Patents

Literature

40results about How to "Good low temperature film forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

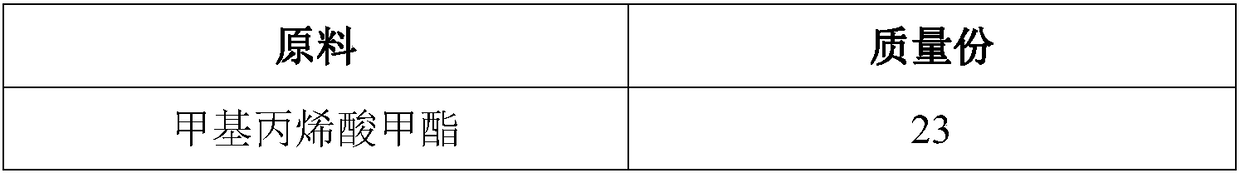

Preparation method and application of acrylate heterozygotic emulsion

ActiveCN101787098ASmall particle sizeWide particle size distributionPolyurea/polyurethane coatingsPolymer scienceLacquer

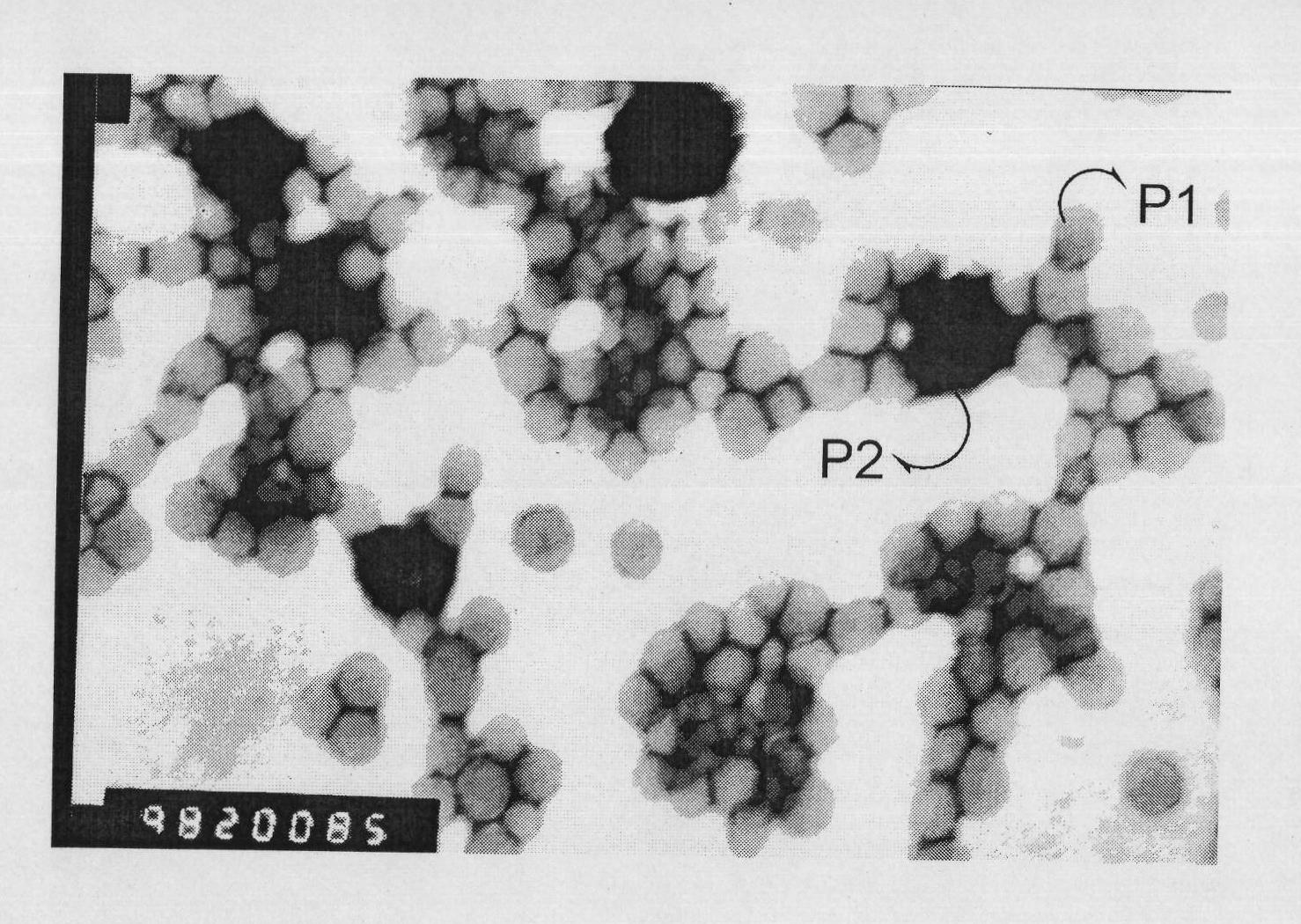

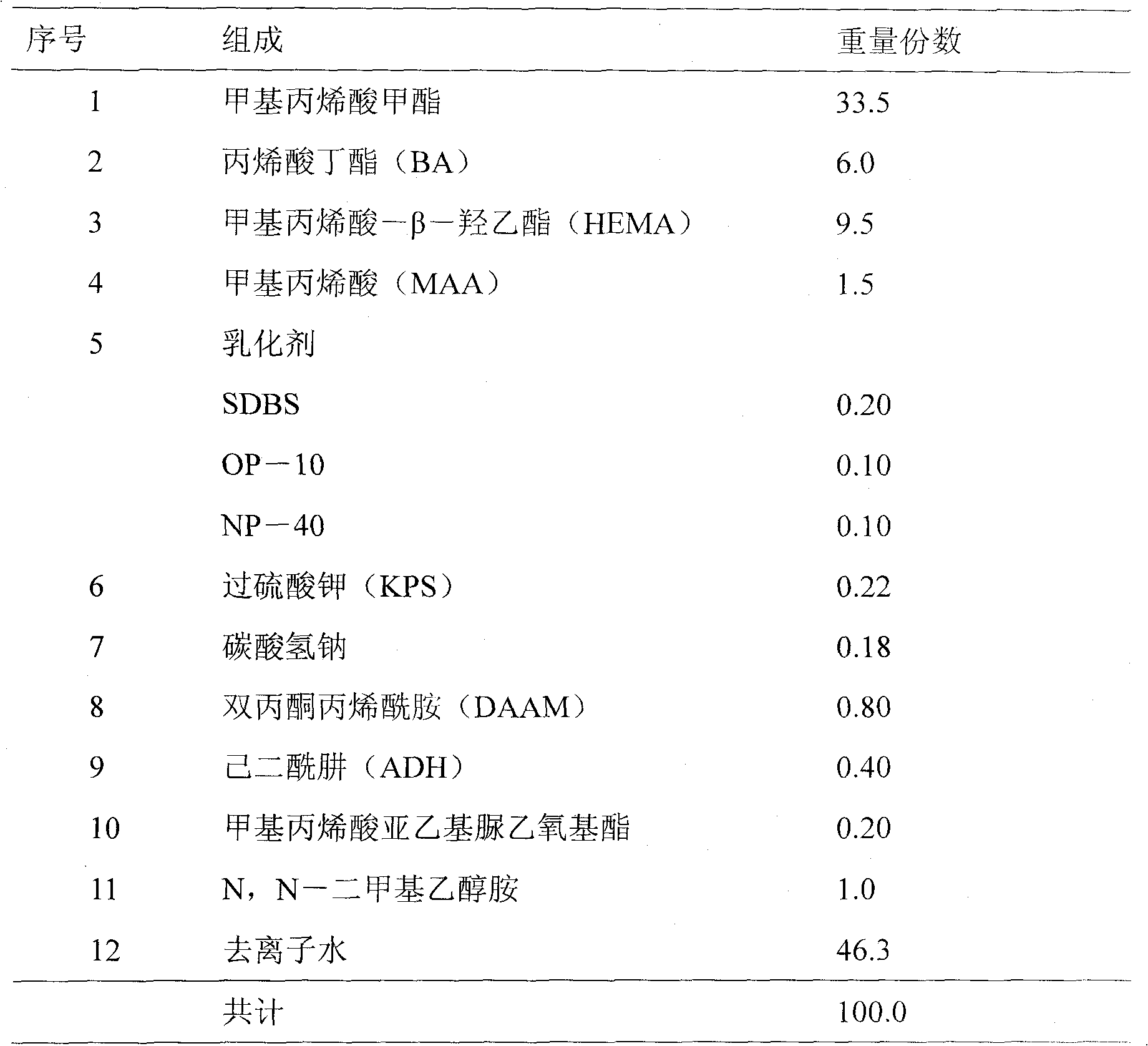

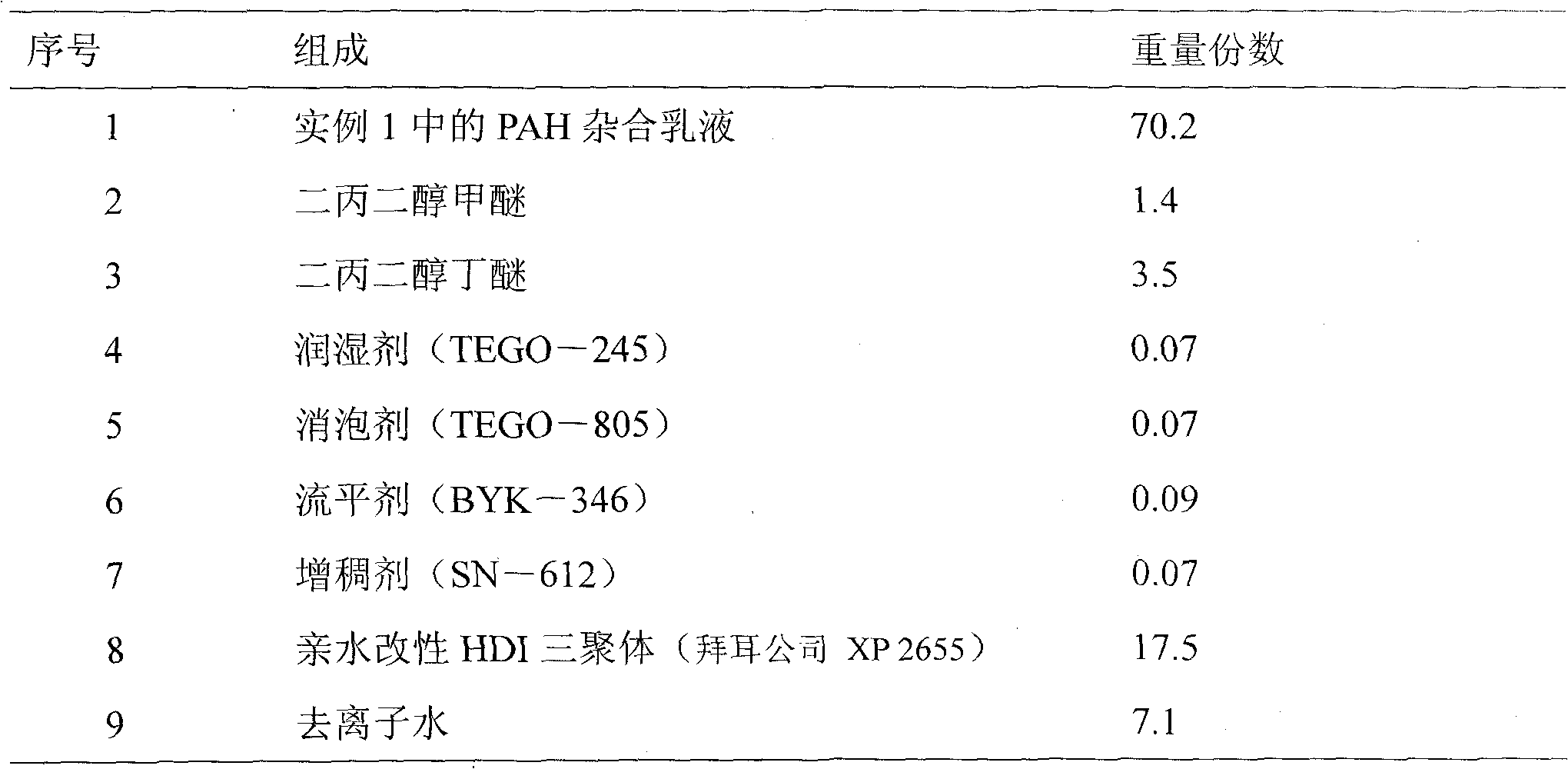

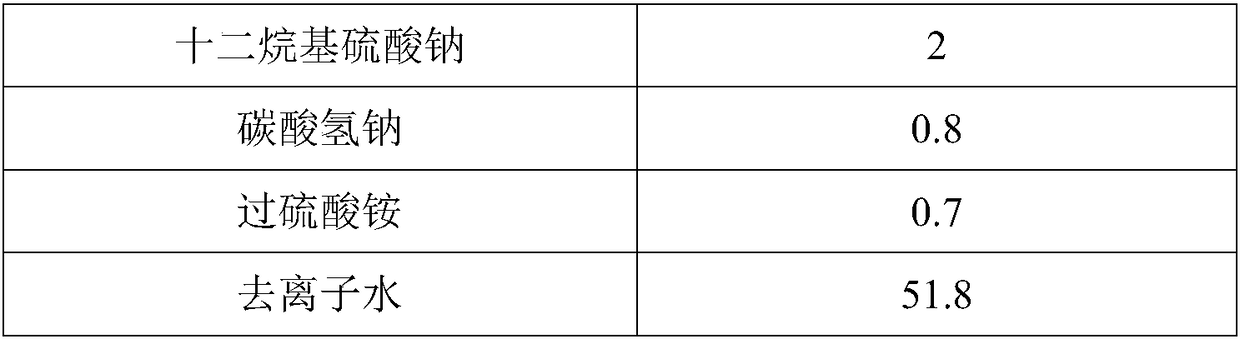

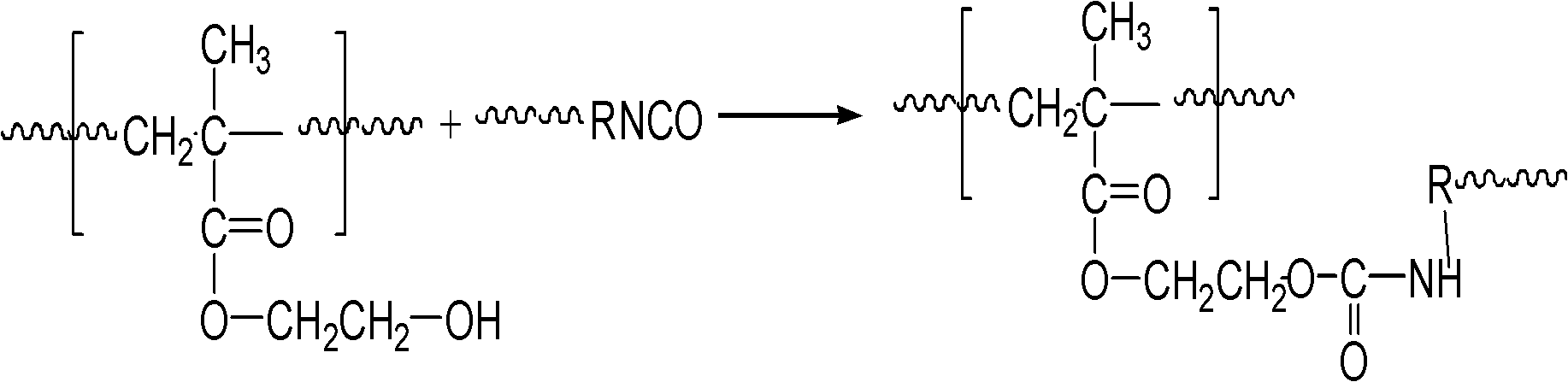

The invention discloses a preparation method and an application of an acrylate heterozygotic emulsion. In the invention, the acrylate heterozygotic emulsion is synthesized by adopting a seed emulsion polymerization process and combining a process of instantly neutralizing and segmentally adding polar monomers. The acrylate heterozygotic emulsion comprises macroparticles consisting of polymers P2 rich in hydroxyl groups on a surface layer and microparticles consisting of polymers P1 rich in carboxylate on the surface layer. Compared with a conventional hydroxy acrylate emulsion, the acrylate heterozygotic emulsion has smaller mean grain size and wider grain size distribution on emulsion particles. The acrylate heterozygotic emulsion can be adopted to prepare aqueous bi-component polyurethane wood coatings, and a coating layer of the coating has excellent property of resisting water and solvents, high crosslinking density and hardness, good mechanical property, scratching resistance and wear resistance. The acrylate heterozygotic emulsion has compact coating structure, high glossiness and better combination property, and not only can be applied to high-grade wood coatings, but also can be applied to automotive refinish paint, metallic anti-corrosion paint, other industrial protective paint, and the like.

Owner:SOUTH CHINA UNIV OF TECH

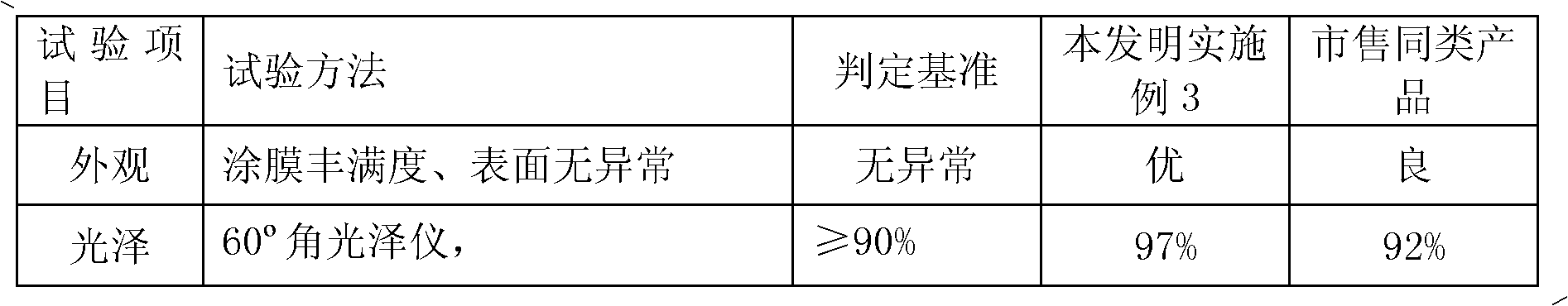

Water-based plastic coating and preparation method thereof

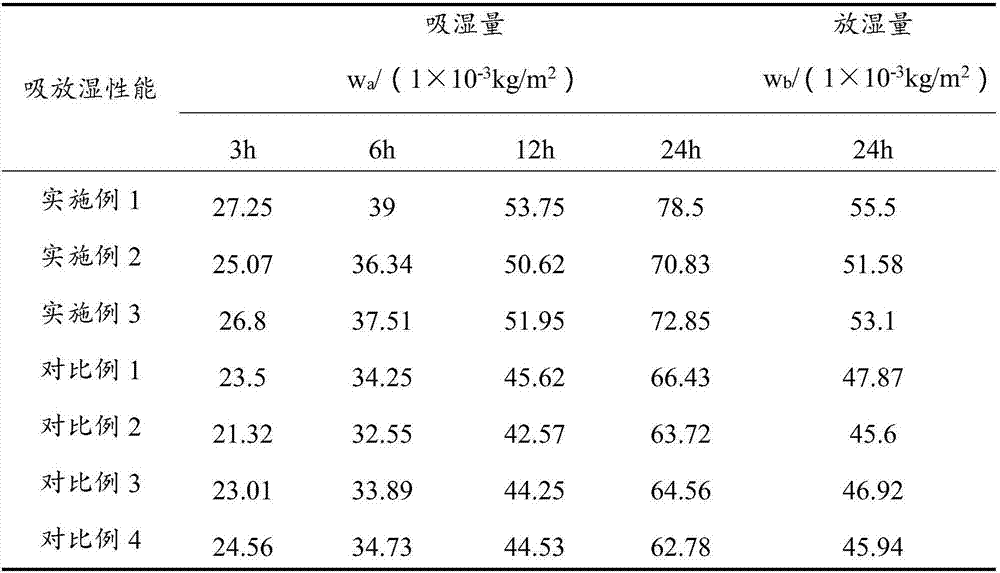

The invention discloses a water-based plastic coating. The water-based plastic coating comprises the following components: a water-based resin emulsion, deionized water, a filler and additives. The invention further designs a preparation method of the water-based plastic coating, and the preparation method comprises the following steps: adding the filler into the water-based resin emulsion, adding an appropriate amount of deionized water, stirring, pouring into a sand mill for grinding, putting into a dispersing cylinder when the fineness is below 80mu m, adding the additives, sealing, stirring and detecting the viscosity for not less than 95s to prepare the water-based plastic coating. The water-based plastic coating has excellent water absorption, water retention, water suction and drainage and a good humidity adjusting effect, can be used for regulating the indoor relative humidity, and has the advantages of relatively high scrubbing resistance, water resistance and solvent resistance, corrosion resistance, alkali resistance, light resistance, weather resistance, good film-forming property, excellent color retention, wear resistance, corrosion resistance, controllable hardness, high performance-price ratio and the like, and the preparation method is simple, easy to operate without pollution, good in construction and safe to use.

Owner:JIANGSU MARINE VICTORY COATING

Emulsion with core-shell structure and environment-friendly interior wall coating containing emulsion

InactiveCN108484834AGood low temperature film formingImprove stain resistanceAntifouling/underwater paintsPaints with biocidesLatex particleDefoaming Agents

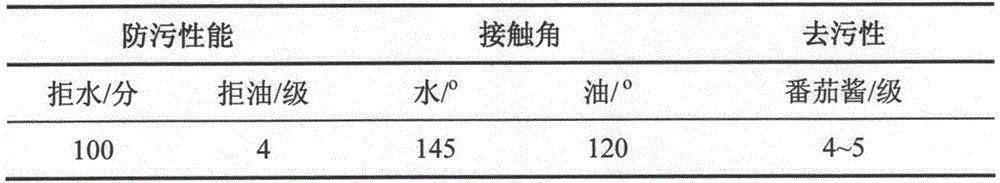

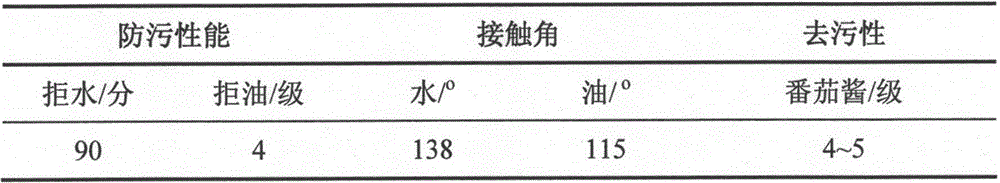

The invention discloses an emulsion with a core-shell structure and an environment-friendly interior wall coating containing the emulsion. The emulsion with the core-shell structure is obtained by semi-continuous polymerization of methyl methacrylate, styrene, butyl acrylate and methacrylic acid, wherein the environment-friendly interior wall coating consists of the emulsion with the core-shell structure, titanium white powder, a filler, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a bactericide, a mildew inhibitor, a pH regulator and water. The latex particles in the emulsion with the core-shell structure provided by the invention have a soft-shell hard-core structure, wherein soft shells can ensure that the prepared coating product also has excellent low-temperature film forming property without the addition of a film-forming auxiliary agent, and hard cores can ensure that the prepared coating product has high hardness after film formation of the coating product, does not turn soft or sticky at a high temperature, and still has the basic properties of excellent stain resistance, washing resistance and the like. The environment-friendly interior wallcoating provided by the invention does not contain volatile organic compounds (VOC), is safe and environmentally friendly, and has high hardness and excellent stain resistance and washing resistanceafter the film formation.

Owner:NIPPON PAINT GUANGZHOU

Water-based wooden toy paint

InactiveCN102093795AEasy to dryGood weather resistancePolyurea/polyurethane coatingsWater basedToxic material

The invention relates to a water-based wooden toy paint, which is prepared by mixing and stirring the following raw materials in percentage by mass: 30 to 40 percent of waterborne acrylic emulsion, 15 to 25 percent of waterborne polyurethane dispersion, 3 to 5 percent of functional resin, 1 to 2 percent of film forming aid, 0.2 to 0.4 percent of wetting agent, 0 to 0.2 percent of leveling agent, 0.01 to 0.02 percent of preservative, 10 to 45 percent of pigment, 0 to 15 percent of water-based color paste, 0.5 to 1 percent of thickening agent and the balance of deionized water. The invention has the advantages that: the water-based wooden toy paint does not contain heavy metals and other toxic substances, meets the toy safety standard, cannot harm the health of children, and also has the characteristics of high drying speed, high film hardness, fullness, wear resistance, water resistance, after tackiness resistance and the like.

Owner:FUZHOU DEXIAN CHEM CO LTD

Sound-insulation noise-reduction water-based wood primer

InactiveCN104403555AGood sound absorption performance and fire performanceDense paint filmFireproof paintsPolyurea/polyurethane coatingsEmulsionCorrosion

Owner:广州益景春环保材料科技有限公司

Nanometer modified rust-proof top-coat for metal

InactiveCN1876742AImprove qualityImprove adhesionLiquid surface applicatorsAnti-corrosive paintsFirming agent2-Butanol

The invention relates the nanometer modified metallic anti-corrosive paint, comprising 50-70wt% host crystal, 20-40wt% curing agent and 1-10wt% oxide addition. The host crystal comprises compound resin, color paste and auxiliary agent, and the curing agent comprises 75% aromatic isocyanate, 75% aliphatic isocyanate, dimethylbenzene, butyl acetate optal and 2-butanol. The invention adds nanometer oxidate to improve the quality of anti-corrosive paint, and adds alcohols solvent in host crystal to reduce noxious constituents in solvent. The invention doesn't use the compounds which contain lead and chromium.

Owner:彭志伟

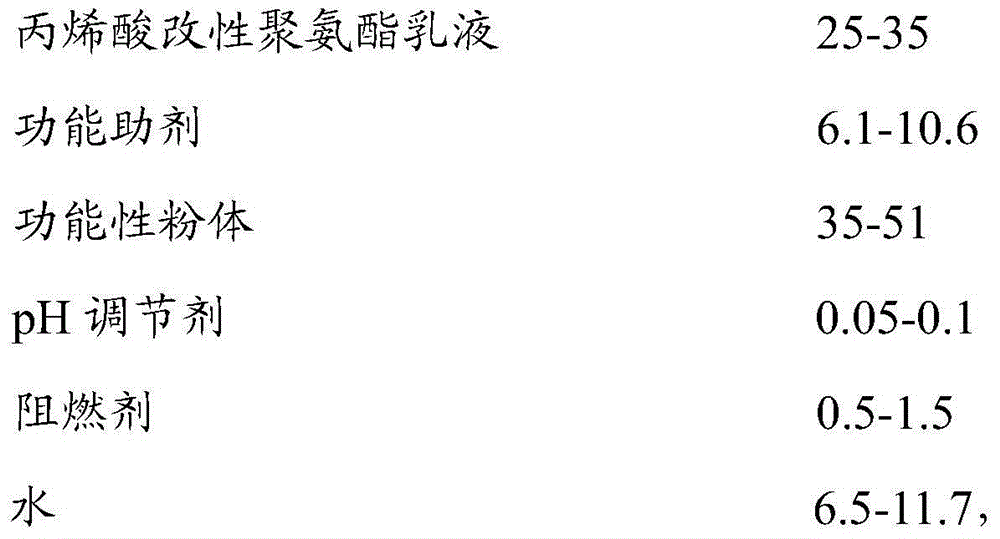

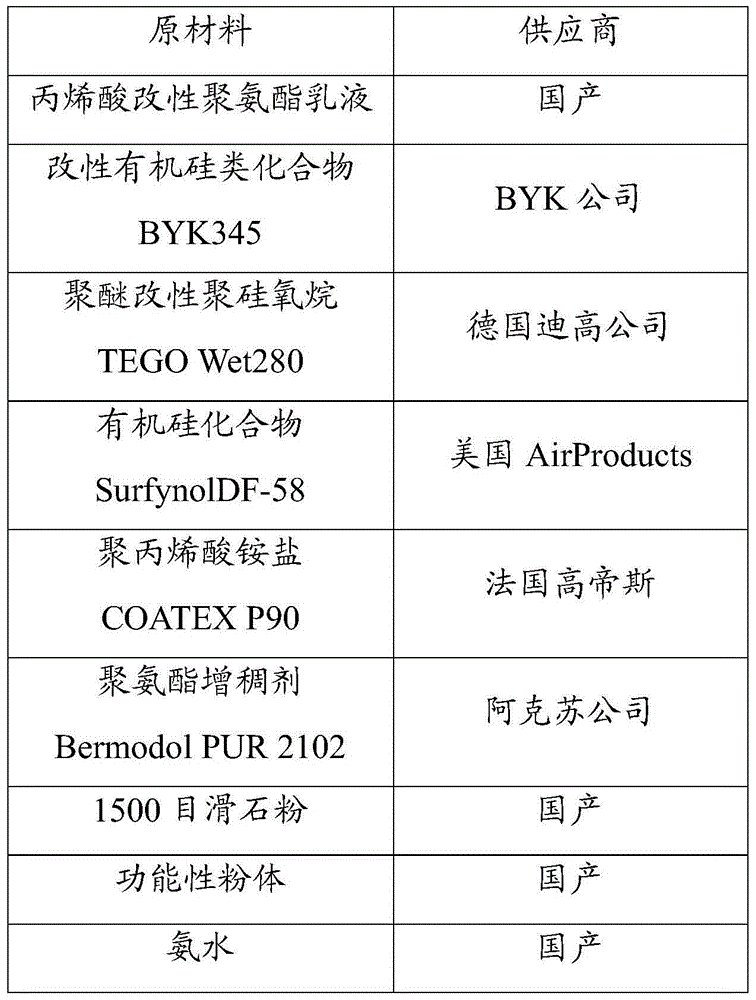

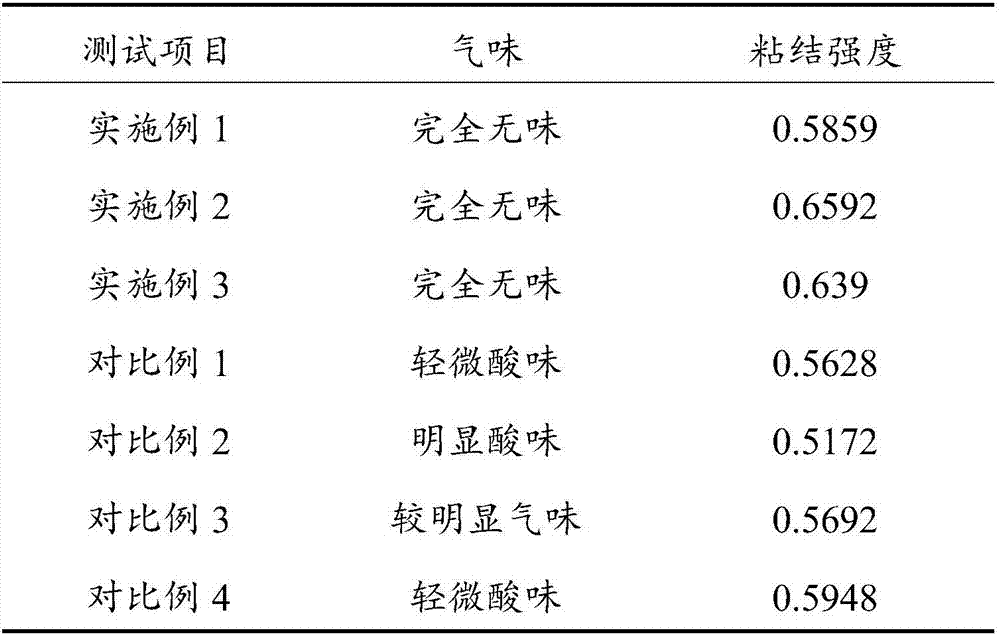

Odorless environment-friendly dried diatom ooze powder and preparation method thereof

InactiveCN107572900AImprove bonding performanceGood low-temperature film-forming propertiesHydroxypropylmethyl celluloseSubstance content

The invention discloses odorless environment-friendly dried diatom ooze powder and a preparation method thereof. The dried diatom ooze powder comprises the following components in parts by mass: 3-7 parts of odorless redispersible latex powder, 20-40 parts of diatomite, 1-6 parts of nanometer titania, 1-30 parts of titanium dioxide, 10-35 parts of ash-calcium, 10-30 parts of coarse whiting, 5-45 parts of quartz powder, 10-30 parts of kaolin, 0.3-1 part of hydroxy propyl methyl cellulose and 0.1-0.5 part of starch ether. The components are uniformly mixed to obtain the odorless environment-friendly dried diatom ooze powder. According to the odorless environment-friendly dried diatom ooze powder disclosed by the invention, the odorless redispersible latex powder is added to serve as a main adhesive substance and achieves a synergistic effect with the other components, so that the dried diatom ooze powder is odorless, has extremely low harmful substance content, and has high adhesive property, excellent low-temperature film-forming performance and the like.

Owner:YOUNGWOO CHEMTECH

Double-liquid polyurethane coating

InactiveCN102627909AImprove adhesionGood weather resistancePolyurea/polyurethane coatingsPlastic materialsAcrylic resin

The invention provides a double-liquid polyurethane coating, which is suitable for water transfer surface coating of automotive trim. A mass ratio of a component A to a component B is 4-4.5:1; the component A includes 38-55% of high hydroxyl acrylic acid resin, 10-15% of low hydroxyl acrylic resin, 34-45% of dimethylbenzene or propylene glycol methyl ether acetate, 0.5-1% of polyether modified polydimethyl siloxane copolymer and 0.5-1% of ultraviolet absorber; and the component B is an aliphatic polyisocyanate curing agent. The double-liquid polyurethane coating of the invention can be sprayed on ABS and ABS+PC plastic materials and widely used in spraying and refinishing paint of automotive trim, and has excellent abrasion resistance, chemical resistance, low temperature film forming, flexibility, decorative performance and weather resistance, etc.

Owner:东莞大宝化工制品有限公司 +1

Anti-pilling finishing agent of wool fabric

InactiveCN107227618AGood film formingReduce interactionLight resistant fibresGrip property fibresChemistryWool fiber

The invention discloses an anti-pilling finishing agent of wool fabric and belongs to the technical field of preparation of textile auxiliaries. The anti-pilling finishing agent of the wool fabric, disclosed by the invention, can be obtained through preparing a wool strengthening solution and a wool dissolved solution from wool, carrying out cross-linking with a fibroin solution so as to obtain an anti-pilling agent, and then, mixing substances such as the anti-pilling agent, a softener, amino powder and tea saponin. The anti-pilling finishing agent of the wool fabric, disclosed by the invention, has a relatively good anti-pilling effect on the fabric; after the anti-pilling finishing agent is used, the fabric is relatively good in hand feeling and can still keep a high whiteness value after rinsing, the sliding friction among cashmere fibers is lowered and removed, the wool fibers are prevented from moving and cohesion, and the aims of preventing shrinking and pilling are achieved.

Owner:常州美帛纺织品有限公司

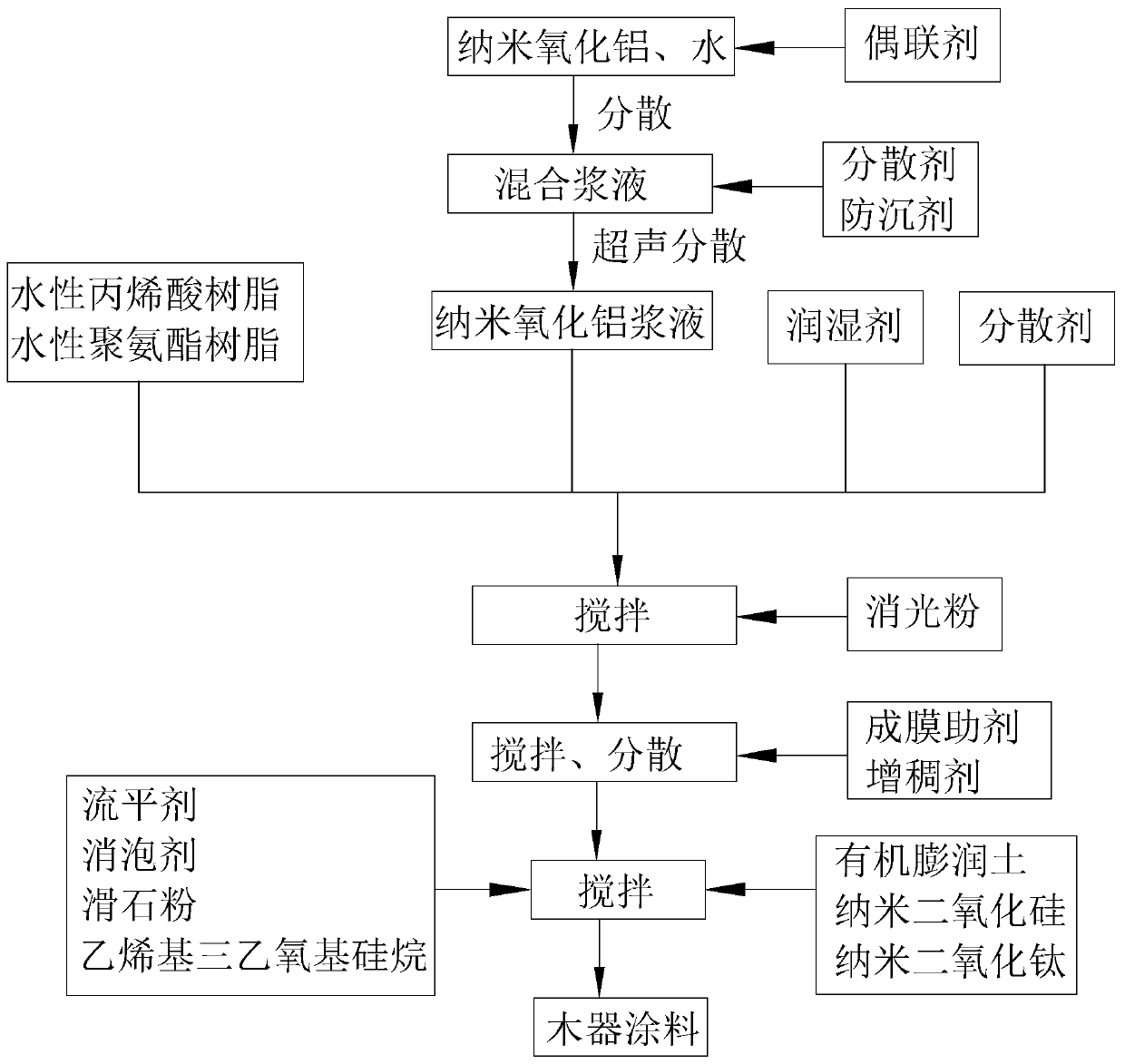

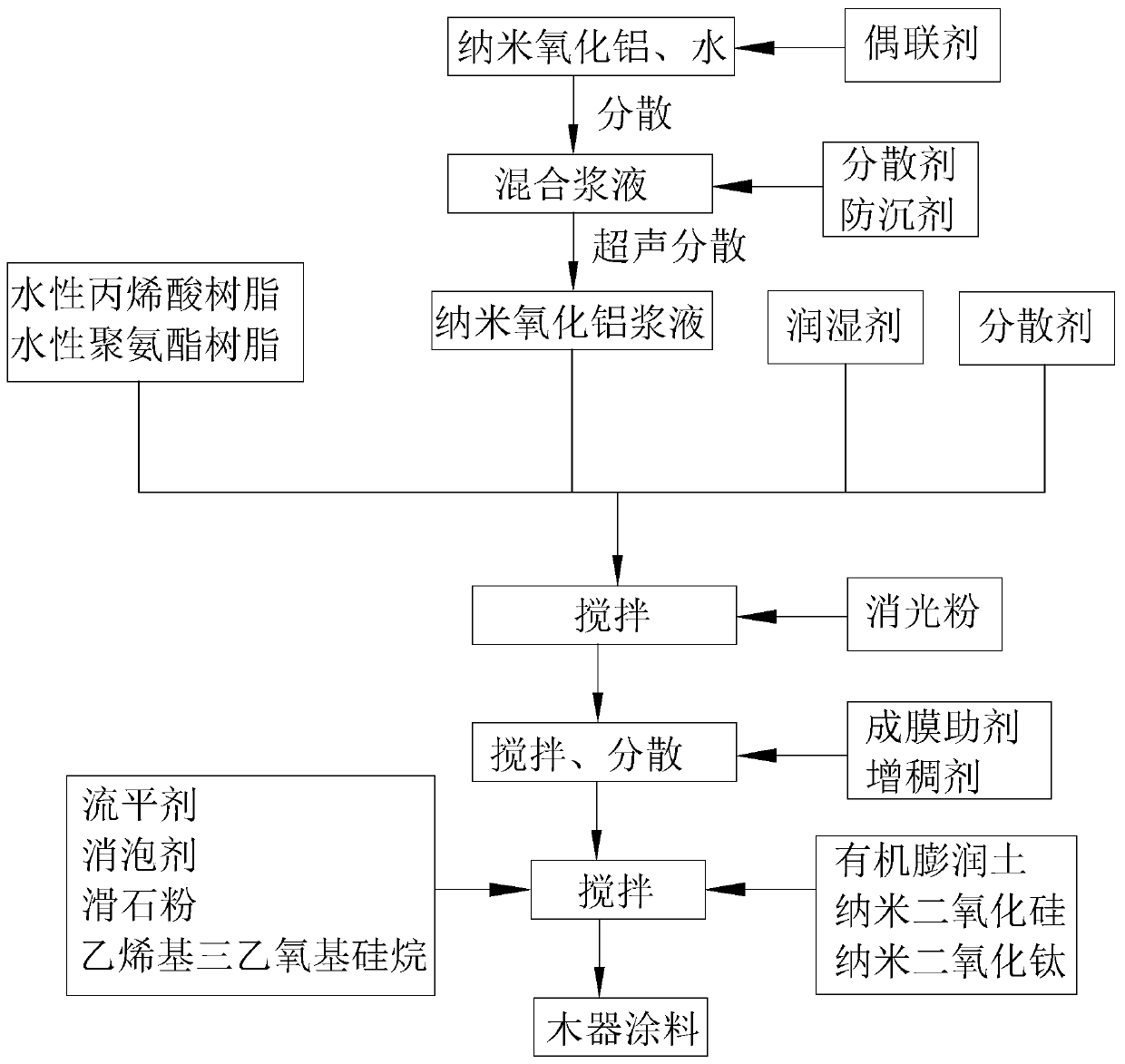

Water-based single-component wood coating and preparation method thereof

InactiveCN111171691AStrong volume effectStrong quantum size effectPolyurea/polyurethane coatingsPolymer scienceNano al2o3

The invention relates to a water-based single-component wood coating and a preparation method thereof. The water-based single-component wood coating comprises, by weight, 30-40 parts of waterborne polyurethane resin, 35-40 parts of waterborne polyurethane resin, 4-6 parts of organic montmorillonite,10-15 parts of a nano-alumina slurry, 3-5 parts of nano silicon dioxide, 1-3 parts of nano titaniumdioxide, 0.5-1 parts of a wetting agent, 0.1-0.5 part of an antifoaming agent, 6-8 parts of a coalescing agent, 0.3-0.5 part of a leveling agent, 1-2 parts of a thickener, 0.2-0.3 part of a dispersingagent, 0.4-0.8 part of talcum powder, 0.1-0.3 part of vinyltriethoxysilane and 3-5 parts of an extinction powder. The hardness of a coating film is improved, so that the wood coating is suitable forhigh-grade wood furnitures.

Owner:成都迪泰化工有限公司

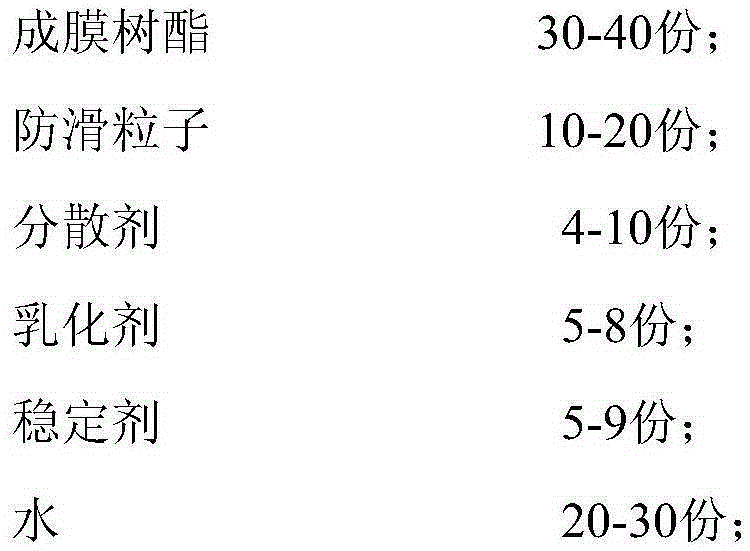

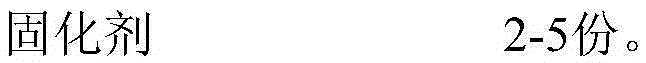

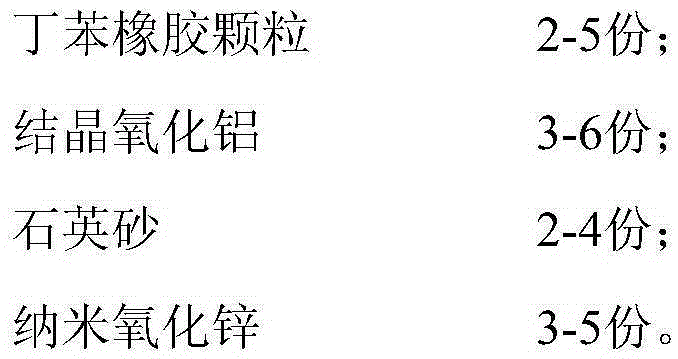

Skid-resistant coating and preparation method thereof

InactiveCN105295656AStable storageNo layered precipitationPolyurea/polyurethane coatingsEpoxy resin coatingsEnvironmental effectMaterials science

Disclosed is a skid-resistant coating and a preparation method thereof, which belong to the technical field of a coating. The skid-resistant coating is prepared by taking a film-forming resin and a skid-resistant particle as main components, and the main components together with a dispersant, an emulsifier, a stabilizing agent, and water form a stable system. The skid-resistant coating produces no delamination and precipitation during storage and transportation, and can be stably stored for more than 2 years. The skid-resistant particle is uniformly dispersed in other medium, is stable, and is not prone to fall off after construction. The skid-resistant coating is good in low-temperature film-forming property, is not affected by environment, and is subjected to construction at all season under any weather conditions.

Owner:JINAN HAOZE ENVIRONMENTAL PROTECTION TECH CO LTD

Graphite lubricant with good high temperature adhesion

InactiveCN105273813AImprove wear resistanceImprove antioxidant capacityLubricant compositionContact pressureToluene diisocyanate

The present invention discloses a graphite lubricant with good high temperature adhesion, the graphite lubricant is prepared from the following raw materials in parts by weight: 25-35 parts of petroleum ether, 4-8 parts of absolute ethanol, 5-9 parts of engine oil, 0.2-0.4 part of calcium salicylate, 1-2 parts of ethylene bis stearamide, 2-4 parts of polyethylene wax, 2.5-4 parts of nano-graphite, 3-5 parts of sodium gluconate, 1-2 parts of polyacrylamide, 1-2 parts of toluene diisocyanate, 4-9 parts of methyl isobutyl ketone and 15-25 parts of modified graphite powder; the graphite lubricant is reasonable in raw material distribution, both can ensure good low-temperature film forming performance, also ensures good high temperature adhesion and suspension dispersion property, and has high temperature resistance, high contact pressure resistance and adequate load wear-resisting capacity, the manufacturing process can meet the needs of aluminum extrusion, the cost is moderate, and the performance cost ratio is high.

Owner:DANGTU WEISIGONGCHUANG IND PROD DESIGN CO LTD

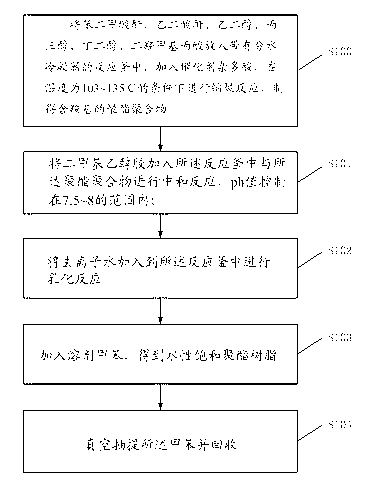

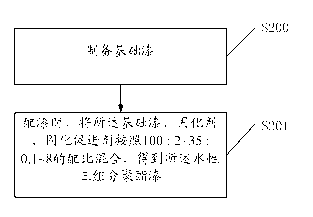

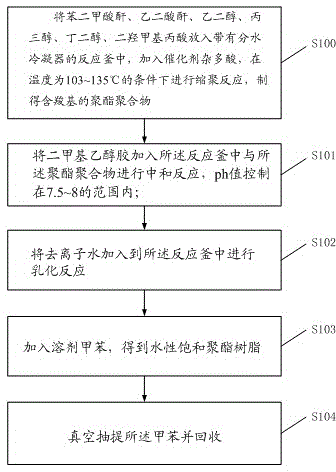

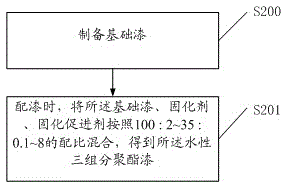

Waterborne three-component polyester paint and preparation method thereof

The invention discloses a waterborne three-component polyester paint, comprising a base paint, a curing agent, and a curing accelerator, wherein the curing agent is aliphatic diisocyanate, the curing accelerator is stannous octoate, and the ratio of the base paint to the curing agent to the curing accelerator is 100:2-35:0.1-8. Correspondingly, the invention also discloses a preparation method of the waterborne three-component polyester paint, comprising the steps of preparing a waterborne saturated polyester resin, preparing the base paint and preparing the waterborne three-component polyester paint. According to the invention, the waterborne three-component polyester paint has good low-temperature film-forming property, frost resistance, yellowing resistance, adhesion resistance, water resistance, high temperature resistance, chemical resistance, good flame retardant ability, etc., contains no volatile benzene, dimethylbenzene, formaldehyde, esters, ketones, or harmful heavy metal elements, is environmentally friendly and non-toxic, and is a novel green paint.

Owner:FOSHAN HAITE CHEM TECH

Base material coloring agent and preparation method thereof

InactiveCN111849295AImprove water resistanceGood sealingAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganic chemistry

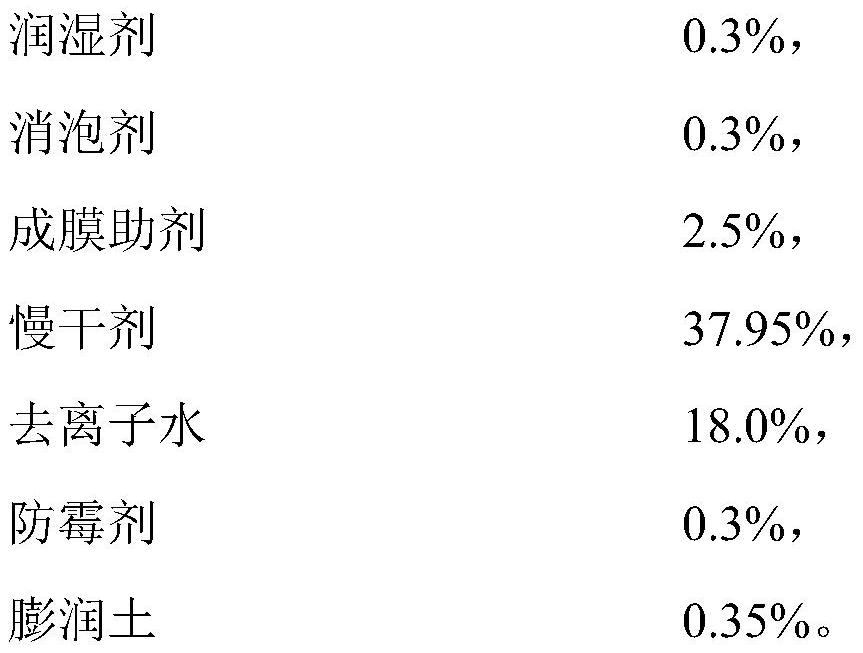

The invention provides a base material coloring agent, which comprises a main component and a matched color paste. The main component and the matched color paste are mixed according to a proportion of100:(5-30); the main component is composed of the following components by weight percentage: 10-50% of a water-based acrylic emulsion, 0.2-0.5% of a pH regulator, 0.3-0.5% of a wetting agent, 0.2-0.5% of a defoaming agent, 2-5% of a film-forming assistant, 5-40% of a slow drying agent, 5-20% of deionized water, 0.1-0.3% of a mildew preventive and 0.3-0.5$ of bentonite. According to the base material coloring agent, the multi-layer core-shell structure water-based acrylic emulsion is used as the main body resin, and is matched with other auxiliary agents, so that a paint film has excellent wiping property and coloring property, and good packaging effect and color naturalness can be achieved by applying the coloring agent without spraying a water-based seal primer. The invention further provides a preparation method of the base material coloring agent.

Owner:HUIZHOU CHANGRUNFA PAINT

Waterborne polyurethane ultraviolet curing coating and preparation method thereof

InactiveCN106752541ASelf-dryingSelf-crosslinkingFireproof paintsPolyurea/polyurethane coatingsWaxHydrogen

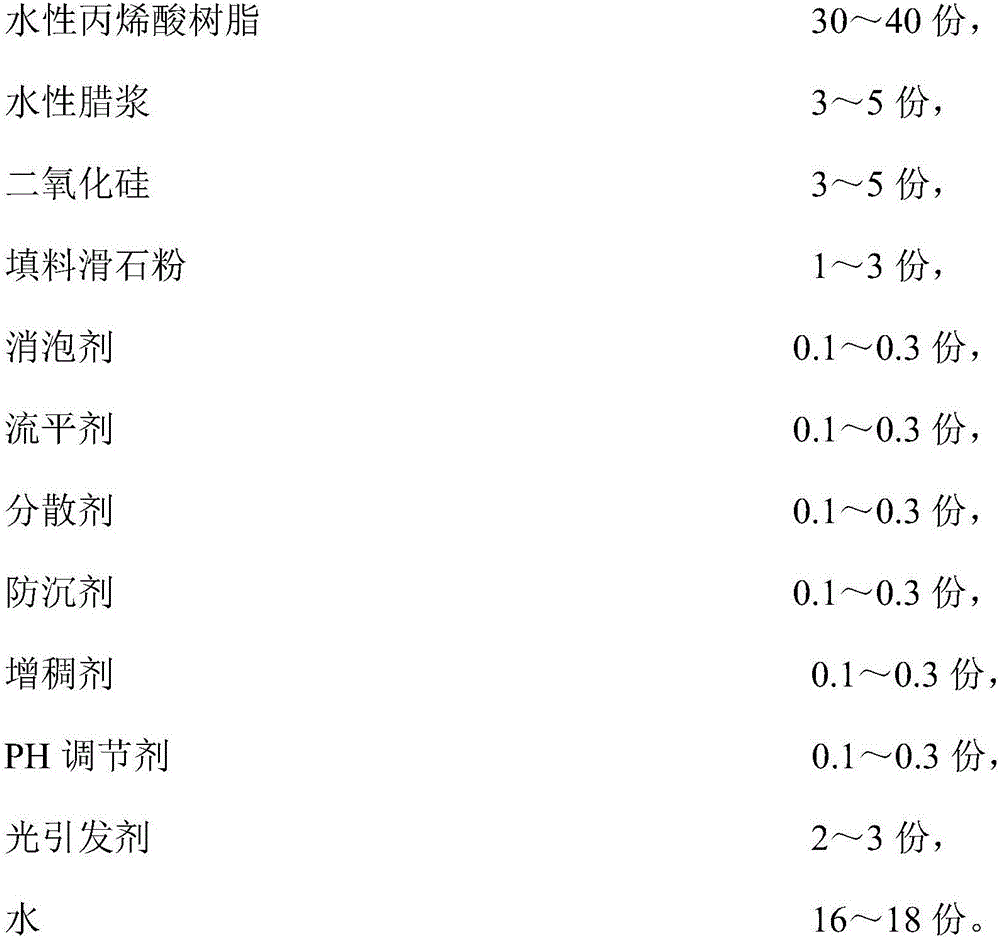

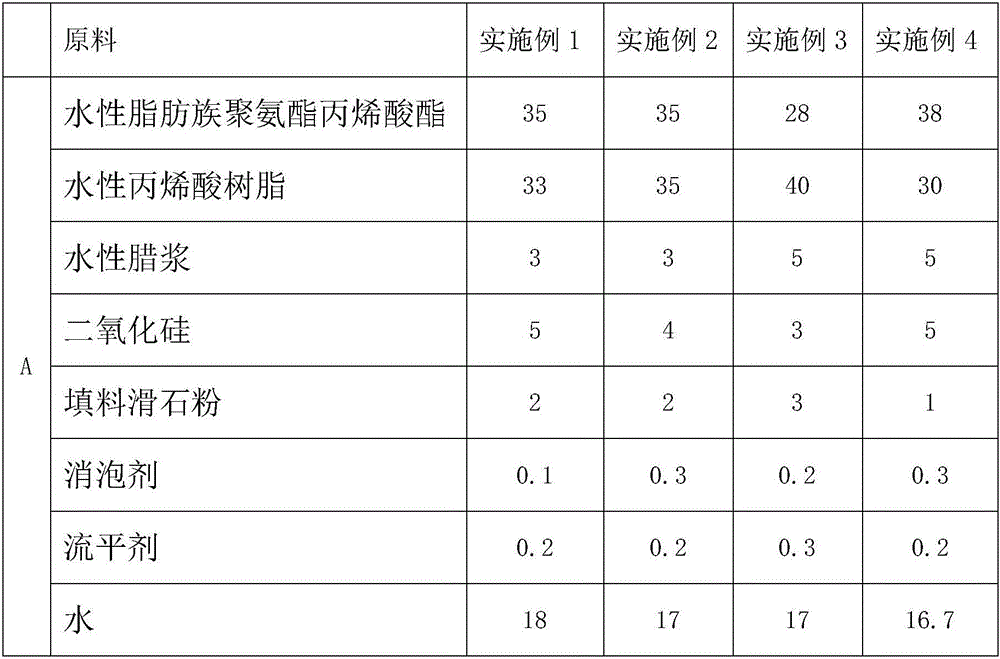

The invention discloses a waterborne polyurethane ultraviolet curing coating and a preparation method thereof. The waterborne polyurethane ultraviolet curing coating is prepared from the following substances in parts by weight: 28 to 38 parts of waterborne aliphatic polyurethane acrylate, 30 to 40 parts of waterborne acrylic resin, 3 to 5 parts of waterborne wax liquor, 3 to 5 parts of silicon dioxide, 1 to 3 parts of filler talcum powder, 0.1 to 0.3 part of defoaming agent, 0.1 to 0.3 part of flatting agent,0.1 to 0.3 part of dispersing agent, 0.1 to 0.3 part of anti-settling agent, 0.1 to 0.3 part of thickening agent, 0.1 to 0.3 part of PH (Potential of Hydrogen) regulator, 2 to 3 parts of photoinitiator and 16 to 18 parts of water. The invention provides the waterborne polyurethane ultraviolet curing coating. The invention also provides the preparation method of the waterborne polyurethane ultraviolet curing coating.

Owner:中山市鑫峰光固化材料有限公司

Waterproof coating and preparation method thereof

InactiveCN111793401AReduce addImprove water whitening resistanceCoatingsPolymer scienceBuffering agent

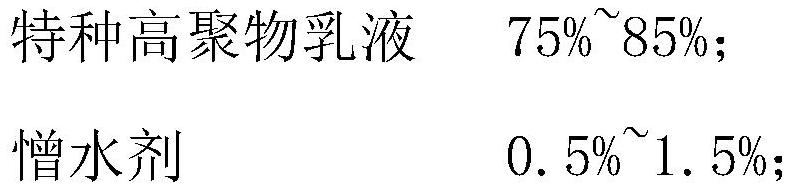

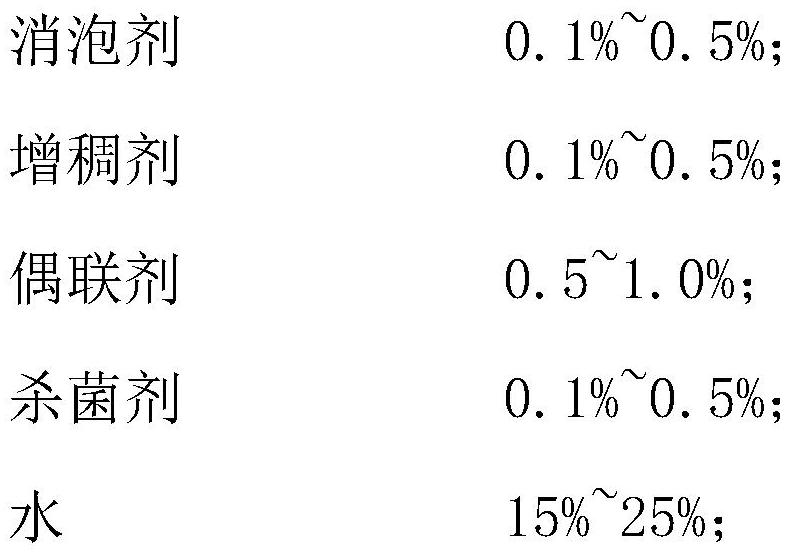

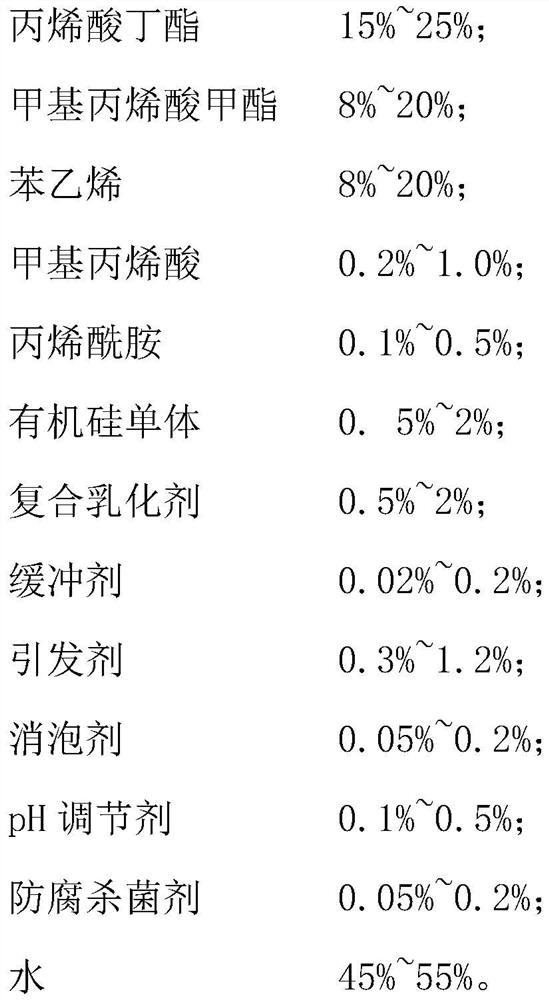

A waterproof coating comprises, by weight, 75-85% of a special high polymer emulsion, 0.5-1.5% of a water repellent, 0.1-0.5% of a defoaming agent, 0.1-0.5% of a thickening agent, 0.5-1.0% of a coupling agent, 0.1-0.5% of a bactericide and 15-25% of water, wherein the special high polymer emulsion comprises 15-25% of butyl acrylate, 8-20% of methyl methacrylate, 8-20% of styrene, 0.2-1.0% of methacrylic acid, 0.1-0.5% of acrylamide, 0.5-2% of an organosilicon monomer, 0.5-2% of a compound emulsifier, 0.02-0.2% of a buffer agent, 0.3-1.2% of an initiator, 0.05-0.2% of a defoaming agent, 0.1-0.5% of a pH adjusting agent, 0.05-0.2% of an antiseptic bactericide and 45-55% of water. The invention also discloses a preparation method of the waterproof coating. The waterproof coating disclosed bythe invention is good in water white resistance, environment-friendly and non-toxic, and the strength of a waterproof film is improved while the low-temperature film forming performance is guaranteed.

Owner:西卡(上海)管理有限公司 +1

Water-based metal printing ink for lining paper for cigarettes and preparation method

The invention relates to the technical field of printing and in particular relates to water-based metal printing ink for lining paper for cigarettes and a preparation method. The water-based metal printing ink is prepared from the following raw materials in percentage by weight: 15 percent to 35 percent of metal pigment, 50 percent to 70 percent of water-soluble resin, 20 percent to 50 percent ofmixed solvent, 0.5 percent to 3 percent of dispersant, 3 percent to 10 percent of surfactant, 0.1 percent to 0.3 percent of a de-foaming agent and 0.5 percent to 2.5 percent of adhesion promoter. After the water-based metal printing ink provided by the invention forms a film, the film has a good adhesive force; the water-based metal printing ink has a good printing effect and strong adaptability and can meet requirements of various actual printing requirements.

Owner:昆明天尔成包装材料有限公司 +1

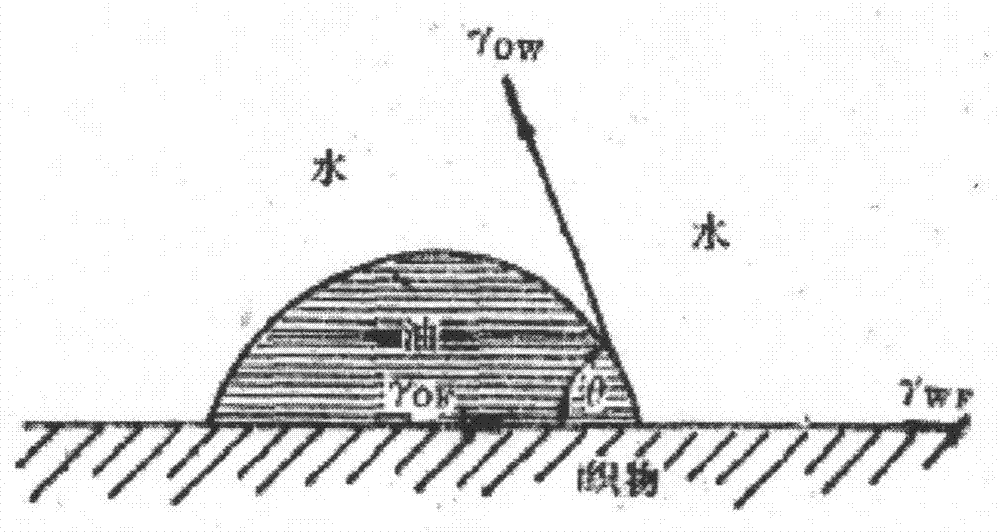

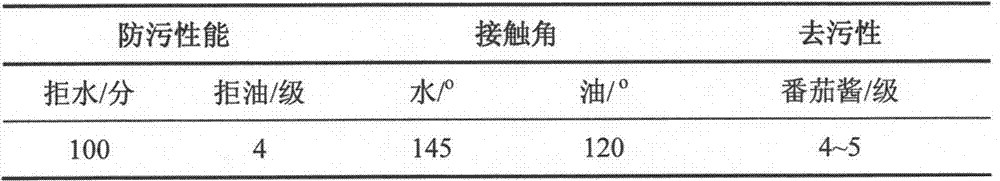

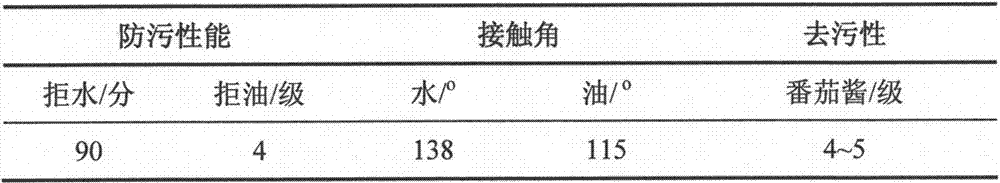

Method for preparing stain release jacquard fabric

The invention provides a method for preparing a stain release jacquard fabric. The method is characterized by comprising the steps that firstly, finishing liquid is prepared, wherein modified SiO2 hydrosol, hydrophilic components and water are taken to be mixed according to the weight ratio of (3-5):(1-3):(92-96), stirring is carried out, and the finishing liquid is obtained; secondly, a jacquard fabric is finished in the finishing liquid and dried, then the jacquard fabric is baked for 1-3 min at the temperature of 150 DEG C to 170 DEG C, and the treated stain release jacquard fabric is obtained. The stain release finishing agent of the stain release jacquard fabric is prepared from fluoride-free superhydrophobic ingredients of the modified nanosilicon dioxide hydrosol, the hydrophilic components containing acrylic acid and water, and has good stability, excellent water repellency and good low-temperature film forming performance, the hardness of a film can be adjusted by changing the composition of a copolymer, and good adhesivity on fibers is achieved. The soil release finishing agent is applied to the jacquard fabric, a padding finishing process is adopted, the method is simple, the application range is wide, high operability is achieved, and the need for developing the high-grade jacquard fabric can be met conveniently.

Owner:DONGHUA UNIV +1

Epoxy resin modified waterborne acrylic resin dispersion

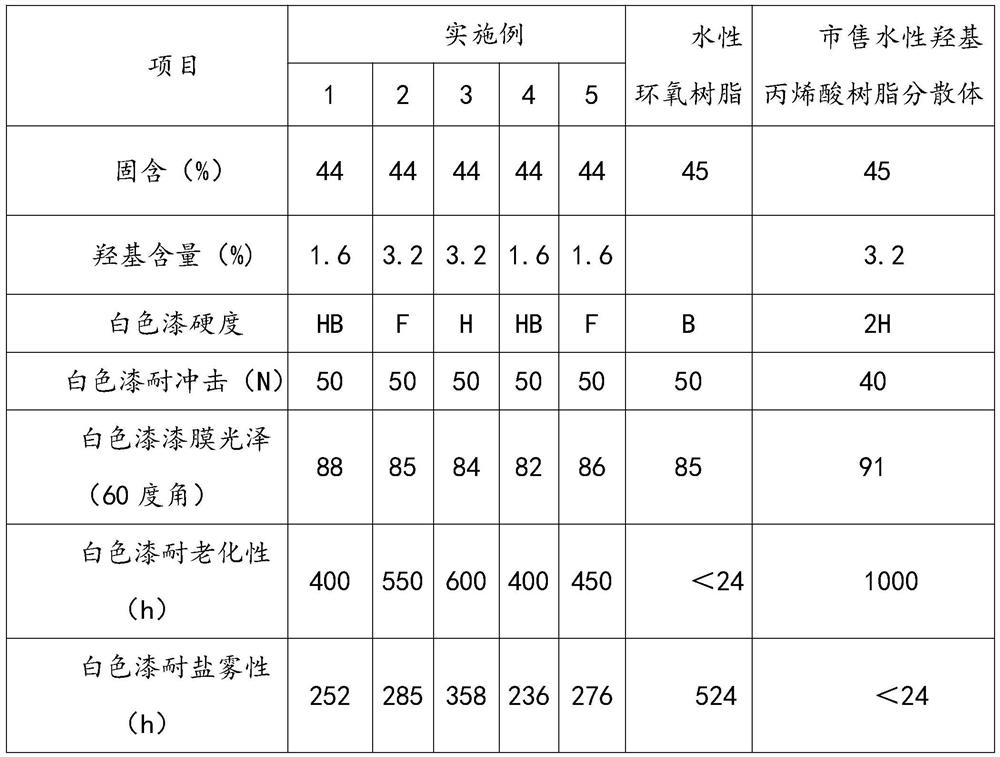

PendingCN113603841AGood resistance to salt sprayGood low temperature film formingAnti-corrosive paintsEpoxyMethacrylate

The invention discloses an epoxy resin modified waterborne acrylic resin dispersion which comprises the following raw materials: epoxy ester resin and acrylic resin, and the acrylic resin comprises the following components: an acrylic monomer a1, an acrylic monomer a2, an acrylic monomer a3, an acrylic monomer a4 and an initiator; the acrylic monomer a1 is ester generated by alcohol with 1-12 carbons and acrylic acid or methacrylic acid; the acrylic monomer a2 is an acrylic acid or methacrylate monomer containing at least one hydroxyl group; the acrylic monomer a3 is a compound containing an unsaturated polyoxyalkylene chain; and the acrylic monomer a4 is a monomer containing an amine-neutralizable acidic functional group. According to the invention, the epoxy ester resin and the acrylic resin are hybridized and compounded together to obtain the resin dispersion integrating the advantages of the two resins, the defects of the two resins are overcome, and the resin dispersion has the characteristics of better hardness, high glossiness, aging resistance and excellent salt spray resistance.

Owner:广东花果山环保科技有限公司

A kind of preparation method of easy decontamination jacquard fabric

InactiveCN105484018BImprove stabilityImprove adhesionStain/soil resistant fibresFiberAdditive ingredient

The invention provides a method for preparing a stain release jacquard fabric. The method is characterized by comprising the steps that firstly, finishing liquid is prepared, wherein modified SiO2 hydrosol, hydrophilic components and water are taken to be mixed according to the weight ratio of (3-5):(1-3):(92-96), stirring is carried out, and the finishing liquid is obtained; secondly, a jacquard fabric is finished in the finishing liquid and dried, then the jacquard fabric is baked for 1-3 min at the temperature of 150 DEG C to 170 DEG C, and the treated stain release jacquard fabric is obtained. The stain release finishing agent of the stain release jacquard fabric is prepared from fluoride-free superhydrophobic ingredients of the modified nanosilicon dioxide hydrosol, the hydrophilic components containing acrylic acid and water, and has good stability, excellent water repellency and good low-temperature film forming performance, the hardness of a film can be adjusted by changing the composition of a copolymer, and good adhesivity on fibers is achieved. The soil release finishing agent is applied to the jacquard fabric, a padding finishing process is adopted, the method is simple, the application range is wide, high operability is achieved, and the need for developing the high-grade jacquard fabric can be met conveniently.

Owner:DONGHUA UNIV +1

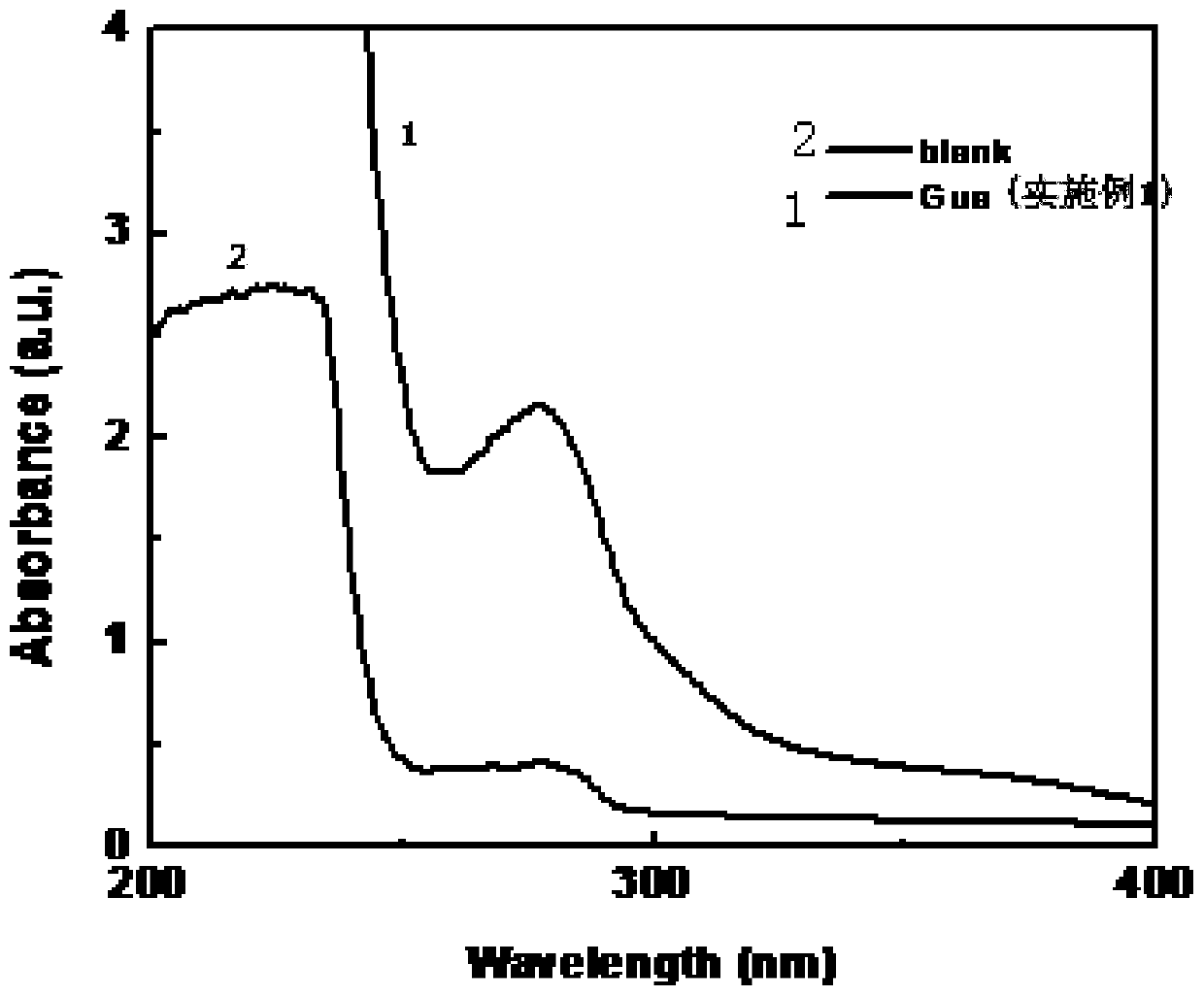

Preparation method of fish gelatin edible antioxidant film containing guava leaf extract

InactiveCN110607075ALow priceRich sourcesFlexible coversWrappersUltraviolet lightsPsidium guajava leaf extract

The invention discloses a preparation method of a fish gelatin edible antioxidant film containing guava leaf extract, and belongs to the technical field of packaging films. The guava skin care productis prepared from the following raw material components in percentage by mass: 2 to 8 percent of fish gelatin, 0.5 to 5 percent of guava leaf extract, 1 percent of glycerinum and the balance of deionized water. The edible anti-oxidation film has the advantages of edibility, oxidation resistance, good ultraviolet light barrier property, wide raw material source, simple and feasible preparation process, low cost, safety and no toxicity.

Owner:BEIJING UNIV OF CHEM TECH +1

Inorganic polymer exterior wall coating as well as preparation method and application thereof

InactiveCN111171636ARich materialLow costAntifouling/underwater paintsCovering/liningsChemical reactionPolyvinyl alcohol

The invention discloses an inorganic polymer exterior wall coating as well as a preparation method and application thereof. The coating is composed of water, a waterproof agent, a wetting dispersant,a defoaming agent, bactericide, 800-mesh light calcium carbonate, AMP-95, barium sulfate, rutile titanium dioxide, color paste, talcum powder, 4000-mesh calcined kaolin, styrene-acrylic emulsion, potassium silicate, dihydric alcohol, emulsified OP-10, water glass, a coalescing agent, polyvinyl alcohol, hydroxyethyl cellulose, ash calcium powder, mica powder, quartz powder, vanadium pentoxide, calcium fluoride, zinc phosphate, aluminum silicate, calcium pyrophosphate, sodium hydroxide and titanium oxide. The coating has excellent low-temperature film-forming property and thick-film cracking resistance, has Brinell viscosity of 20-80cps, is mildew-proof and heat-insulating, has silicate groups chemically reacted with a cement lime base material, permeates into a wall surface by 0.5-1mm to form a waterproof and acid-proof layer, and can avoid cracking, peeling and stripping.

Owner:NANJING SHUANGSHAN PAINT

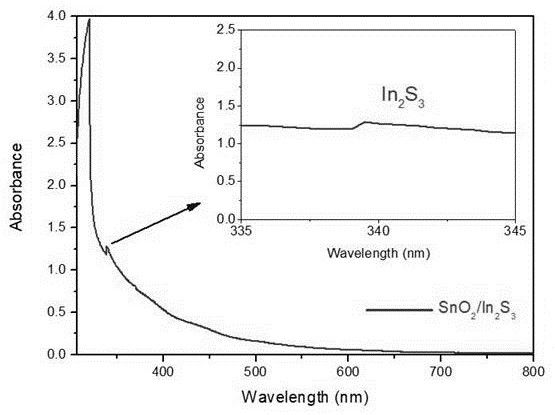

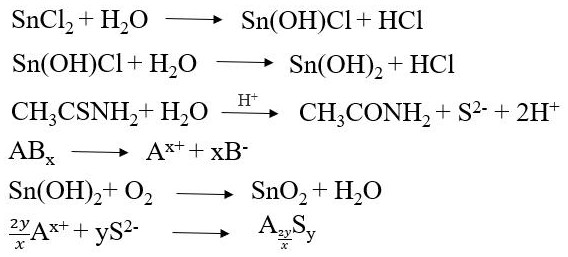

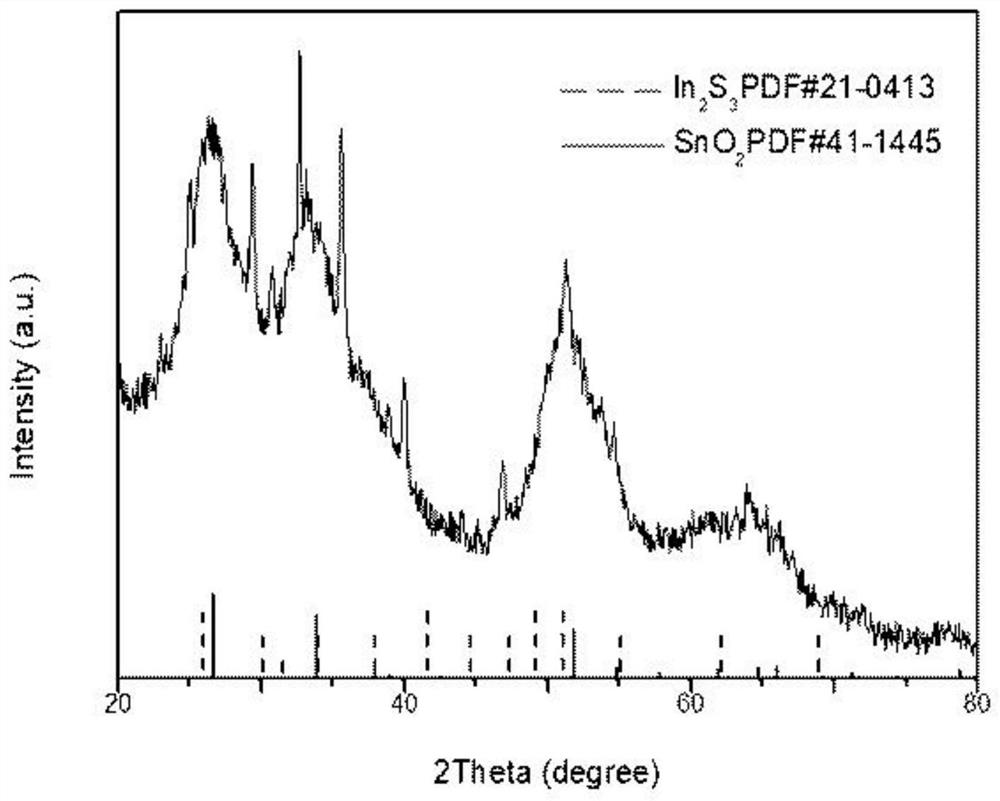

Preparation method of tin dioxide/metal sulfide composite electron transport layer and its application in perovskite solar cells

ActiveCN112582552BEasy to prepareLow costSolid-state devicesSemiconductor/solid-state device manufacturingTin dioxidePerovskite (structure)

The invention discloses a preparation method of a tin dioxide / metal sulfide composite electron transport layer and its application in a perovskite solar cell. Specifically, when the tin dioxide is prepared, a corresponding metal salt and a sulfur source are added to the precursor solution. compound, one-step in-situ compounding to obtain a tin dioxide / metal sulfide solution, which is then spin-coated on conductive glass and subjected to low-temperature annealing to obtain a composite electron transport layer, followed by deposition of a perovskite layer, and blade-coated carbon electrodes to assemble the perovskite Solar battery. When preparing tin dioxide, the invention can in-situ composite metal sulfide, which can passivate the defect state of tin dioxide to increase its electron mobility, adjust its energy band structure and introduce intermediate energy levels to improve the energy level of perovskite. The matching property can also increase the interface contact with the perovskite layer and reduce the interface defects, and realize the preparation of efficient and stable perovskite solar cells. The invention has the advantages of simple preparation process, mild reaction conditions, low cost, easy popularization and commercial application prospect.

Owner:OCEAN UNIV OF CHINA

Nano modified anti-rust special primer

InactiveCN100390240CImprove qualityImprove adhesionAnti-corrosive paintsHazardous substanceToxic material

A nanometre-sized modified special rust-inhibiting primer is characterized in that it includes the following components (mass %): 29.0-60.0 % anti-corrosive paint host, 1.0-10.0 % nano oxide addition,5.0-15.0 % curing agent and 30.0-65 % diluent. The said anti-corrosive paint consists of rust-preventive material, coloring pigment, compounded resin and auxiliary agent, the curing agent is compounded by 75 % aromatic isocyanate, dimethylbenzene, butyl acetate, propanol and 2-butanol and the diluent is combination of alcohol and ester solvent. The invention has conducted adequate optimization and association for the components of the rust-inhibiting primer and its proportioning, which has largely reduced the contents of the toxic substance and the harmful substance in the total weight of the products, not only can guarantee the champion cryogenic film-forming property, but also can reduce the degree of pollution to the environment, which can effectively support the health of the maker, the user and the surrounding people, fitting requirement of the environmental protection, simultaneously can further improved the quality of the rust-inhibiting primer.

Owner:彭志伟

Waterborne three-component polyester paint and preparation method thereof

ActiveCN102863879BImprove drying rateImprove yellowing resistancePolyester coatingsKetoneTemperature resistance

The invention discloses a waterborne three-component polyester paint, comprising a base paint, a curing agent, and a curing accelerator, wherein the curing agent is aliphatic diisocyanate, the curing accelerator is stannous octoate, and the ratio of the base paint to the curing agent to the curing accelerator is 100:2-35:0.1-8. Correspondingly, the invention also discloses a preparation method of the waterborne three-component polyester paint, comprising the steps of preparing a waterborne saturated polyester resin, preparing the base paint and preparing the waterborne three-component polyester paint. According to the invention, the waterborne three-component polyester paint has good low-temperature film-forming property, frost resistance, yellowing resistance, adhesion resistance, water resistance, high temperature resistance, chemical resistance, good flame retardant ability, etc., contains no volatile benzene, dimethylbenzene, formaldehyde, esters, ketones, or harmful heavy metal elements, is environmentally friendly and non-toxic, and is a novel green paint.

Owner:FOSHAN HAITE CHEM TECH

Nanometer modified rust-proof top-coat for metal

InactiveCN100413936CImprove qualityImprove adhesionLiquid surface applicatorsAnti-corrosive paintsAlcoholButyl acetate

The invention relates the nanometer modified metallic anti-corrosive paint, comprising 50-70wt% host crystal, 20-40wt% curing agent and 1-10wt% oxide addition. The host crystal comprises compound resin, color paste and auxiliary agent, and the curing agent comprises 75% aromatic isocyanate, 75% aliphatic isocyanate, dimethylbenzene, butyl acetate optal and 2-butanol. The invention adds nanometer oxidate to improve the quality of anti-corrosive paint, and adds alcohols solvent in host crystal to reduce noxious constituents in solvent. The invention doesn't use the compounds which contain lead and chromium.

Owner:彭志伟

Preparation method of jacquard fabric easy to cleanse

InactiveCN108729212AImprove stabilityGood low temperature film formingStain/soil resistant fibresLiquid repellent fibresFiberHardness

The invention provides a preparation method of jacquard fabric easy to cleanse, comprising the steps of first, preparing a finishing liquid, to be specific, mixing modified SiO2 hydrosol, a hydrophilic component and water in a weight ratio of (3-5):(1-3):(92-96), and stirring to obtain the finishing liquid; second, finishing the jacquard fabric in the finishing liquid, drying, and baking at 150-170 DEG C for 3 min to obtain treated jacquard fabric easy to cleanse. A finishing agent with good cleansing performance for the jacquard fabric easy to cleanse disclosed herein is composed of modifiednano silica hydrosol a fluorine-free super-hydrophilic component, a hydrophilic component containing acrylic acid, and water; the finishing agent has good stability, excellent water repellence and good low-temperature film-forming property; by changing the composition of a copolymer, it is possible to adjust softness and hardness of film, and good adhesion to fibers is achieved; the finishing agent with good cleansing performance is added to the jacquard fabric by means of padding finishing; the preparation method is simple, widely applicable and highly operable and allows the requirement forthe development of high-end jacquard fabrics to be conveniently met.

Owner:如皋市海鑫织造有限公司

Water-based woodware gloss finishing coat

InactiveCN106634610AImprove wear resistanceExcellent chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedPolyurethane dispersion

The invention discloses a water-based woodware gloss finishing coat which is prepared from 71 parts of water emulsion, 7.8 parts of a polyurethane dispersing body, 0.1 part of a dispersing agent, 7.8 parts of a coalescing agent, 3.4 parts of an anti-scratching agent, 0.5 part of a deforming agent, 2 parts of a wetting agent, 0.4 part of a bactericide, 4.4 parts of a PH adjusting agent and 2.1 parts of a rheology modifier. The water-based woodware gloss finishing coat prepared from the water-based polyurethane has the advantages of high low temperature film forming property, high leveling property, high fullness, wear resistance, good handfeel, excellent chemical resistance and after tackiness resistance and the like, and also has the characteristics of high adhesion force, wear resistance, chemical resistance and flexibility of polyurethane.

Owner:大连佳秀百隆新材料股份有限公司

Environmentally-friendly wood lacquer containing alcohol ester

InactiveCN108299955ALow costGood low temperature film formingAntifouling/underwater paintsPaints with biocidesHazardous substanceAcrylic resin

The invention discloses an environmentally-friendly wood lacquer containing alcohol ester. The environmentally-friendly wood lacquer comprises the following raw materials by weight: alcohol ester, activated carbon, rosin extract, quartz powder, modified talcum powder, titanium dioxide, glucomannan, acrylic resin, bamboo carbon powder and a proper amount of water. The environmentally-friendly woodlacquer of the invention has the advantages of reasonable cost, good low-temperature film forming properties, high wear resistance, strong adhesion, and no harmful gases and harmful substances such asformaldehyde; and the used activated carbon has moisture absorption and deodorization performance, mildew resistance and moisture resistance, and is natural and environment-friendly.

Owner:SICHUAN MEIDENG FURNITURE CO LTD

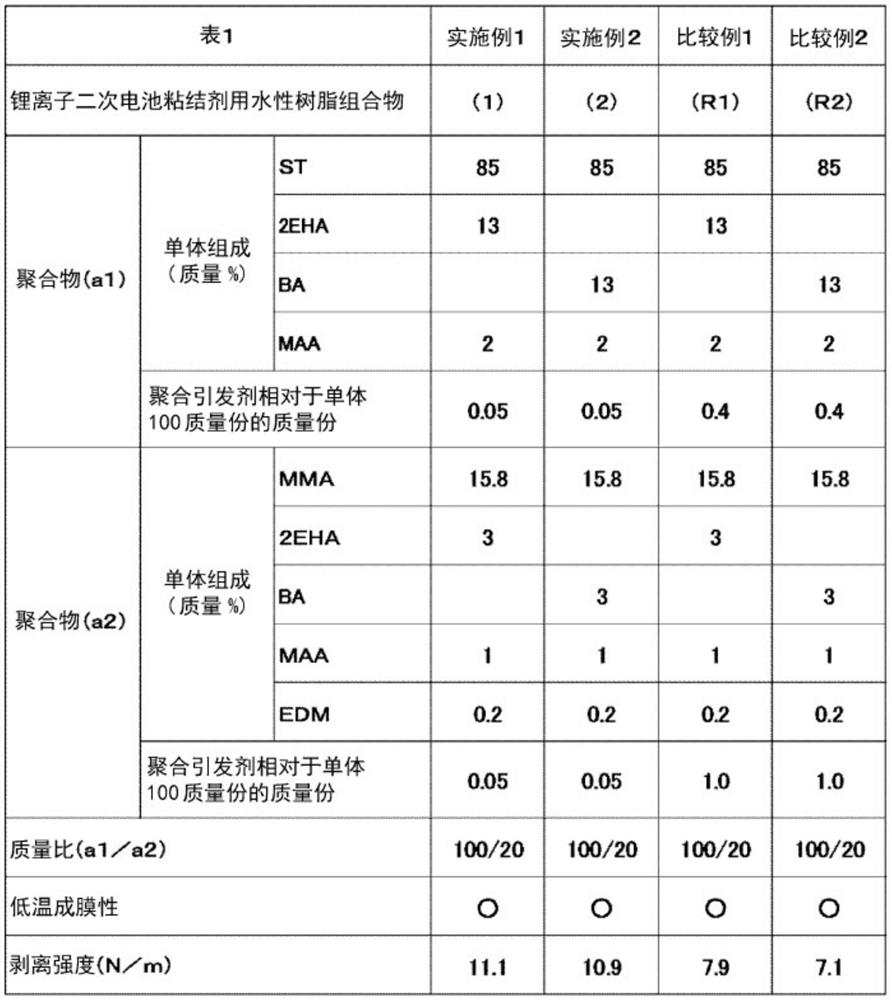

Aqueous resin composition for lithium ion secondary battery binder, and separator for lithium ion secondary battery

PendingCN114342175AExcellent adhesionGood low temperature film formingCell seperators/membranes/diaphragms/spacersSecondary cellsPhysical chemistryAqueous medium

Provided is an aqueous resin composition for a lithium ion secondary battery binder, the aqueous resin composition being characterized by containing core-shell particles (A) having a core part containing a polymer (a1) and a shell part containing a polymer (a2), the polymerization initiator in the starting material of the polymer (a1) being 0.01-0.2 parts by mass per 100 parts by mass of the monomer, and the aqueous medium (B) being a mixture of the core-shell particles (A), the shell part containing the polymer (a2), and the core part containing the polymer (a1) and the shell part containing the polymer (a2). The polymerization initiator in the raw material of the polymer (a2) is 0.01-0.2 parts by mass per 100 parts by mass of the monomer. The aqueous resin composition has excellent low-temperature film-forming properties, and can obtain a binder having excellent adhesion to a porous body and an electrode constituting a separator, and thus is suitable for use as a binder for a lithium ion secondary battery.

Owner:DIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com