High temperature-resistant fireproof coating and preparation method thereof

A fire retardant coating and high temperature resistance technology, applied in fire retardant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor high temperature resistance, restricting the development of the construction field, unsatisfactory flame retardant effect, etc. and water resistance, non-toxic removal, high volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

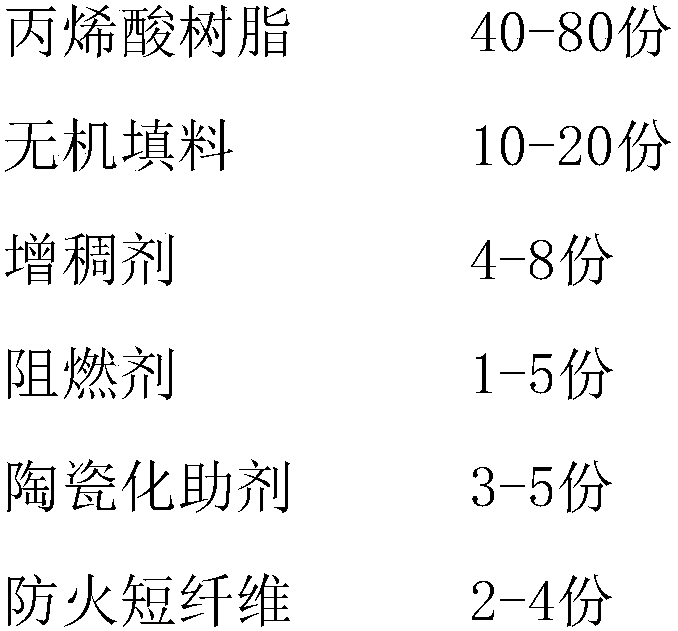

[0045] A high-temperature-resistant fireproof coating, comprising the following raw materials in parts by weight:

[0046]

[0047] The acrylic resin is novolak epoxy acrylic resin.

[0048] The inorganic filler is a mixture composed of modified nano kaolin, modified nano zirconium powder, modified calcium sulfate whiskers and rare earth mixture in a weight ratio of 0.4:0.8:1:0.2.

[0049]The thickener is a mixture of methyl cellulose, hydroxyethyl cellulose or hydroxypropyl methyl cellulose in a weight ratio of 1:0.5:1; the flame retardant is made of microencapsulated red phosphorus, A mixture of expanded graphite and N-P expanded flame retardant in a weight ratio of 0.4:1:1.

[0050] The ceramization aid is a mixture of zinc borate, wollastonite powder and silicate glass powder in a weight ratio of 0.5:1:1.5; the short fireproof fiber is made of phenolic fiber, glass fiber and aluminum silicate fiber A mixture composed of a weight ratio of 0.5:1.5:1.

[0051] The cross...

Embodiment 2

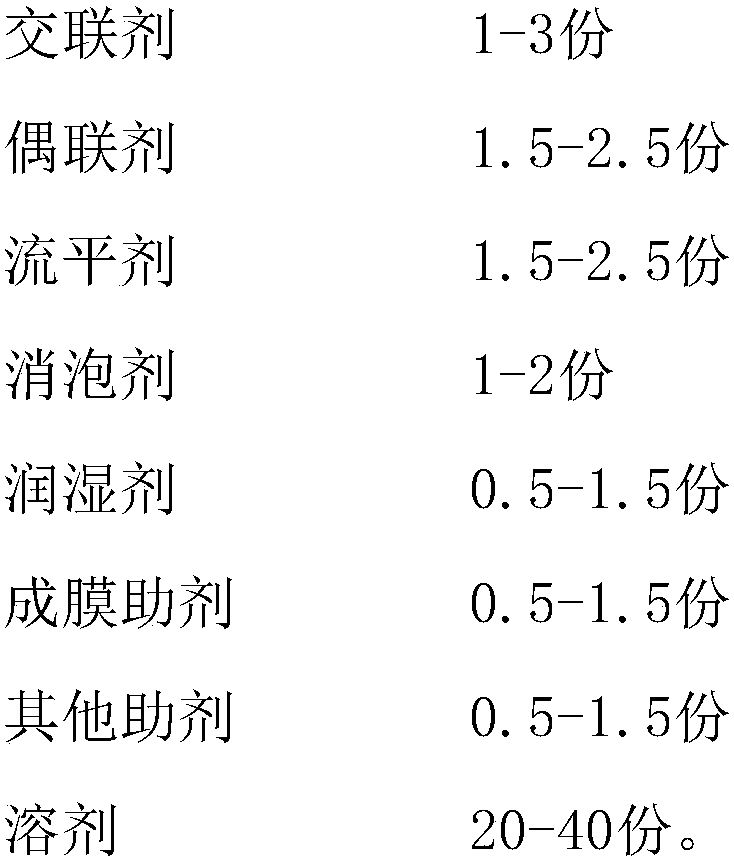

[0057] A high-temperature-resistant fireproof coating, comprising the following raw materials in parts by weight:

[0058]

[0059]

[0060] The acrylic resin is novolak epoxy acrylic resin.

[0061] The inorganic filler is a mixture composed of modified nano kaolin, modified nano zirconium powder, modified calcium sulfate whiskers and rare earth mixture in a weight ratio of 0.5:0.9:1:0.3.

[0062] The thickener is a mixture of methyl cellulose, hydroxyethyl cellulose or hydroxypropyl methyl cellulose with a weight ratio of 1.2:0.8:1; the flame retardant is made of microencapsulated red phosphorus, A mixture of expanded graphite and N-P expanded flame retardant in a weight ratio of 0.5:1.2:1.

[0063] The ceramization aid is a mixture of zinc borate, wollastonite powder and silicate glass powder in a weight ratio of 0.8:1:1.8; the short fireproof fiber is made of phenolic fiber, glass fiber and aluminum silicate fiber A mixture composed of a weight ratio of 0.8:1.8:1. ...

Embodiment 3

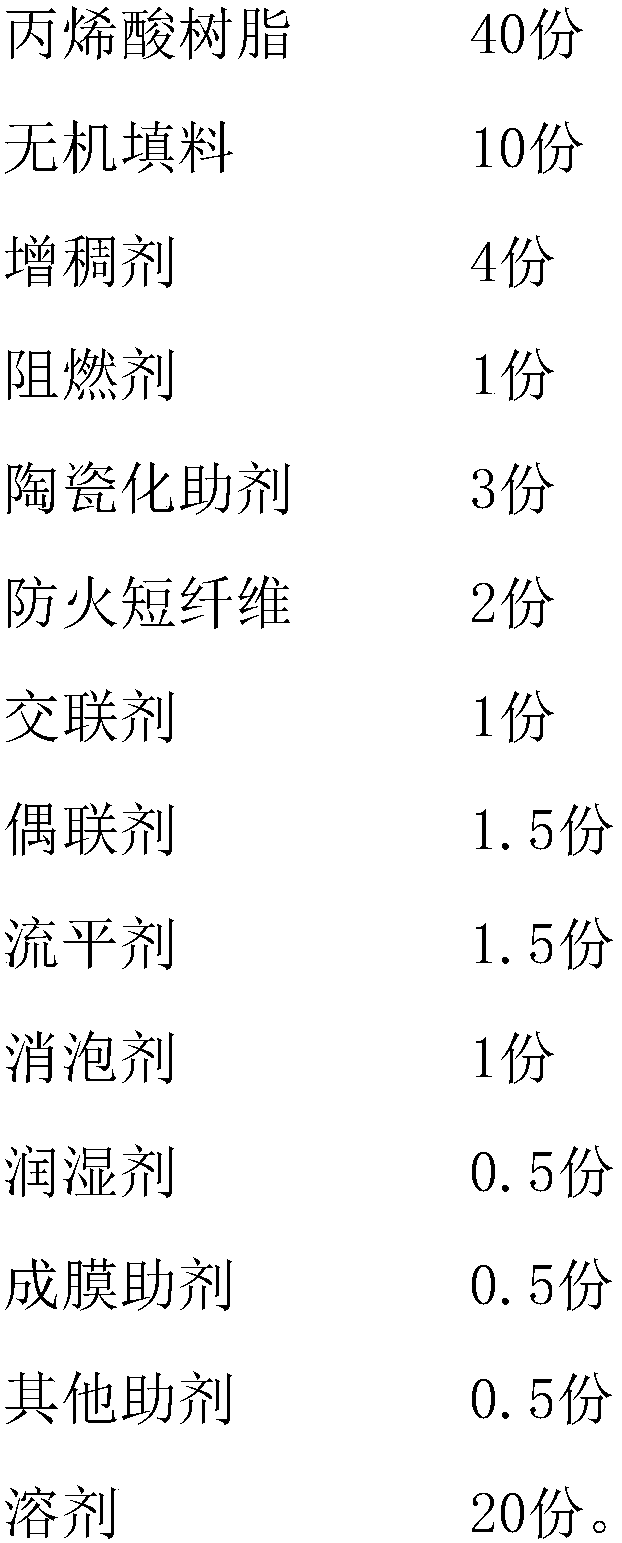

[0070] A high-temperature-resistant fireproof coating, comprising the following raw materials in parts by weight:

[0071]

[0072]

[0073] The acrylic resin is novolak epoxy acrylic resin.

[0074] The inorganic filler is a mixture composed of modified nano kaolin, modified nano zirconium powder, modified calcium sulfate whiskers and rare earth mixture in a weight ratio of 0.6:1:1:0.4.

[0075] The thickener is a mixture of methylcellulose, hydroxyethylcellulose or hydroxypropylmethylcellulose in a weight ratio of 1.5:1:1; the flame retardant is made of microencapsulated red phosphorus, A mixture of expanded graphite and N-P expanded flame retardant in a weight ratio of 0.6:1.5:1.

[0076] The ceramization aid is a mixture of zinc borate, wollastonite powder and silicate glass powder in a weight ratio of 1:1:2; the short fireproof fiber is made of phenolic fiber, glass fiber and aluminum silicate fiber A mixture composed of a weight ratio of 1:2:1.

[0077] The cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com