High-strength fiber-reinforced cement-based composite material as well as preparation method and application thereof

A high-strength fiber and cement-reinforced technology, which is applied in the field of building materials, can solve problems such as increased risk of bridge deck system cracking, poor synergistic workability, and poor high-temperature resistance, and achieve good synergistic workability, fast setting speed, and good Effects of Composite Adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

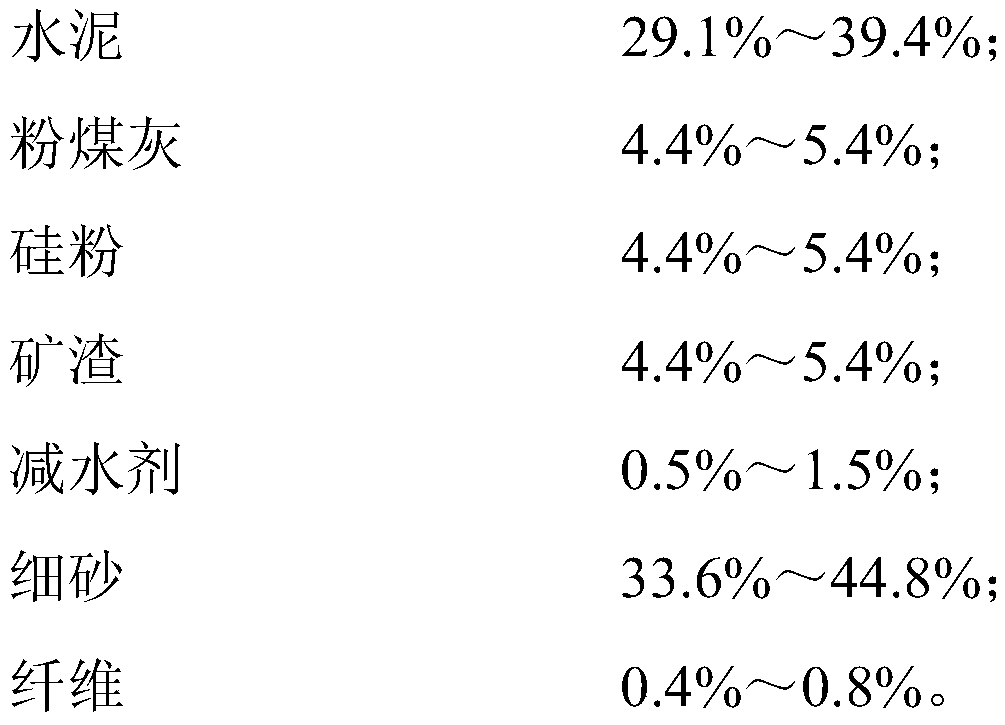

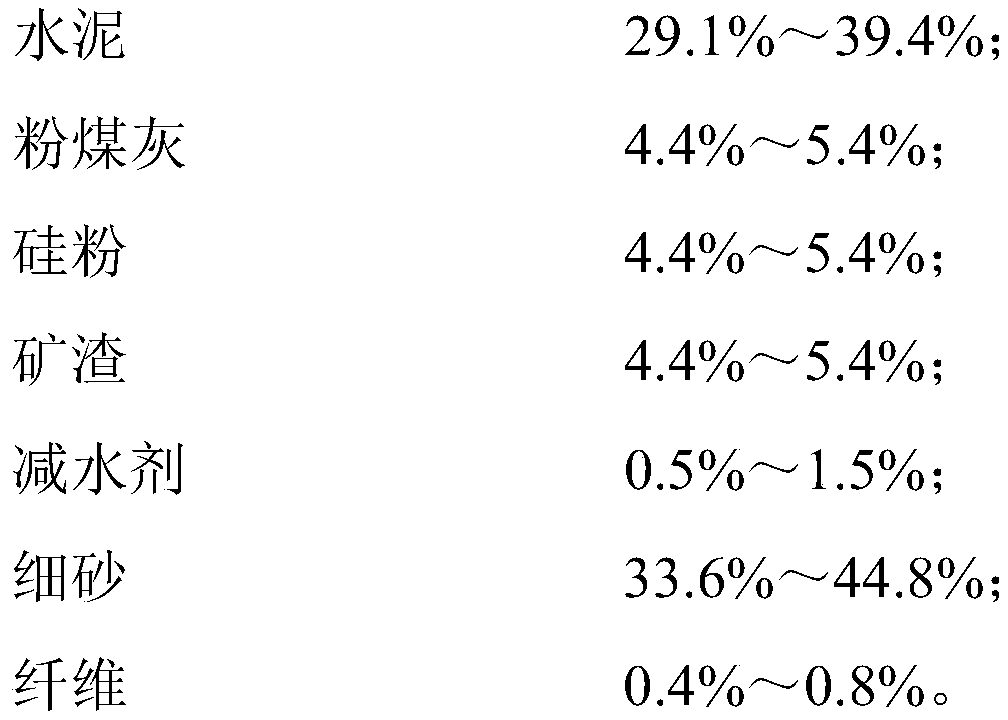

[0031] A high-strength fiber-reinforced cement-based composite material, which is made of cement, fly ash, silica fume, slag, water reducer, fine sand, fiber and water, wherein cement, fly ash, silica fume, slag, The total mass percentage of water reducer, fine sand and fiber is 90.4%, and the total mass percentage of water is 9.6%.

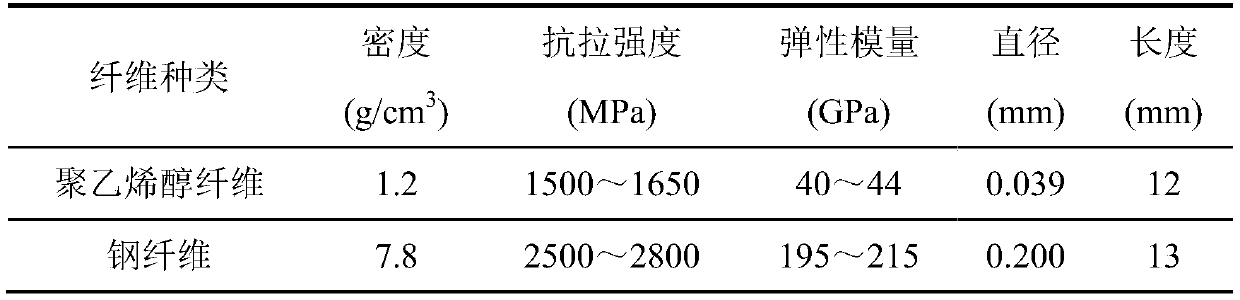

[0032] The cement is rapid-hardening sulfoaluminate cement with a strength grade of 42.5; the fly ash is the first-class low-calcium fly ash; the silica fume is the micro-silica fume produced by Gansu Sanyuan Silicon Material Co., Ltd.; the slag is S95 granulated blast furnace Slag; superplasticizer is polycarboxylate high-efficiency superplasticizer; fine sand is 100-200 mesh quartz sand; polyvinyl alcohol fiber is produced by Japan Kuraray Company, with a length of 12mm, a diameter of 39μm, a tensile strength of 2750MPa, and an elastic modulus 210GPa; the steel fiber is produced by Anshan Iron and Steel Plant, with a length of 13mm, a diameter ...

Embodiment 2

[0039] A high-strength fiber-reinforced cement-based composite material, which is made of cement, fly ash, silica fume, slag, water reducer, fine sand, fiber and water, wherein cement, fly ash, silica fume, slag, The total mass percentage of water reducer, fine sand and fiber is 93.0%, and the mass percentage of water is 7.0%.

[0040] The cement is rapid-hardening sulfoaluminate cement with a strength grade of 42.5; the fly ash is the first-class low-calcium fly ash; the silica fume is the micro-silica fume produced by Gansu Sanyuan Silicon Material Co., Ltd.; the slag is S95 granulated blast furnace Slag; superplasticizer is polycarboxylate high-efficiency superplasticizer; fine sand is 100-200 mesh quartz sand; polyvinyl alcohol fiber is produced by Japan Kuraray Company, with a length of 12mm, a diameter of 39μm, a tensile strength of 2750MPa, and an elastic modulus 210GPa; the steel fiber is produced by Anshan Iron and Steel Plant, with a length of 13mm, a diameter of 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com