Early strength cement grout with low dehydration ratio for grouting

A technology of cement slurry and water separation rate, applied in the field of cement slurry, can solve the problems of poor suspension stability and uncontrollable diffusion distance of single-liquid cement slurry, improve the suspension stability, effectively control the diffusion radius, and improve the resistance to water dilution. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The low water-separation rate early-strength cement slurry for coal wellbore grouting in this embodiment consists of the following components: 100 kg of No. 425 ordinary Portland cement, 80 kg of water, 10 kg of silica sol, 1 kg of sodium carbonate, and 0.03 kg of diethanolamine.

[0016] The water separation rate of the cement slurry in this embodiment is 0, the initial setting time is 4.5 hours, and the final setting time is 5.4 hours.

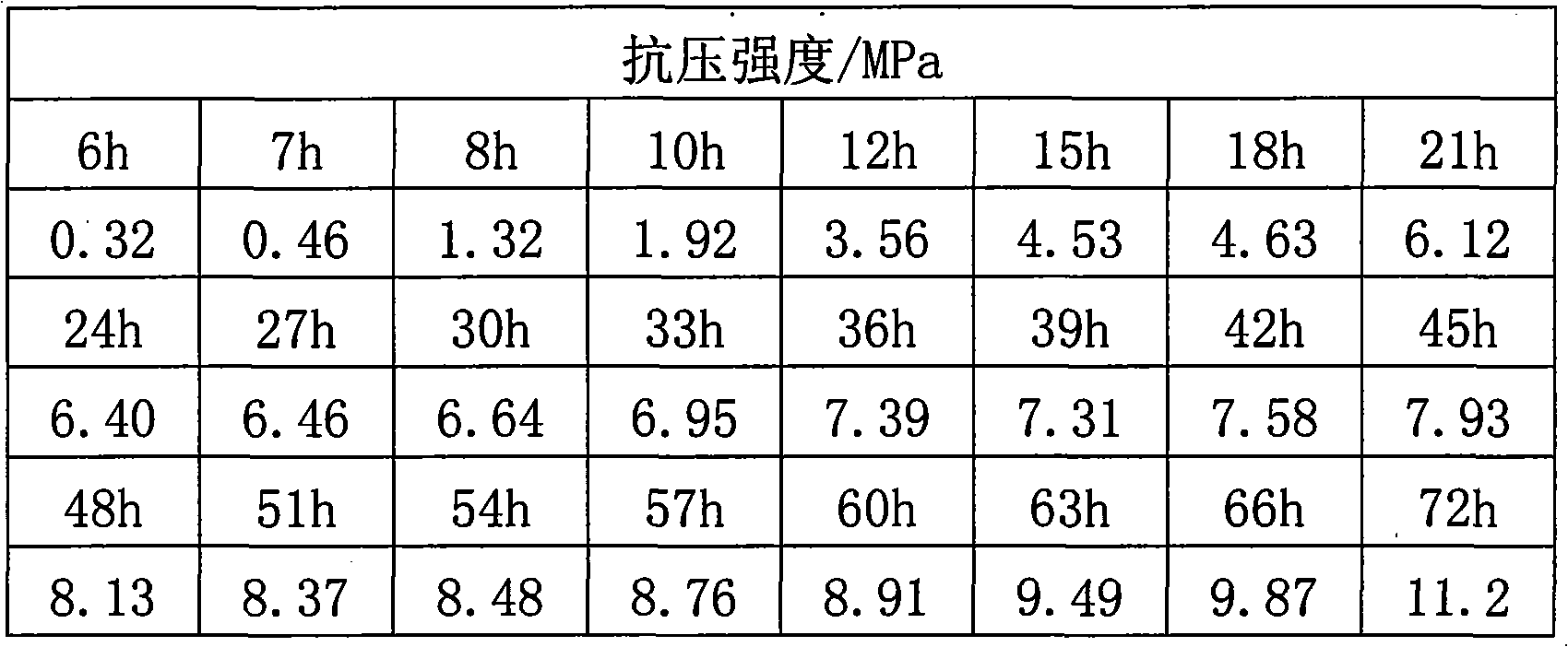

[0017] In order to further characterize the early strength performance of the slurry, the hourly compressive strength of the slurry stone body was measured. The experimental results are shown in Table 1.

[0018] Early compressive strength of grout Table 1

[0019]

[0020] It can be seen from Table 1 that the early strength of the slurry is significantly improved, and the compressive strength of the stone body can reach 0.32MPa in 6 hours, and the compressive strength can reach more than 3.5MPa in 12 hours.

[0021] The addition...

Embodiment 2

[0029] The low water-separation rate early-strength cement slurry used for coal shaft grouting in this embodiment is composed of the following components: 100 kg of No. 425 ordinary Portland cement, 80 kg of water, 12 kg of silica sol, 1 kg of sodium carbonate, and 0.08 kg of triisopropanolamine .

[0030] The water separation rate of the cement slurry in this embodiment is 0%, the initial setting time is 4.3 hours, and the final setting time is 5.2 hours.

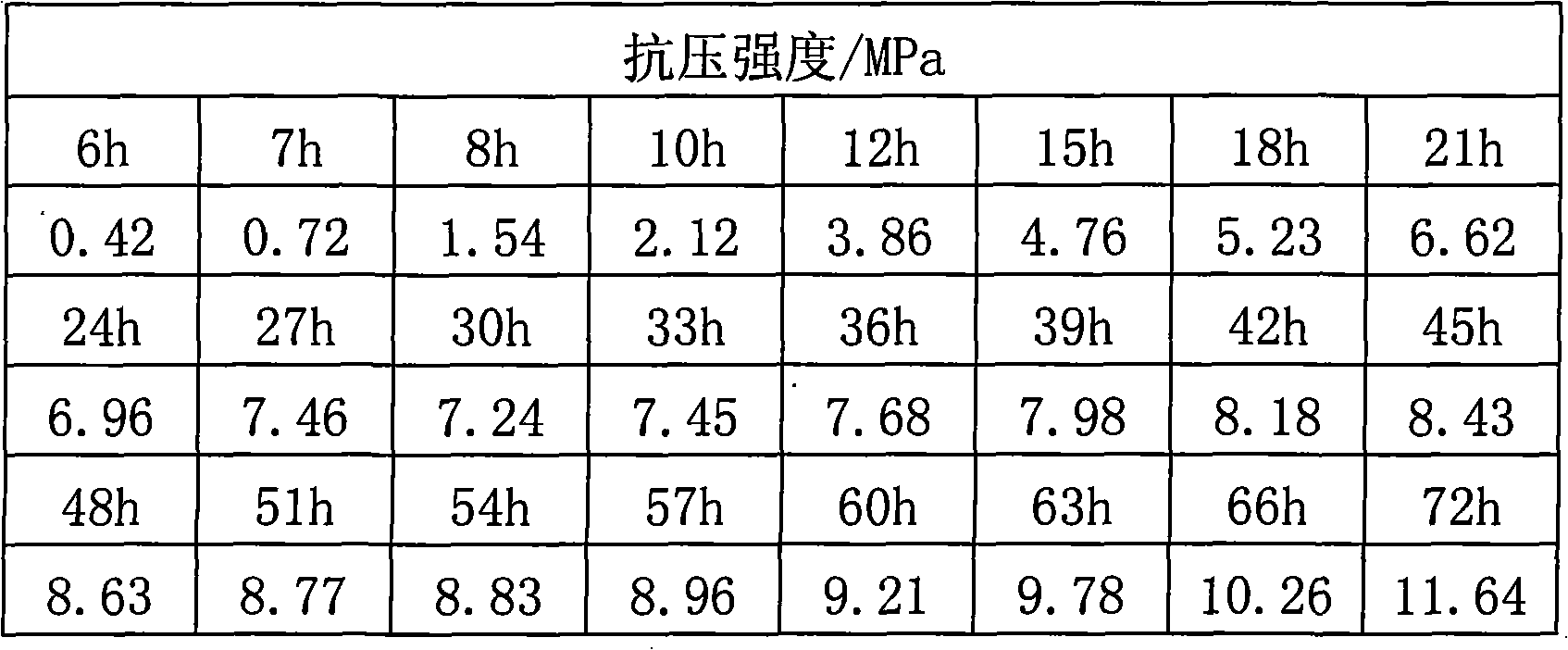

[0031] In order to further characterize the early strength performance of the slurry, the hourly compressive strength of the slurry stone body was measured. The experimental results are shown in Table 3.

[0032] Early compressive strength of grout Table 3

[0033]

[0034] It can be seen from Table 3 that the early strength of the slurry is significantly improved, and the compressive strength of the stone body can reach 0.4MPa in 6 hours, and the compressive strength can reach more than 3.8MPa in 12 hours.

[0035] ...

Embodiment 3

[0042] The low water-separation rate early-strength cement slurry for coal wellbore grouting in this embodiment consists of the following components: 100 kg of No. 425 ordinary Portland cement, 100 kg of water, 36 kg of silica sol, 1 kg of sodium carbonate, and 0.06 kg of diethanolamine.

[0043] The water separation rate of the cement slurry in this embodiment is 1%, the initial setting time is 5.3 hours, and the final setting time is 5.8 hours.

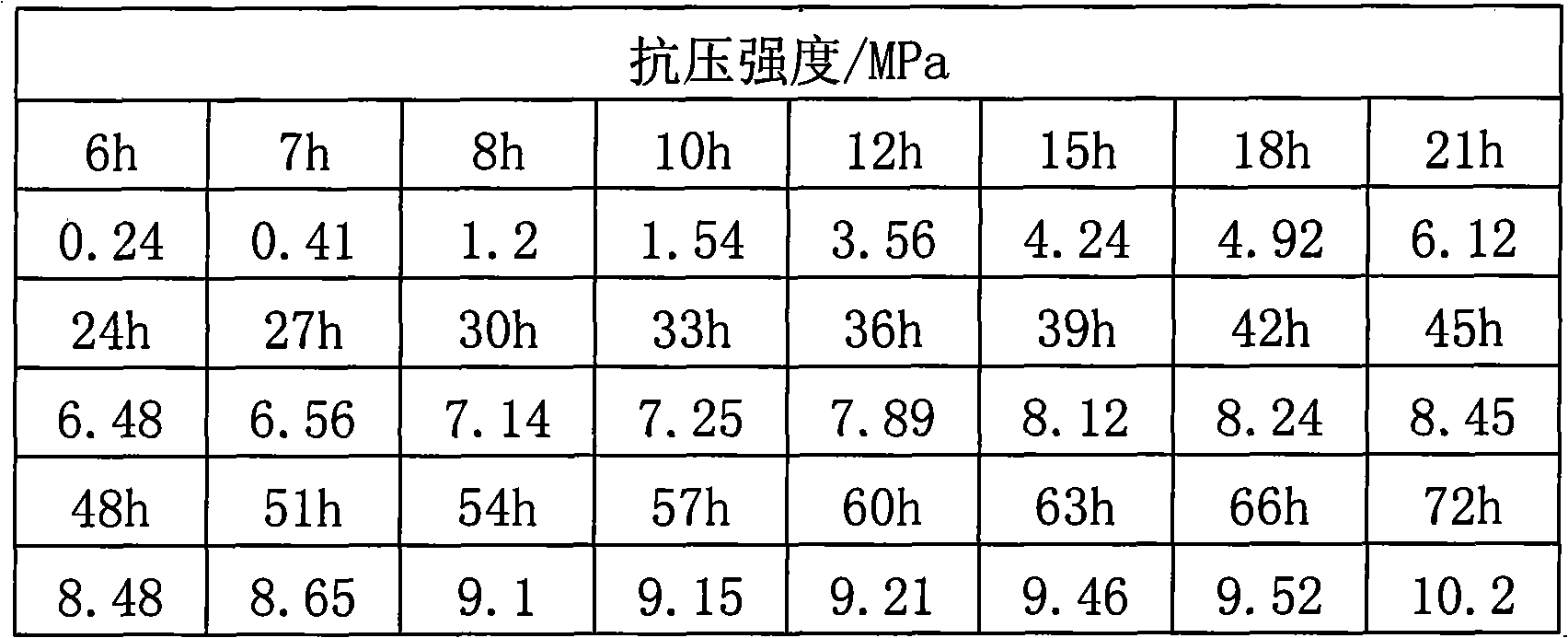

[0044] In order to further characterize the early strength performance of the slurry, the hourly compressive strength of the slurry stone body was measured. The experimental results are shown in Table 5.

[0045] Early compressive strength table of grout Table 5

[0046]

[0047]It can be seen from Table 5 that the early strength of the slurry is significantly improved, and the compressive strength of the stone body can reach 0.2MPa in 6 hours, and the compressive strength can reach more than 3.5MPa in 12 hours.

[0048] The ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com