A 3d printed colorful decorative mortar

A 3D printing and decorative mortar technology, applied in the field of color decorative mortar and its preparation, can solve the problems of long setting time, fluidity, inapplicability, etc., and achieve high early strength, stable development, and excellent thixotropic properties of the paste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

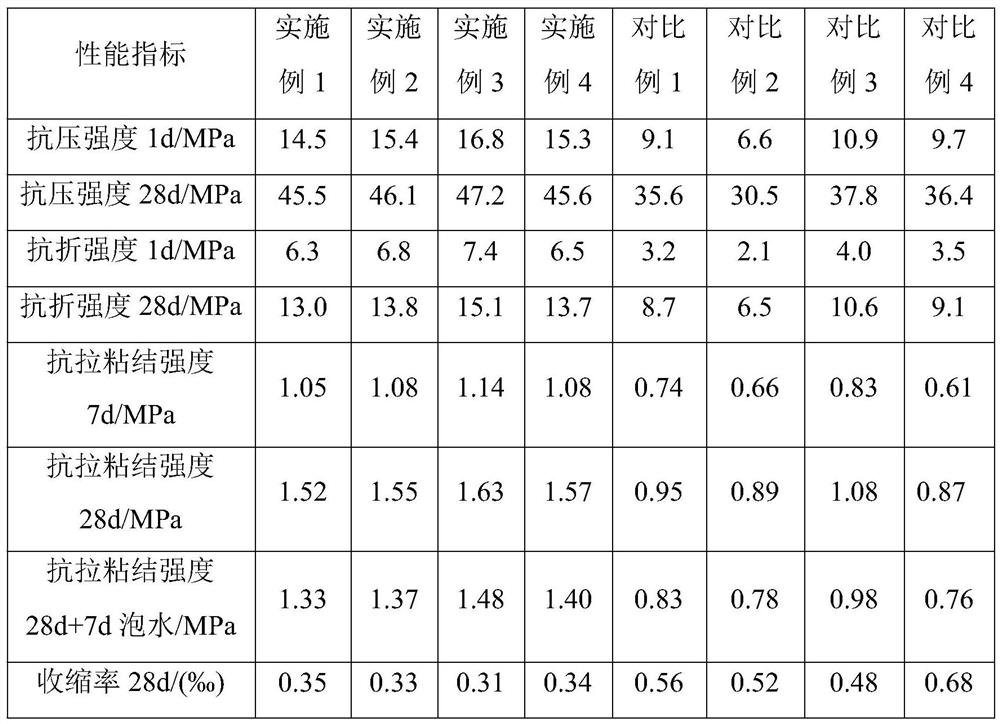

Examples

Embodiment 1

[0038] Mortar preparation:

[0039] S1. Put 80Kg of white high-alumina cement and 30Kg of high-strength gypsum powder into a mortar mixer and stir to disperse the cementitious material evenly; add 50Kg of water and continue stirring, then add 10Kg of polyacrylate emulsion and mix evenly to obtain cement paste;

[0040] S2. put 10Kg inorganic pigment chrome yellow and 100Kg fine sand and 50Kg coarse sand into another mortar mixer and stir and mix to obtain uniform colored sand;

[0041] S3. Add the colored sand to the cement slurry and continue to stir, then add 5Kg polycarboxylate water reducer, 5Kg wood fiber, 5Kg ettringite expansion agent, 10Kg 3D printing special thixotropic agent (made of sodium carboxymethyl cellulose, Superfine heavy calcium carbonate powder and gelatin are obtained according to the mass ratio of sodium carboxymethyl cellulose: superfine heavy calcium carbonate powder: gelatin is 2:1:1), 5Kg lithium carbonate and 5Kg sodium gluconate are mixed evenly, ...

Embodiment 2

[0043] Mortar preparation:

[0044] S1. Put 100Kg of white high-alumina cement and 50Kg of high-strength gypsum powder into a mortar mixer and stir to disperse the cementitious material evenly; add 70Kg of water and continue stirring, then add 20Kg of polyacrylate emulsion and mix evenly to obtain cement slurry;

[0045] S2. Put 20Kg inorganic pigment iron blue, 150Kg fine sand and 100Kg coarse sand into another mortar mixer and stir to obtain uniform colored sand;

[0046] S3. Add the colored sand into the cement slurry and continue to stir, then add 10Kg polycarboxylate water reducer, 10Kg wood fiber, 10Kg ettringite expansion agent, 20Kg 3D printing special thixotropic agent (made of sodium carboxymethyl cellulose, Superfine heavy calcium carbonate powder and gelatin are obtained according to the mass ratio of sodium carboxymethyl cellulose: superfine heavy calcium carbonate powder: gelatin is 5:1:3), 10Kg lithium hydroxide and 5Kg citric acid, 5Kg four Mix sodium borate e...

Embodiment 3

[0048] Mortar preparation:

[0049] S1. Put 100Kg of white high-alumina cement and 45Kg of high-strength gypsum powder into a mortar mixer and stir to disperse the cementitious material evenly; add 60Kg of water and continue stirring, then add 15Kg of polyacrylate emulsion and mix evenly to obtain cement slurry;

[0050] S2. put 16Kg inorganic pigment cadmium red and 120Kg fine sand and 70Kg coarse sand into another mortar mixer and stir and mix to obtain uniform colored sand;

[0051] S3. Add the colored sand to the cement slurry and continue to stir, then add 6Kg polycarboxylate water reducer, 8Kg wood fiber, 7Kg ettringite expansion agent, 16Kg 3D printing special thixotropic agent (made of sodium carboxymethyl cellulose, Superfine heavy calcium carbonate powder and gelatin are obtained according to the mass ratio of sodium carboxymethyl cellulose: superfine heavy calcium carbonate powder: gelatin (3:1:2), 8Kg sodium sulfate, 3Kg tartaric acid, 3Kg tripolyphosphoric acid T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com