Organic silicon modified PAE polyurea coating

A silicone and modified technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor high temperature resistance, short construction time, low temperature embrittlement, etc., and achieve high temperature resistance coating strength, Improved anti-corrosion performance and complete resin protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

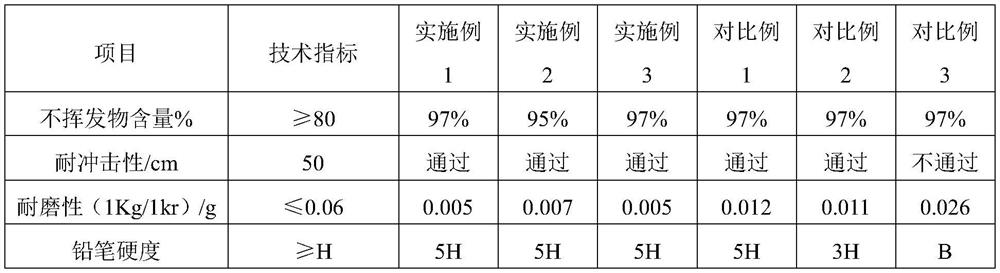

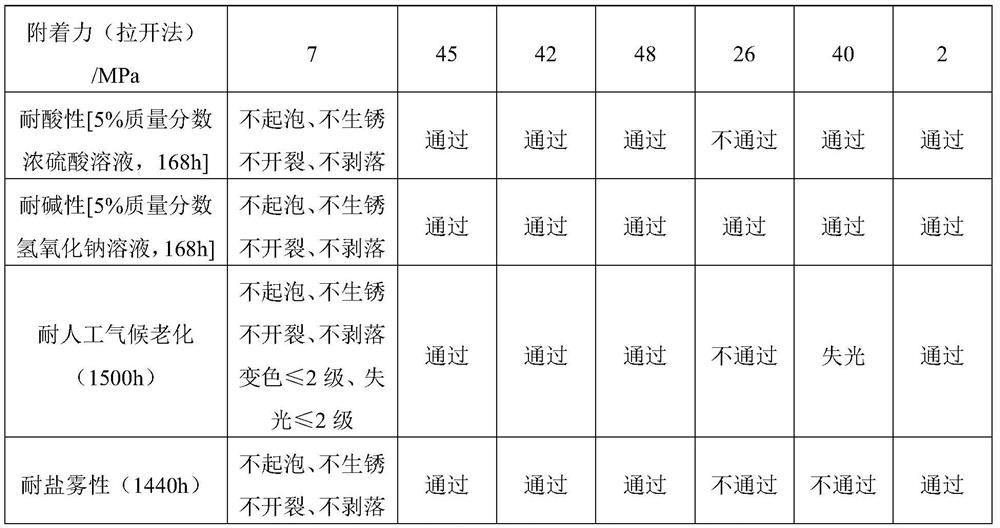

Examples

Embodiment 1

[0035] A silicone modified PAE polyurea coating, comprising A component and B component that the mass ratio is 2:1;

[0036] A component is silicone modified polyaspartic acid ester, and its preparation method is:

[0037] (1) Mix allyl glycidyl ether after dehydration with heptamethyltrisiloxane in a molar ratio of 1.1:1, add 8 ppm chloroplatinic acid catalyst, and react at 120° C. for 2 hours to obtain epoxy silicone oil;

[0038] (2) Add epoxy silicone oil dropwise to maleic anhydride at 60°C, control the dropping time for 1h, and the molar ratio of epoxy silicone oil to maleic anhydride is 2.1:1; Obtain dipolysiloxane maleate;

[0039] (3) Add 4,4'-diaminodicyclohexylmethane to dipolysiloxane maleate, the mole of 4,4'-diaminodicyclohexylmethane to dipolysiloxane maleate The ratio is 1:2.1; and a sodium methoxide catalyst with a total mass of 0.03% of reactants is added, and reacted at 60° C. for 10 h under nitrogen protection to obtain the silicone-modified polyaspartic ...

Embodiment 2

[0045] A silicone modified PAE polyurea coating, comprising A component and B component that the mass ratio is 2.1:1;

[0046] A component is silicone modified polyaspartic acid ester, and its preparation method is:

[0047] (1) Mix allyl alcohol after dehydration with heptamethyltrisiloxane in a molar ratio of 1:1, add 4ppm chloroplatinic acid catalyst, and react at 90°C for 4h to obtain hydroxylated silicone oil;

[0048] (2) Add hydroxylated silicone oil and dimethyl maleate with a molar ratio of 2:1 to xylene, react at 150° C. for 4 hours, and remove the solvent under reduced pressure to obtain dipolysiloxane maleate;

[0049] (3) Add IPDA to dipolysiloxane maleate, the molar ratio of IPDA to dipolysiloxane maleate is 1:2; React at 40° C. for 12 hours under protection to obtain the organosilicon-modified polyaspartic acid ester.

[0050] B component is polyisocyanate silicone oil curing agent, its preparation method is:

[0051] A) Mix dehydrated 1,4-dichloro-2-butene a...

Embodiment 3

[0055] A silicone modified PAE polyurea coating, comprising A component and B component with a mass ratio of 2.2:1;

[0056] A component is silicone modified polyaspartic acid ester, and its preparation method is:

[0057] (1) Mix the dehydrated hydroxyethyl acrylate and heptamethyltrisiloxane at a molar ratio of 1:1.2, add 10 ppm of chloroplatinic acid catalyst, and react at 150° C. for 1 hour to obtain hydroxylated silicone oil;

[0058] (2) Esterify hydroxylated silicone oil and maleic anhydride at 135°C for 4 hours, the molar ratio of hydroxylated silicone oil to maleic anhydride is 2.2:1; obtain dipolysiloxane maleate;

[0059] (3) Add menthane diamine to dipolysiloxane maleate, the molar ratio of menthane diamine to dipolysiloxane maleate is 1:2.2; and add 0.1% of the total mass of reactants sodium methoxide catalyst, reacted at 80° C. for 8 hours under the protection of nitrogen to obtain the organosilicon-modified polyaspartic acid ester.

[0060] B component is poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com