Patents

Literature

44results about How to "Improve safety and environmental performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-component silane modified polyether sealant composition and sealant and preparation method thereof

ActiveCN108795360AGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUv absorber

The invention relates to the field of high molecular sealing materials and discloses a single-component silane modified polyether sealant composition and a sealant prepared from the single-component silane modified polyether sealant composition. The single-component silane modified polyether sealant composition disclosed by the invention is prepared from silane modified polyether resin, alkoxy terminated polydimethylsiloxane, a plasticizing agent, reinforcing filler, a water removal agent, a light stabilizing agent, an ultraviolet absorbent, a coupling agent and a catalyst. The sealant disclosed by the invention has the advantages of good smell, good ageing resistance, high recovery rate and the like.

Owner:浙江中天东方氟硅材料股份有限公司

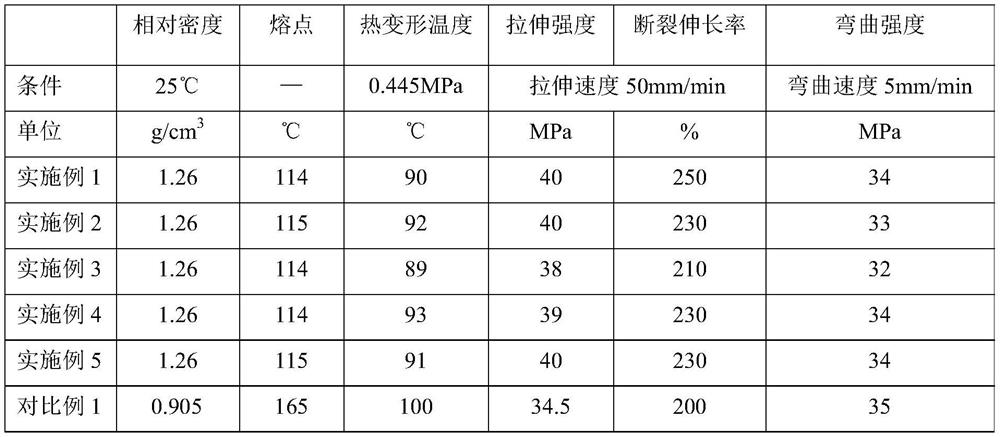

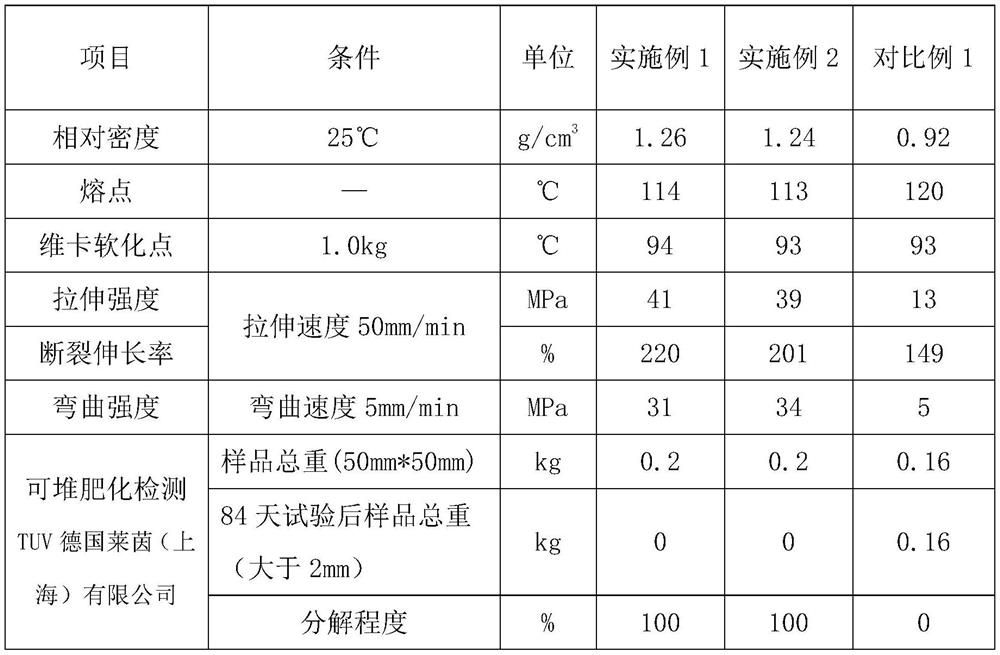

Biodegradable straw and preparation method thereof

The invention discloses a biodegradable straw and a preparation method thereof, and relates to the field of biodegradable materials. The biodegradable straw is prepared from the following raw materials in parts by mass: 100 parts of aliphatic polyester resin, 0-50 parts of filler, 0.5-5 parts of compatilizer, 0.5-3 parts of chain extender, 0.01-0.5 part of initiator, 0.5-3 parts of grafting monomer, 1-3 parts of lubricant and 0.3-0.6 part of antioxidant, wherein the aliphatic polyester resin is PBS, PBAT, PLA or a mixture of PBS, PBAT and PLA. The preparation method comprises the steps of preparing a required filler and a compatilizer, placing the filler and the compatilizer in a high-speed mixer for mixing, and discharging the mixture; and adding the mixture into a continuous internal mixer for internal mixing, enabling the mixture to fall into a conical double-forced feeding machine to be fed into a double-screw extruder for granulation to obtain required formula granules, extrudingthe required formula granules into a pipe through the extruder, and cutting the pipe to obtain the straw. The straw can be completely biodegraded after being discarded, has the using performance similar to that of a polypropylene straw, and is cold-resistant and heat-resistant. The method is suitable for industrial production and low in cost.

Owner:漳州新迪新材料科技有限公司

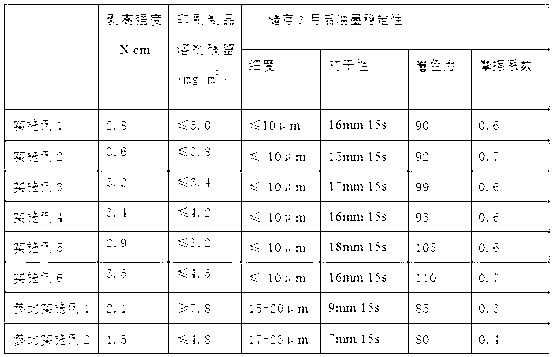

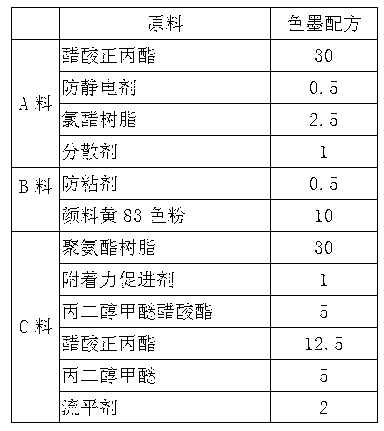

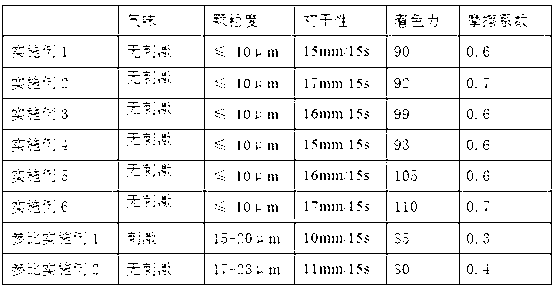

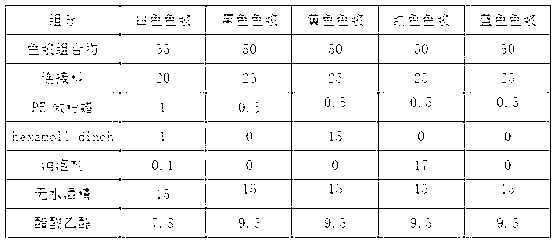

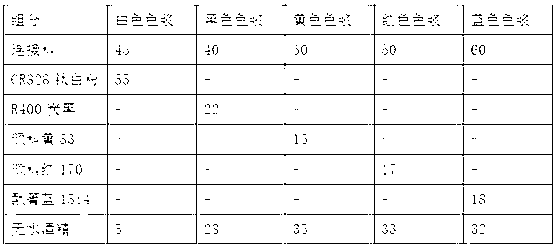

Lipophilic intaglio compound printing ink and preparation method thereof

The invention relates to intaglio compound printing ink, in particular relates to lipophilic polyurethane printing ink and a preparation method thereof, and belongs to the field of printing ink. In order to overcome the technical defects of big smell, more residual solvent and poor resin fastness of the printing ink in the prior art, the invention provides the lipophilic intaglio compound printing ink and the preparation method thereof. The lipophilic intaglio compound printing ink has excellent early dry performance and tinting strength, is very suitable for automatic packaging and has a good industry popularization value, and the friction coefficient is between 0.6 and 0.7.

Owner:BAUHINIA VARIEGATA INK & CHEM (ZHONGSHAN) LTD

Health-care functional fabric for leisure wear, and preparation method and application thereof

ActiveCN106427109AImprove antibacterial propertiesLower surface energyCellulosic plastic layered productsArtificial filaments from viscoseCinnamomum camphoraCarbon fibers

The invention relates to the technical field of functional fabric production, and in particular, relates to a China-hemp health-care functional fabric for leisure wear, wherein the fabric includes a health-care layer and a base layer; the health-care layer is made of viscose fibers prepared from fir and cinnamomum camphora as raw materials; the base layer is formed through interweaving warp yarns and weft yarns, the warp yarns are blended yarns of China-hemp, combed cotton and bamboo fibers, and the weft yarns are composed of China-hemp, carbon fibers and cotton. The fabric provided by the invention has good moisture absorption, has the characteristics of bacteriostasis, comfort, cool and the like, and has the hygiene and health-care effects on human bodies.

Owner:山东申士制衣有限公司

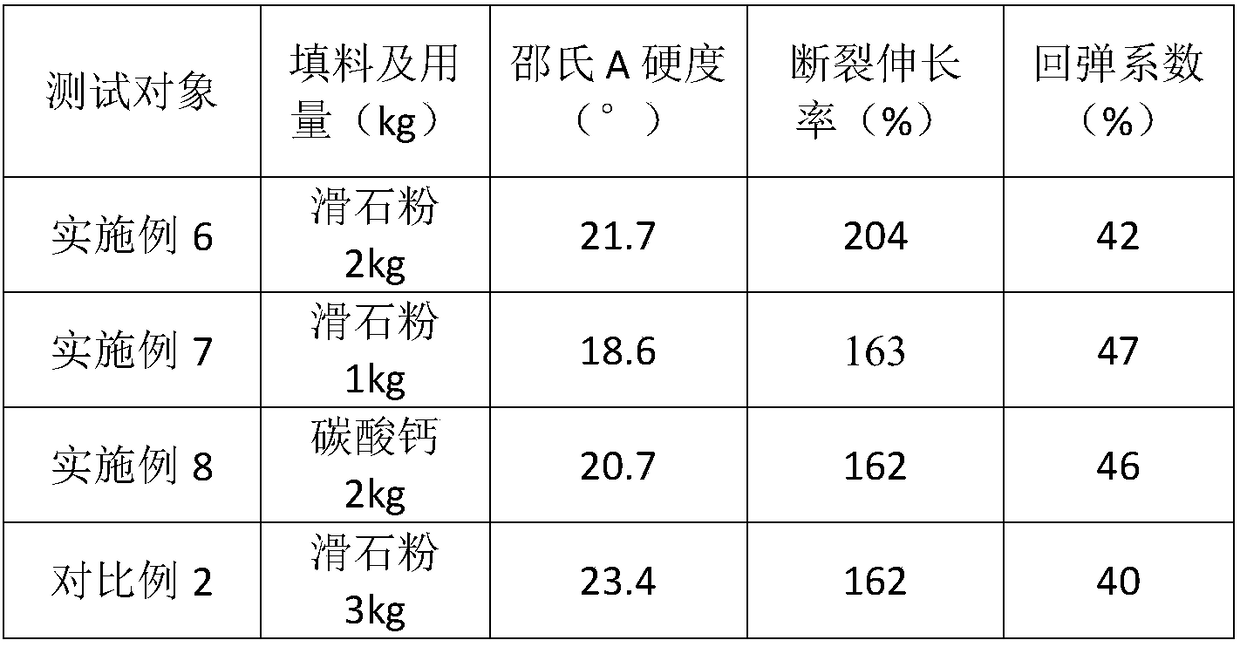

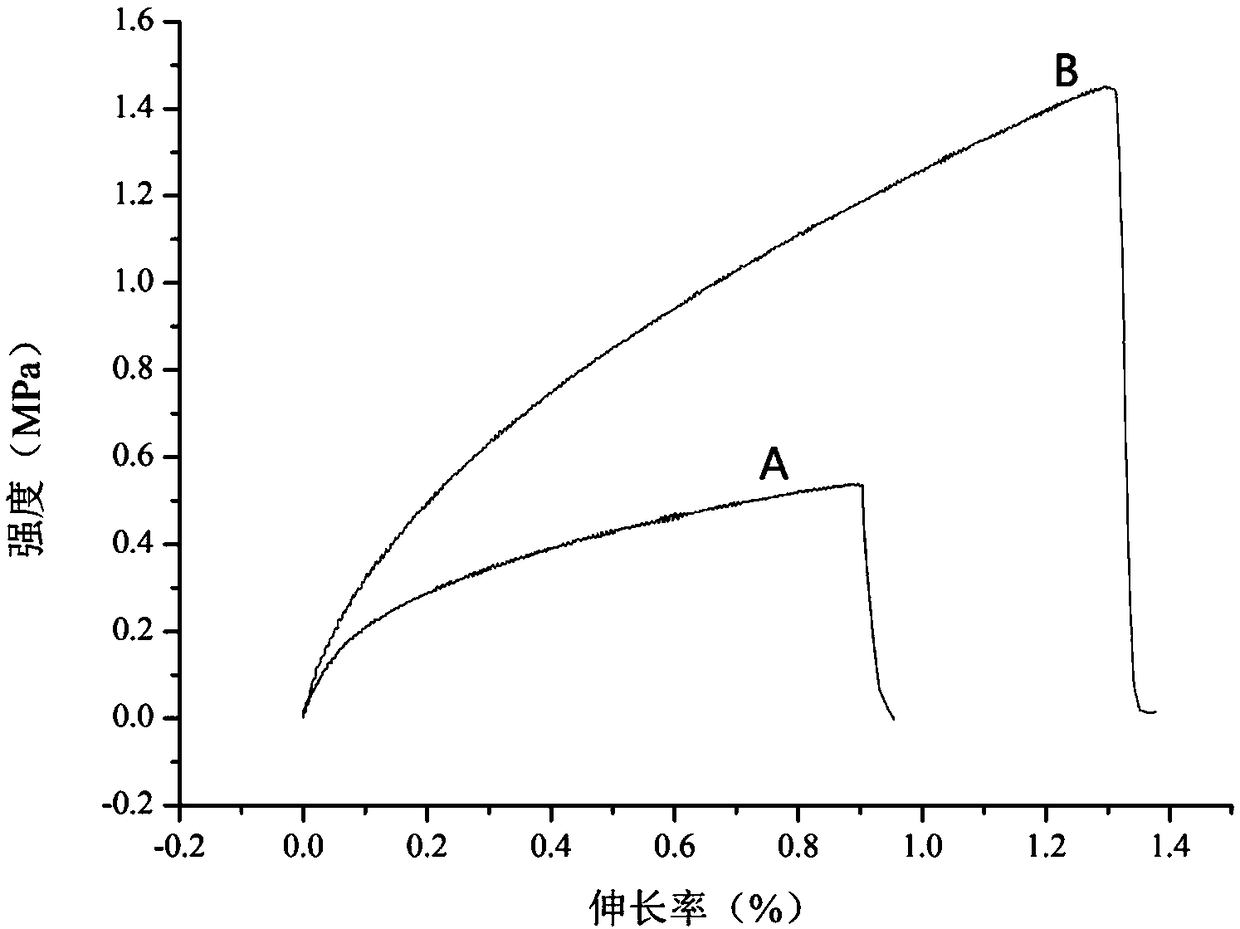

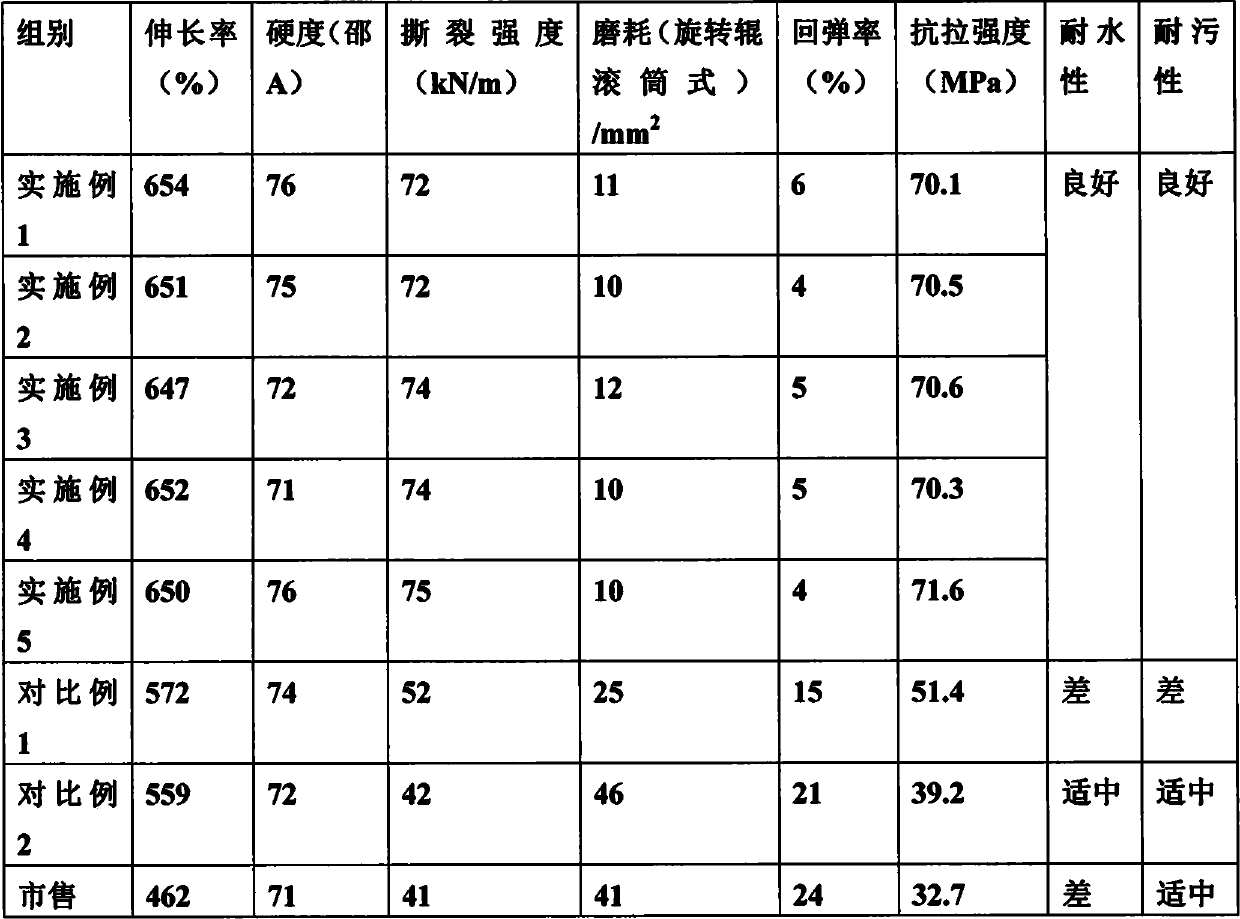

High-strength polyolefin foaming material as well as preparation method and application thereof

The invention discloses a high-strength polyolefin foaming material as well as a preparation method and application thereof. The high-strength foaming material is prepared by partially or totally replacing a filler with a fibrous or flake reinforced material, and the mechanical strength of the whole foam mat is improved by utilizing one-dimensional strength of a fiber material or two-dimensional strength of a sheet material, so that the foam mat meets the tension-torque national standard. The tension-torque test of the prepared finished product far exceeds the national toy standard (70N), thehardness of the foam mat is almost the same as that of an ordinary foam mat when the tension-torque, tensile strength and rebound resilience are improved, and the service performance is not changed; the preparation material does not contain formaldehyde, a plasticizer and any other harmful substance, the problem that dioxin is produced from chlorides is solved, and the safety and environmental performance are high; the preparation method can be directly applied to an original production line, the technological process is not increased, and the method is suitable for industrial production; andthe production and improvement cost is reduced.

Owner:MEITOKU PLASTIC

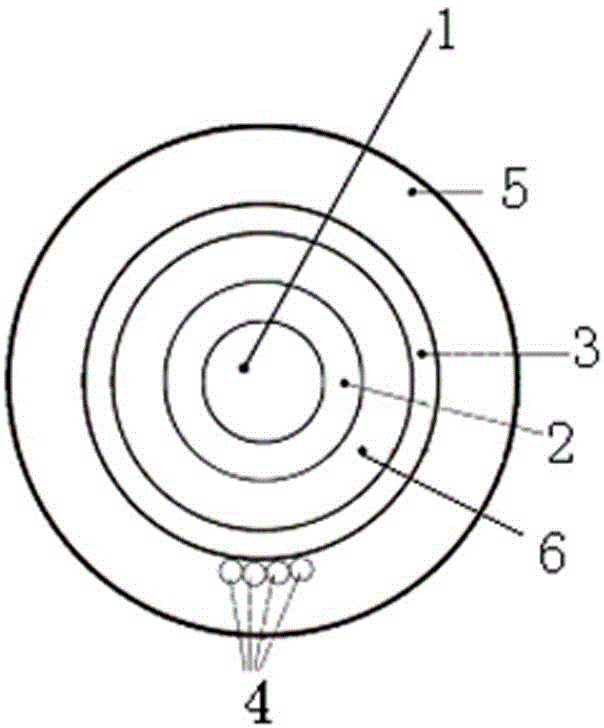

Anti-radiation carbon fiber heating cable

InactiveCN104981037AGuaranteed safety grounding functionEnsure that the cable has a safety grounding functionHeating element shapesHeating element materialsFiberCarbon fibers

The present invention discloses an anti-radiation carbon fiber heating cable. The anti-radiation carbon fiber heating cable comprises a heating wire harnesses consisting of carbon fibers, wherein an insulation protection layer is wrapped outside the heating wire harnesses; a conductive plastic layer is wrapped outside the insulation protection layer; conductive wires are laid outside the conductive plastic layer in parallel and are clung to the conductive plastic layer in parallel; and a protective sheath is wrapped outside the conductive wires and the conductive plastic layer. A novel shielding layer is arranged in the cable, so that the cable not only can be adaptive to softness and bend-ability of the carbon fibers, is good in shield effect, convenient to package and construct, but also is easy to manufacture, relatively low in cost and long in service life.

Owner:HEBEI SHENGJIA ELECTRONICS TECH

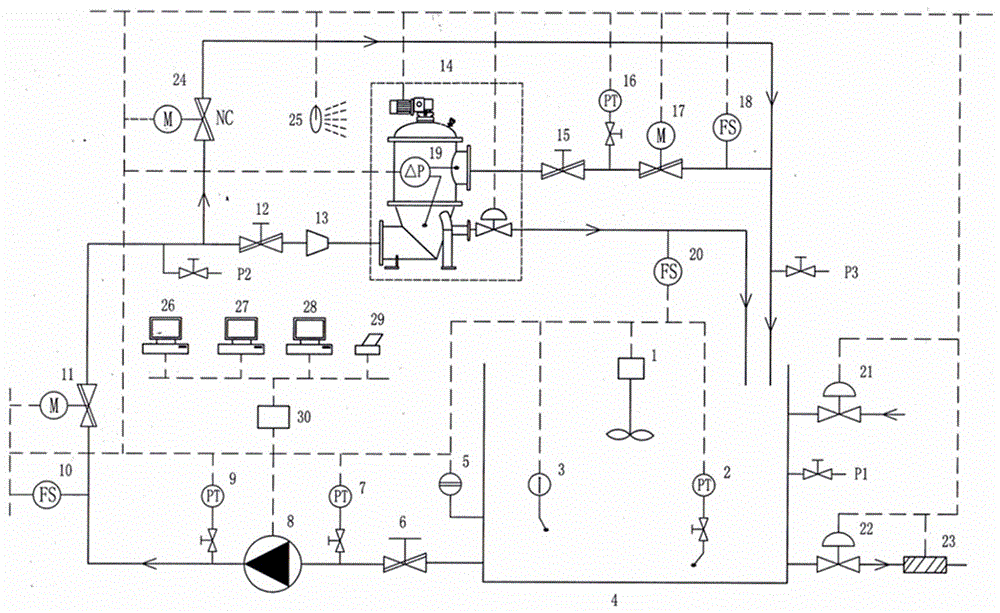

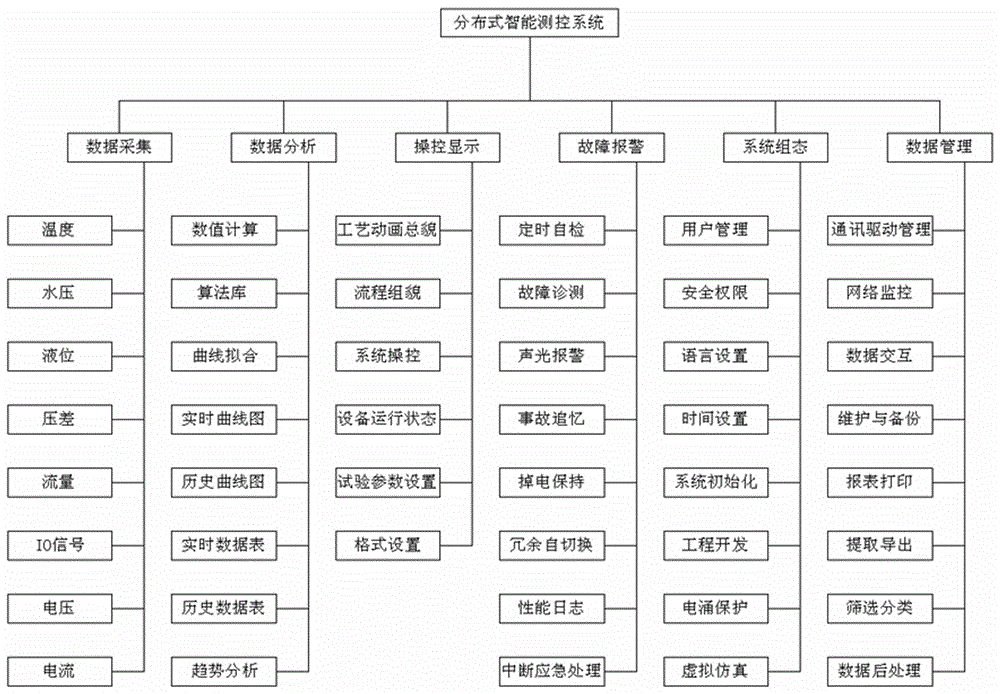

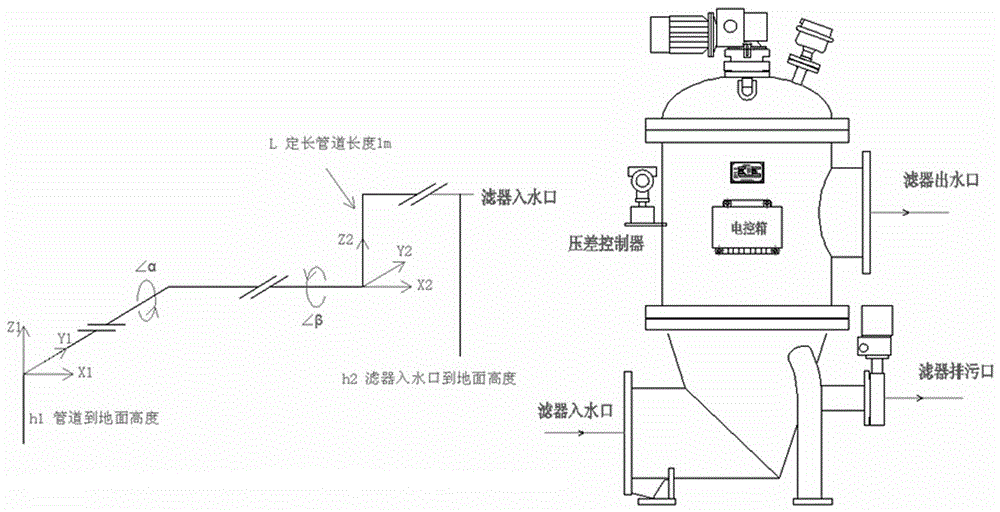

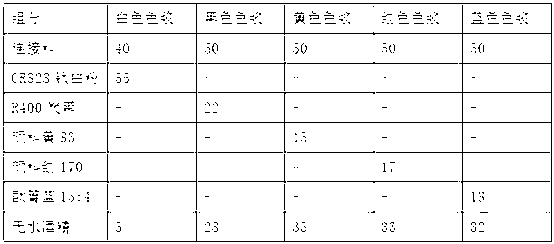

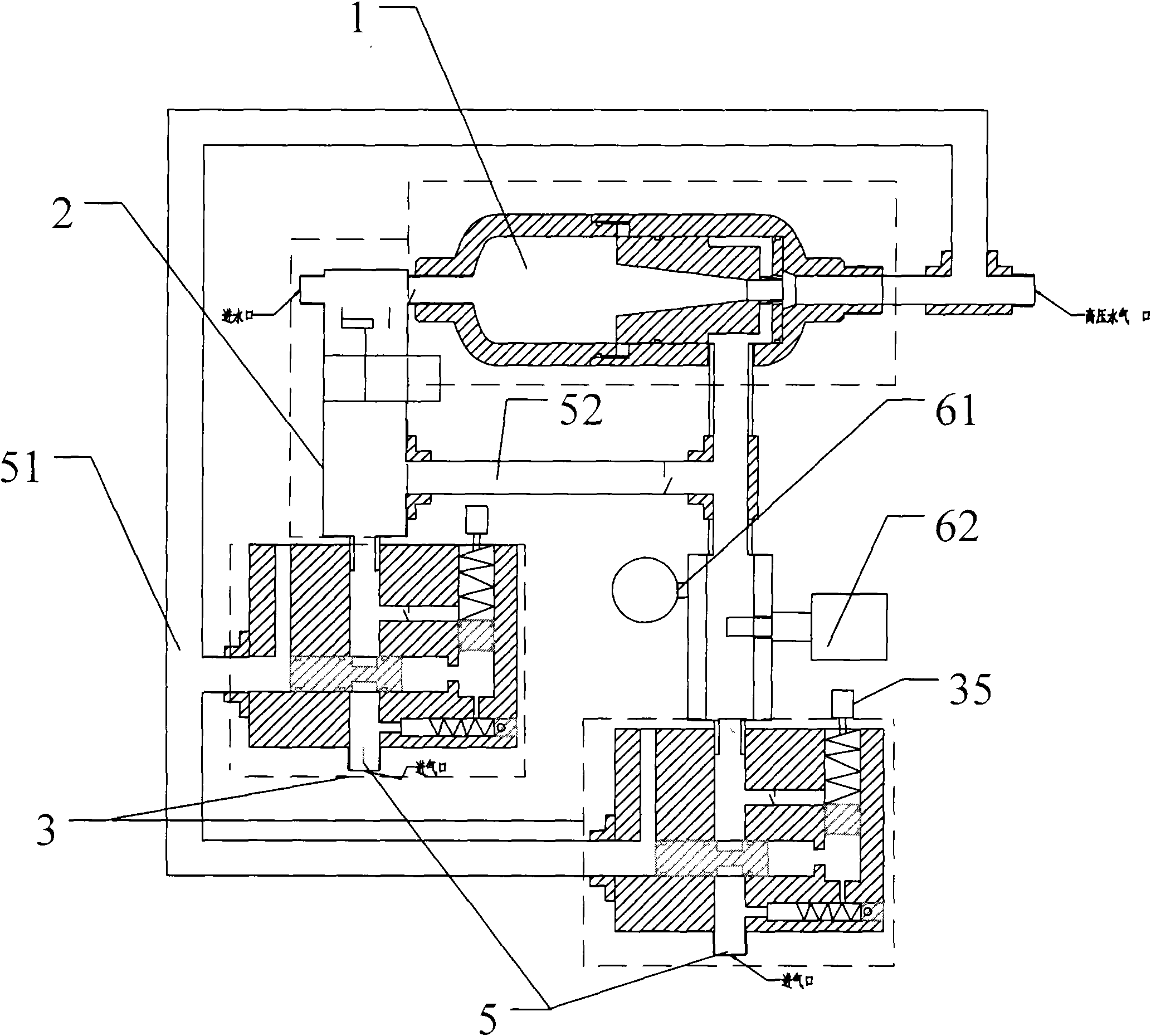

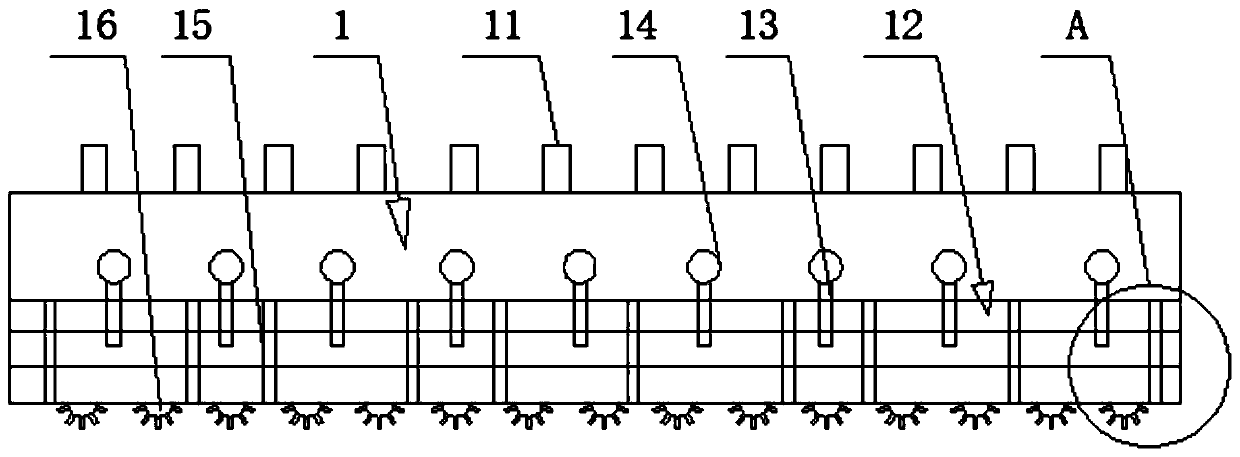

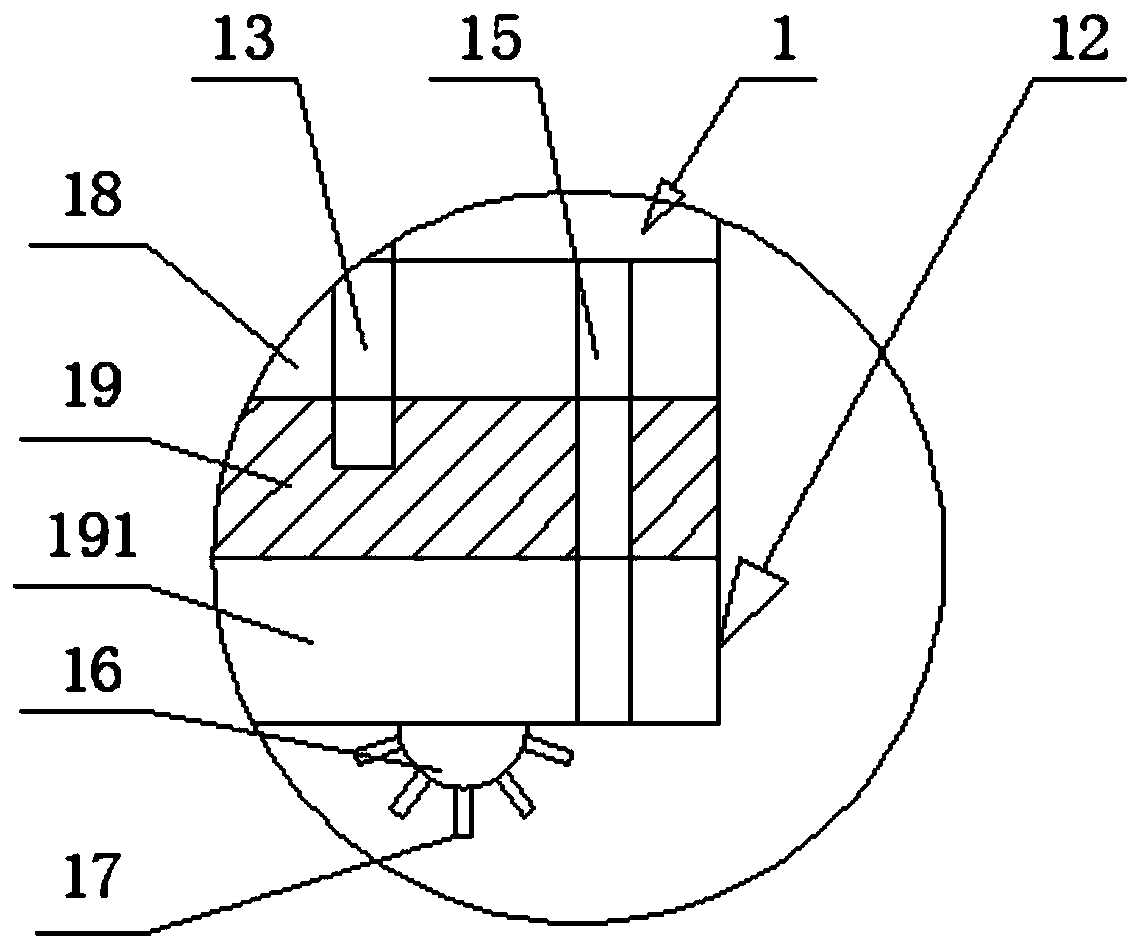

Ship ballast water filter performance experiment device

ActiveCN106370445AGuaranteed uptimeImprove scalabilityStructural/machines measurementWater desalinationSuspended particles

The present invention relates to a ship ballast water filter performance experiment device. The device comprises a circulating water system unit, a heterogeneous product access unit, and a distributed intelligent measurement and control system. The heterogeneous product access unit is configured to improve the mode of the filter access experiment device, take fresh water, sea water or other industrial water as fluid medium, and take plankton, suspended particles and organic carbon granules to simulate the inner impurities of the engineering environment to perform performance test of an automatic reverse cleaning filter access device for engineering of the ship ballast water, the sea drilling platform, the sea water desalination, the nuclear power plant water treatment and wastewater treatment, and the aqueous medium circulation mode accords with the real industry flow mode, so that the test result can reflect the scene real application state to a certain extent. Through building of the invention, the ship ballast water filter performance experiment device can realize the performance test of the automatic reverse cleaning filter access device at home and abroad to lay the foundation for researching a filter with big flow, low loss of pressure and high reliability and pushing the automatic reverse cleaning filter localization.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Alcohol type gravure surface printing ink and preparation method thereof

The invention relates to gravure surface printing ink and in particular relates to alcohol type gravure surface printing ink and a preparation method thereof, belonging to the field of printing ink. In order to overcome the technical defects that the odor is pungent, and solvent residue is high in the polyamide resin printing ink and other types of resins are low in fastness in the prior art, the invention provides alcohol type gravure surface printing ink and the connecting material thereof. The connecting material of the alcohol type gravure surface printing ink comprises 20-30 parts of polyvinyl butyral resin, 2-6 parts of aldehyde resin, 47-60 parts of anhydrous alcohol and 10-18 parts of acetic ether. The printing ink prepared by utilizing the vehicle is excellent in initial dryness performance and tinting strength, has the friction coefficient of 0.6-0.7, is suitable for the requirements on automatic packaging and has a high industrial popularization value.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

Method for preparing artificial plate adhesive

InactiveCN108424734AImprove adsorption capacityImprove qualityNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesivePhenol

The invention discloses a method for preparing an artificial plate adhesive and belongs to the field of adhesives. According to the artificial plate adhesive, an extract of ginkgo seed coat and nano zinc borate are used; due to substances such as ginkgolic acid and phenol in the ginkgo seed coat, the security and environment protection properties of a wooden product can be improved, and the livingenvironment can be protected; due to addition of the nano zinc borate, the decomposition reaction process and directions of wood can be changed, and pyrolytic reactions of the wood can be developed to generate relatively rich charcoal; meanwhile, a substrate is covered by generated molten boric oxide, so that the flame retardancy of the wooden product can be improved, and the body security can befurther improved. By adopting the method, the problems that a great amount of an adhesive is used in conventional artificial plate production, most adhesives are good in combination property, but poor in function and thus the formaldehyde release amount of an artificial plate is kept at a high level and the living environment can be deteriorated, can be solved.

Owner:翟琳

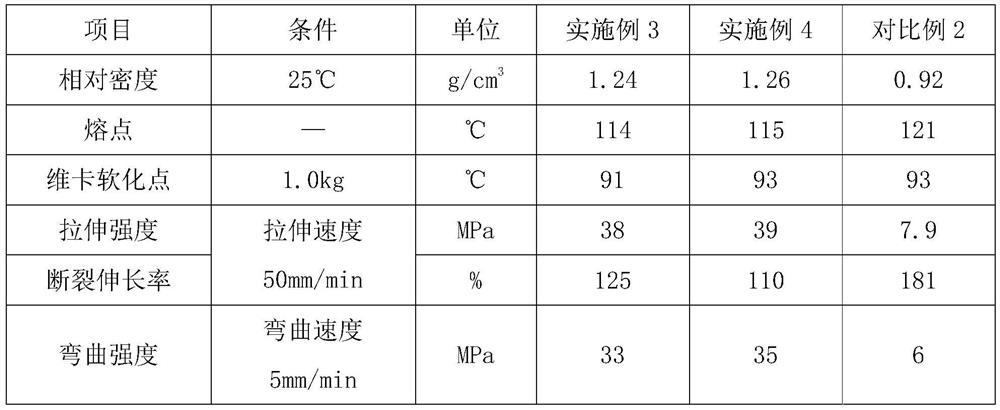

Compostable full-degradable disposable tableware and preparation method thereof

The invention discloses compostable full-degradable disposable tableware and a preparation method thereof, which relate to the field of biodegradable materials. The compostable full-degradable disposable tableware is prepared from the following raw materials in parts by mass: 100 parts of aliphatic polyester resin, 0-40 parts of filler, 0.5-5 parts of compatilizer, 0.5-5 parts of chain extender, 0.01-1 part of initiator, 0.5-3 parts of grafting monomer, 1-4 parts of lubricant and 0.3-0.6 part of antioxidant. The preparation method comprises the following steps of preparing a required filler and a compatilizer, putting the filler and the compatilizer into a high-speed mixer for mixing at the temperature of 50-90 DEG C for 10-30 minutes, and discharging, adding the mixture into a continuousinternal mixer, carrying out internal mixing at 90-140 DEG C for 2-3 minutes, dropping the mixture into a conical double-forced feeding machine, and feeding the mixture into a double-screw extruder for granulation, so as to obtain required formula granules, pressing the mixture into sheets by a sheet machine at 120-180 DEG C, and carrying out plastic molding as required to obtain a finished product, or directly carrying out injection molding on the formula granules through an injection molding machine.

Owner:漳州新迪新材料科技有限公司

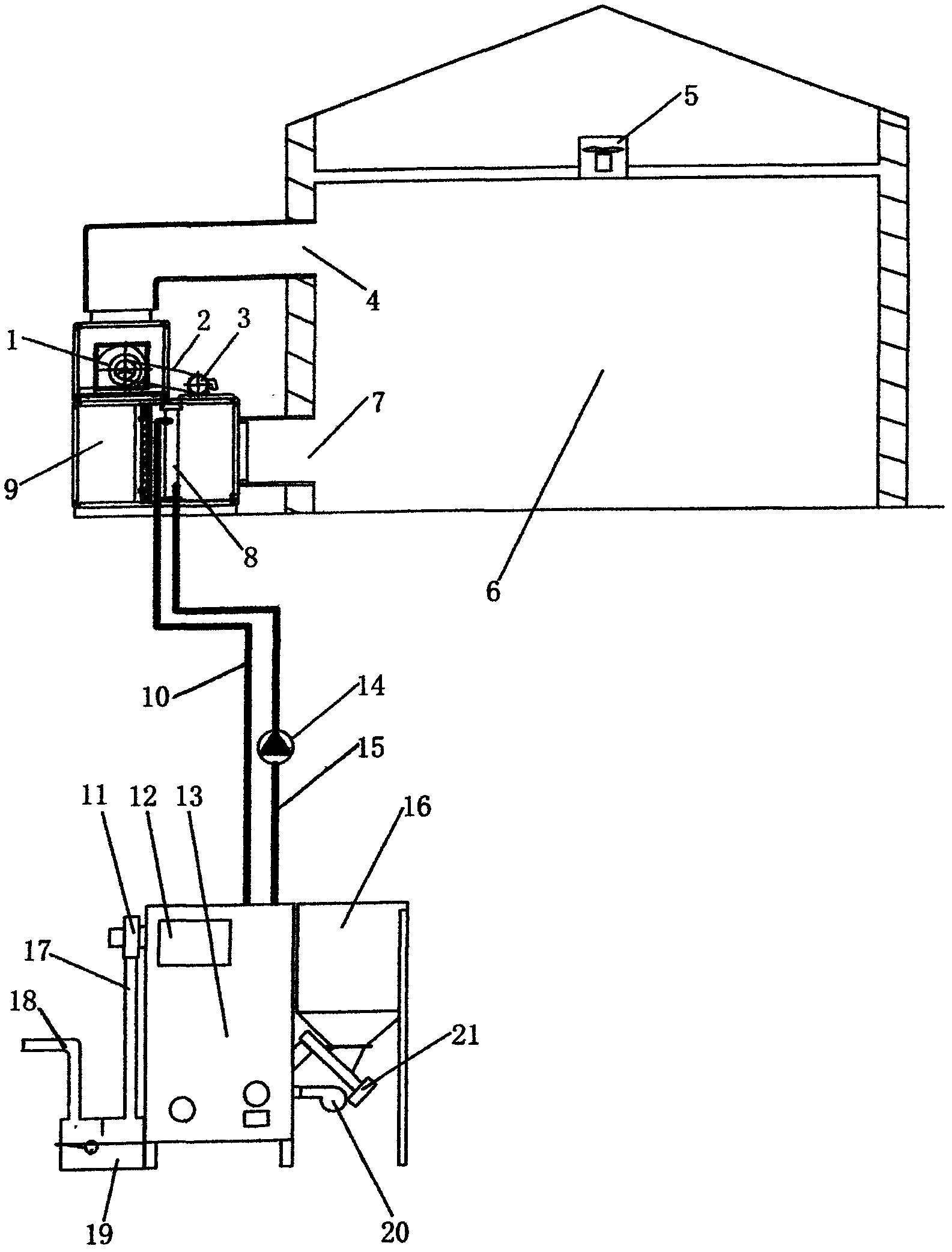

Safety and high-efficiency biomass energy hothouse system

InactiveCN102519236ANot affectedHigh degree of automationStorage heatersDrying gas arrangementsEngineeringDust collector

The invention discloses a safety and high-efficiency biomass energy hothouse system. The system has a biomass boiler. A dry type induced draft dust collector of the biomass boiler is connected with a wet flue gas exhauster. A water chamber of the biomass boiler is connected with a surface cooler of a cabinet fan through a water outlet pipe equipped with a hot water circulating pump, and a water return pipe connects the surface cooler to the water chamber of the biomass boiler. An air supply outlet of the cabinet fan is connected to a hothouse, the cabinet fan is also connected with the hothouse through a centrifugal fan via an air return port, and the centrifugal fan is driven to operate by an explosion-proof motor through a transmission belt. Under the control of an automatic operation control system, the circulating pump pumps hot water to the surface cooler of the cabinet fan, the hot water exchanges heat with air exhausted from the hothouse by the centrifugal fan, and the heated air returns to the hothouse to make a temperature of the hothouse rise to the desired temperature. The invention adopts high-compression biomass particles as fuel, which has high combustion heat value, is not affected by environment, and has environmental friendliness and good economic benefit. An air circulation channel between the cabinet fan and the hothouse is free of electrical contacts, and is safe and reliable.

Owner:徐海江

Silane modified polyurethane adhesive for bottom layer material of plastic runway and preparation method and application of silane modified polyurethane adhesive

InactiveCN111534264AGood storage stabilityLow viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention relates to the field of adhesives, in particular to a silane modified polyurethane adhesive for a bottom layer material of a plastic runway and a preparation method and application of the silane modified polyurethane adhesive. The silane modified polyurethane adhesive is prepared from the following raw materials in parts by weight: 90 to 110 parts of polyether polyol, 20 to 30 partsof isocyanate silane, 0.1 to 1 part of an antioxidant, 0.01 to 0.05 part of a catalyst and 0.1 to 0.5 part of a stabilizer. The silane modified polyurethane adhesive has the advantages of being environmentally friendly, good in storage stability, low in viscosity, easy to construct and free of foaming after construction forming.

Owner:上海抚佳精细化工有限公司

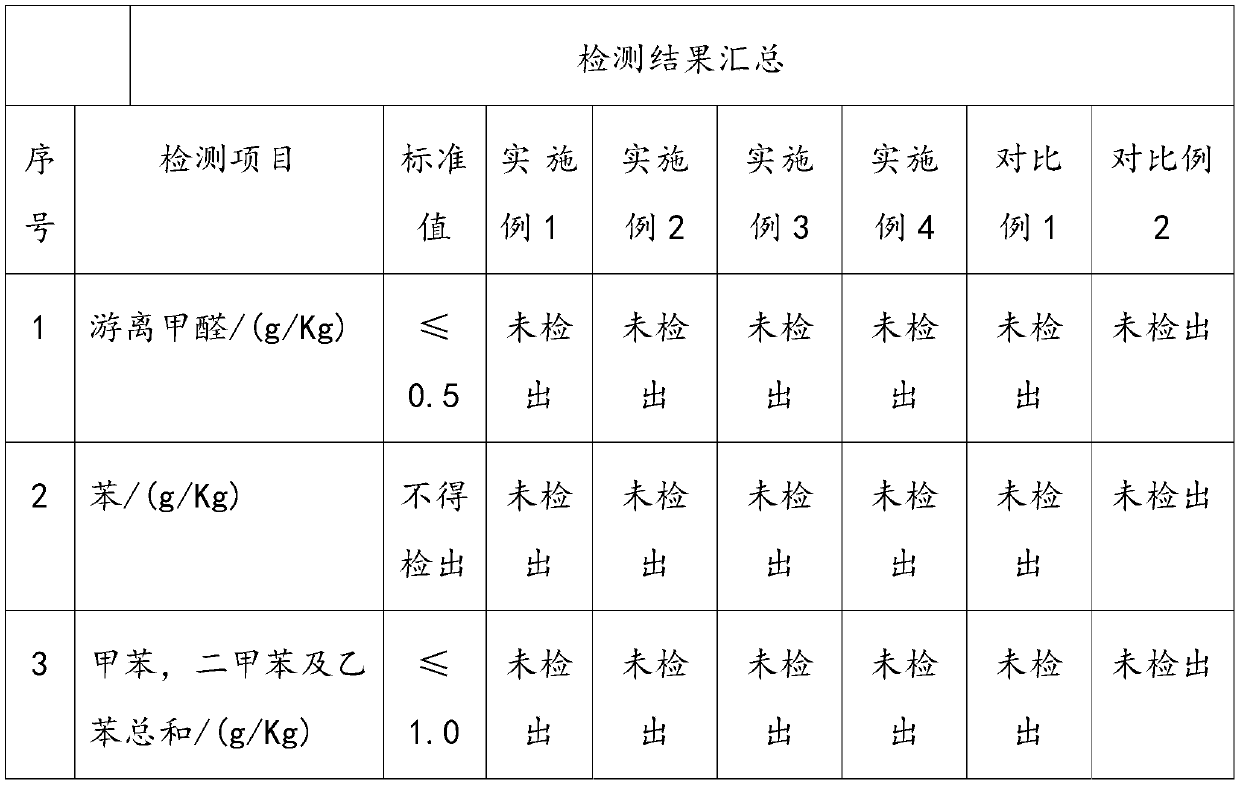

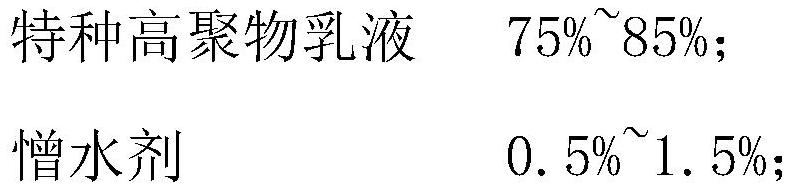

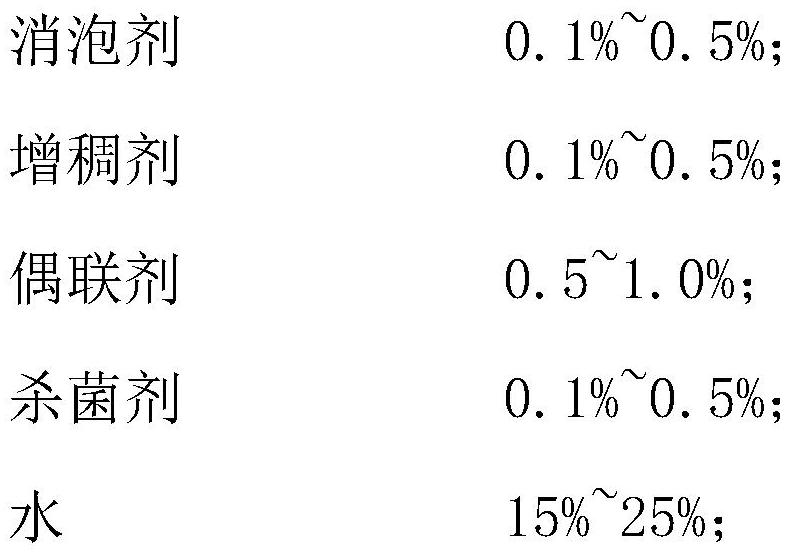

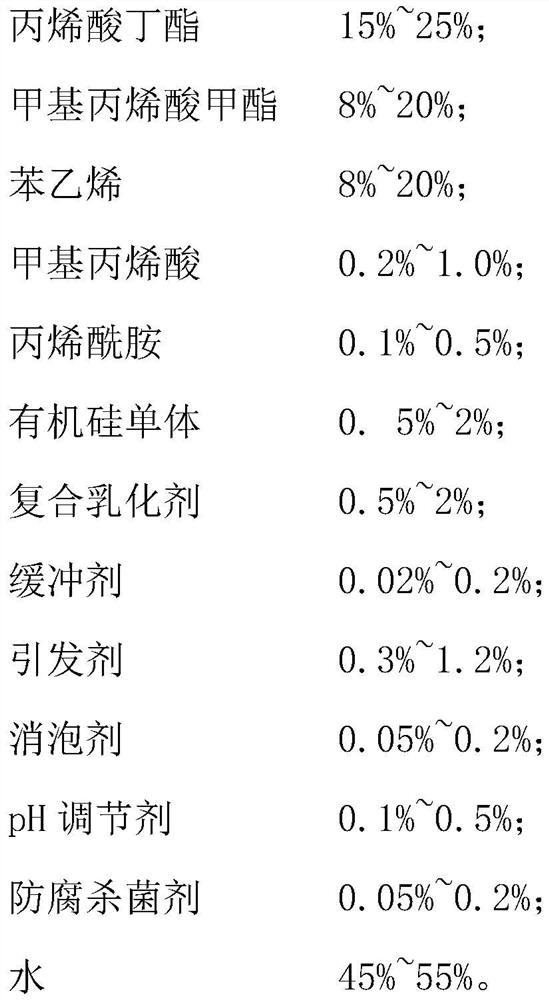

Waterproof coating and preparation method thereof

InactiveCN111793401AReduce addImprove water whitening resistanceCoatingsPolymer scienceBuffering agent

A waterproof coating comprises, by weight, 75-85% of a special high polymer emulsion, 0.5-1.5% of a water repellent, 0.1-0.5% of a defoaming agent, 0.1-0.5% of a thickening agent, 0.5-1.0% of a coupling agent, 0.1-0.5% of a bactericide and 15-25% of water, wherein the special high polymer emulsion comprises 15-25% of butyl acrylate, 8-20% of methyl methacrylate, 8-20% of styrene, 0.2-1.0% of methacrylic acid, 0.1-0.5% of acrylamide, 0.5-2% of an organosilicon monomer, 0.5-2% of a compound emulsifier, 0.02-0.2% of a buffer agent, 0.3-1.2% of an initiator, 0.05-0.2% of a defoaming agent, 0.1-0.5% of a pH adjusting agent, 0.05-0.2% of an antiseptic bactericide and 45-55% of water. The invention also discloses a preparation method of the waterproof coating. The waterproof coating disclosed bythe invention is good in water white resistance, environment-friendly and non-toxic, and the strength of a waterproof film is improved while the low-temperature film forming performance is guaranteed.

Owner:西卡(上海)管理有限公司 +1

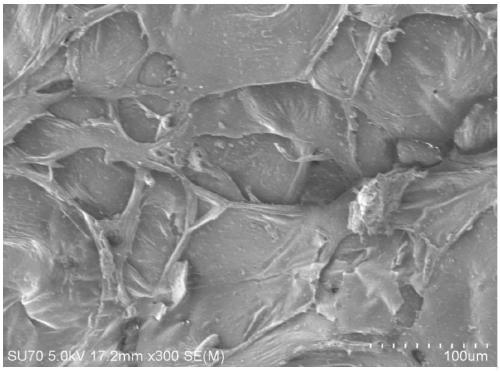

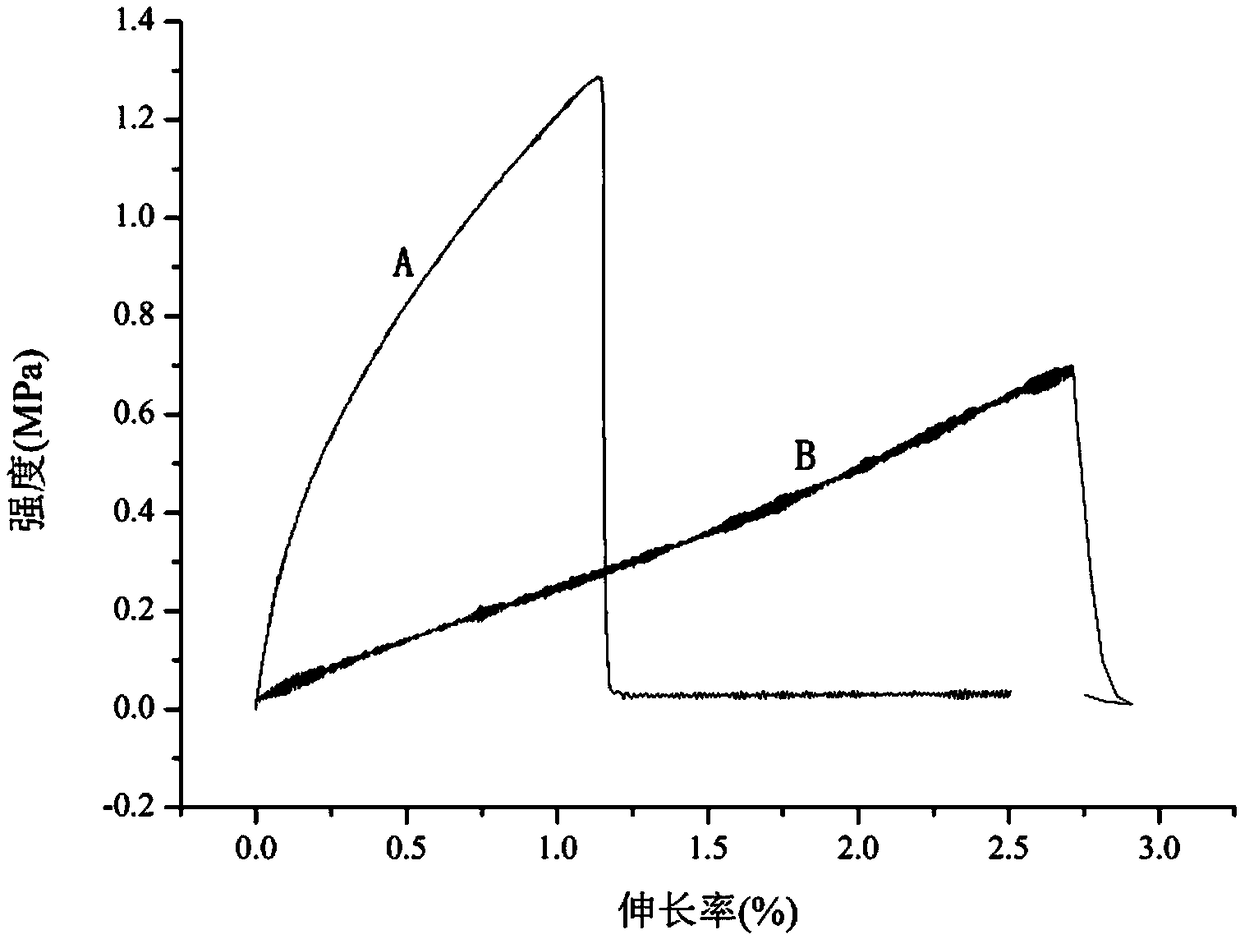

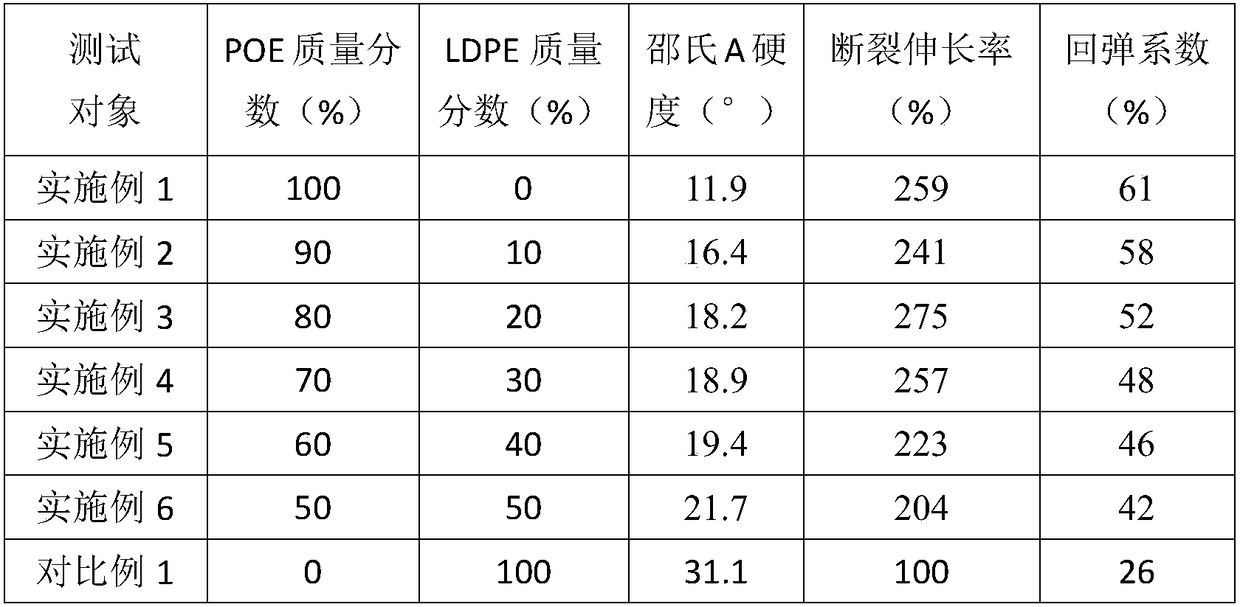

High-elasticity foam material based on polyolefin elastomer as well as preparation method and application of high-elasticity foam material

The invention discloses a high-elasticity foam material based on a polyolefin elastomer as well as a preparation method and application of the high-elasticity foam material. The foam material with high elasticity is prepared from the polyolefin elastomer partially or wholly replacing a common polymer raw material; a prepared finished product not only is soft and has the Shore A hardness (smaller than 22) obviously superior to the Shore A hardness (more than 30) of a traditional material, but also is good in rebound resilience and high in elongation at break and has anti-fatigue and antiskid effects; in addition, molecules of the polyolefin elastomer do not contain oxidation-sensitive carbon-carbon double bonds, and therefore, the finished product has more excellent anti-aging property; theprepared material does not contain harmful substances such as formaldehyde and a plasticizer, further has no problem of dioxin generated by chlorides and is high in safety and environment friendliness; the preparation method can be directly used on an original production line without increasing technological processes and is suitable for industrial production; and the production improvement costis reduced.

Owner:MEITOKU PLASTIC

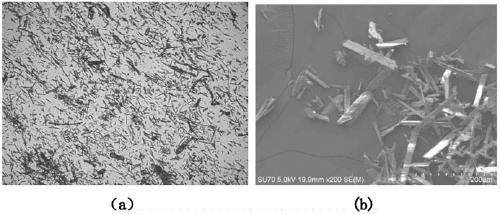

Self-enhancement type polyolefin foaming material as well as preparation method and application thereof

The invention discloses a self-enhancement type polyolefin foaming material as well as a preparation method and application thereof. Linear low density polyethylene LLDPE is used as a self-enhancementmaterial to partially or wholly replace a traditional polyolefin material to prepare the high-strength foaming material; a specific fish-bone-shaped molecule microstructure (a regular and very shortand small branch chain structure) is utilized to increase the anti-tearing strength, so that national standards of tension and torque force are realized; a tension and torque force test of a preparedfinished product exceeds national toy standards (70 N); the tension and torque force, the tensile strength and the resilience are improved, the rigidity is almost the same as that of a common foam floor mat and the utilization performance is not changed; preparation materials do not contain harmful substances including formaldehyde and, a plasticizer and the like so that the problem that dioxin isgenerated by chloride is solved and the safety and environment-friendly performance is improved; the preparation method can be directly used on an original production line and a technological flow isnot increased, so that the production method is suitable for industrial production; the production and improvement cost is reduced.

Owner:如皋市鼎泉电子商务有限公司

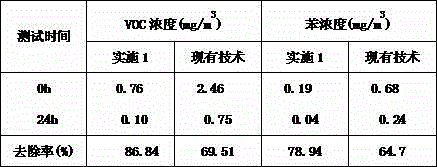

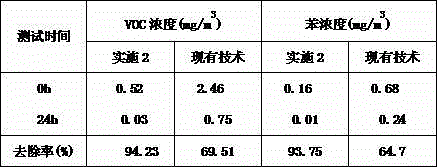

Interior wall latex paint containing oxidized corn starch and preparation method thereof

InactiveCN104449123AGood adhesivenessReduce combustible componentsStarch dervative coatingsAntifouling/underwater paintsHydroxyethyl celluloseDefoaming Agents

The invention discloses interior wall latex paint containing oxidized corn starch and a preparation method thereof. The interior wall latex paint is prepared from the following raw material components in parts by weight: 4-8 parts of oxidized corn starch, 0.6-0.9 part of trimethylamine, 1-2 parts of bamboo charcoal powder, 0.2-0.4 part of photocatalyst, 12-18 parts of acetic styrene-acrylic emulsion, 0.2-0.6 part of hydroxyethyl cellulose thickening agent, 0.1-0.3 part of wetting dispersant, 0.1-0.3 part of defoaming agent, 0.6-0.9 part of coalescing agent, 6-10 parts of titanium dioxide, 15-20 parts of coarse whiting, 4-9 parts of calcined kaolin, 4-10 parts of talcum powder, 0.15-0.35 part of a preservative and 0.15-0.35 part of a mildew preventive. The preparation method comprises the following steps: sequentially preparing the oxidized corn starch and trimethylamine, adding the aids, respectively mixing and reacting, thereby obtaining the final product. The interior wall latex paint containing the oxidized corn starch has the characteristics of no toxicity and environment friendliness and has the effects of adsorbing and digesting volatile organic compounds (VOC) generated by various indoor home decorations.

Owner:杨俊宇

Environment-friendly wire cutting liquid and preparation method thereof

InactiveCN107723076AImprove safety and environmental performanceAvoid excessive heatLubricant compositionWire cuttingChemistry

The invention discloses environment-friendly wire cutting liquid. The environment-friendly wire cutting liquid is prepared from the following substances in parts by weight: 5.8 to 6.2 parts of sorbitan monooleate, 5.2 to 6.5 parts of oleic acid, 3.8 to 4.3 parts of antirust agent, 3.5 to 4.2 parts of Turkey red oil, 0.8 to 1.1 parts of potassium hydroxide, 0.6 to 1.1 parts of deionized water, 1.0to 1.4 parts of methyl alcohol, 0.01 to 0.05 part of 1H- benzotriazole, 1 to 1.2 parts of anticorrosive inhibitor, 70 to 80 parts of low-viscosity naphthenic base oil and the balance of a less amountof defoaming agent. A preparation method of the environment-friendly wire cutting liquid comprises the following steps: (1) successively adding the low-viscosity naphthenic base oil, the sorbitan monooleate, the oleic acid and the Turkey red oil into a mixing kettle according to a ratio, and then heating and stirring; and (2) then successively adding potassium hydroxide, the deionized water, the antirust agent, methyl alcohol, benzotriazole, the anticorrosion inhibitor and the defoaming agent according to a ratio, and stirring. By adopting the environment-friendly wire cutting liquid and the preparation method thereof, the safety and environment-friendly performance of the cutting liquid can be greatly improved, the overhigh temperature in a cutting region is avoided, a cut workpiece is good in heat conductivity, free from smoke and deterioration, safe, environmentally friendly, and free from peculiar smell.

Owner:郑州市欧普士科技有限公司

Waterborne acrylic wear-resistant road marking paint and preparation method thereof

InactiveCN110423497AImprove mechanical propertiesImprove wear resistanceCoatingsWear resistantAcrylic resin

The invention provides a waterborne acrylic wear-resistant road marking paint, which is prepared from the following raw materials by weight: 100-200 parts of modified acrylic resin, 1-3 parts of diacetone acrylamide, 1-3 parts of adipic acid dihydrazine, 5-15 parts of neopentyl glycol, 7-17 parts of maleic anhydride, 10-20 parts of a film-forming assistant, 10-15 parts of filler, 3-7 parts of a dispersant and 1-5 parts of a defoamer. The preparation method is simple, the raw materials are simple and easily available, the mechanical properties and wear resistance of the paint can be significantly improved, the curing time is short, and the formed film is fine and uniform, has improved strength and toughness, and beautiful appearance, therefore the waterborne acrylic wear-resistant road marking paint has broad application prospects.

Owner:山东路辰交通科技有限公司

Construction adhesive and preparation method thereof

InactiveCN108822745AHigh strengthImprove tensile propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotassium persulfateEpoxy

The invention provides a construction adhesive and a preparation method thereof. The adhesive is composed of the following raw materials in percentages by mass: 40-60% of polyvinyl alcohol, 5-20% of epoxy resin, 5-10% of hydroxymethyl cellulose, 4-12% of vinyl acetate, 5-10% of polyacrylamide, 1-2% of potassium persulfate, 0.5-1% of N,N-dimethylbenzylamine, 3-5% of an alkaline liquid, 0.5-1% of asurfactant, 0.5-1% of a modifier, and the balance water. The adhesive provided by the invention has high-strength tensile properties, does not contain an aldehyde compound, and has high safety and environmental protection performance.

Owner:四川文希科技有限公司

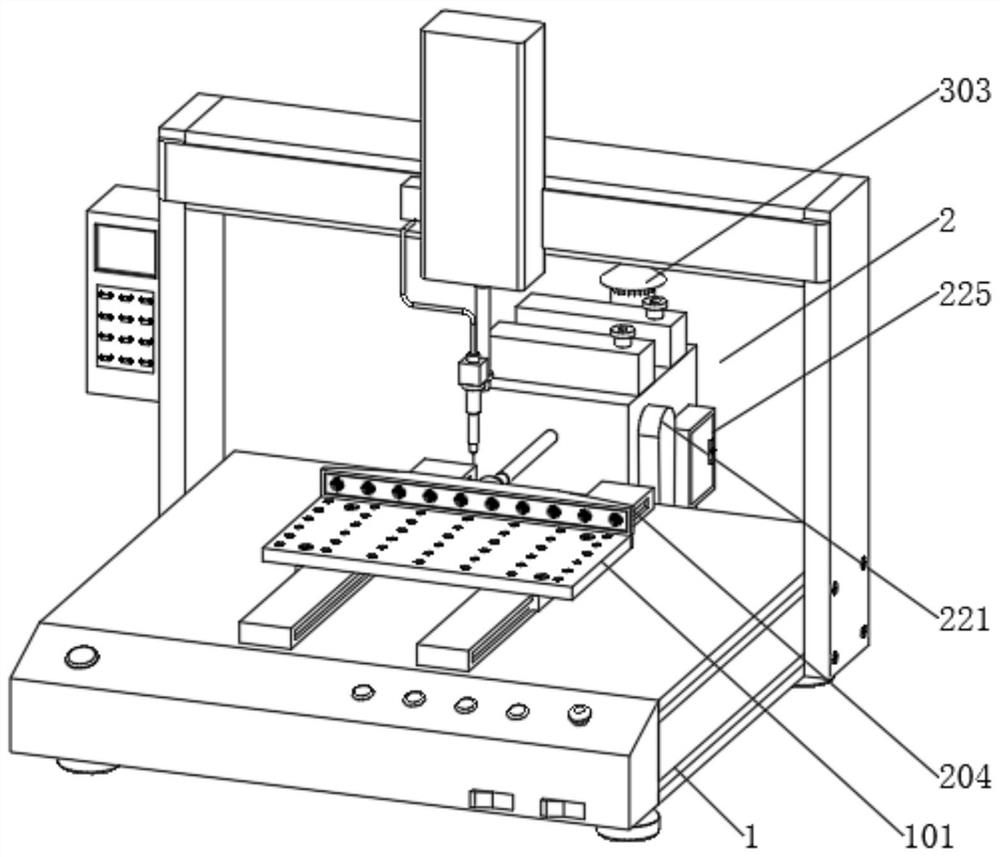

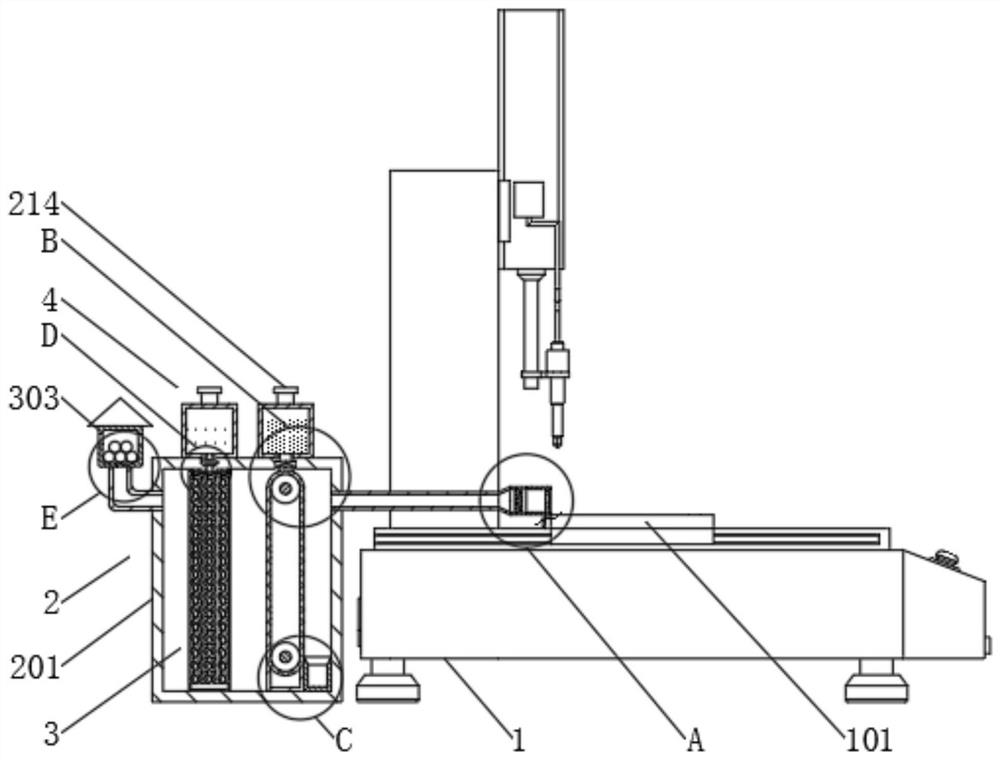

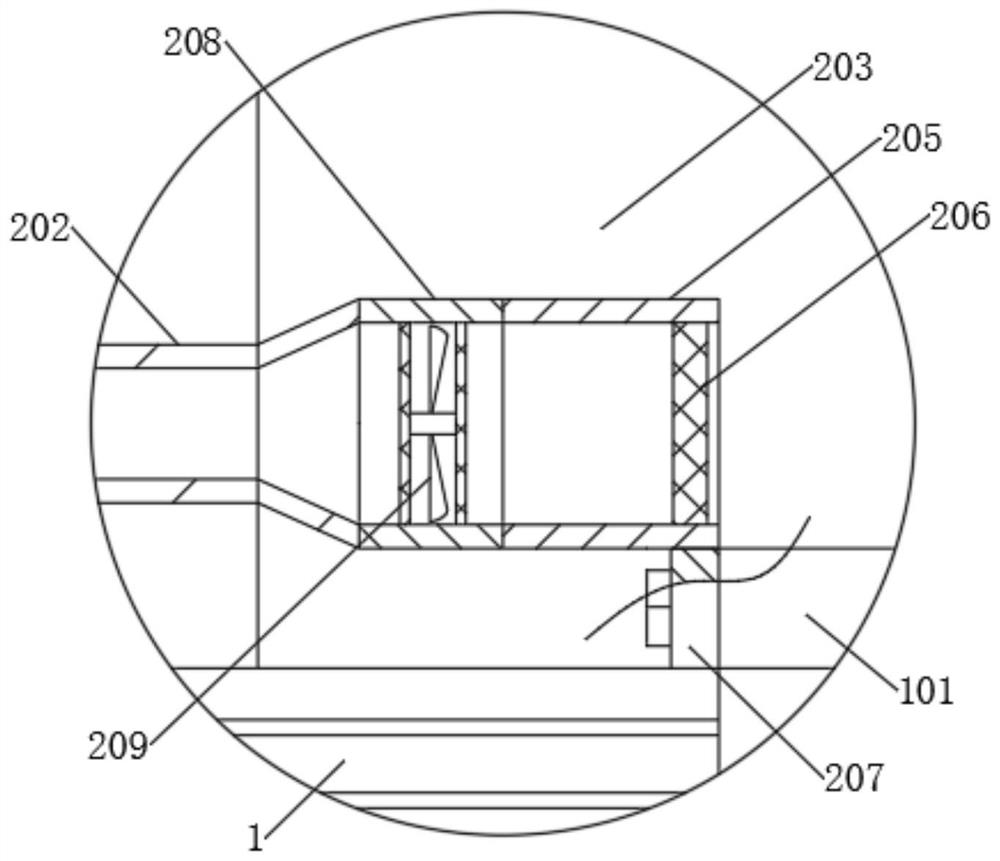

Medical equipment circuit board maintenance spot welding machine with purification function and use method

PendingCN113230797AImprove safety and environmental performanceDamage reductionCombination devicesWelding/cutting auxillary devicesProcess engineeringFlue gas

The invention discloses a medical equipment circuit board maintenance spot welding machine with a purification function, and the spot welding machine comprises a spot welding machine body; a movable workbench is arranged on the spot welding machine body, one side of the movable workbench is connected with a flue gas collecting and purifying mechanism, and the flue gas collecting and purifying mechanism comprises a flue gas purifying box. The side, close to the movable workbench, of the flue gas purification box is connected with a flue gas conveying pipe, a flue gas collecting mechanism is connected between the flue gas conveying pipe and the movable workbench, a dust removal purification mechanism is arranged in the flue gas purification box, and the dust removal purification mechanism is matched with the flue gas collecting mechanism. The corresponding smoke collecting and purifying mechanism is additionally arranged on the spot welding machine, smoke generated in the using process of the spot welding machine can be purified and filtered, the safety and environmental protection performance of the spot welding machine in the using process is remarkably improved, damage to the body health of operators is greatly reduced, the welding quality of the spot welding machine is improved, and the using effect of the spot welding machine is improved.

Owner:芮文礼

Printing ink of woven bag and processing technology thereof

The invention discloses a printing ink of a woven bag, wherein the printing ink is prepared from the following raw materials in parts by weight: 30-40 parts of polyurethane-polyacrylate, 20-25 parts of ethanol, 10-15 parts of a pure acrylic emulsion, 8-10 parts of nano cellulose, 6-9 parts of a non-toxic pigment, 6-9 parts of water-borne wax, 1-3 parts of a defoaming agent, 1-3 parts of a macromolecular dispersant, and 0.5-1 part of nano Au25(SCH2CH3)18 clusters. The invention also discloses a processing technology of the woven bag, wherein the processing technology includes the steps: (1) preparing a resin solution; (2) preparing a coarse material color paste; (3) fully grinding the coarse material color paste to obtain a small-fineness colloidal liquid; (4) preparing a printing ink finished product; and (5) filtering. The polyurethane-polyacrylate non-toxic to human bodies is used as a graft material, ethanol is used as a solvent, the non-toxic and harmless pure acrylic emulsion andthe non-toxic pigment are added, and a printed product has no pungent smell and has high safety and environmental protection performance. The printing ink prepared by the printing ink formula and thepreparation technology has the advantages of uniform particle size, small fineness, excellent initial dry performance, and stable and excellent coloring strength and friction coefficient.

Owner:安徽省临泉县万隆塑料包装有限公司

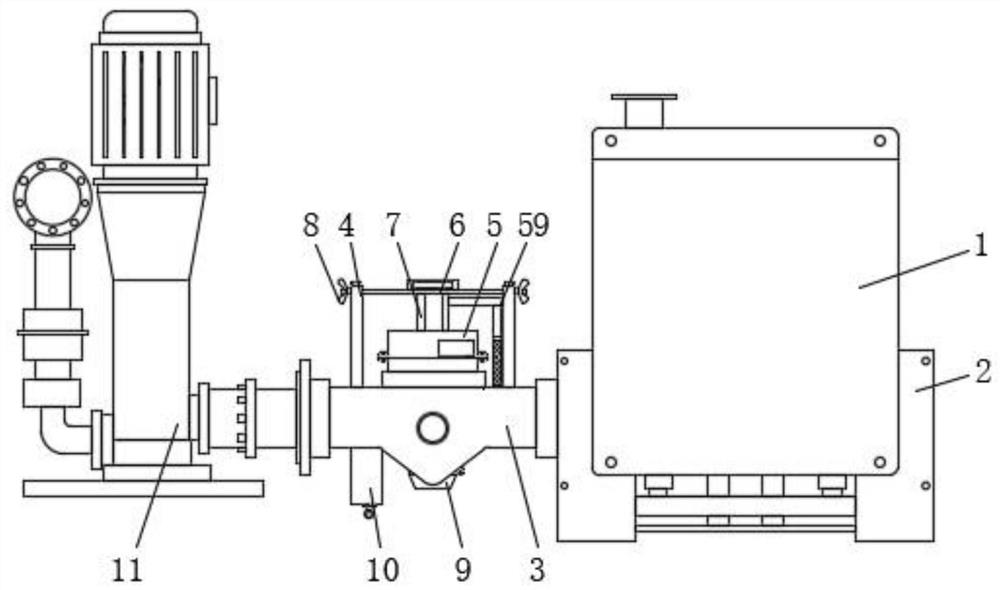

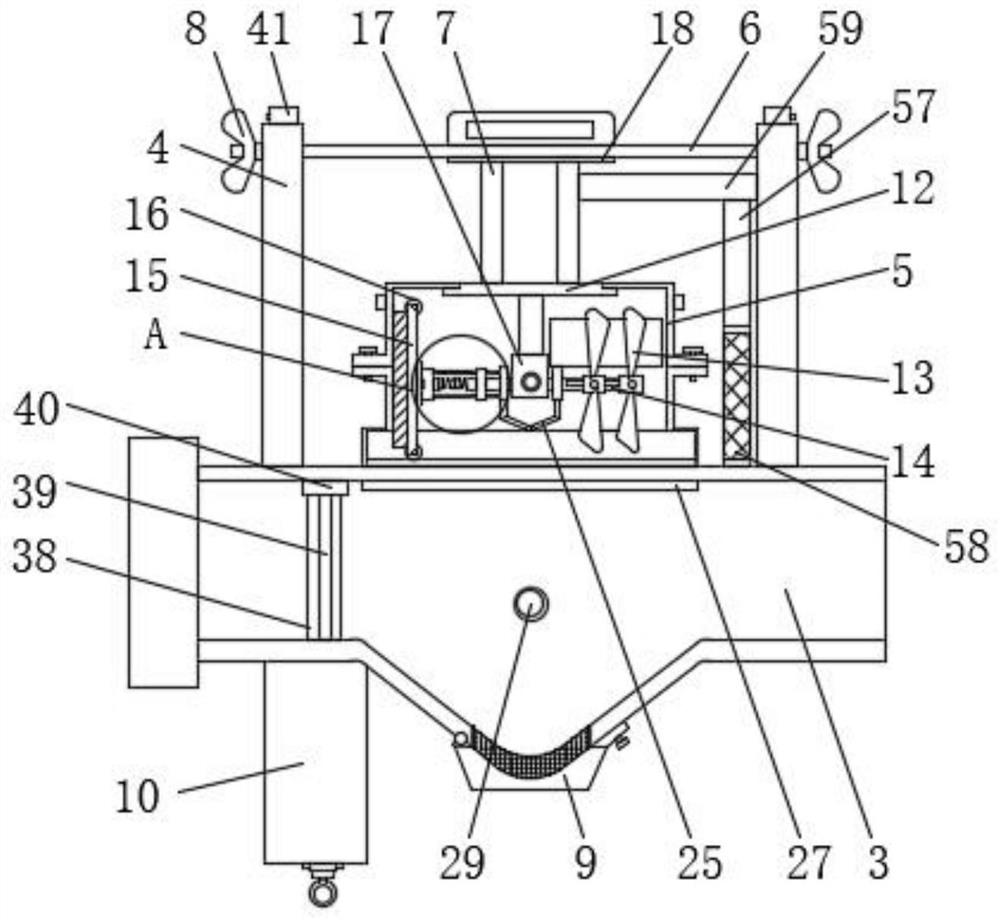

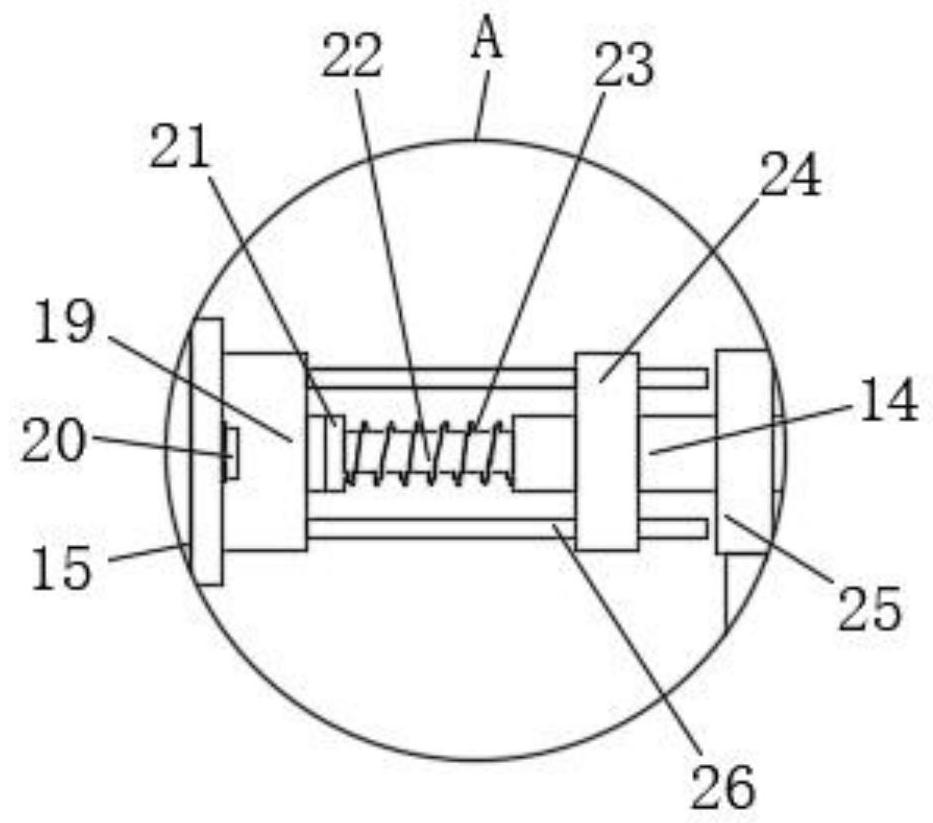

Water tank constant-pressure water supply device

InactiveCN112922080AContinuous filtrationEase of containmentHollow article cleaningWater supply tanksWater storage tankWater flow

The invention discloses a water tank constant-pressure water supply device, and particularly relates to the technical field of water supply devices. The water tank constant-pressure water supply device comprises a water storage tank, wherein the bottom end of the water storage tank is fixedly connected with a supporting seat; and a water outlet of the water storage tank communicates with a water supply mechanism through a flow guiding main tube. When the water tank constant-pressure water supply device needs to be cleaned, a hollow rotating shaft descends, a propeller blade is driven to rotate under the effect of water flow, a cleaning scraper and a bottom brush are driven to rotate to automatically clean water scale, when the hollow rotating shaft descends, a side cross rod is driven to descend synchronously, a pressing plate drives a primary filter plate to enter the flow guiding main tube, meanwhile, by a movable rod and a damping spring, the propeller blade is accommodated in a storage box conveniently, in the mode, power is provided by water flow to drive a cleaning structure to automatically clean the water scale, in a cleaning process, continuous filtering of the water flow is ensured, the circumstance that the water scale is accumulated in the equipment to affect the equipment is prevented, the cleaning structure has an integral accommodating function, and stability is provided for constant-pressure water supply of the equipment.

Owner:凌池英

Aqueous acrylic water-resistant road marking coating and preparation method thereof

InactiveCN111205726AImprove safety and environmental performanceGood acid resistanceAnti-corrosive paintsMaleic anhydrideAcrylic acid

The invention provides an aqueous acrylic water-resistant road marking coating. The coating is prepared from the following raw materials in parts by weight: 100-200 parts of modified acrylic resin, 1-3 parts of diacetone acrylamide, 1-3 parts of adipic dihydrazine, 5-10 parts of neopentyl glycol, 10-15 parts of maleic anhydride, 3-7 parts of adipate, 10-20 parts of a coalescing agent, 5-10 parts of a dispersing agent and 5-10 parts of a defoaming agent. The preparation method is simple, and the prepared coating is an aqueous coating, has good environmental friendliness and low VOC emission, also has good gloss retention, water resistance, acid resistance and chemical corrosion resistance, can form a film quickly, finely and uniformly, has good strength and mechanical properties after filmforming, and has a wide application prospect.

Owner:王春林

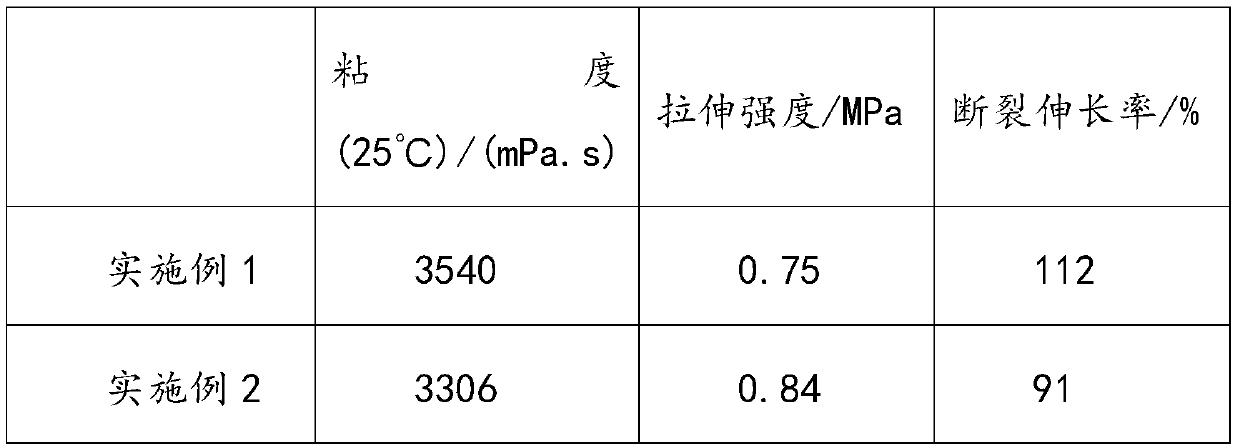

One-component silane-modified polyether sealant composition, sealant and preparation method thereof

ActiveCN108795360BGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesPolyether adhesivesEndcappingPolymer science

The invention relates to the field of high molecular sealing materials and discloses a single-component silane modified polyether sealant composition and a sealant prepared from the single-component silane modified polyether sealant composition. The single-component silane modified polyether sealant composition disclosed by the invention is prepared from silane modified polyether resin, alkoxy terminated polydimethylsiloxane, a plasticizing agent, reinforcing filler, a water removal agent, a light stabilizing agent, an ultraviolet absorbent, a coupling agent and a catalyst. The sealant disclosed by the invention has the advantages of good smell, good ageing resistance, high recovery rate and the like.

Owner:浙江中天东方氟硅材料股份有限公司

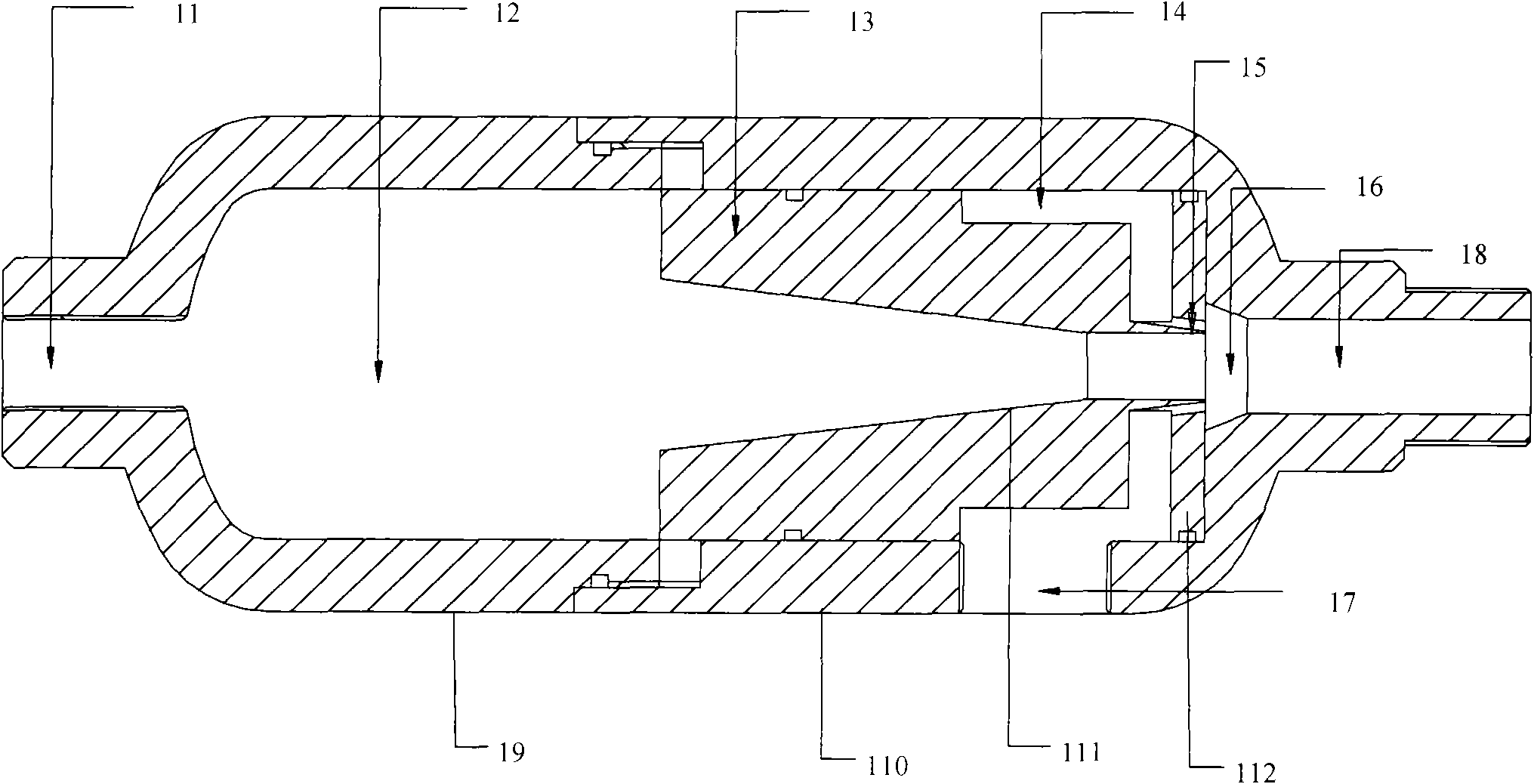

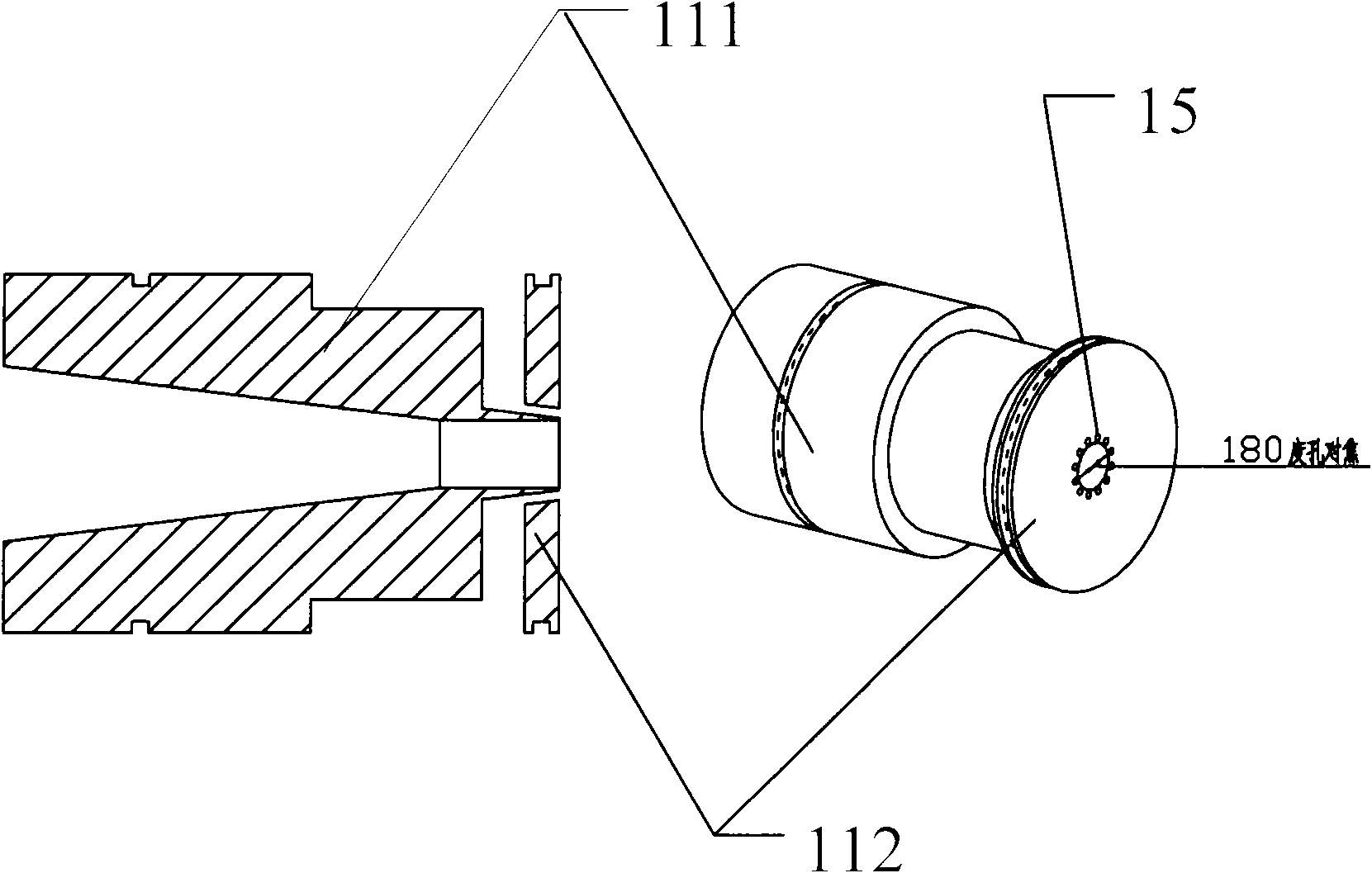

High-pressure cleaning equipment capable of saving water and energy and fusing air and water

InactiveCN101618386BAchieving Driverless DesignPressure safety is more reliableVehicle cleaning apparatusLiquid spraying apparatusWorking pressureHoneycomb

The invention relates to high-pressure cleaning equipment capable of saving water and energy and fusing air and water, comprising a main installation shell, a cleaning gun, a pressure sensing valve, a main water pump, an air pressure adjusting valve, a plurality of connecting pipes and a honeycomb type Venn high-pressure air-water fusion tank, wherein the main water pump is connected with a waterinlet of the honeycomb type Venn high-pressure air-water fusion tank; the air pressure adjusting valve is arranged on a main air passage of an air pump communicated with the tank; and the shape structures in a honeycomb type Venn integrated exhaust hole in the tank have three kinds of design of an inclined type, a spiral type and a tapered Venn type. The integral cleaning equipment can be controlled to work by a buffer throttling valve and the air pump. The invention establishes a structure for realizing pulse high-pressure cleaning by the fusion of high-pressure air and water, and the working pressure is not too high; the pressure is designed outside an outlet during pulse, the pressure of the tank is safe and reliable, and the non-drive design can be realized. The design scheme has simple structure, convenient installation and use and favorable water and energy saving as well as safe and environmental-friendly capacities, reduces the maintenance cost and improves the use efficiency and the stability of equipment.

Owner:王鹏

A kind of health-care functional fabric for home clothes and its preparation method and application

ActiveCN106427109BImprove antibacterial propertiesLower surface energyCellulosic plastic layered productsArtificial filaments from viscoseFiberPolymer science

The invention relates to the technical field of production of functional fabrics, in particular to a hemp health-care functional fabric for home clothes, including a health-care layer and a base layer; the health-care layer is viscose fiber made of fir and camphor; the The base layer is formed by interweaving warp yarns and weft yarns, the warp yarns are blended yarns of hemp, combed cotton and bamboo fiber, and the weft yarns are hemp, carbon fibers and pure cotton; the fabric provided by the invention has good hygroscopicity and has Antibacterial, comfortable, cool and other characteristics, it has health care effect on human body.

Owner:山东申士制衣有限公司

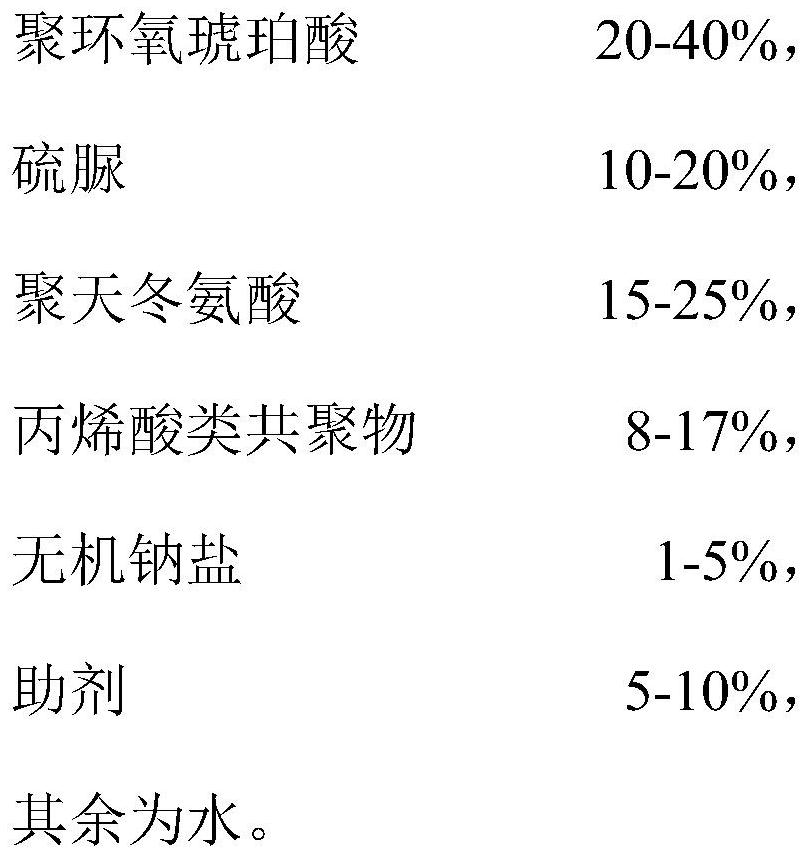

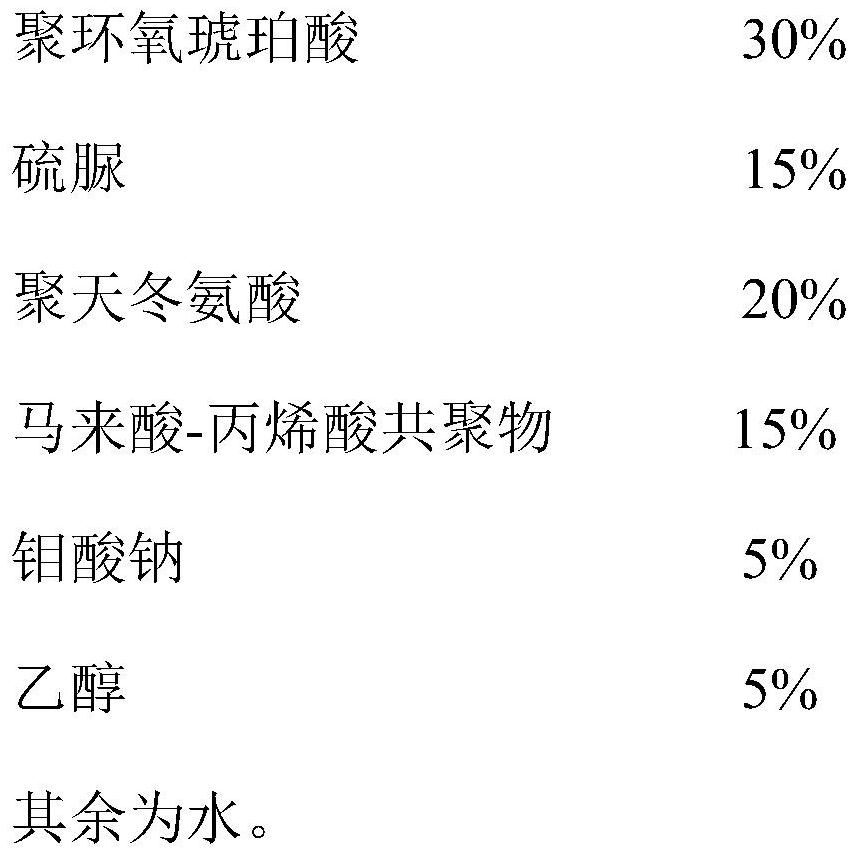

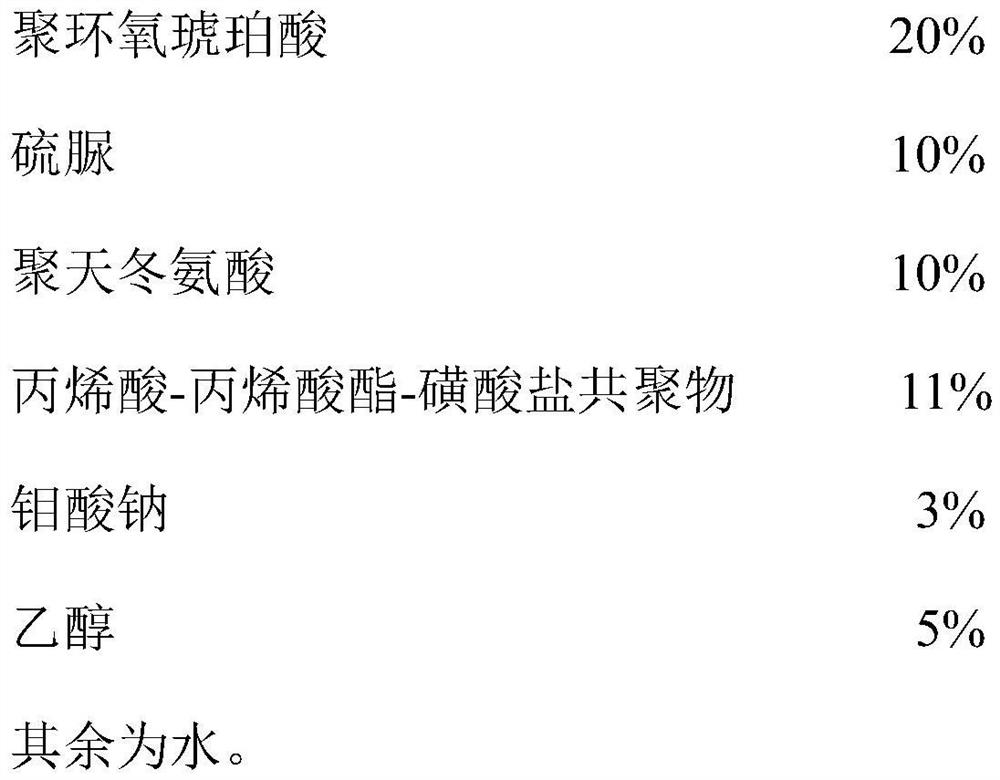

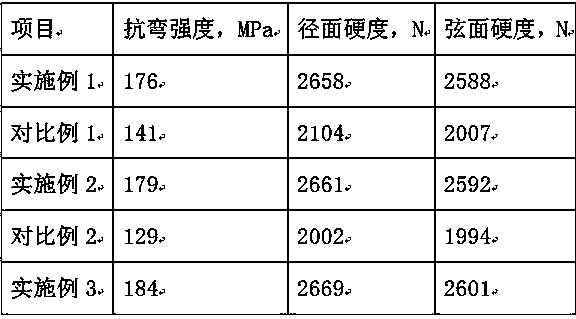

A kind of phosphorus-free slow-release scale inhibitor and its synthesis method

ActiveCN111099752BExcellent slow-release scale and anti-scaling effectImprove solubilityScale removal and water softeningOrganophosphorous compoundsThiourea

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for improving weatherability of outdoor woodware

InactiveCN109354960AImprove permeabilityImprove waterproof performanceAntifouling/underwater paintsPaints with biocidesEthylenediamineGlycidyl methacrylate

The invention discloses a method for improving weatherability of outdoor woodware. The method includes following steps: (1), chipping benzoil trunk, caulis aristolochiae manshuriensis and radix cudraniae, adopting petroleum ether, and extracting to obtain a mixed tree oil finished product; (2), mixing the mixed tree oil finished product, lubricating silicone grease, nano ATO and hafnium oxide to obtain modified mixed tree oil; (3), taking glycidyl methacrylate, methallyl methacrylate and neopentyl diacrylate as monomer to obtain a polymerization emulsion; (4), mixing the polymerization emulsion, the modified mixed tree oil, polydimethylsiloxane, N-octyl diaminoethyl glycine hydrochloride, ethylenediamine sodium propanesulfonate and deionized water to obtain composite paint; (5), grinding the surface of woodware, brushing the composite paint on the surface of the woodware, and naturally airing to obtain the outdoor woodware. The outdoor woodware prepared by the method is good in waterproof performance and illumination-resistant performance and less prone to cracking and color changing when in use.

Owner:界首永恩机电科技有限公司

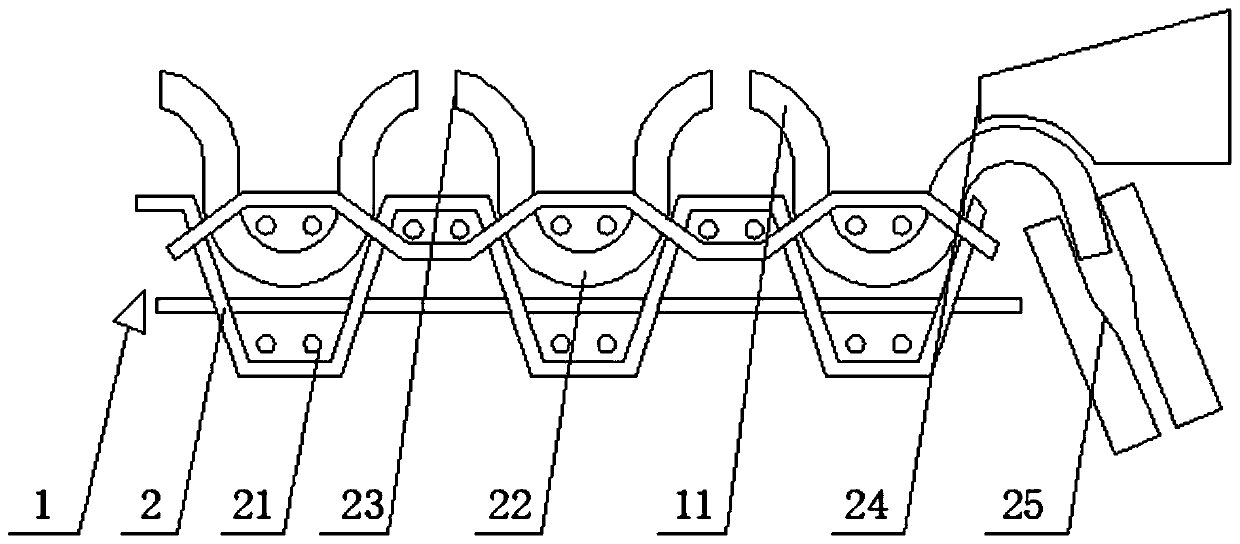

Woven track and weaving method

InactiveCN110039844AImprove structural strengthAvoid affecting utilitySynthetic resin layered productsGround pavingsFiberYarn

The invention discloses a woven track and a weaving method and belongs to the track field. The woven track comprises a track fabric body, wherein a wool yarn layer is arranged on the upper surface ofthe track fabric body, the lower surface of the track fabric body is fixedly bonded with an auxiliary reinforcement layer, flexible rubber connectors are fixedly inlaid in the inner surface of the auxiliary reinforcement layer, flexible rubber balls are fixedly connected with the upper surfaces of the flexible rubber connectors, outer surfaces of the flexible rubber balls are fixedly inlaid in inner gaps of the track fabric body, water-permeable through holes are formed in the auxiliary reinforcement layer, antiskid bulges are arranged on lower surfaces of the auxiliary reinforcement layer, bulge connecting strips are arranged on outer surfaces of the antiskid bulges, and the auxiliary reinforcement layer comprises a polyurethane adhesive layer, a polypropylene ethylene support layer and anylon fiber protection layer. The woven track is easy to produce and process, more convenient and efficient to lay and capable of effectively reducing the use cost.

Owner:日照聚润体育工程有限公司

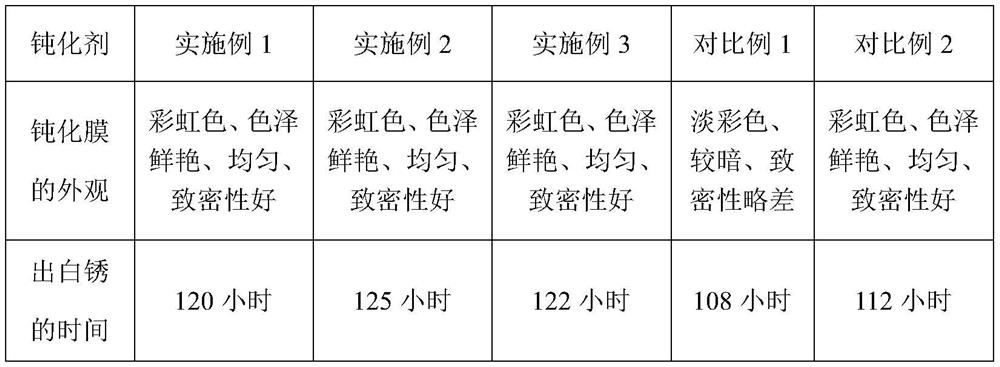

Formula of trivalent chromium colored zinc passivator with strong antirust performance

PendingCN114752925ABright colorEffective protectionHot-dipping/immersion processesMetallic materialsAccelerant

The invention discloses a formula of a trivalent chromium colored zinc passivator with strong antirust performance, which comprises the following raw materials by weight: 5-30 parts of a film-forming agent; 5-20 parts of an organic complexing agent; 5-20 parts of an oxidizing agent; 1 to 10 parts of a film forming accelerant; 0.5 to 2 parts of a metal additive; 1-5 parts of a sealing agent; 20 to 65 parts of deionized water; the film-forming agent comprises soluble trivalent chromium salt. The passivator can form a uniform and compact colored passivation film on the surface of a zinc coating, the passivation film is bright in color and high in corrosion resistance, the zinc coating is effectively protected, then metal materials such as steel and iron are protected, and the antirust performance is high.

Owner:SHENZHEN XINFUHUA SURFACE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com