Anti-radiation carbon fiber heating cable

A technology of carbon fiber heating and radiation protection, applied in the direction of heating element material, heating element shape, etc., to achieve the effect of improving safety and environmental protection performance, good flexibility, not easy to break and crack due to fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

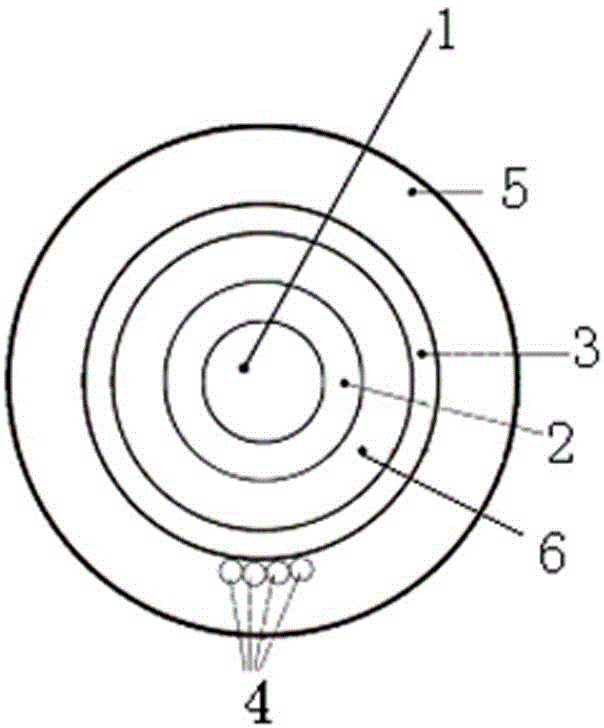

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

[0012] Such as figure 1 As shown, an insulating protective layer is wrapped on the outside of the heating wire harness 1 composed of carbon fibers. The insulating protective layer can be made of a layer of insulating material, and can also be divided into two layers: an inner insulating protective layer 2 and an outer insulating protective layer 6. The inner insulating protective layer Layer 2 is made of polytetrafluoroethylene material, which has toughness and anti-aging. The outer insulating protective layer 6 can be made of polyvinyl chloride material to play the role of insulation again. A conductive plastic layer 3 is wrapped outside the insulating protection layer. Conductive plastics are functional macromolecular materials that are processed by mixing resins and conductive substances in the same way as plastics, which is a prior art. The conductive plastic can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com