Non-toxic environmentally-friendly oriented electrical steel insulation coating and preparation method thereof

A technology of oriented electrical steel and insulating coating, applied in coatings, anti-corrosion coatings, etc., can solve the problems of heat resistance and poor punching performance, and achieve improved moisture absorption and stickiness, simple preparation method, and good insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

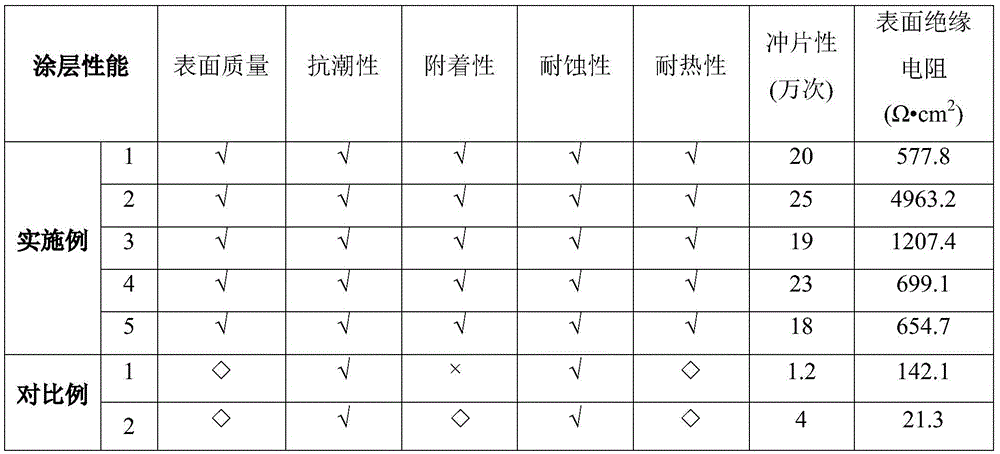

Examples

Embodiment 1

[0043] According to the following ratio and method, configure the insulating coating provided by the invention:

[0044] Aluminum dihydrogen phosphate, 50%;

[0046] Boric acid, 4%;

[0047] Colloidal silicon dioxide, 10%;

[0048] TiO 2 , ZnO mixed powder, 4%;

[0049] Vinyl acetate, acrylic resin, phenolic resin, 13%;

[0050] Propylene glycol polyethylene oxide polypropylene oxide ether, 0.08%;

[0051] The rest is deionized water

[0052] The specific steps are:

[0053] 1) Al with a molar ratio of 0.2 2 o 3 with H 3 PO4 Mix and stir to make it fully react to obtain Al(H 2 PO 4 ) 3 solution, ready to use;

[0054] 2) After mixing vinyl acetate, acrylic resin, and phenolic resin according to the ratio of 2:1:2, add them into the reactor together with deionized water, and mix well;

[0055] 3) TiO with a particle size of 20-30nm 2 1. After the ZnO powder is mixed according to the ratio of 2:1, it is added to the mixed resin in 2)...

Embodiment 2

[0060] According to the following ratio and method, configure the insulating coating provided by the invention:

[0061] Aluminum dihydrogen phosphate, 45%;

[0063] Boric acid, 6%;

[0064] Colloidal silicon dioxide, 10%;

[0065] TiO 2 , ZnO mixed powder, 5%;

[0066] Vinyl acetate, acrylic resin, phenolic resin, 8%;

[0067] Propylene glycol polyethylene oxide polypropylene oxide ether, 0.03%;

[0068] The rest is deionized water

[0069] The specific steps are:

[0070] 1) Al(OH) with a molar ratio of 0.3 3 with H 3 PO 4 Mix and stir to make it fully react to obtain Al(H 2 PO 4 ) 3 solution, ready to use;

[0071] 2) After mixing vinyl acetate, acrylic resin, and phenolic resin according to the ratio of 1:1:2, add them into the reactor together with deionized water, and mix well;

[0072] 3) TiO with a particle size of 20-30nm 2 1. After the ZnO powder is mixed according to the ratio of 1:1, it is added to the mixed resin in 2)...

Embodiment 3

[0077] According to the following ratio and method, configure the insulating coating provided by the invention:

[0078] Magnesium dihydrogen phosphate, 43%;

[0079] Zinc molybdate, 25%;

[0080] Boric acid, 8%;

[0081] Colloidal silicon dioxide, 8%;

[0082] TiO 2 , MgO mixed powder, 3%;

[0083] Styrene-acrylic resin copolymerization, phenolic resin, 10%;

[0084] Propylene glycol polyethylene oxide polypropylene oxide ether, 0.07%;

[0085] The rest is deionized water

[0086] The specific steps are:

[0087] 1) MgO and H with a molar ratio of 0.45 3 PO 4 Mix and stir to make it fully react to obtain Mg(H 2 PO 4 ) 2 solution, ready to use;

[0088] 2) After mixing styrene-acrylic resin copolymer and phenolic resin according to the ratio of 1:1, add them into the reactor together with deionized water, and mix well;

[0089] 3) TiO with a particle size of 10-20nm 2 After the MgO powder is mixed according to the ratio of 1:1, it is added to the mixed resin in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com