Water-based dip coating for 3D printing sand mold and preparation method thereof

A 3D printing and sand molding technology, applied in casting molding equipment, coating, molding and other directions, can solve the problems of unstable quality, the overall quality is not suitable for 3D printing sand molding, etc., to improve the use environment, efficient suspension stability, Excellent coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1—9

[0022] Water-based dip-coating coatings for 3D printing sand molds are made through the following steps:

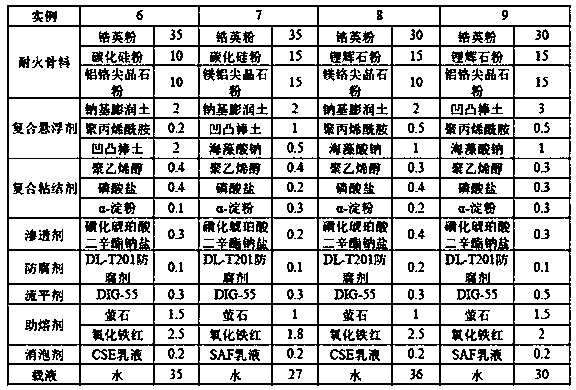

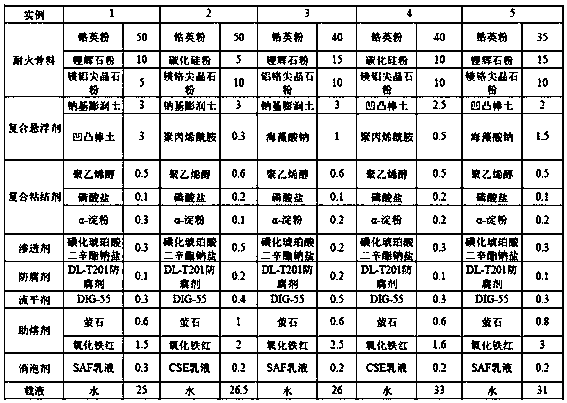

[0023] A) according to the mass ratio requirement of the embodiment corresponding embodiment in table 1, weigh each component material;

[0024] B) Pretreatment of the composite suspending agent: Mix the components of the composite suspending agent in equal proportions with the same mass of water under stirring conditions, so that the components are completely dispersed and uniform, and stand for 12 to 24 hours to obtain the pretreated Composite floating agent;

[0025] C) Pretreatment of each component of the composite binder: Because phosphate does not require pretreatment, it can be directly put into dissolution when used, so the pretreatment of the composite binder components is divided into pretreatment of polyvinyl alcohol and α - The pretreatment of starch, and the pretreatment of the two components must be ready-to-use and ready-to-use to ensure the use effect. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com