Water-based single-component wood coating and preparation method thereof

A wood coating, one-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high brittleness, unsuitable for high-grade wood furniture, reduced hardness, etc. The effect of improving the hardness of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Table 1 is each raw material and its weight of a kind of water-based one-component wood coating in embodiment 1

[0038] raw material Weight (kg) raw material Weight (kg) Waterborne Acrylic Resin 30 Dipropylene glycol methyl ether 6 Waterborne polyurethane resin 40 BYK-333 0.3 Organic Montmorillonite 4 Hydroxyethyl cellulose 1 Nano alumina slurry 10 Dispersant 731A 0.3 Nano silica 3 talcum powder 0.6 Nano Titanium Dioxide 3 Vinyltriethoxysilane 0.1 3-Aminopropyltrimethoxysilane 0.5 Matting Powder TS-100 3 Polyether modified silicone defoamer 0.1

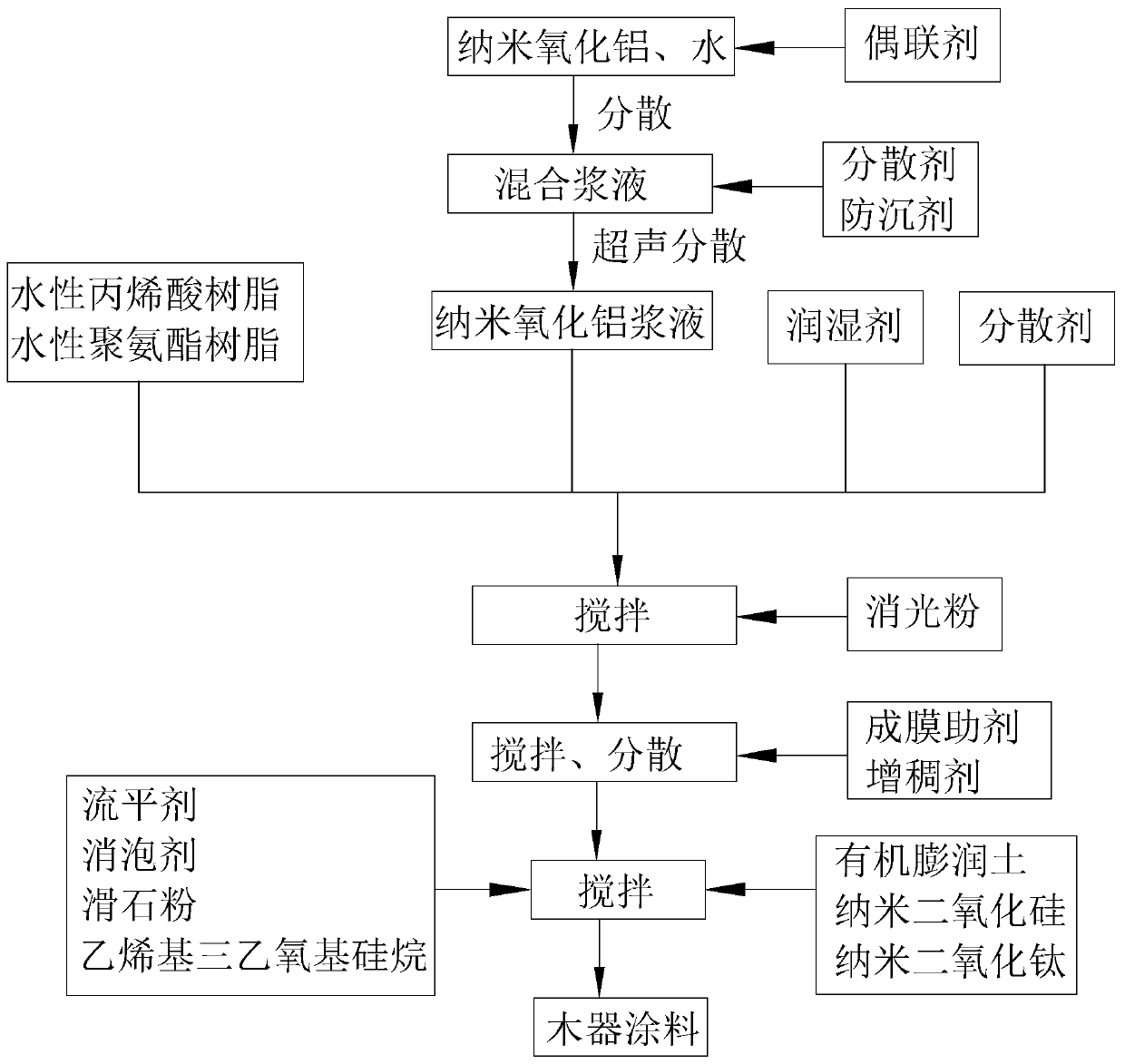

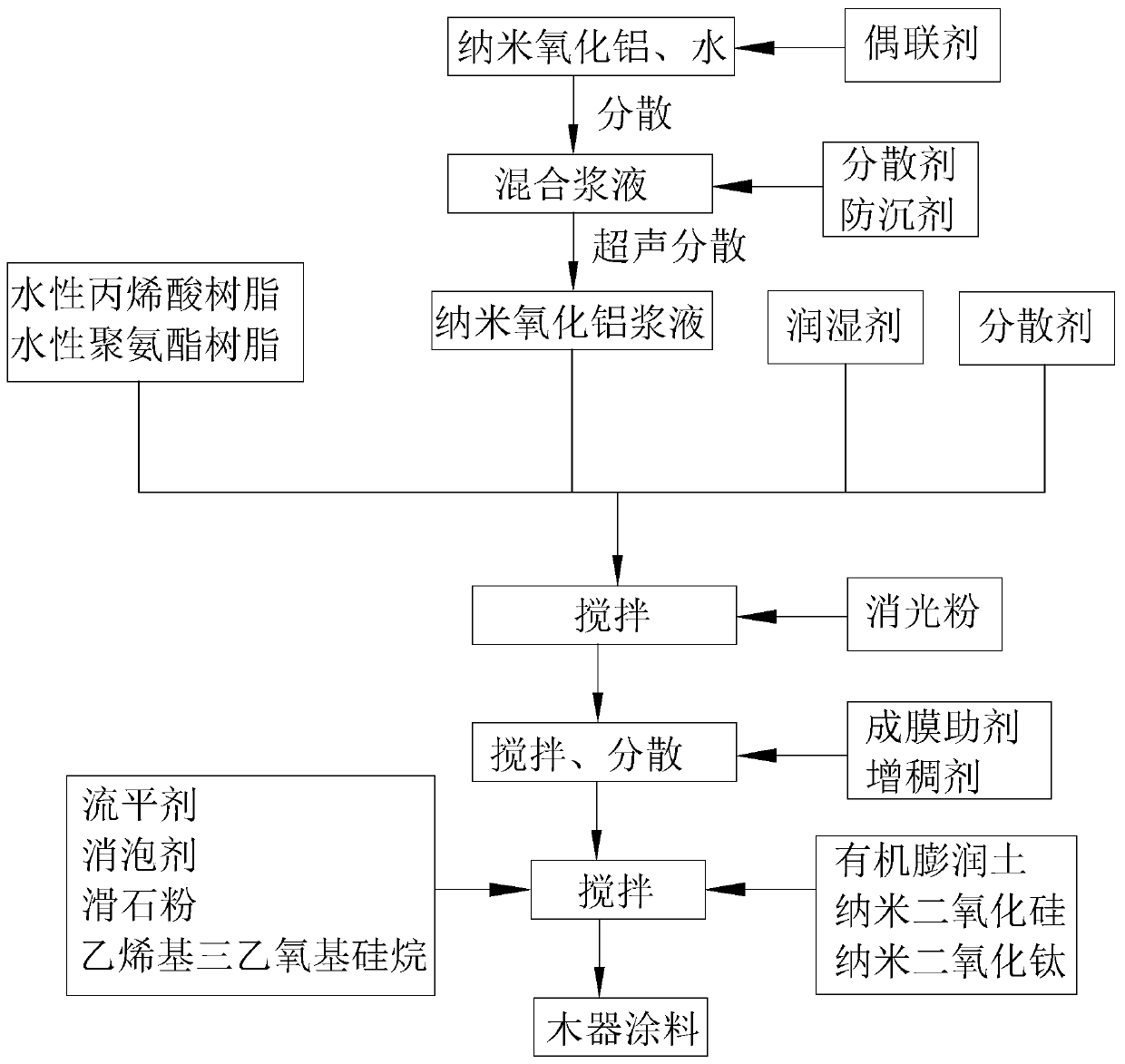

[0039] The preparation method of nano-alumina slurry is as follows: 1) Evenly disperse 10kg of nano-alumina in 50kg of water, then add 2kg of silane coupling agent KH550 and stir for 20min; 2) After stirring, add 1kg of dispersant 3204, 0.5kg of anti-sedimentation Agent BYK420, ultrasonically dispersed for 30 minutes to obtain nano-alum...

Embodiment 2

[0045] Table 2 is each raw material and its weight of a kind of water-based one-component wood coating in embodiment 2

[0046]

[0047] The preparation method of nano-alumina slurry is as follows: 1) uniformly disperse 10kg of nano-alumina in 60kg of water, then add 2kg of titanate coupling agent NDZ201 and stir for 30min; 2) after the stirring, add 2kg of dispersant 3204, 1kg of Precipitating agent BYK420, ultrasonically dispersed for 40 minutes to obtain nano-alumina slurry.

[0048] A preparation method of water-based one-component wood coating, specifically comprising the steps of:

[0049] Step 1. Weigh the water-based acrylic resin, water-based polyurethane resin, nano-alumina slurry, wetting agent, and dispersant in the container according to the formula, and disperse them evenly in the container, and keep stirring, and the stirring speed is controlled at 2000r / min;

[0050] Step 2, add matting powder and continue stirring, the stirring speed is controlled at 3000r...

Embodiment 3

[0053] Table 3 is each raw material and its weight of a kind of water-based one-component wood coating in embodiment 3

[0054] raw material Weight (kg) raw material Weight (kg) Waterborne Acrylic Resin 40 Dipropylene glycol n-butyl ether 3 Waterborne polyurethane resin 37 lauryl alcohol ester 3 Organic Montmorillonite 6 BYK-333 0.5 Nano alumina slurry 14 Hydroxyethyl cellulose 2 Nano silica 5 Dispersant 731A 0.2 Nano Titanium Dioxide 1 talcum powder 0.8 3-Aminopropyltrimethoxysilane 1 Vinyltriethoxysilane 0.3 Polyether modified silicone defoamer 0.5 Matting Powder TS-100 5

[0055] The preparation method of the nano-alumina slurry is as follows: 1) uniformly disperse 10kg of nano-alumina in 70kg of water, then add 1.5kg of titanate coupling agent NDZ201 and 1.5kg of silane coupling agent KH550 and stir for 30min; 2) after the stirring is completed , add 1.5kg dispersant 3204, 0.8kg anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com