Porous structural elastic composite material for extracting uranium from seawater and preparation method

An elastic composite material and porous structure technology, which is applied in seawater treatment, chemical instruments and methods, and other chemical processes, can solve the problems of impossibility and low adsorption rate of adsorption materials, achieve simple process, excellent mechanical properties, and improve material flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

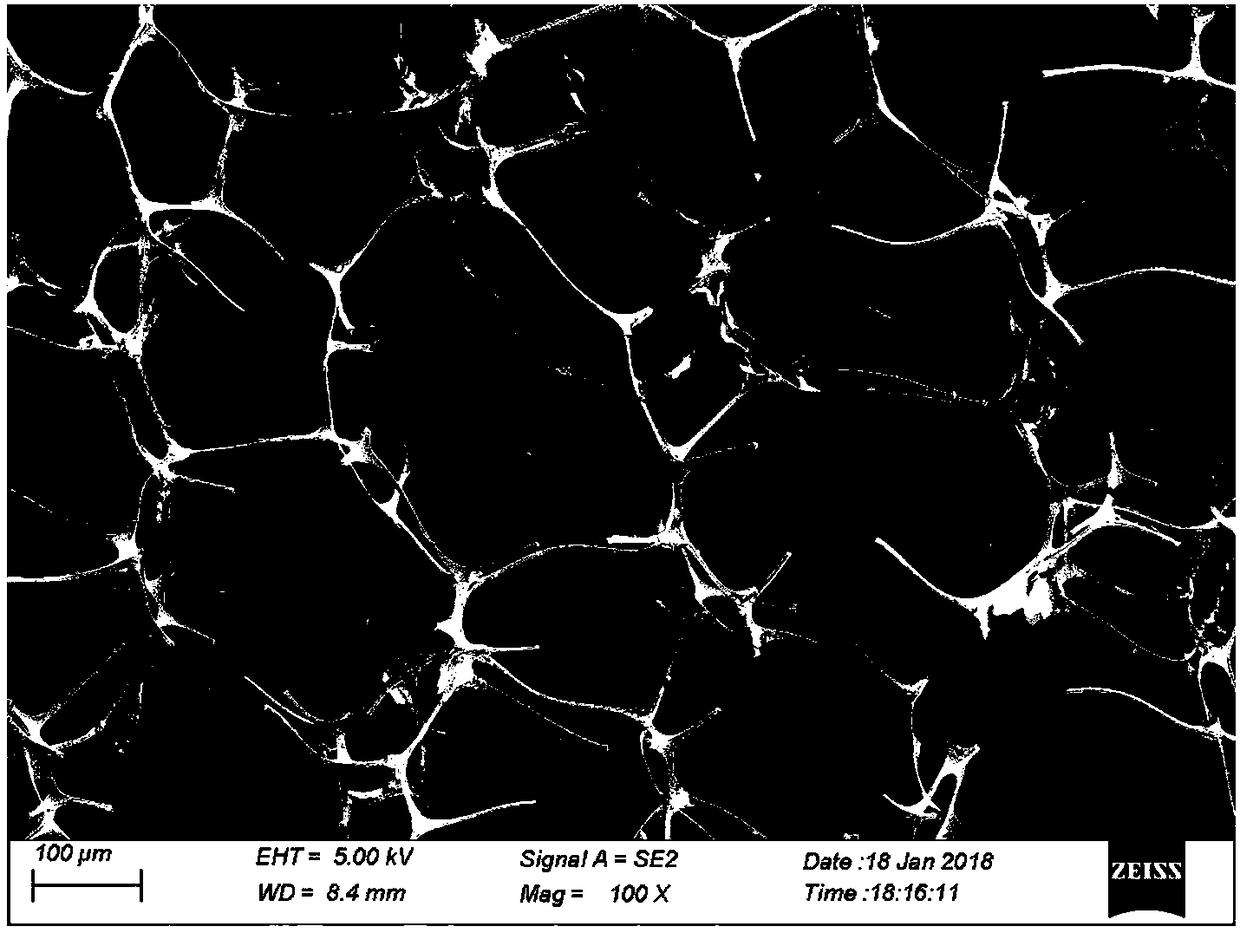

Image

Examples

preparation example Construction

[0033] The present invention proposes a method for preparing a porous structure elastic composite material for extracting uranium from seawater, comprising the following steps:

[0034] (1) Calculated by weight ratio, add 8 to 20 parts of hydroxylamine hydrochloride into a flask containing 500 parts of DMF or DMSO or DMAC, stir until completely dissolved, then add 3 to 15 parts of basic solid powder, preferably vigorously stirred at room temperature 0.5 to 2 hours, then add 5 to 25 parts of polyacrylonitrile raw material powder, after sealing, preferably stir and react in a constant temperature environment of 60 to 90 ° C for 6 to 48 hours, after cooling, centrifuge to remove solid insolubles, and collect the gemstone in the supernatant DMF or DMSO or DMAC solution of amidoximated polyacrylonitrile; during this step, the alkaline solid powder can be sodium hydroxide, sodium carbonate, potassium hydroxide or sodium bicarbonate, etc. to adjust the pH value.

[0035] (2) heating ...

Embodiment 1

[0044] A method for preparing a porous structure elastic composite material for extracting uranium from seawater, comprising the following steps:

[0045] (1) Add 8g of hydroxylamine hydrochloride to the flask containing 500g of DMF, preferably magnetic stirring, until fully dissolved, then add 3g of sodium hydroxide powder, stir vigorously at room temperature for 30 minutes, then add 5g of polyacrylonitrile raw material powder, seal and place in Stir and react in a constant temperature environment of 60°C for 48 hours, after cooling, centrifuge at a speed of 30,000r / min to remove solid insoluble matter, and collect the DMF solution of amidoximated polyacrylonitrile in the supernatant.

[0046] (2) The DMF solution of amidoximated polyacrylonitrile is miscible with aqueous sodium hydroxide solution and kept heating and stirring until completely dissolved into a clear homogeneous solution, wherein the DMF solution of amidoximated polyacrylonitrile The mass concentration is 0.5%, ...

Embodiment 2

[0054] A method for preparing a porous structure elastic composite material for extracting uranium from seawater, comprising the following steps:

[0055] (1) Add 15g of hydroxylamine hydrochloride into a flask containing 500g of DMF, stir magnetically until completely dissolved, then add 10g of potassium hydroxide powder, stir vigorously at room temperature for 40 minutes, then add 18g of polyacrylonitrile raw material powder, seal it at 75 Stir and react in a constant temperature environment at ℃ for 24 hours. After cooling, centrifuge at a speed of 20,000 r / min to remove solid insoluble matter, and collect the DMF solution of amidoximated polyacrylonitrile in the supernatant.

[0056] (2) The DMF solution of the amidoximated polyacrylonitrile of equal volume is miscible with potassium hydroxide aqueous solution and keeps heating and stirring to dissolve into a clear homogeneous solution, and the mass concentration of the DMF solution of amidoximated polyacrylonitrile is: 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com