Waterproof coating and preparation method thereof

A waterproof coating and seed technology, applied in the direction of coating, etc., can solve problems such as difficult to balance cohesive strength and low-temperature film-forming performance, affect various properties of waterproof materials, and destroy the internal structure of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

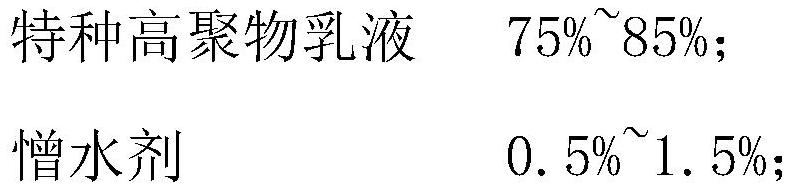

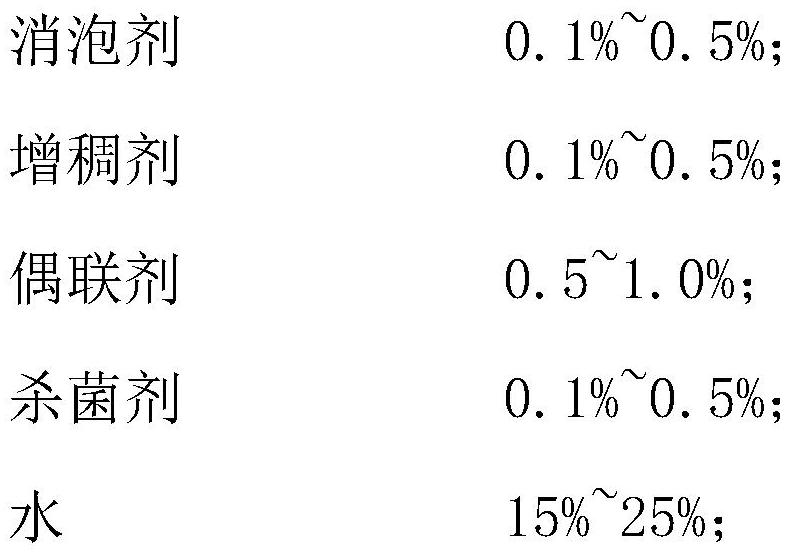

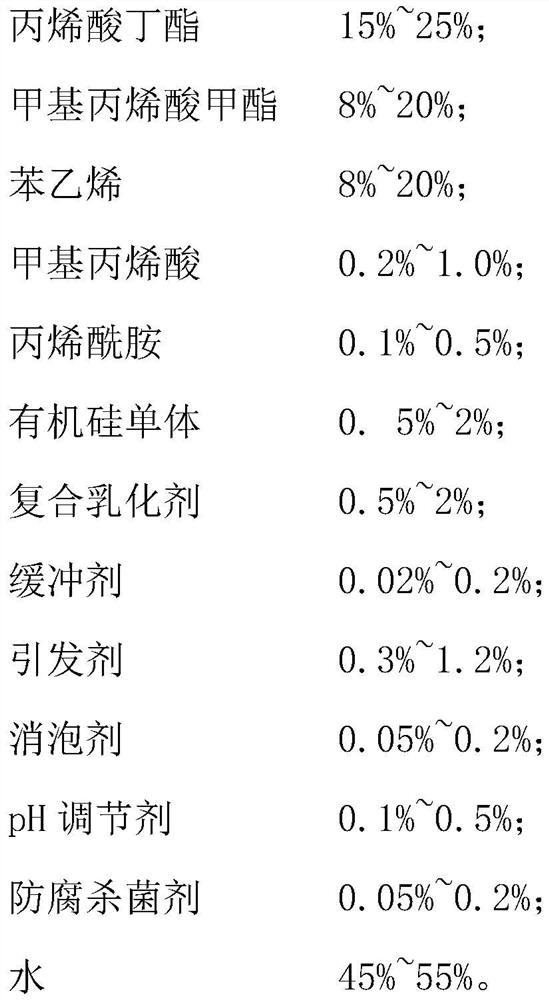

[0042] Embodiment 1-4, a kind of waterproof coating

[0043] Specifically, Table 1 shows the components and weight percentages of a waterproof coating in Examples 1-4, and Table 2 shows the components and weight percentages of special polymer emulsions. It should be emphasized that in Table 2, the proportion of "seed emulsion "Refers to the seed emulsion in the preparation of the seed emulsion described in the above preparation method, which is an intermediate product for the preparation of the special polymer emulsion, and is not included in the final weight ratio of the special polymer emulsion components.

[0044] Table 1

[0045]

[0046]

[0047] Table 2

[0048]

[0049] A kind of waterproof coating of embodiment 1-4 is prepared according to the following method:

[0050] (1) Preparation of seed emulsion:

[0051] ①Mix appropriate amount of water, compound emulsifier, styrene, butyl acrylate, methacrylic acid and acrylamide and disperse at high speed for 25-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com