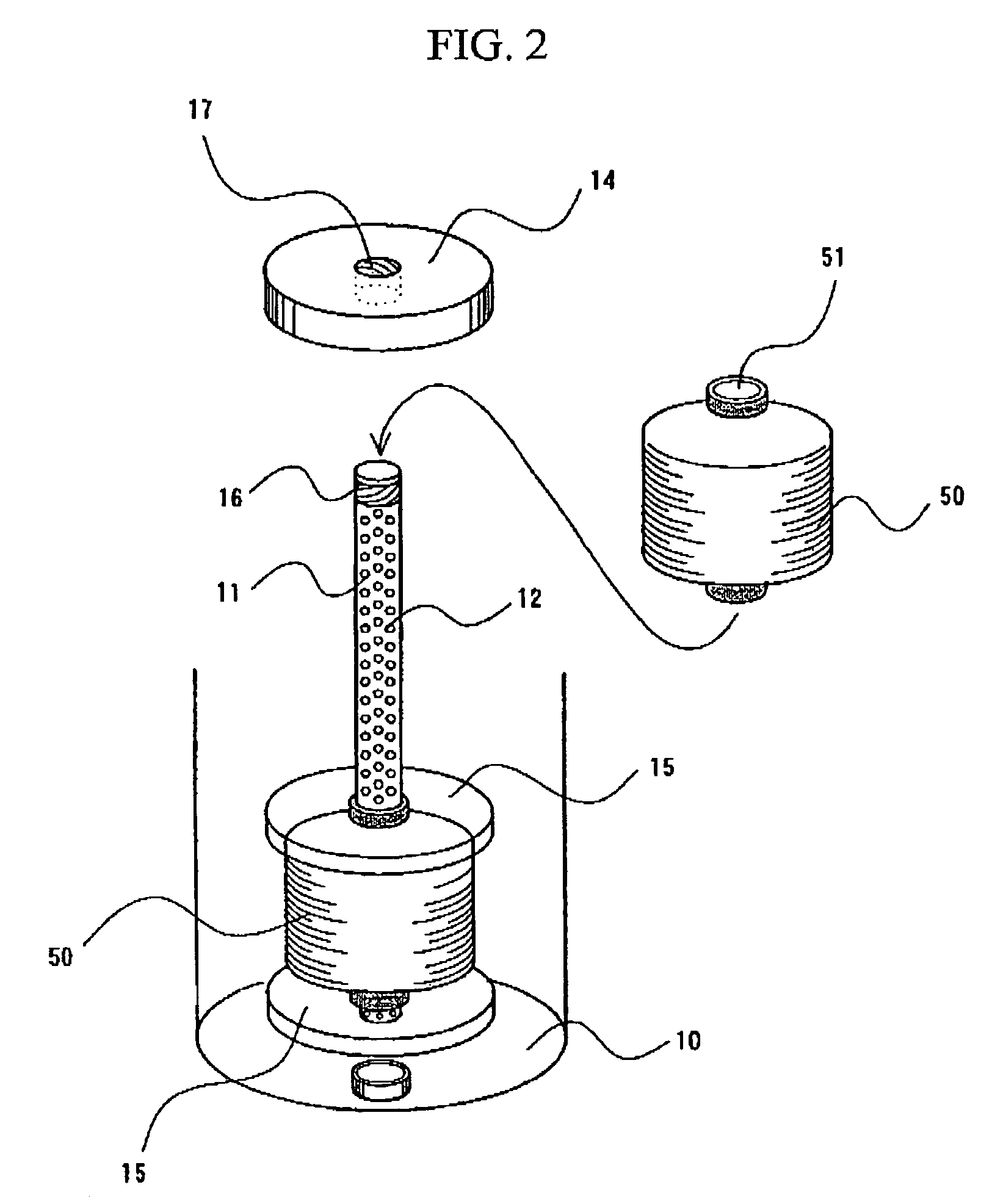

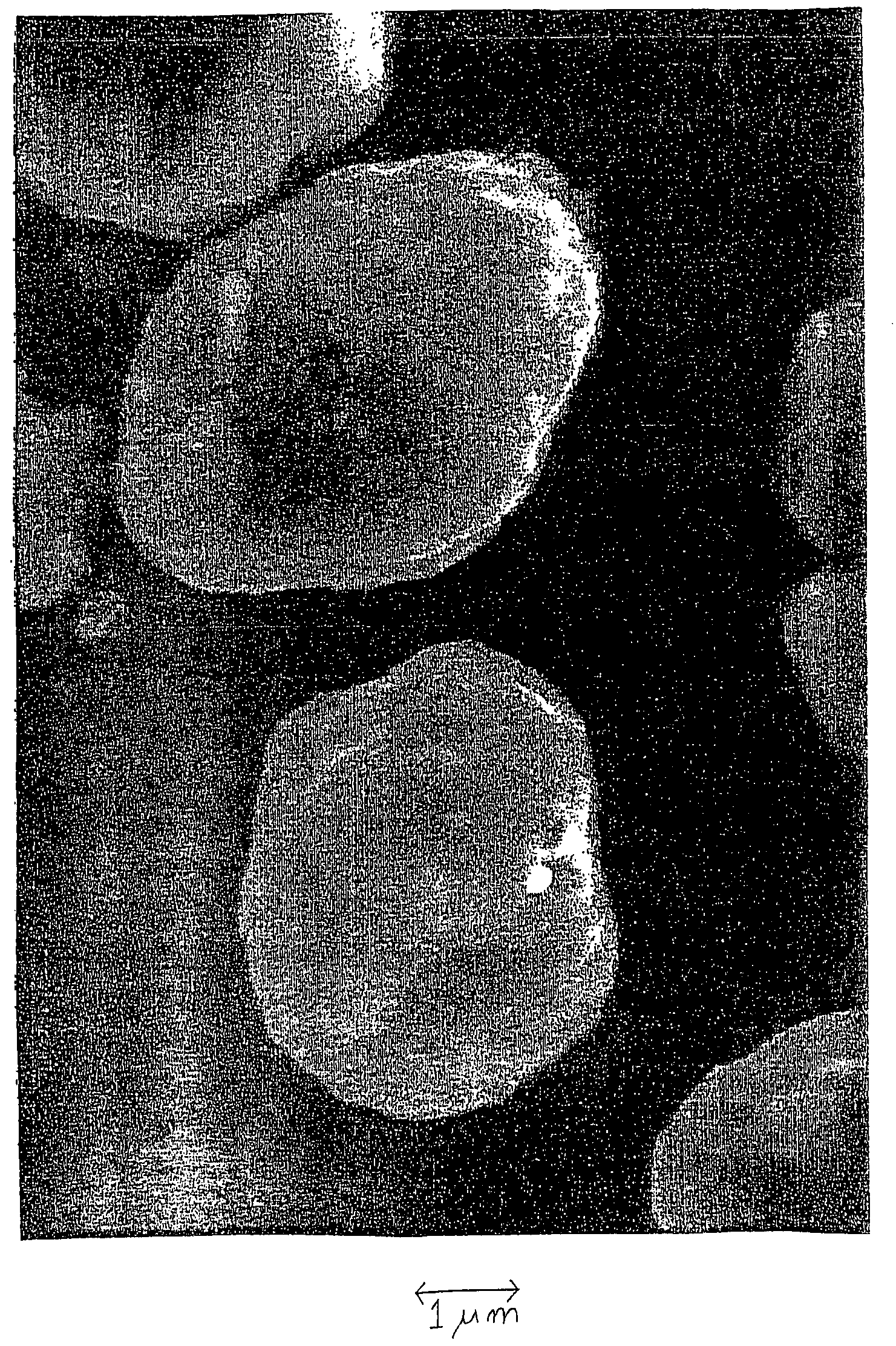

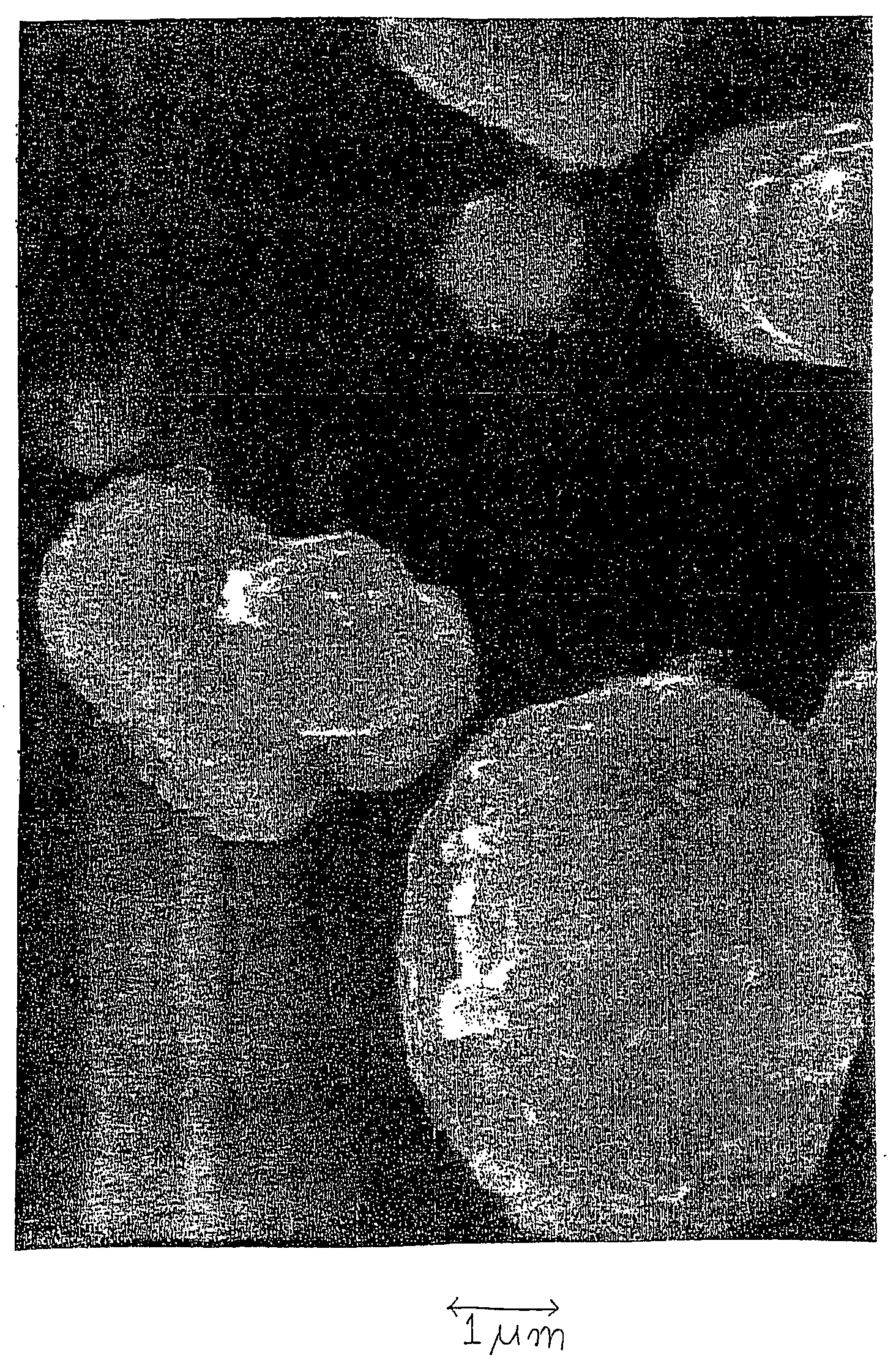

InactiveUS7166354B2High coating strengthReduce the ratioFibre treatmentPretreated surfacesFiberMetal coating

The present invention provides a metal coated fiber with excellent coating strength and corrosion resistance, and a conductive resin composition with excellent conductivity. A feature of a metal coated fiber of the present invention is that following provision of a metal coating on the surface of the fiber, heat treatment is conducted at a temperature greater than the crystallization temperature but less than the melting temperature of the fiber. Gradual cooling is preferably performed following the heat treatment. Furthermore, a conductive metal coating may be provided as the metal coating, and an additional corrosion resistant metal coating then laminated onto the surface of the conductive metal coating. In addition, a feature of a conductive resin composition of the present invention is that metal coated short fibers, formed by providing a conductive metal coating on the surface of a substrate fiber formed from a synthetic resin and then conducting heat treatment, are mixed into a substrate resin.

Owner:MITSUBISHI MATERIALS CORP +1

Carbon-covered lithium transition metal oxide, secondary cell positive electrode material and secondary cell

InactiveUS20050153205A1Low resistivityGood dispersionPositive electrodesCobalt compoundsFiberLithium

A carbon-covered lithium transition metal oxide which comprises a lithium transition metal oxide and carbon black attached on the surface thereof, wherein the carbon black covers 80% or more of the lithium transition metal oxide; a carbon-covered lithium transition metal oxide which comprises a lithium transition metal oxide and carbon fiber attached on the surface thereof; and a positive electrode material for a secondary cell which comprises the carbon-covered lithium transition metal oxide.

Owner:MIKUNI SHIKISO

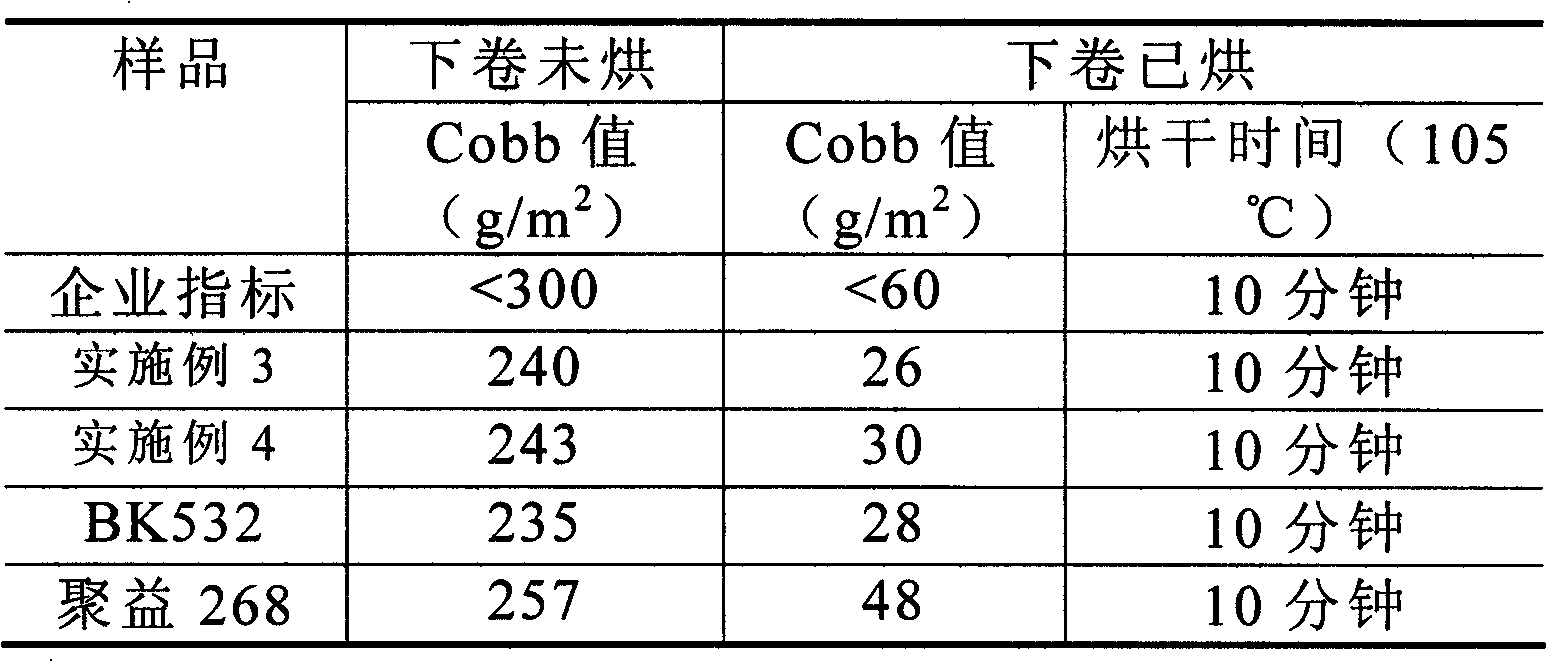

Preparation method for paper nanometer level surface sizing agents capable of realizing fast curing

ActiveCN102351973AOvercome the disadvantage of strong water absorptionIncrease the effective contact areaWater-repelling agents additionFiberPolyamide

The invention relates to a paper surface sizing agent, in particular to a preparation method for paper nanometer level surface sizing agents capable of improving the paper water resistance, surface intensity and annular pressure intensity and realizing the fast curing, which belongs to the technical field of chemical engineering and solves the technical problems of poor product quality and the like in the prior art. The surface sizing agent is prepared by the method of firstly preparing cation type polymer emulsifying agents and then preparing nanometer styrene-acrylates microemulsion. The method has the advantages that the defect of strong self water absorption performance of small molecular emulsifying agents is overcome, and in addition, the effective contact area between the surface sizing agent and the paper surface fiber is greatly improved, so the curing speed after the paper surface sizing and the sizing effect can be respectively and obviously accelerated and improved. The characteristic that paper making wet reinforcing agents of polyamide propylene oxide chloride resin can be fast combined with the fiber, and the cation type polymer emulsifying agents are adopted for taking reaction with epoxy chloropropane to obtain cation charges, so the fast combination of products with the paper surface fiber in the sizing process is promoted, and the curing speed is accelerated.

Owner:ZHEJIANG KESIKE CHEM NEW MATERIAL CO LTD

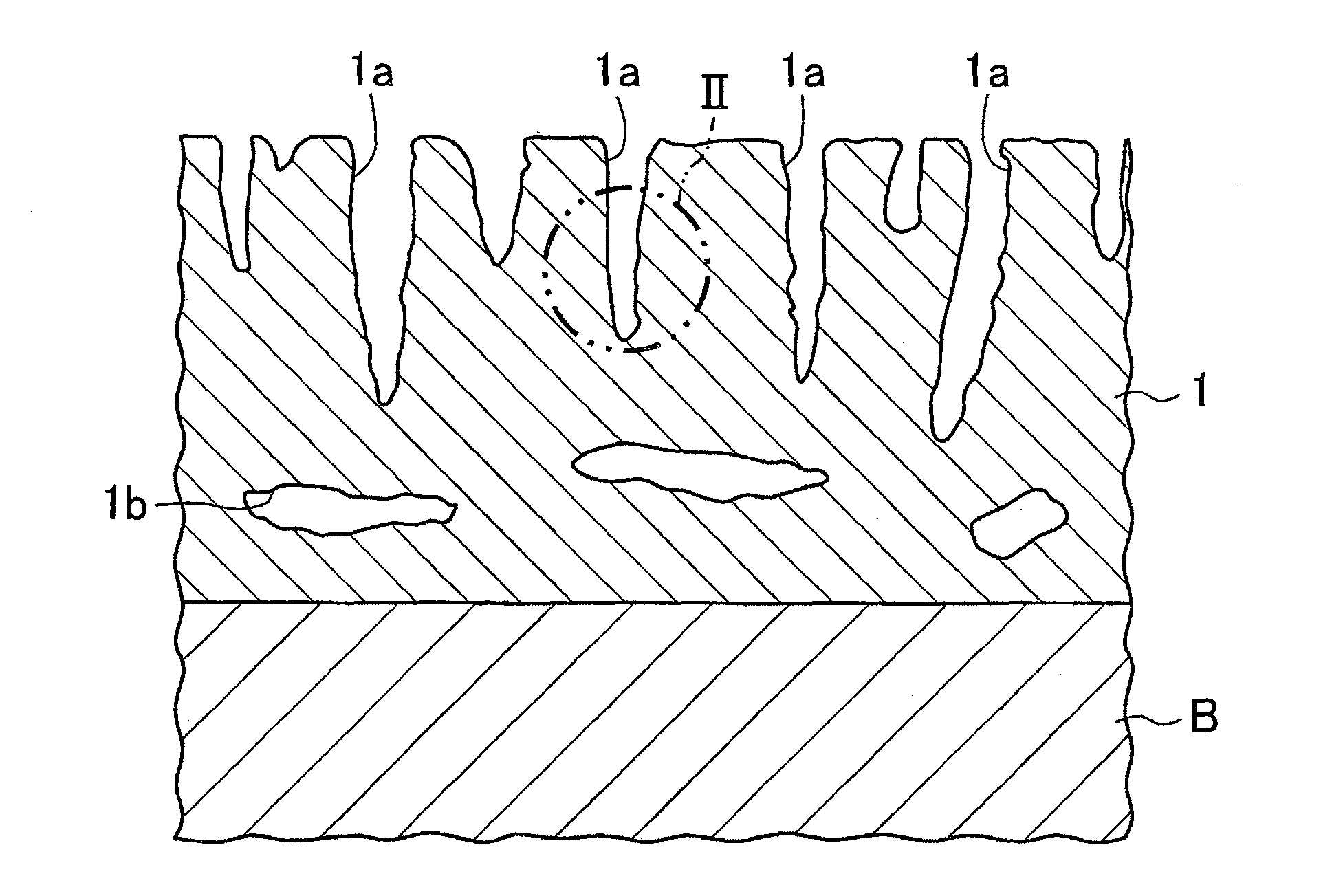

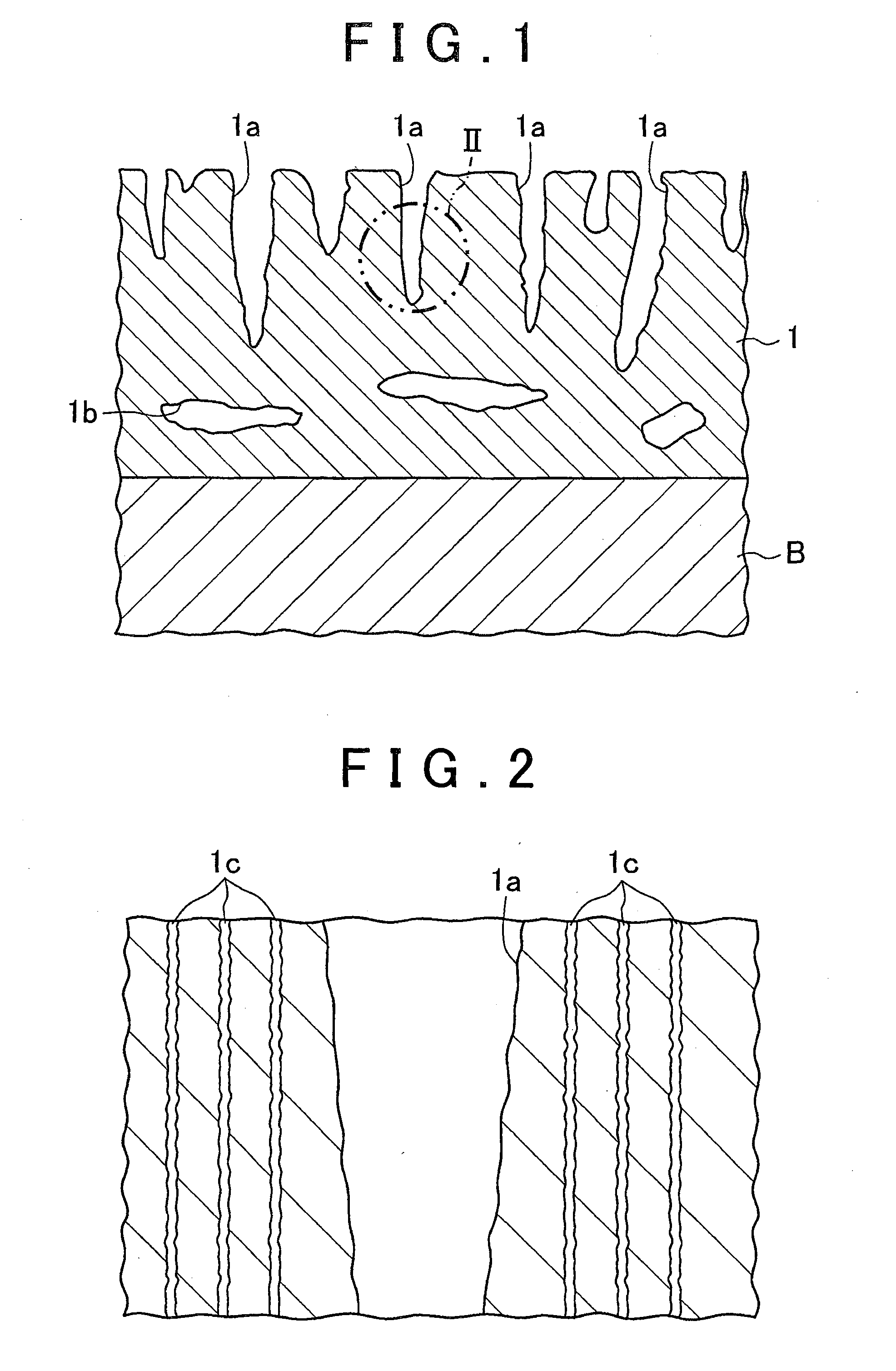

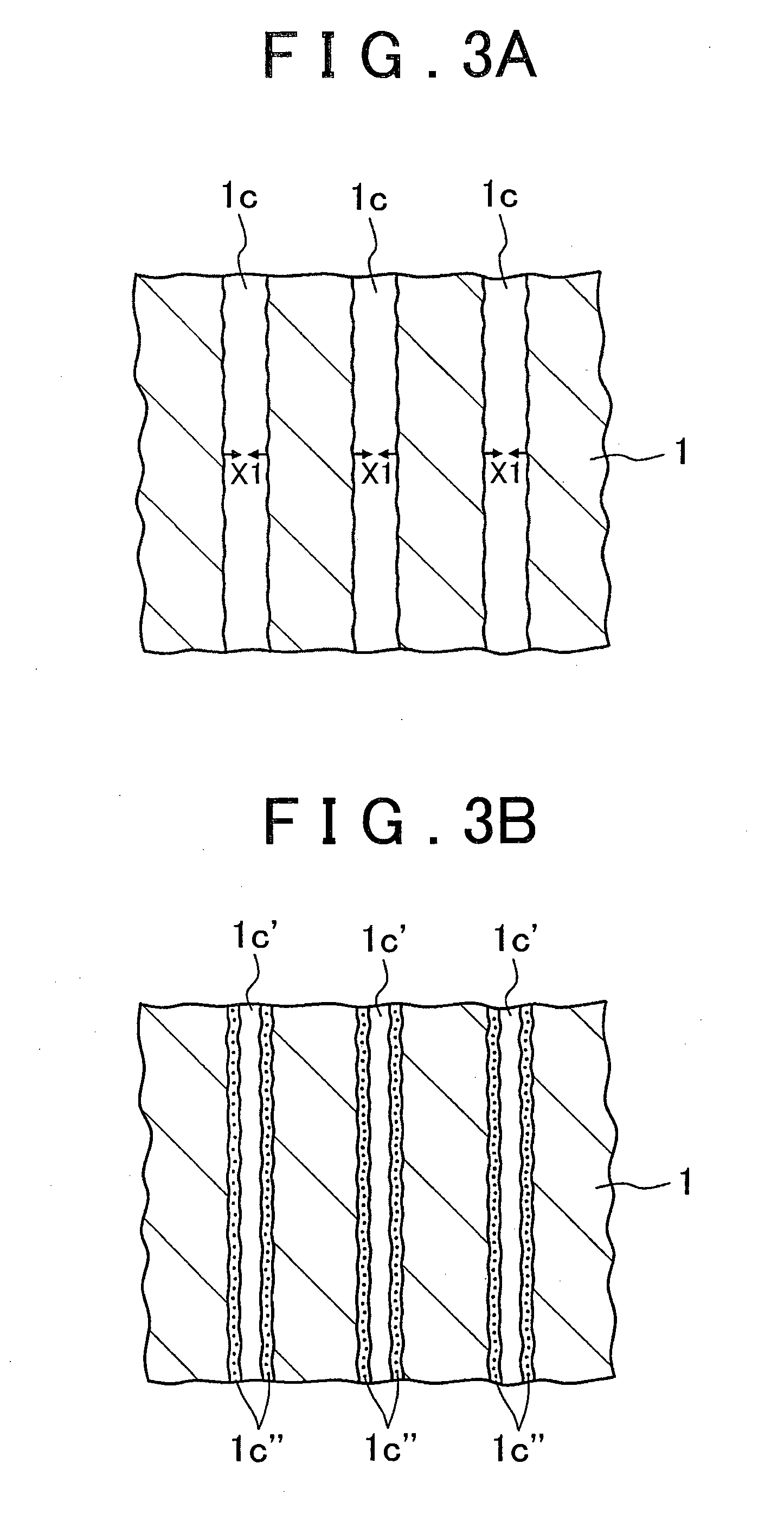

Internal combustion engine and method for manufacturing the same

ActiveUS20140245994A1Reduce heating capacityLow thermal conductivityAnodisationCylinder headsExternal combustion engineEngineering

An internal combustion engine having an anodic oxidation coating formed on at least a part of a wall surface that faces a combustion chamber, wherein the anodic oxidation coating has voids and nano-holes smaller than the voids; at least part of the voids are sealed with a sealant derived by converting a sealing agent; and at least a part of the nano-holes are not sealed.

Owner:TOYOTA JIDOSHA KK

Releasing agent and application method thereof

InactiveCN104759578AHigh strengthAvoid breakingFoundry mouldsFoundry coresGranularitySurface roughness

The invention belongs to the technical field of casting, and particularly relates to a releasing agent and an application method thereof. The invention aims at solving the technical problems that the existing releasing agent is difficult in demolding and pollutes the environment. The releasing agent consists of machine oil and silica powder; the granularity of the silica powder is 600 to 2500 meshes, and the content of SiO2 is more than 99.5 percent. The invention also provides an application method of the releasing agent. By adopting the releasing agent, the flatness and smoothness of the surface of a coating outer layer can be guaranteed, excellent surface roughness is guaranteed, the demolding force is reduced, and the transfer rate of the coating is approximately 100 percent.

Owner:SOUTHWEST UNIV

Heat-dissipation paint for iron casting surfaces

The invention provides a heat-dissipation paint for iron casting surfaces, relating to the technical field of heat-dissipation paints. The invention is characterized in that the heat-dissipation paint is composed of the following components in parts by weight: 30 parts of water-soluble epoxy resin, 5 parts of kyanite powder, 3 parts of silica sol, 4 parts of zircon flour, 3 parts of aluminum oxide, 5 parts of calcined potash feldspar, 2 parts of xylitol, 2 parts of calcined kaolin, 3 parts of barite powder, 5 parts of large-granule graphite, 50 parts of deionized water 2 parts of hexatitanium crystal whisker, 2 parts of flake graphite, 2 parts of zirconia, 5 parts of modifier, 2 parts of nano anion powder, 2 parts of silicon nitride, 2 parts of chromite powder, 2 parts of boric acid water solution, 1 part of nano titanium dioxide, 2 parts of polyester polyol and 2 parts of slaked lime powder. By adding the modifier into the traditional formula to perform modification treatment, the coated heat-dissipation paint can effectively achieve the effects of radiation and heat dissipation, has the advantages of low cost, low harm to the human body, high coating strength, no crack, no blister, uniform coating and high surface quality.

Owner:NINGGUO WANNAN FITNESS MATERIAL

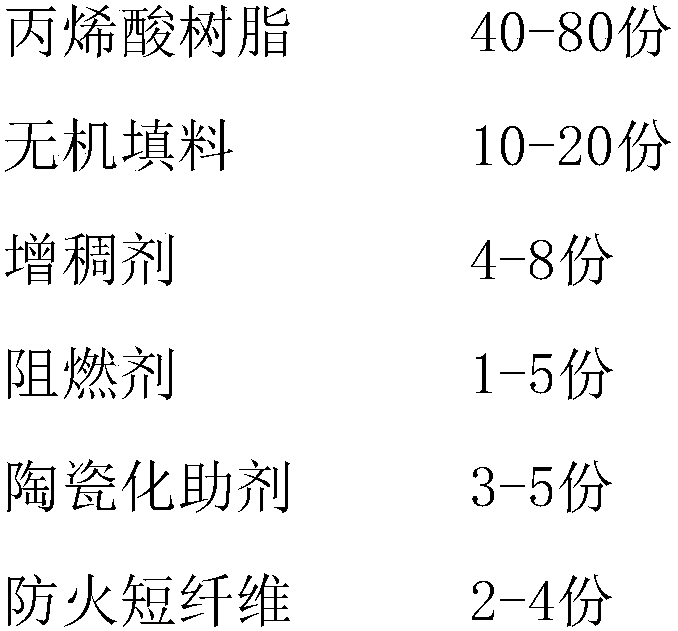

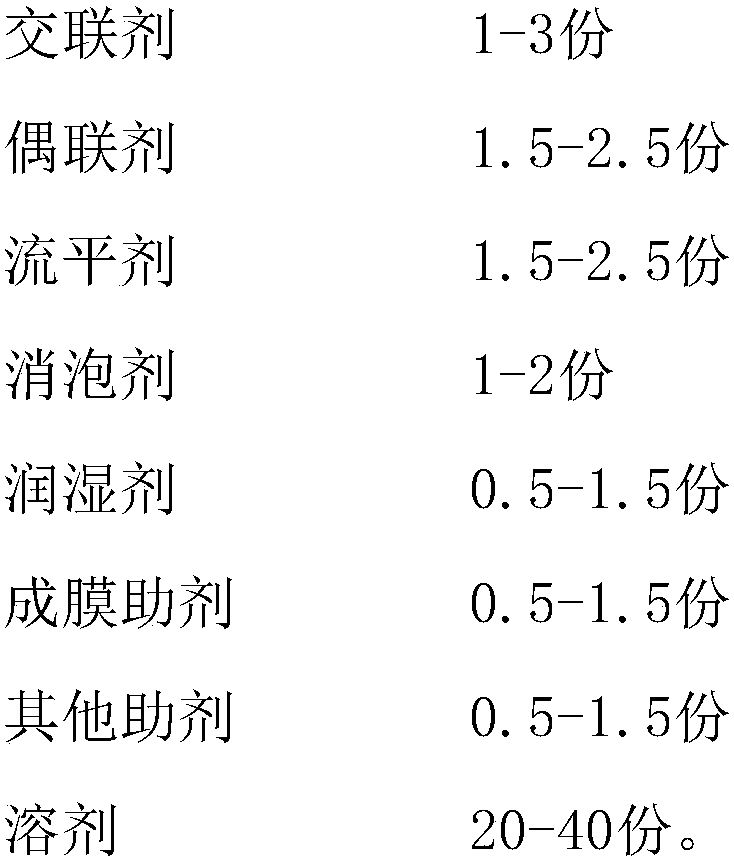

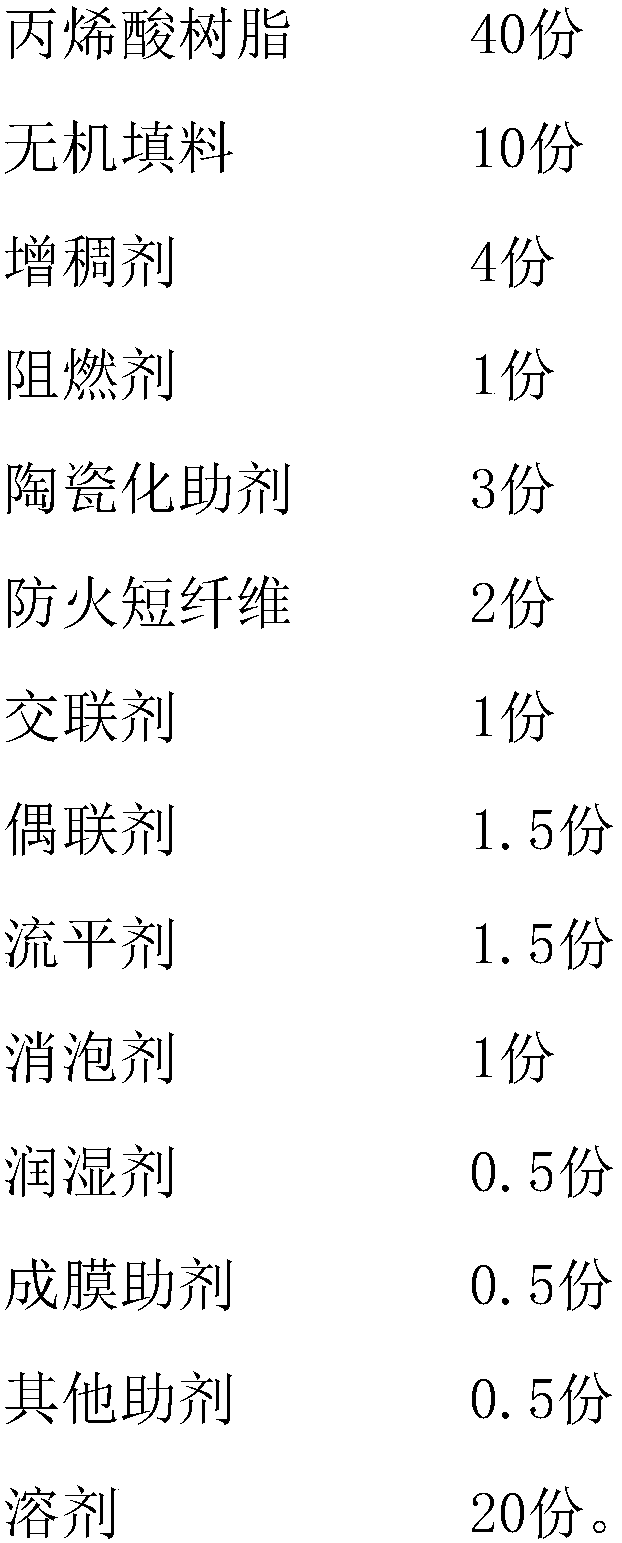

High temperature-resistant fireproof coating and preparation method thereof

ActiveCN108504257AGood weather resistanceImprove performance such as salt spray resistanceFireproof paintsEpoxy resin coatingsFiberAcrylic resin

The invention relates to the technical field of coatings, in particular to a high temperature-resistant fireproof coating and a preparation method thereof. The high temperature-resistant fireproof coating is prepared from the following raw materials in parts by weight: acrylic resin, inorganic filler, a thickener, a flame-retardant agent, a ceramic additive, fireproof short fibers, a crosslinkingagent, a coupling agent, a flatting agent, a defoaming agent, a wetting agent, a film forming additive, other additives and solvents. The high temperature-resistant fireproof coating has the advantages that high temperature can be endured, the flame-retardant property is good, the propagation of fire condition is well blocked, and the fireproof property is excellent; the effect of resisting long-time impact by 1100 DEG C hydrocarbon high-temperature fire hazard is realized; the weather-resistant property and waterproof property are realized, the shrinkage is avoided, the coating strength is high, and the surface is flat.

Owner:GUANGDONG ZHICHENG CHEM +1

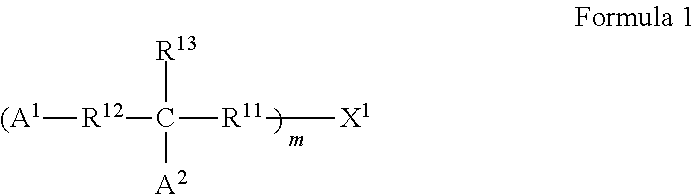

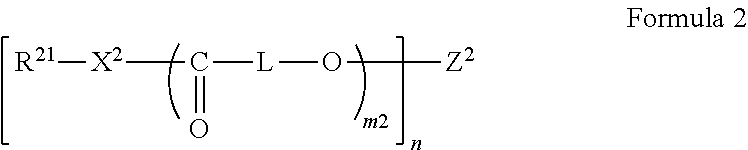

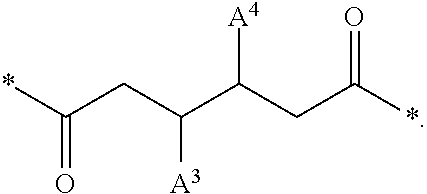

Magnetic recording medium composition and method of manufacturing magnetic recording medium

ActiveUS20160284450A1Good dispersionIncreased durabilityInorganic material magnetismRecord information storagePolyesterWeight range

The magnetic recording medium composition contains ferromagnetic powder, binder, and a crosslinkable component selected from the group consisting of a component capable of forming a crosslinking structure by a radical reaction, a component capable of forming a crosslinking structure by an ionic reaction, and a component capable of forming a crosslinking structure by a pericyclic reaction, wherein the crosslinkable component contains at least polyester, and the polyester has a weight average molecular weight ranging from 1,000 to 20,000, as well as contains, per molecule, one or more acidic groups, and one or more reactive groups selected from the group consisting of a radical reactive group, an ionic reactive group, and a pericyclic reactive group.

Owner:FUJIFILM CORP

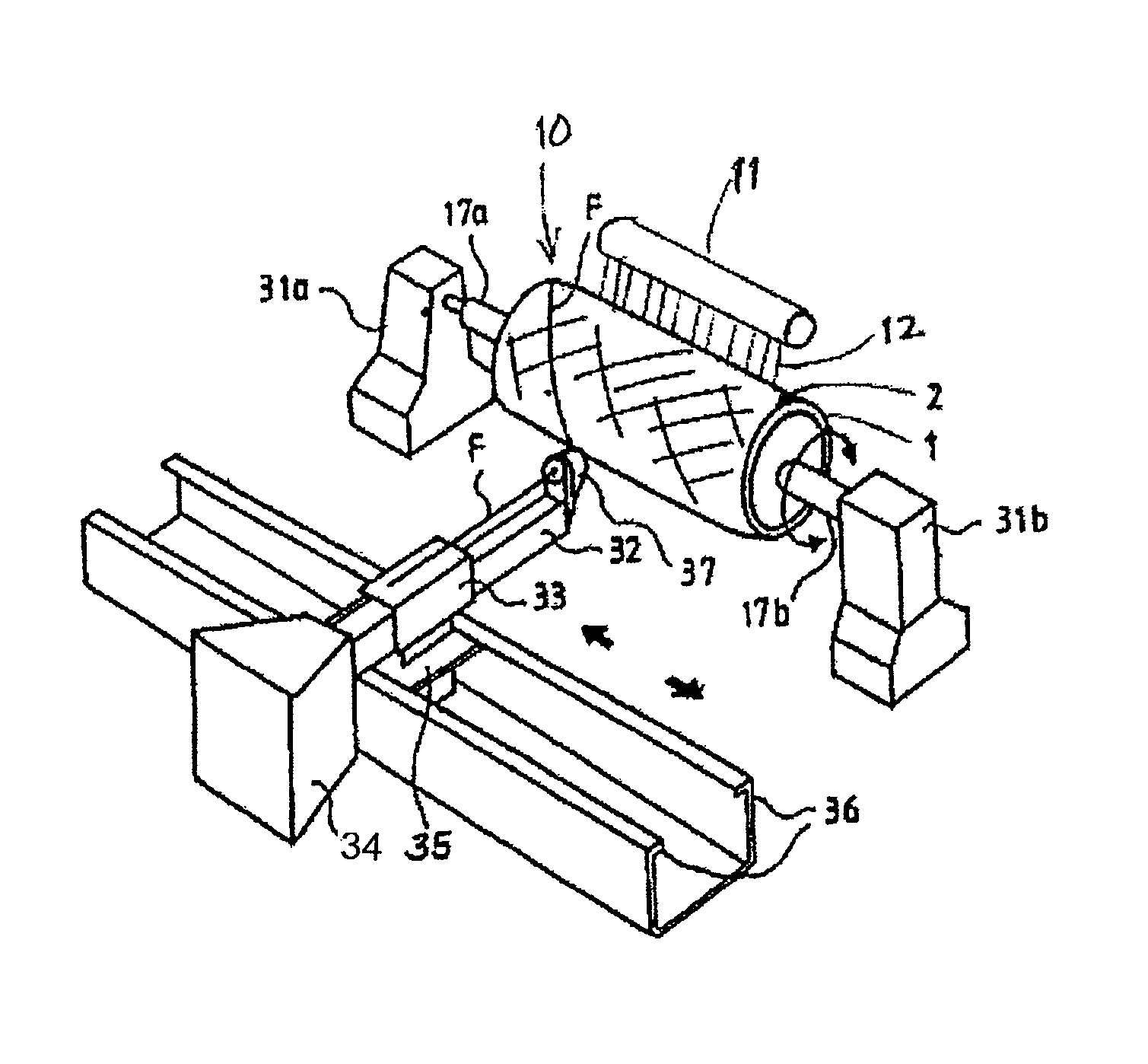

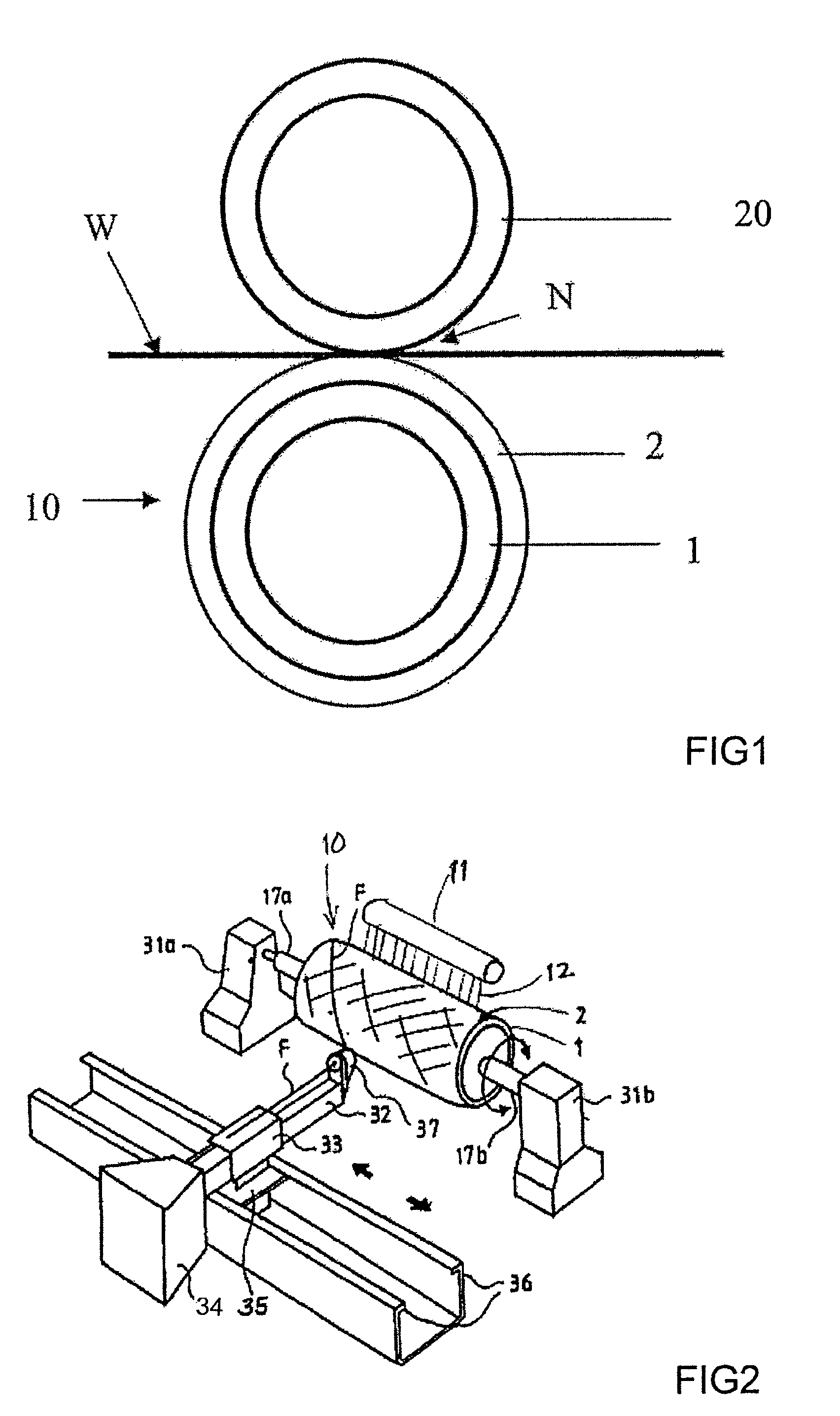

Roll coating roll and method for its manufacture

InactiveUS8647475B2Avoid crackingReduce stressLiquid surface applicatorsMechanical working/deformationFiberUltimate tensile strength

Owner:VALMET TECH INC

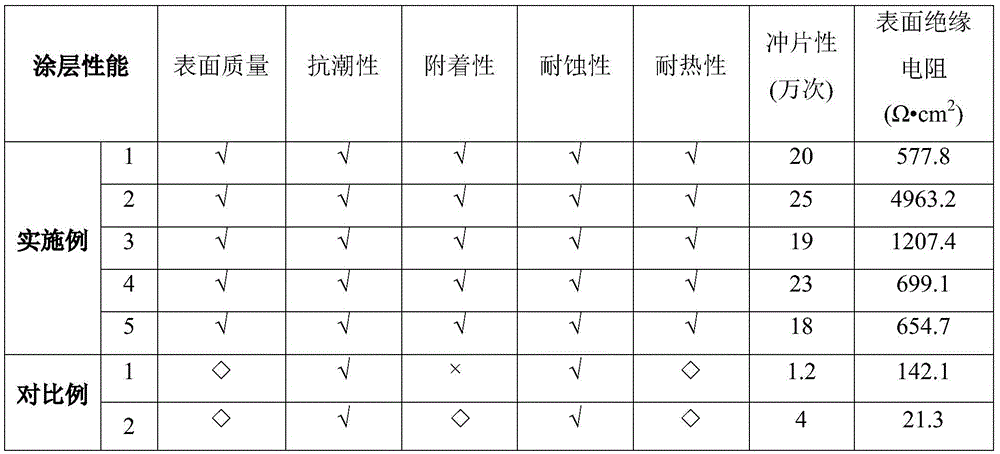

Non-toxic environmentally-friendly oriented electrical steel insulation coating and preparation method thereof

InactiveCN105566970AImprove the problem of moisture absorption and stickinessImprove heat resistanceAnti-corrosive paintsPhosphateMoisture absorption

The present invention provides an oriented electrical steel insulation coating and a preparation method thereof, and the coating is prepared from the following ingredients by mass: 35 to 50 % of a metal dihydric phosphate, 16 to 25 % of zinc molybdate, 4 to 10% of boric acid, 5 to 10% of colloidal silicon dioxide, 2 to 5% of nano oxide powder, 2 to 13% of organic resin, 0.01-0.08% of a nonionic surfactant and the balance of water. The oriented electrical steel insulation coating is free from chromium elements, non-toxic and environmentally-friendly, has good insulating property, adhesion property and blanking property, can ensure the coating uniformity, corrosion resistance, and heat resistance, is low in moisture absorption tendency to tacky, can be saved stably for long term, is simple in preparation method and low in requirements on equipment, and industrialization is easy to realize.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

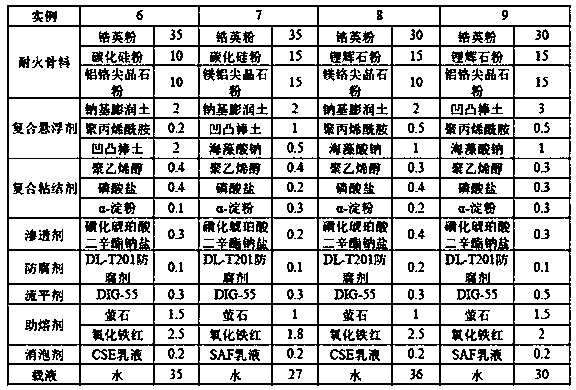

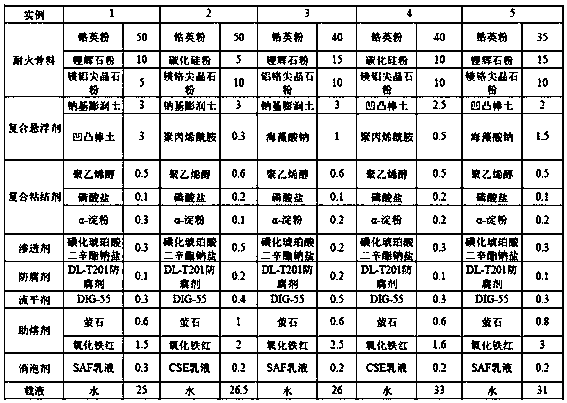

Water-based dip coating for 3D printing sand mold and preparation method thereof

ActiveCN108655332AImprove thixotropic propertiesGood thickening effectFoundry mouldsFoundry coresWater basedPreservative

The invention relates to the technical field of coatings for casting sand molds, in particular to a water-based dip coating for a 3D printing sand mold and a preparation method thereof. The water-based dip coating for the 3D printing sand mold is prepared from the following components, by mass: 50-75% of composite refractory aggregate, 3-6% of a composite suspending agent, 0.8-1.2% of a compositebinder, 0.1-0.5% of a penetrating agent, 0.2-0.6% of a leveling agent, 0.05-0.2% of a preservative, 2-5% of a fluxing agent, 0.1-0.3% of a defoaming agent and the balance water, and is characterized in that the composite refractory aggregate is formed by mixing one or a mixture of zircon powder, spodumene powder and carborundum powder with spinel powder according to the mass ratio of 50:(4.5-16.5), wherein the spinel powder is magnesium aluminate spinel powder, magnesium-chromium spinel powder or aluminum-chromium spinel powder, and the particle size of each component is 320-600 meshes. The water-based dip coating has the advantages of being excellent in coating performance, proper in permeability, good in leveling property, efficient in suspension stability, proper in coating thickness, good in sintering stripping property and super-strong in anti-sand-burning property.

Owner:NINGXIA KOCEL MOLD

Earpiece moulding method by implanting plastic into metal fittings

The invention discloses an earpiece moulding method by implanting plastic into a metal fittings. The method comprises the steps of: (1) putting the metal fittings into a cavity of a mould; (2) arranging an thimble on the mould, wherein the thimble stretches into the cavity and supports the metal fittings, in this way, the metal fittings is suspended in the cavity; (3) injecting fused plastic into the cavity, enabling the thimble to contract and supporting the metal part by the cured plastic when the fused plastic is close to the thimble; (4) keeping on injecting the fused plastic till the whole cavity is full of the fused plastic and the metal part is enveloped; and (5) cooling, opening the mould, and de-moulding so as to obtain the moulded earpiece. With the adoption of the method, the moulding of the earpiece is finished by one plastic injection process, the moulding time is saved effectively and the production efficiency is enhanced; the enveloping strength of the moulded plastic to the metal part is higher, the undesirable effects of burst, separation, and the like, are avoided, so that the whole quality of the product is stable, and the manufacturing cost is reduced simultaneously.

Owner:刘蓉君

Organic silicon modified PAE polyurea coating

ActiveCN113861816AImprove the level ofImprove anti-corrosionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceSide chain

The invention discloses an organic silicon modified PAE polyurea coating which comprises a component A and a component B. The preparation method of organic silicon modified polyaspartic acid ester in the component A comprises the following steps: reacting vinyl alcohol or a vinyl epoxy compound with end hydrogen-containing silicone oil to obtain functionalized silicone oil; reacting the functionalized silicone oil with dialkyl maleate or maleic anhydride to obtain dipolysiloxane maleate; and reacting maleic acid dipolysiloxane ester with aliphatic binary primary amine. The preparation method of the isocyanate silicone oil curing agent in the component B comprises the following steps: reacting vinyl dihalide or a polyhalogen compound with hydrogen-containing silicone oil to obtain polyhalogenated silicone oil; reacting the polyhalogenated silicone oil with phthalimide salt, and then heating and hydrazinolysis to obtain polyamino silicone oil; and dropwise adding trichloromethyl chloroformate into the polyamino silicon oil, and irradiating with an incandescent lamp for reaction. According to the invention, polysiloxane is respectively introduced into side chains of the component A and the component B, so that the PAE polyurea coating with good leveling property, high corrosion resistance, high temperature resistance and high coating strength can be obtained.

Owner:浙江艾特普科技有限公司

Preparation method of nanometer modified polymer super-hydrophobic coating

The invention discloses a preparation method of a nanometer modified polymer super-hydrophobic coating, and belongs to the technical field of coating preparation. Firstly, butadiene styrene rubber with abrasive resistance is melted at a high temperature to obtain a softening fluid, so that a system has abrasion resistance; secondly, tetraethoxysilane, 1H,1H,2H,2H-perfluorooctyltrimethoxysilane, absolute ethyl alcohol and ammonia water are mixed and stirred for reacting, and a hydrophobic effect is achieved. In the preparation method, montmorillonoid is subjected to an activating reaction and an organic reaction and ground to obtain modified montmorillonoid powder, the interlamellar spacing can be increased, and intercalation of base material substances is facilitated. Modified silicon dioxide powder and the modified montmorillonoid powder in the preparation method can be cross-linked with hydroxyl groups in polytetrafluoroethylene, a network structure is formed, and the structure of asystem layer is made to be denser; the system has extremely good chemical stability, corrosion of strong acid, strong base and various chemical products is effectively resisted, the corrosion resistance of the super-hydrophobic coating is further improved, and the preparation method has wide application prospects.

Owner:邹峰

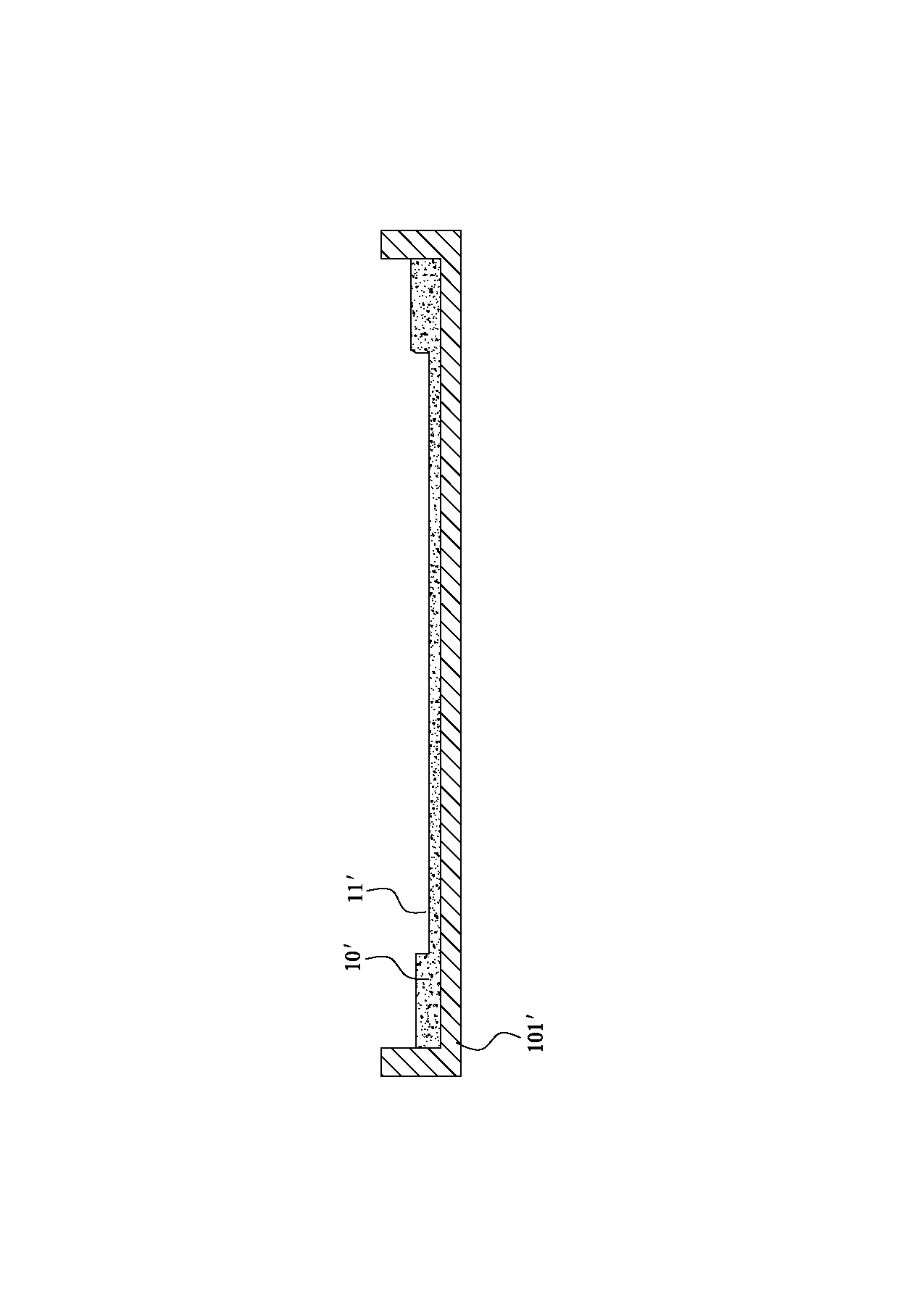

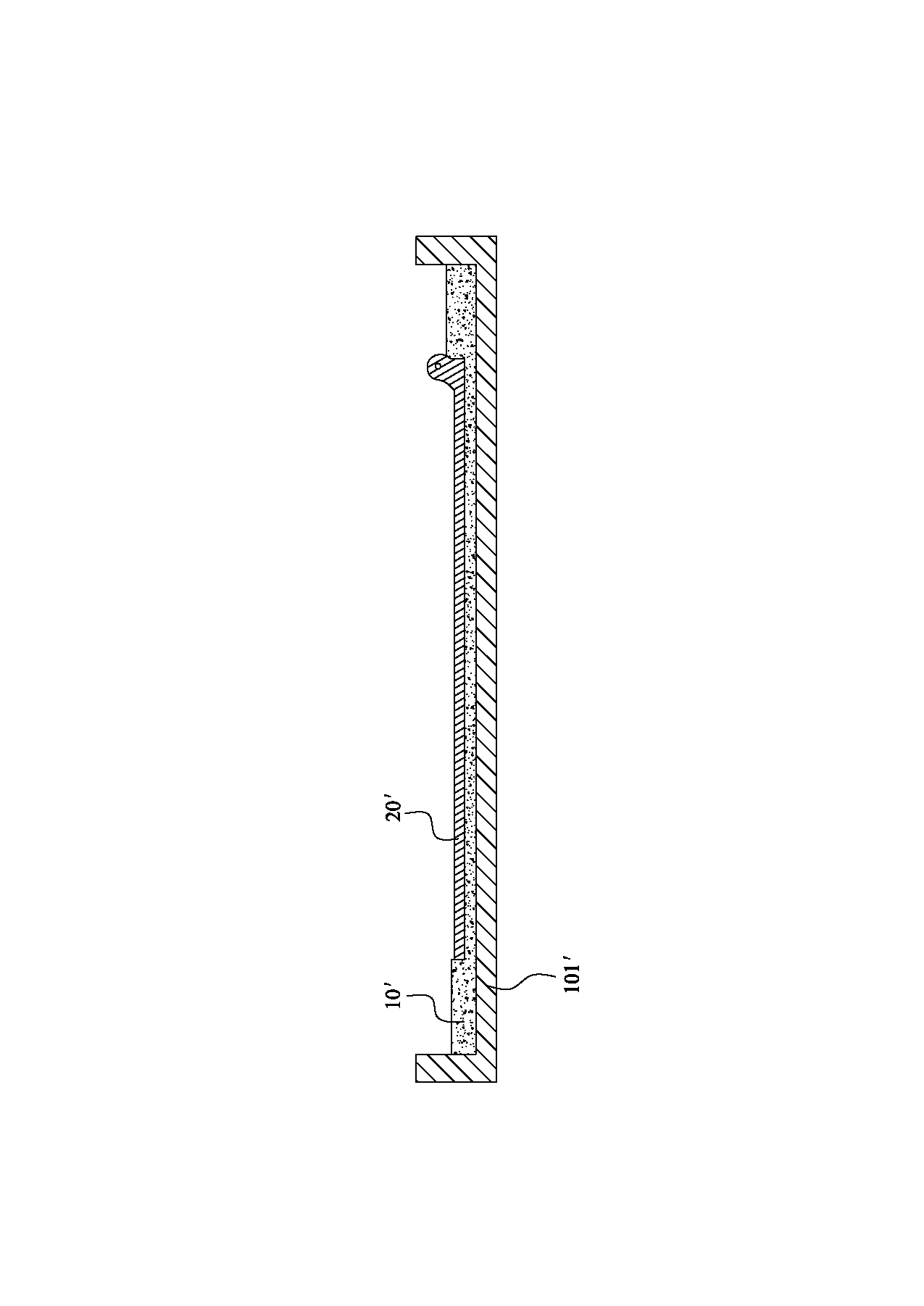

Mold and coating used for mold

PendingCN109988502AStir wellHigh coating strengthFireproof paintsAnti-corrosive paintsWater basedSolvent

The application provides a mold and a coating used for the mold, and belongs to the technical field of coating compositions. The coating comprises the following components, in percentages by mass: 25-35% of bonding resin, 5-15% of a filler, 2-10% of an auxiliary agent and 35-50% of a solvent, wherein the bonding resin adopts a mixed water-based resin dispersion liquid; the filler is one or a mixture of more selected from the group consisting of chromium oxide green micro powder, silicon carbide micro powder, nano silicon dioxide powder and molybdenum disulfide micro powder; and the solvent iswater. When the coating provided by the invention is applied to the mold, especially fluorine-silicon modified tire mold processing, the demolding property is ensured, the adhesion between the coatingand the mold is improved, and the green environmentally-friendly pollution-free processing is realized.

Owner:ZHEJIANG LAIFU MOLD

Preparation method of stainless steel screen load TiO2 nanometer membrane photochemical catalyst

InactiveCN1654118ASmall particle sizeRaw materials are easy to getCatalyst activation/preparationWire gauzeTitanium

The preparation process of stainless steel wire net supported nanometer TiO2 film as photocatalyst includes dipping and lifting clean stainless steel wire net in stable titanium alkoxide sol to form wet TiO2 film and drying 80-120 deg.c, repeating the dipping and drying step until reaching the required film thickness, and high temperature treating at 300-600 deg.c to prepare the stainless steel wire net supported nanometer TiO2 film as photocatalyst. The present invention has the features of simple process, low production cost, high coating strength, small TiO2 grains and high photocatalytic activity.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com