Aqueous resin composition for lithium ion secondary battery binder, and separator for lithium ion secondary battery

A technology of resin composition and secondary battery, which is applied in the direction of secondary battery, battery components, separators/films/diaphragms/spacers, etc., and can solve the problems of insufficient low-temperature film-forming properties of water-based resin compositions, etc. , to achieve the effects of excellent adhesion and low-temperature film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

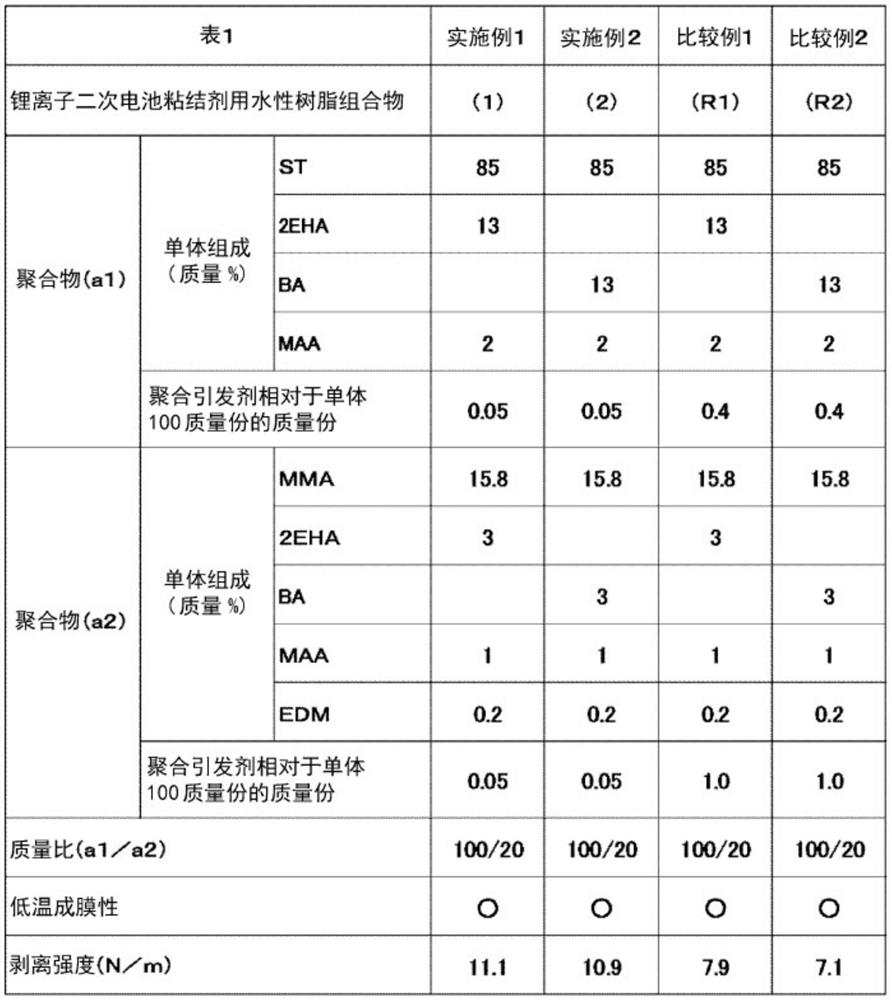

[0050] (Example 1: Preparation and Evaluation of Lithium-ion Secondary Battery Binder Water-based Resin Composition (1))

[0051] 300 parts by mass of ion-exchanged water was put into a 2L reaction vessel equipped with a stirrer, a thermometer, and a cooler, and heated to 80° C., and 85 parts by mass of ST and 2-ethylhexyl acrylate (hereinafter referred to as Denoted as "2EHA".) 13 parts by mass and methacrylic acid (hereinafter, abbreviated as "MAA".) 2 parts by mass ion exchange with 3 parts by mass of sodium dodecylbenzenesulfonate and 0.05 parts by mass of ammonium persulfate 40 parts by mass of water solution was emulsified for 2 hours, after emulsion polymerization, 0.01 part by mass of ammonium persulfate was added, and 15.8 parts by mass of MMA, 3 parts by mass of 2EHA, and MAA of 1 part by mass were added dropwise. and ethylene glycol dimethacrylate (hereinafter, abbreviated as "EDM") 0.2 parts by mass of the mixture for 1 hour, polymerized, kept for 2 hours, cooled t...

Embodiment 2

[0070] (Example 2: preparation and evaluation of the aqueous resin composition (2) for lithium ion secondary battery binder)

[0071] 300 parts by mass of ion-exchanged water was put into a 2L reaction vessel equipped with a stirrer, a thermometer, and a cooler, heated to 80°C, and 85 parts by mass of ST, 13 parts by mass of BA, and 2 parts by mass of MAA was emulsified with 40 parts by mass of ion-exchanged water solution of 3 parts by mass of sodium dodecylbenzenesulfonate and 0.05 parts by mass of ammonium persulfate for 2 hours. After emulsion polymerization, 0.01 mass of ammonium persulfate was dropped. After that, further dropwise add a mixture of 15.8 parts by mass of MMA, 3 parts by mass of BA, 1 part by mass of MAA and 0.2 parts by mass of EDM for 1 hour to carry out polymerization, cool to below 40°C after keeping for 2 hours, and use ammonia water to The pH was adjusted to 7-8, and the non-volatile components were adjusted to 24-26% with ion-exchanged water. The ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com