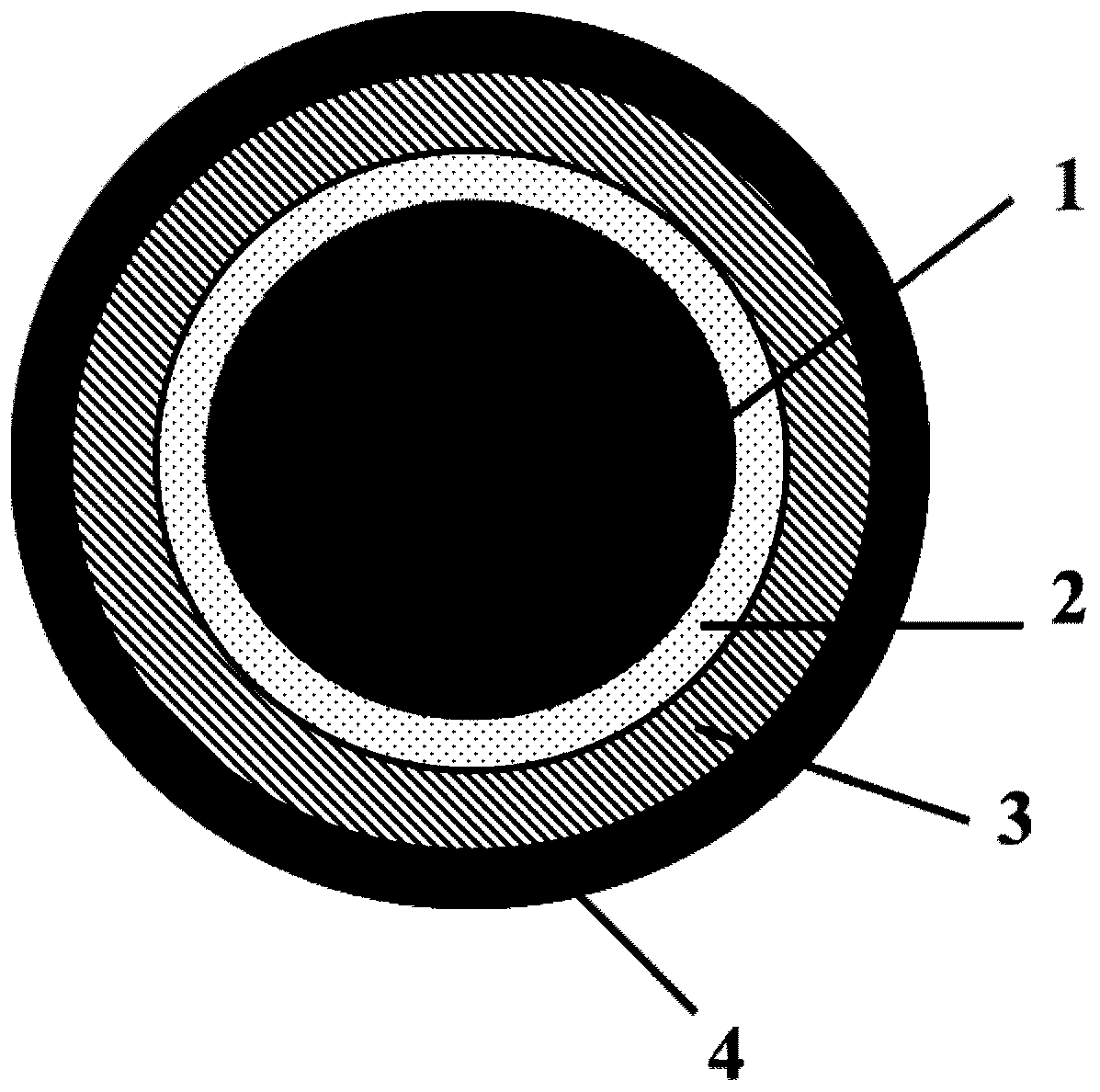

Negative electrode material with multiple coating structures as well as preparation method and application of negative electrode material

A negative electrode material and coating structure technology, which is applied to negative electrode materials with multiple coating structures, in the field of preparation thereof, can solve the problem that it is difficult to uniformly cover the surface of silicon oxide, and cannot effectively improve the interface stability of the material, the ionic conductivity and the interface phase. There is no obvious improvement in capacitance, etc., to achieve the effect of improving interface strength and ionic conductivity, improving cycle stability, improving binder failure and slurry bubbling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

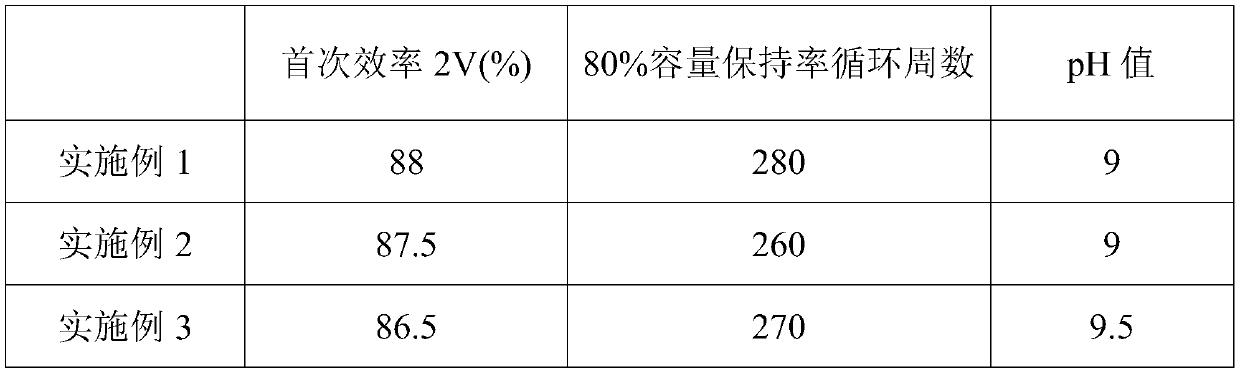

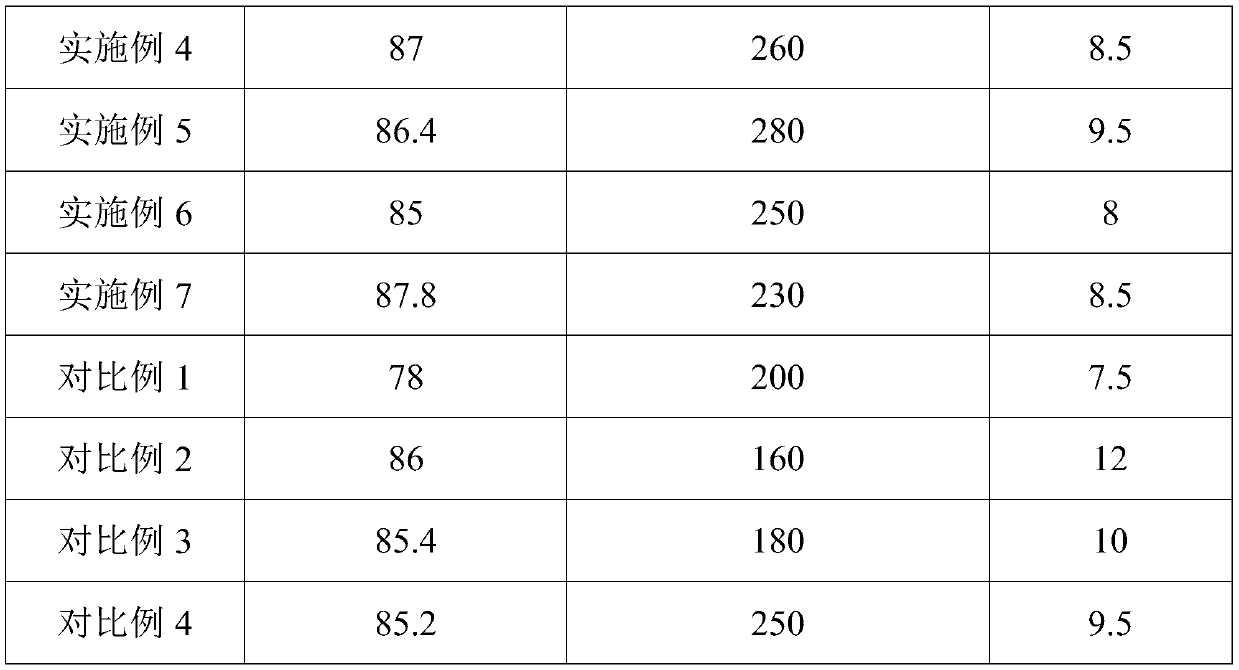

Examples

Embodiment 1

[0064] (1) Heat treatment of 4 μm silicon oxide precursor SiO and lithium hydride at a temperature of 800° C. for 4 hours to obtain lithium-containing silicon oxide with a content of lithium element of 8 wt %;

[0065] (2) Take 10 g of the lithium-containing silicon oxide powder, feed argon (Ar) at a flow rate of 100 sccm / min in a tubular atmosphere furnace, heat up to 300 °C at a rate of 5 °C / min and keep warm at a flow rate of 50 sccm / min flow into carbon dioxide (CO 2 ) gas, after the reaction continued for 20min, the carbon dioxide (CO 2 ) gas to obtain lithium-containing silicon oxide with a lithium salt (lithium carbonate) coating layer;

[0066] (3) Continue to feed argon (Ar), and raise the temperature to 920°C at a rate of 5°C / min, and feed acetylene (C 2 h 2 ) gas, the reaction time continued for 1h, and the acetylene gas was turned off (C 2 h 2 ), continue to feed argon (Ar) to react for 1h, turn off the heating, naturally cool down to room temperature, and tak...

Embodiment 2

[0069] The difference with Example 1 is that the content of lithium element in step (1) lithium-containing silicon oxide is 5wt%, and step (2) controls sulfur dioxide (SO 2 ) gas flow rate is 30 sccm / min, so that in the obtained negative electrode material with multiple coating structure, the content of the lithium sulfate coating layer is 0.1 wt%.

Embodiment 3

[0071] The difference with Example 1 is that the content of lithium element in step (1) lithium-containing silicon oxide is 6.5wt%, and step (2) controls carbon dioxide (CO 2 ) The flow rate of the gas is 30 sccm / min, so that in the obtained negative electrode material with multiple coating structure, the content of the lithium carbonate coating layer is 10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com