Suspending agent of metribuzin methyl oleate

A technology of mecitrione oleic acid and suspending agent, which is applied to herbicides, algicides, biocides, biocides, etc., to reduce the use of organic solvents, stabilize performance, and avoid sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

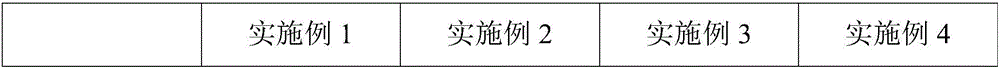

Examples

Embodiment 1

[0019] Mecitrione 10kg, nonylphenol polyethylene glycol ether 2kg, lauryl acrylate and styrene copolymer polycarboxylic acid dispersant 4kg, fly ash 0.5kg, dodecyl sulfonic acid intercalated magnesium aluminum hydrotalcite 0.5kg, silicone 0.1kg, 82.9kg methyl oleate.

[0020] Preparation:

[0021] 1) Add mezimidone technical, nonylphenol polyethylene glycol ether, lauryl acrylate and styrene copolymer polycarboxylic acid dispersant, silicone and methyl oleate into the mixing tank, and stir under high shear Next, the materials are fully mixed evenly to obtain mixture A;

[0022] 2) Then heat the mixture A to 45°C, add fly ash and dodecyl sulfonic acid intercalated magnesium aluminum hydrotalcite, stir continuously, cool to room temperature, put the mixed material into a sand mill for grinding, sand Grind for 2 hours, that's it.

Embodiment 2

[0024] Mecitrione 16kg, fatty alcohol polyoxyethylene ether 4kg, lauryl acrylate and styrene copolymer polycarboxylic acid dispersant 5kg, fly ash 2kg, dodecyl sulfonic acid intercalated magnesium aluminum hydrotalcite 1kg, Octanol 0.5kg, methyl oleate 71.5kg.

[0025] Preparation:

[0026] 1) Add the original drug of mecitrione, fatty alcohol polyoxyethylene ether, lauryl acrylate and styrene copolymer polycarboxylic acid dispersant, n-octanol and methyl oleate into the mixing tank, and stir under high shear, Mix the materials well and evenly to obtain mixture A;

[0027] 2) Then heat the mixture A to 48°C, add fly ash and dodecyl sulfonic acid intercalated magnesium aluminum hydrotalcite, stir continuously, after cooling to room temperature, put the mixed material into a sand mill for grinding, sand Grind for 2 hours, that's it.

Embodiment 3

[0029] Mecitrione 20kg, methyl ricinoleate polyoxyethylene ether 8kg, lauryl acrylate and styrene copolymer polycarboxylic acid dispersant 6kg, fly ash 3.6kg, dodecyl sulfonic acid intercalated magnesium aluminum 3.6kg Hydrotalcite-like, n-octanol 0.8kg, 58kg methyl oleate.

[0030] Preparation:

[0031] 1) Add the original medicine of metrizone, ricinoleic acid methyl ester polyoxyethylene ether, lauryl acrylate and styrene copolymer polycarboxylic acid dispersant, n-octanol and methyl oleate in the mixing kettle, Under stirring, the materials are fully mixed evenly to obtain mixture A;

[0032] 2) Then heat the mixture A to 52°C, add fly ash and dodecyl sulfonic acid intercalated magnesium aluminum hydrotalcite, stir continuously, after cooling to room temperature, put the mixed material into a sand mill for grinding, sand Grind for 2.5 hours, that's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com