Aqueous lithium iron phosphate positive electrode slurry as well as preparation method and application thereof

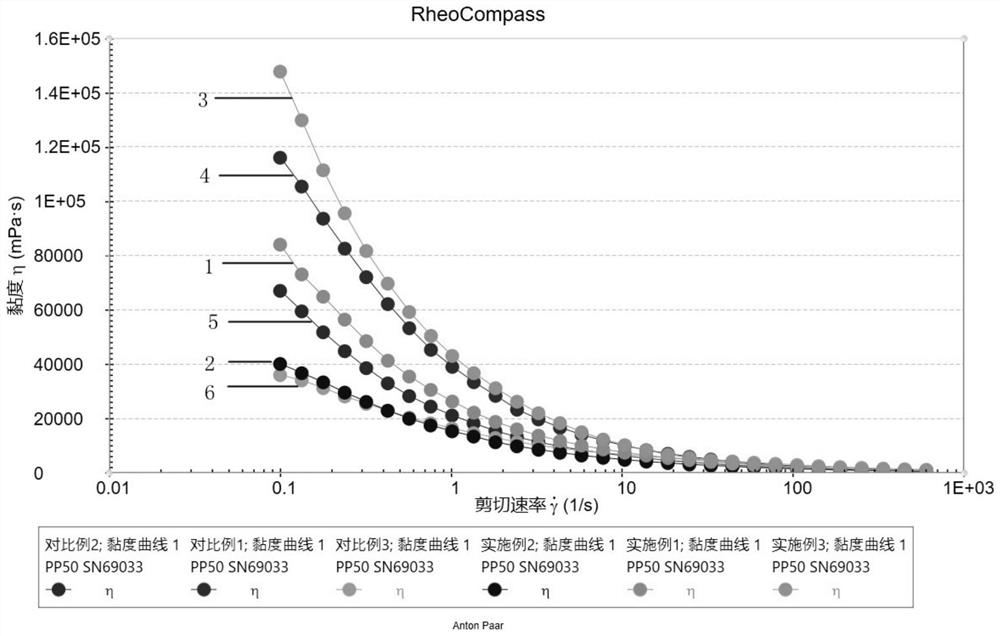

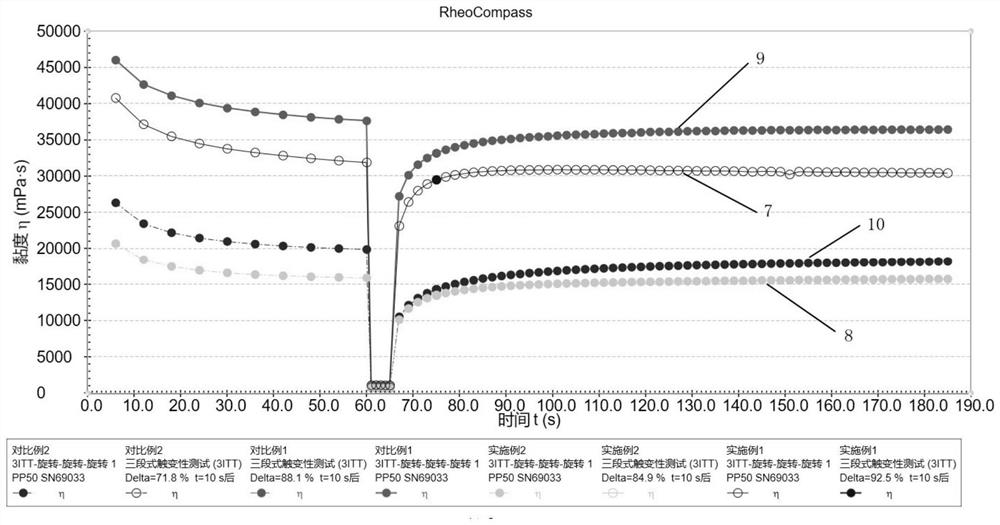

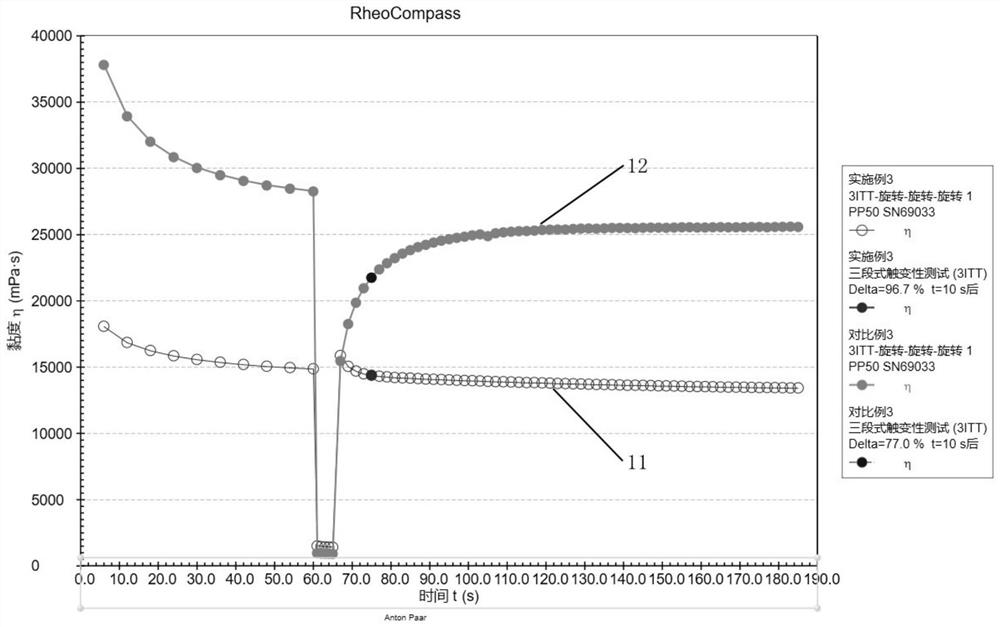

A technology of lithium iron phosphate and positive electrode slurry, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of oily system lithium iron phosphate slurry, such as environmental pollution, high density on one side, and high energy density, and achieve flexibility Effects of high strength, enhanced fluidity, and good thixotropic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A water-based lithium iron phosphate positive electrode slurry is prepared in the following manner:

[0056] 1. Prepare compound glue.

[0057] Stir and mix 1.3 parts of acrylic resin powder with 106 parts of deionized water, and then stir in a planetary slurry mixer at a low speed. After mixing at a low speed, turn on the vacuum, the stirring time is 30min, the stirring speed is 30r / min, and the dispersion speed is 2000r / min, the relative vacuum is -90kPa~-100kPa, and the acrylic resin water-based glue containing the acrylic resin of 1.3% in mass percent concentration is obtained;

[0058] Add 11.33 parts of NV-1A glue in the acrylic resin water-based glue, the solid content of the NV-1A glue is 15%, and the solid matter after 11.33 parts of NV-1A glue is dried, that is, NV-1A glue It is 1.7 parts, then stir at a low speed in a planetary slurry mixer, start vacuuming after mixing at a low speed, the stirring time is 35 minutes, the stirring speed is 30r / min, the disp...

Embodiment 2

[0069] A water-based lithium iron phosphate positive electrode slurry is prepared in the following manner:

[0070] 1. Prepare compound glue.

[0071] Stir and mix 1.15 parts of acrylic resin powder with 106 parts of deionized water, and then stir in a planetary slurry mixer at a low speed. After mixing at a low speed, turn on the vacuum, the stirring time is 30min, the stirring speed is 30r / min, and the dispersion speed is 2000r / min, the relative vacuum is -90kPa~-100kPa, and the acrylic resin water-based glue that contains the acrylic resin with a mass percentage concentration of 1.1% is obtained;

[0072] Add 12.33 parts of NV-1A glue solution in the described acrylic resin water-based glue solution, the solid content of this NV-1A glue solution is 15%, the solid matter after 12.33 parts of NV-1A glue solution drying, namely NV-1A glue solution It is 1.85 parts, then stir at a low speed in a planetary slurry mixer, start vacuuming after mixing at a low speed, the stirring...

Embodiment 3

[0083] A water-based lithium iron phosphate positive electrode slurry is prepared in the following manner:

[0084] 1. Prepare compound glue.

[0085] Stir and mix 1.3 parts of acrylic resin powder with 100 parts of deionized water, and then stir in a planetary slurry mixer at a low speed. After mixing at a low speed, turn on the vacuum, the stirring time is 35min, the stirring speed is 30r / min, and the dispersion speed is 2000r / min, the relative vacuum is -90kPa~-100kPa, and the acrylic resin water-based glue containing the acrylic resin of 1.3% in mass percent concentration is obtained;

[0086] Add 13.33 parts of NV-1A glue solution in the described acrylic resin water-based glue solution, the solid content of this NV-1A glue solution is 15%, the solid matter after 13.33 parts of NV-1A glue solution drying, namely NV-1A glue solution It is 2 parts, then stir at a low speed in a planetary slurry mixer, start vacuuming after mixing at a low speed, the stirring time is 40 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com