Patents

Literature

146results about How to "Leave no gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

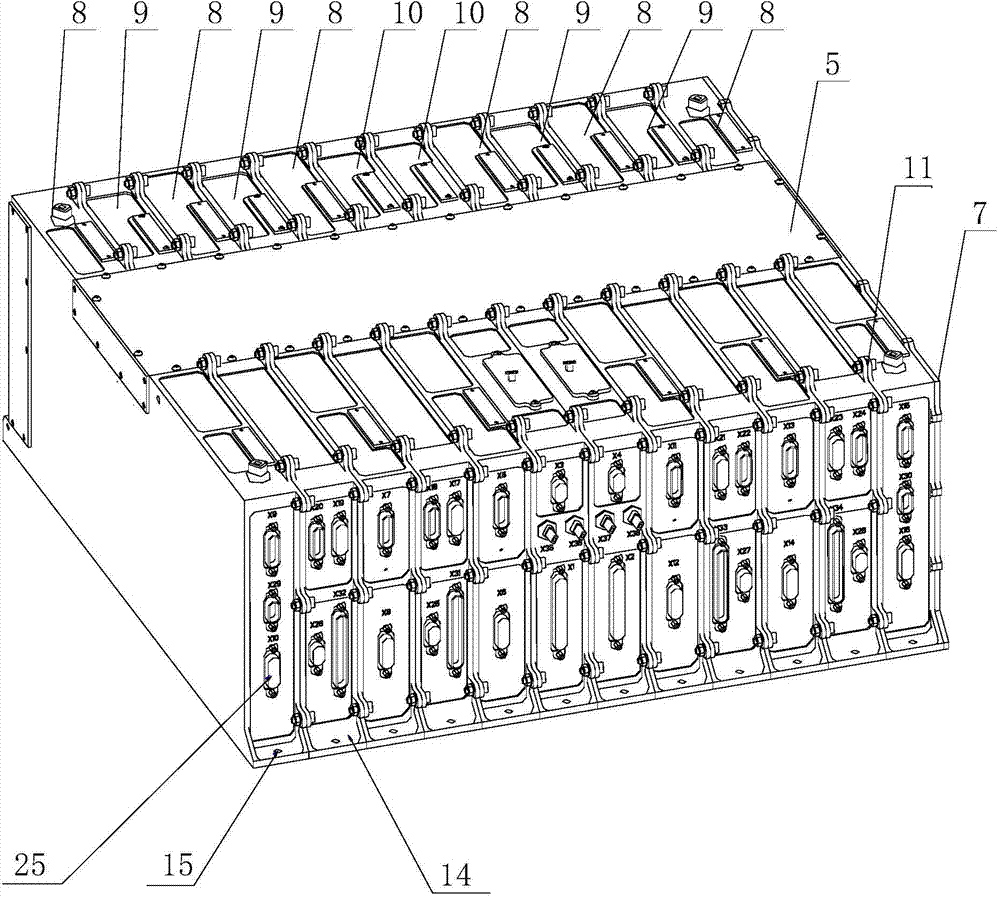

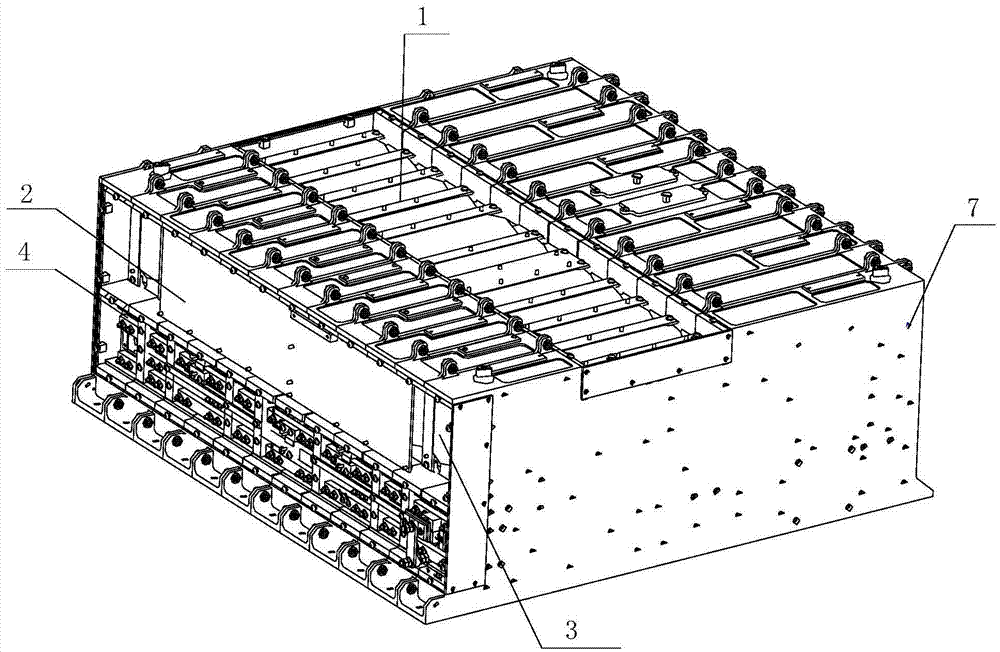

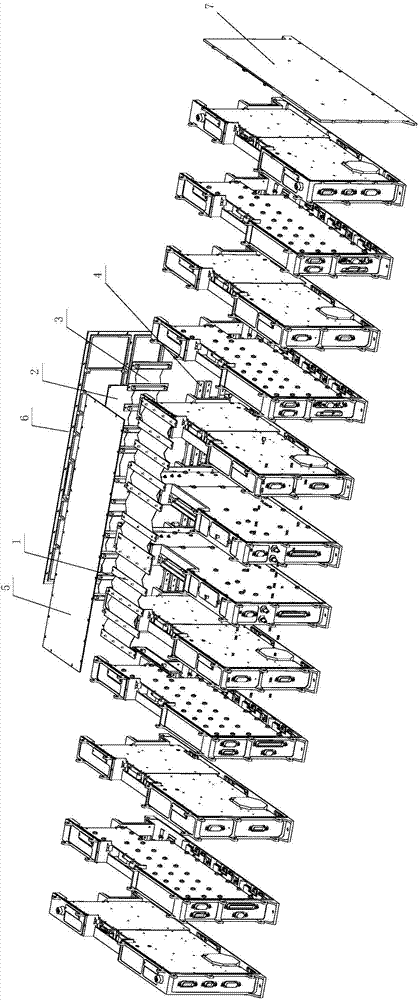

Satellite-borne high-power power conditioning unit platform of extensible structure

ActiveCN103619145AGood mechanical conditionMeet environmental test requirementsMagnetic/electric field screeningCircuit arrangements on support structuresPower controllerRemote control

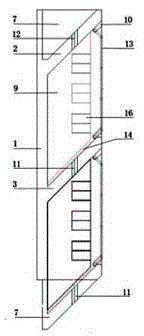

The invention discloses a satellite-borne high-power power conditioning unit platform of an extensible structure. The satellite-borne high-power power conditioning unit platform of the extensible structure comprises a plurality of function modules, remote control and remote measurement flex-rigid printed boards, main error amplifier EMA modules, complete machine bus bars, an upper cover plate, a rear cover plate and side cover plates, wherein the function modules comprises the charge-discharge conditioning modules, the shunt conditioning modules and the remote control and remote measurement modules, the number of the charge-discharge conditioning modules and the number of the shunt conditioning modules are determined according to a power design objective, the main body of each function module is of a wholly-hollowed-out pentahedron structure, the side cover plates are installed after all the function modules are vertically arranged in a stacked mode, every two adjacent function modules are connected with each other through a protruding lug, each remote control and remote measurement flex-rigid printed board is installed in a cavity in the top of the corresponding function module, each error EMA module and each complete machine bus bar are installed in two cavities in the back side of the corresponding function module respectively, and the overall arrangement of the interior of each function module is layered and three-dimensional. The satellite-borne high-power power conditioning unit platform of the extensible structure can meet the environmental testing requirement of satellite-borne electronic equipment and can also meet the heat radiating requirement of a complete machine.

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

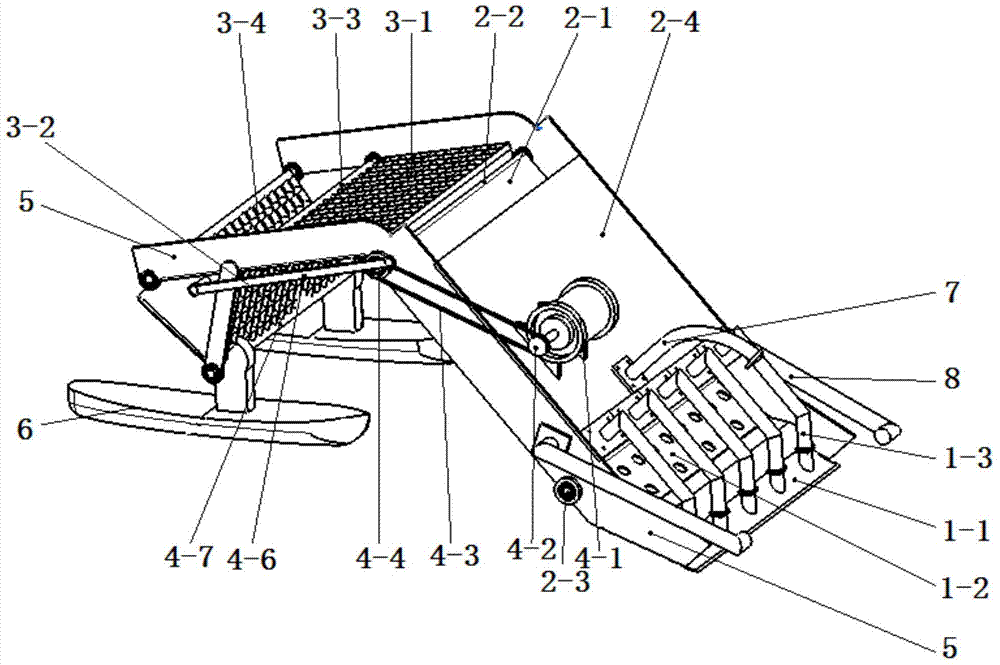

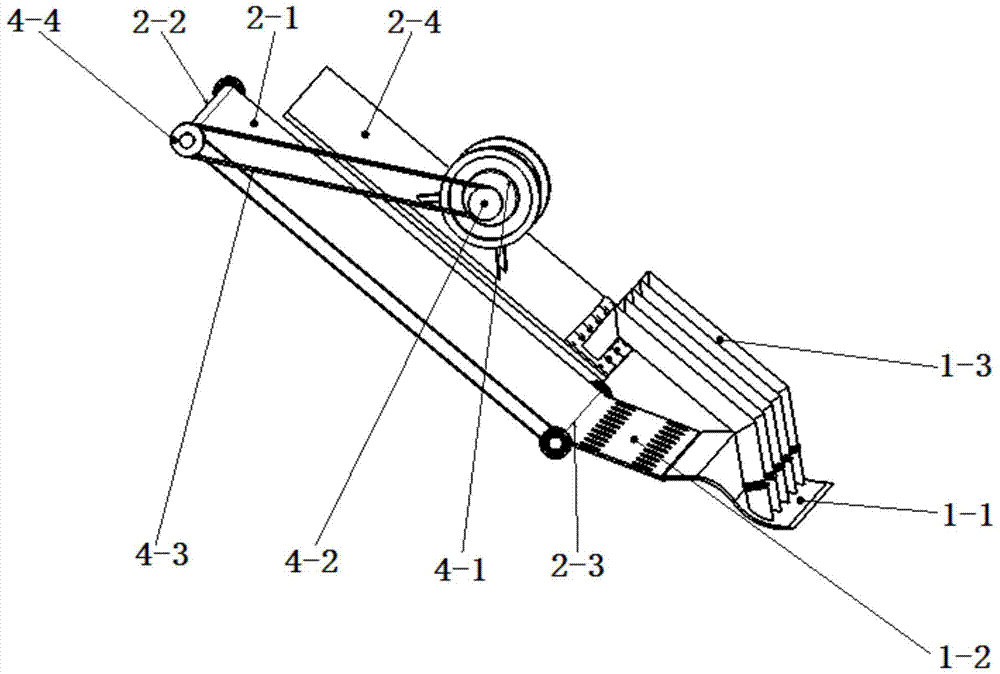

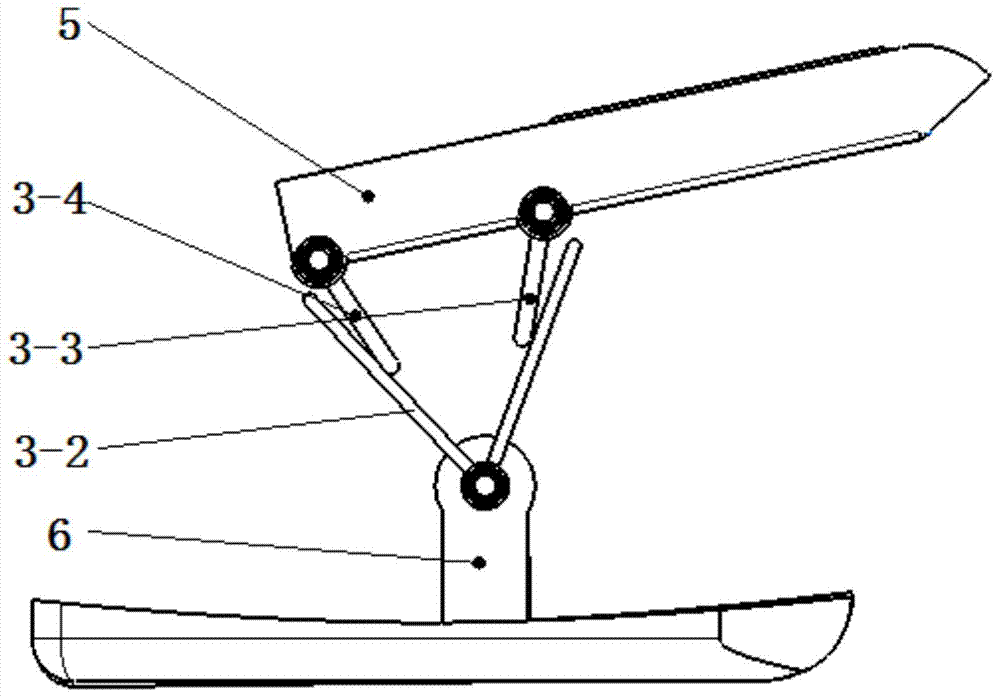

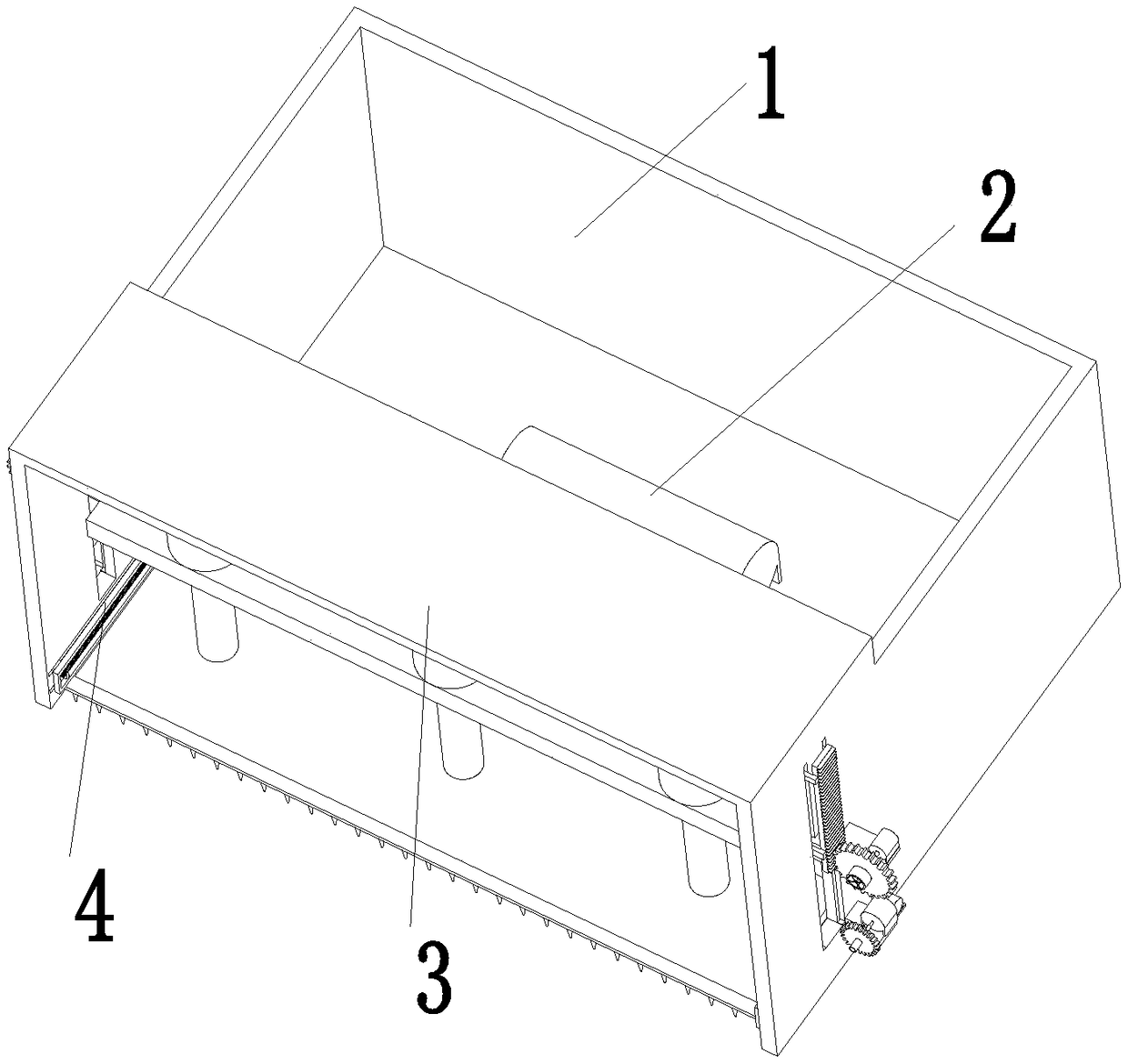

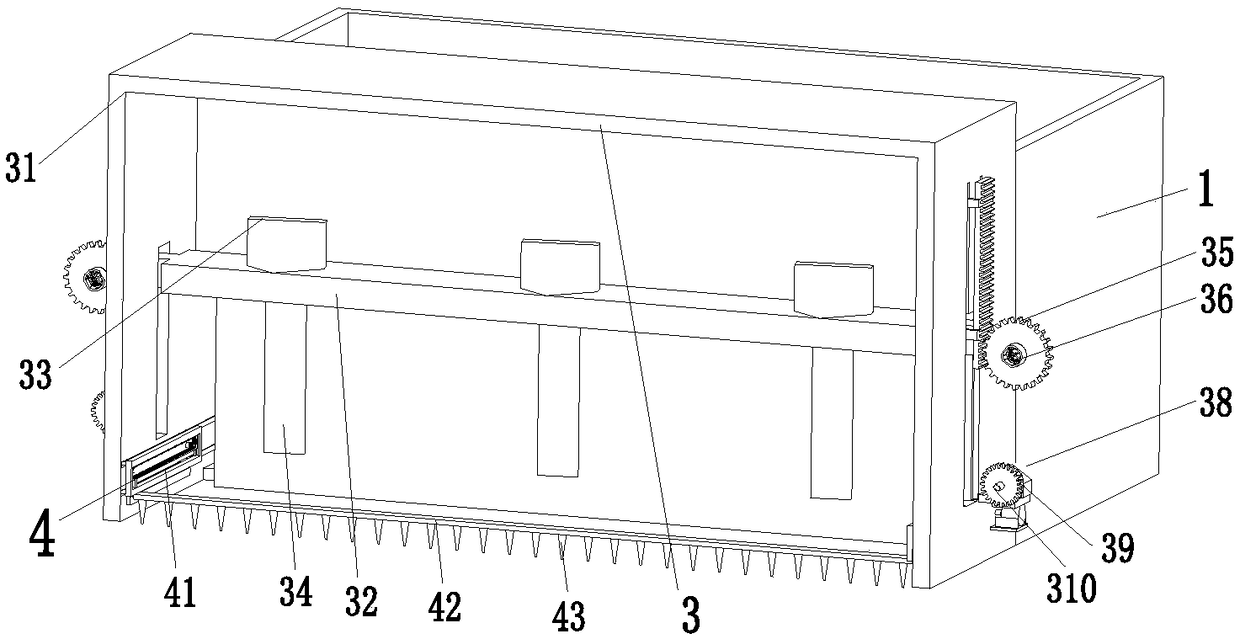

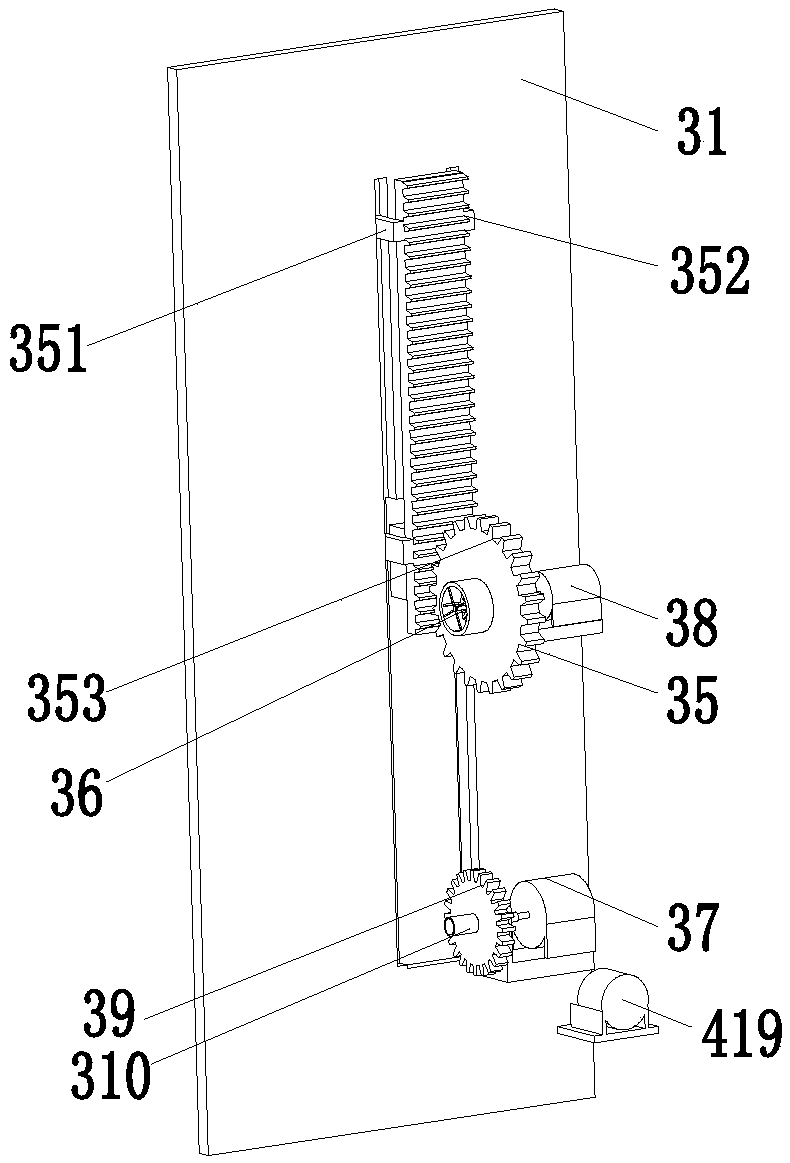

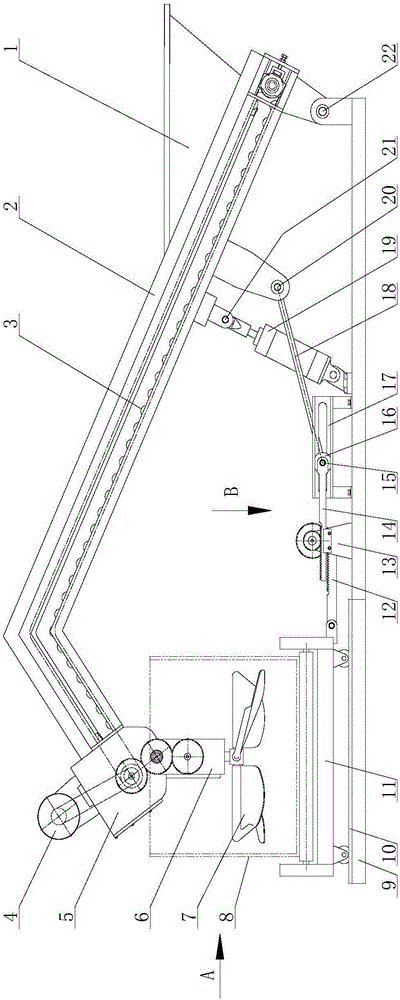

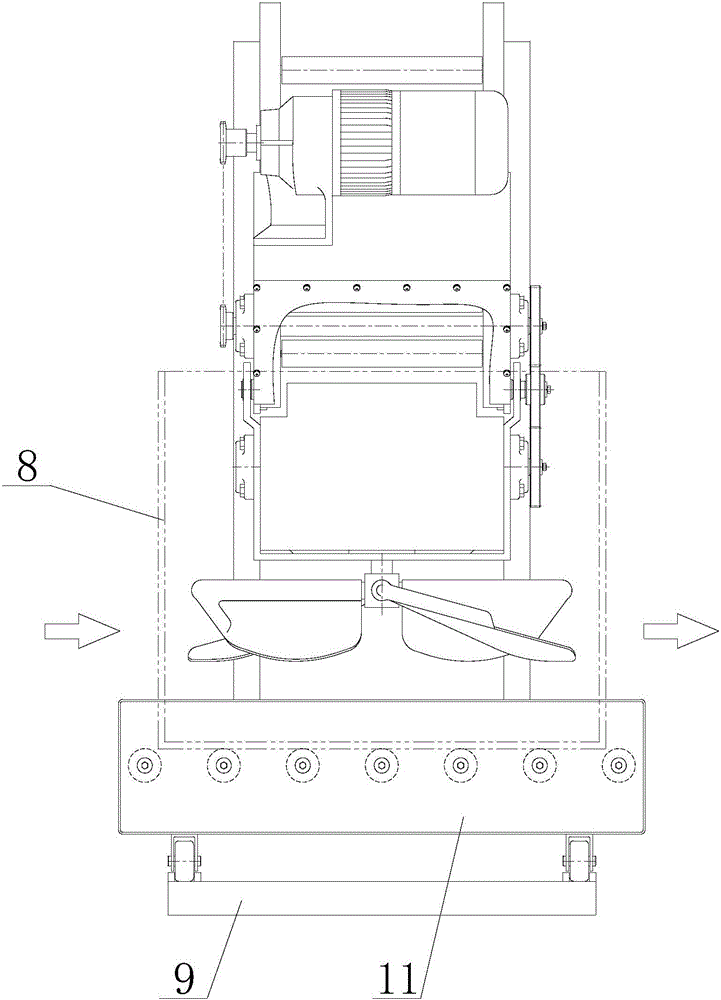

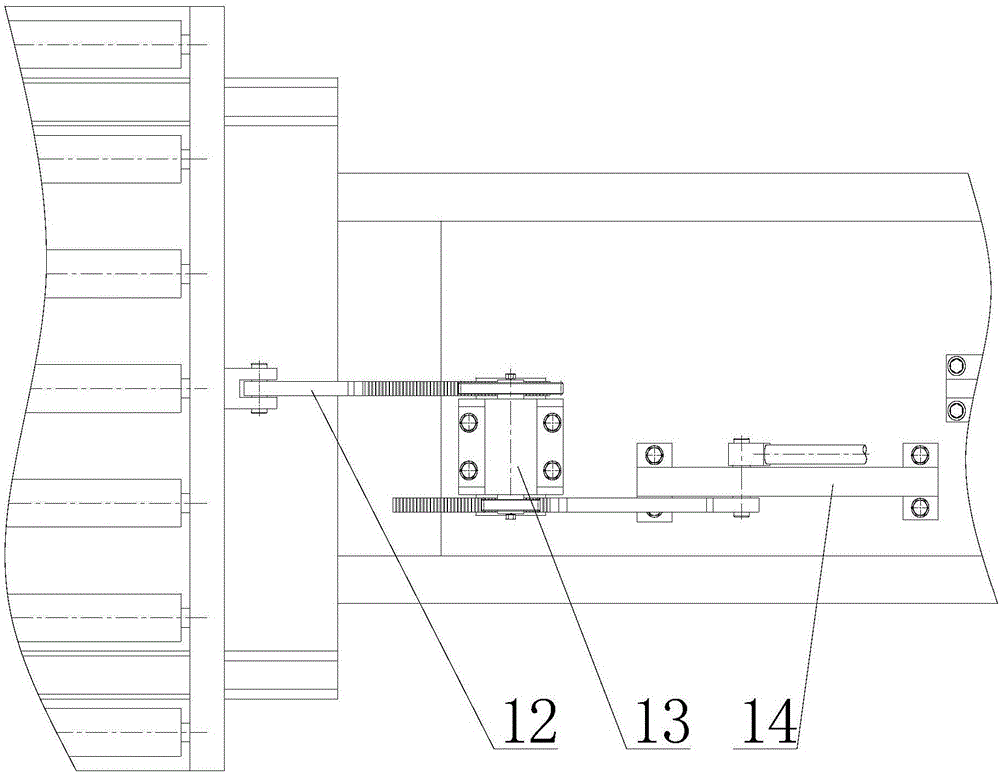

Automatic shellfish collection device

ActiveCN104839106ASimple structureReduce collection costsPisciculture and aquariaMarine engineeringStructural engineering

The invention discloses an automatic shellfish collection device. The automatic shellfish collection device comprises a shoveling device, a diagonal conveying device and a filtering and collecting device. The shoveling device comprises an arc-shaped shovel blade with a low front side and a high rear side, a filtering plate fixedly connected with the rear side of the arc-shaped shovel blade and a plurality of shovel blade connection rods, wherein the front ends of the shovel blade connection rods are fixedly connected with the arc-shaped shovel blade. The diagonal conveying device comprises an upper diagonal driving belt, an upper rolling rod, a lower rolling rod and a an upper stop plate, the upper diagonal driving belt is arranged in rear of the filtering plate, the upper rolling rod and the lower rolling rod are arranged at the upper end and the lower end of the upper diagonal driving belt respectively and drive the upper diagonal driving belt to rotate, and the upper stop plate is arranged above the upper diagonal driving belt. The rear ends of the shovel blade connection rods are fixedly connected with the top of the upper stop plate. The filtering and collecting device comprises a filter screen with a high front side and a low rear side and a V-shaped net cage arranged in rear of the filter screen, and the filter screen is arranged in rear of the upper diagonal driving belt. The automatic shellfish collection device has the advantages of simple structure, low collection cost, high efficiency and low missing rate.

Owner:GUIPING PRODIVITY PROMOTION CENT

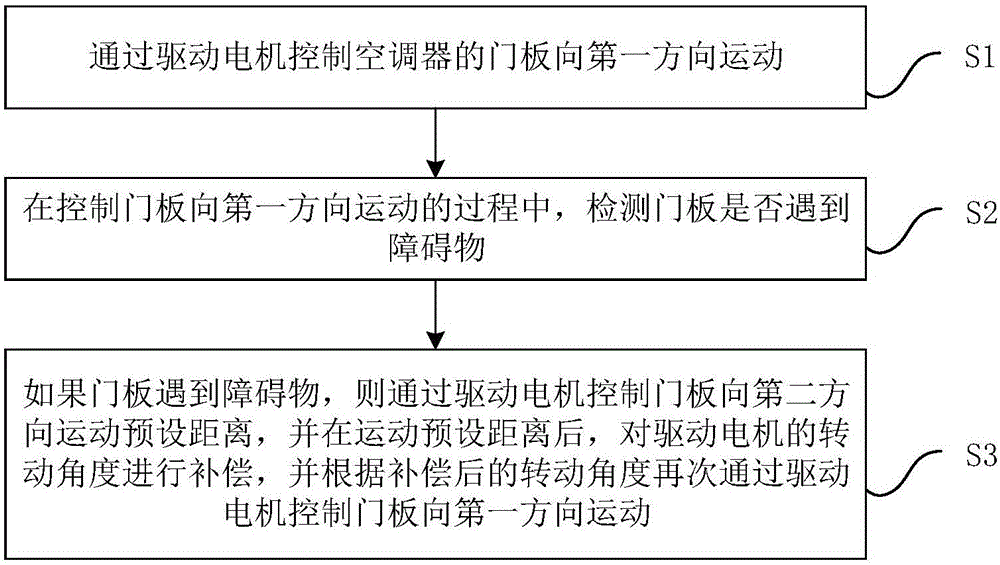

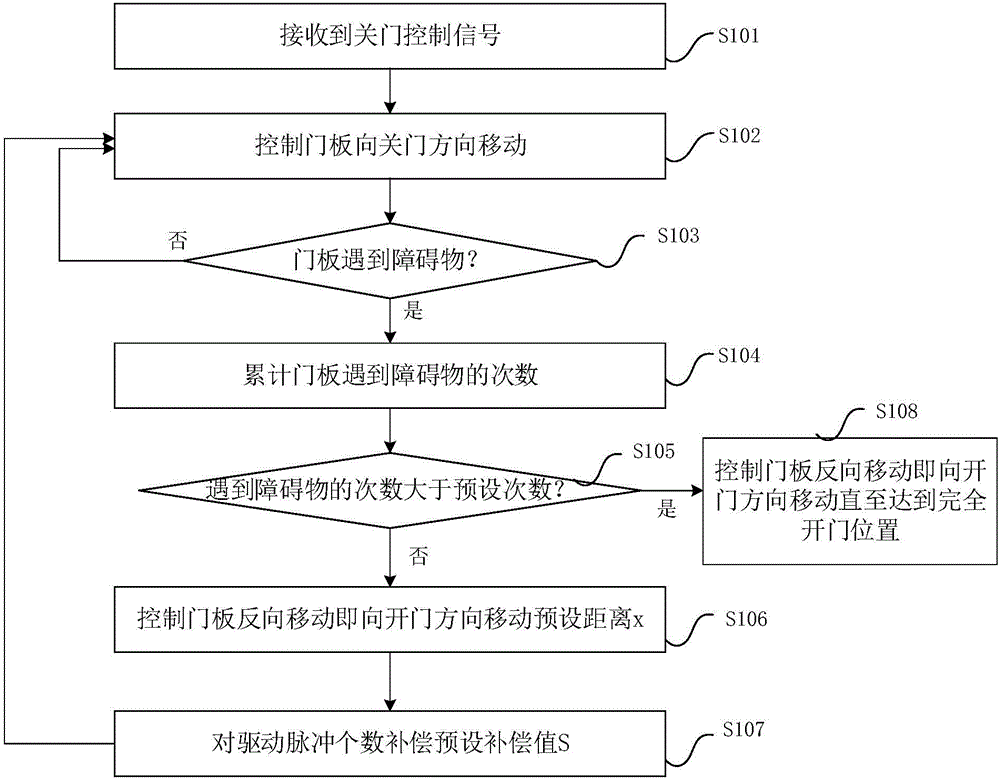

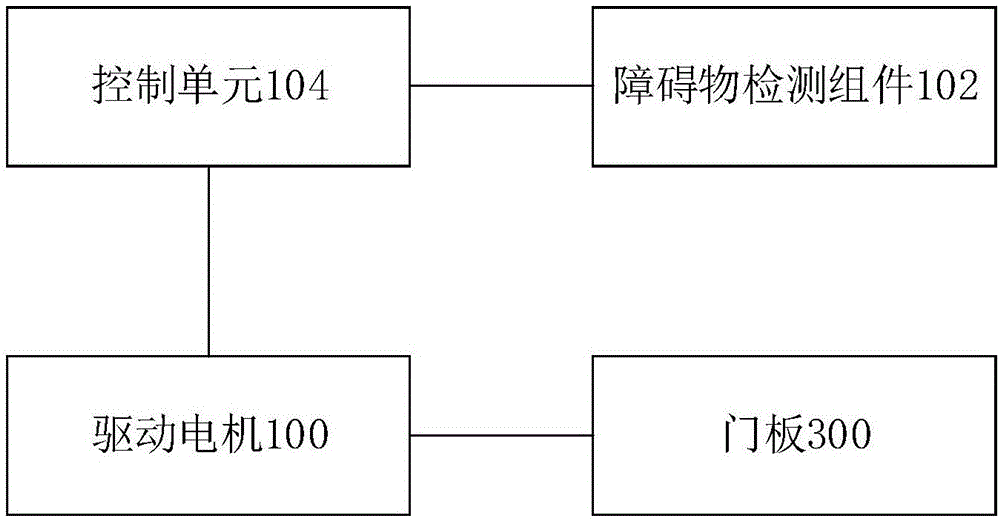

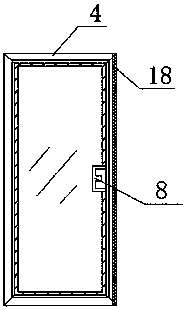

Air conditioner and air conditioner door plank control method and device

ActiveCN106765979AGuaranteed aestheticsImprove experienceMechanical apparatusSpace heating and ventilation safety systemsDrive motorControl theory

The invention discloses an air conditioner and an air conditioner door plank control method and device. The method comprises the steps that the air conditioner door plank control method comprises the following steps that a drive motor is used for controlling a door plank of an air conditioner to move in the first direction; in the process of controlling the movement of the door plank in the first direction, whether the door plank encounters an obstacle or not is detected; and if the door plank encounters the obstacle, the drive motor is used for controlling the door plank to move by the preset distance in the second direction, the rotation angle of the drive motor is offset after the door plank moves by the preset distance, and the drive motor is used for controlling the door plank to move in the first direction again according to the rotation angle obtained after compensation. Accordingly, when it is detected that the door plank encounters the obstacle every time, the rotation angle of the drive motor is offset, it can be guaranteed that after the obstacle is removed, the door plank of the air conditioner can be closed tightly without gaps, the product attractiveness degree is guaranteed, and the experience of users is enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

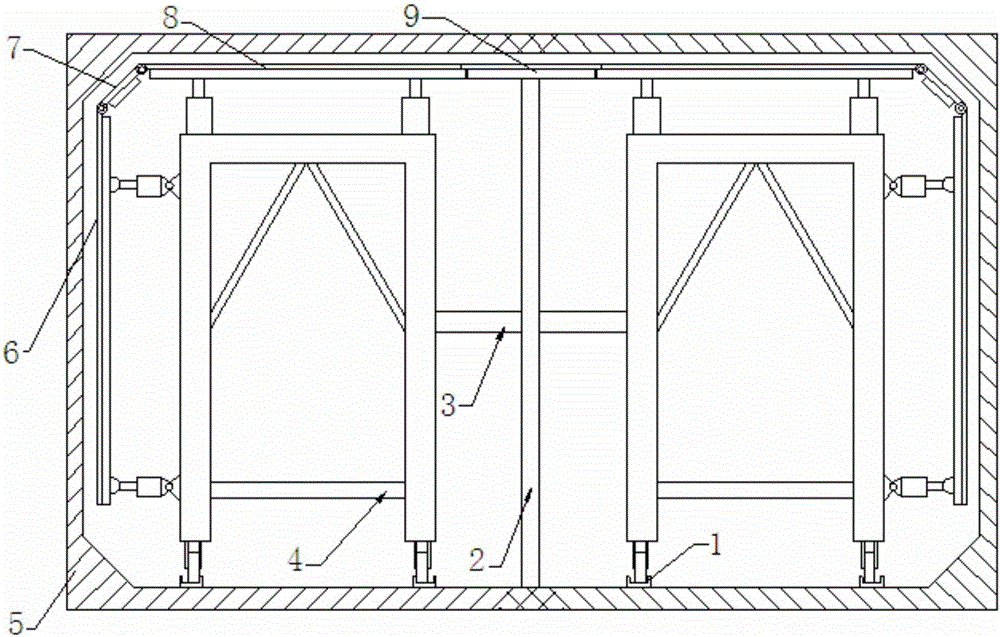

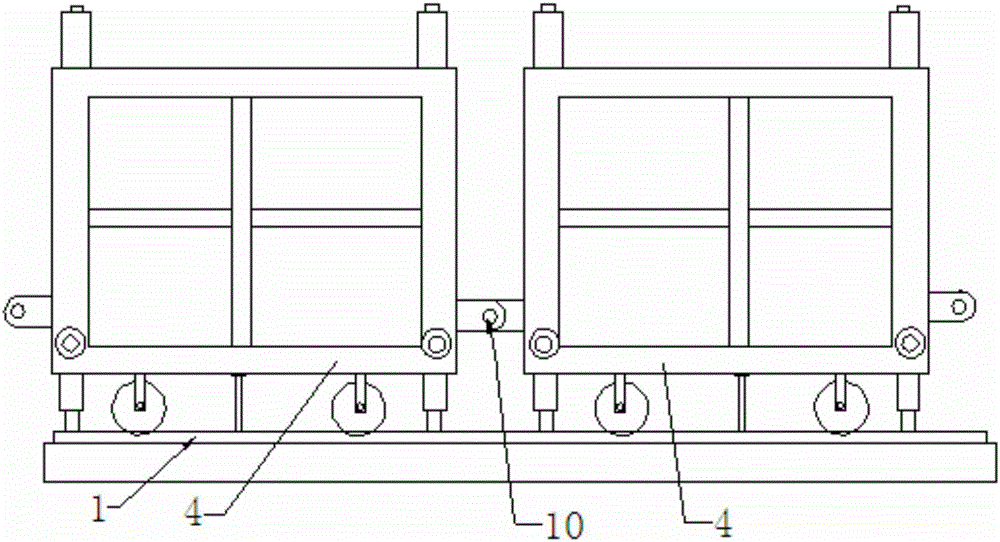

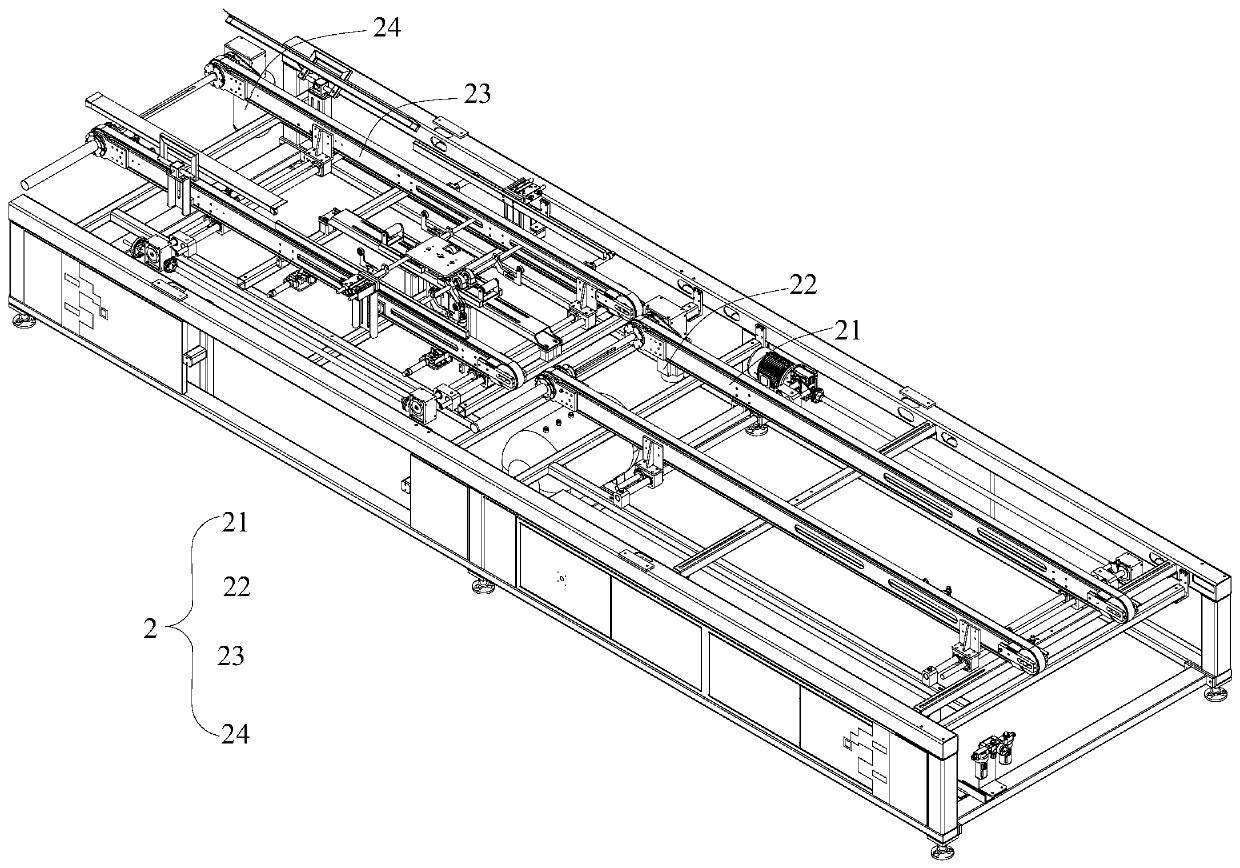

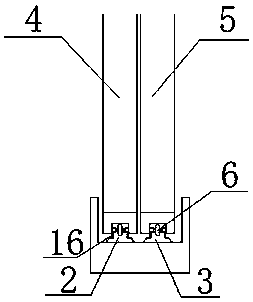

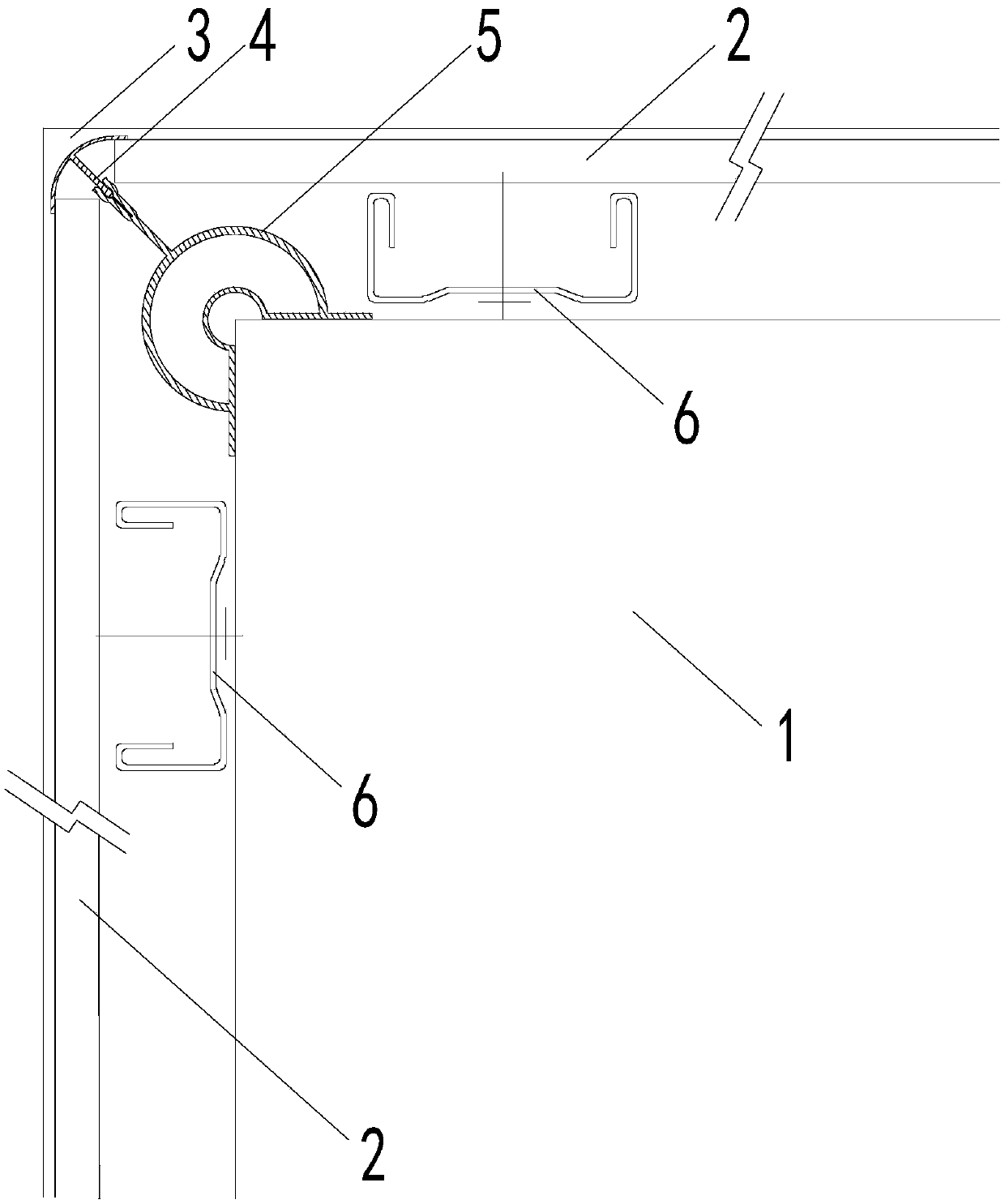

Flow construction method of underground pipe gallery inner mold system

InactiveCN106759487ASmall spanSave time on the moveArtificial islandsUnderwater structuresAutomatic controlUltimate tensile strength

The invention relates to a flow construction method of an underground pipe gallery inner mold system. A pair of mold frame automatic control units is arranged on the same section of a pipe gallery. During construction, after top mold plates, side mold plates and corner mold plates stretch to design positions, an independent early demounting mold plate is mounted at the clearance position of the two top mold plates; complete supporting is formed by the top mold plates, the side mold plates, the corner mold plates and the early demounting mold plate, and pouring is carried out; after concrete reaches certain strength, the top mold plates, the side mold plates and the corner mold plates retract and move to the next work station along with trolleys; and meanwhile, the early demounting mold plate is kept in a supporting state, the early demounting mold plate is demounted after the concrete reaches certain strength, and the demounted early demounting mold plate and the mold frame automatic control units reaching the next work station cooperate to complete subsequent supporting. According to the method, the mold demounting wait time is shortened, the movement and preparation time of the mold frame automatic control units is saved, and repeated utilization is convenient.

Owner:CHINA FIRST METALLURGICAL GROUP

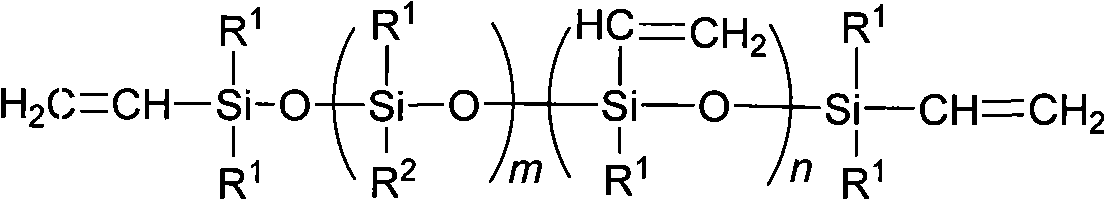

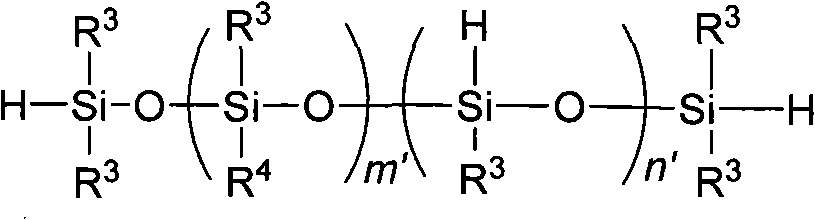

Packaging material applied to light-emitting diode (LED) and preparation method and using method thereof

The invention discloses a packaging material applied to a light-emitting diode (LED), which is characterized by consisting of a pouring sealant body and a thickening primer coating, wherein the thickening primer coating comprises the following components in part by weight: 100 parts of organic solvent; 1 to 20 parts of silicon resin; 0.1 to 30 parts of silane coupling agent and reactive group-containing siloxane and 10<-5> to 4 parts of titanate or platinum complex. In the invention, a condensate obtained after the pouring sealant body is solidified can provide good mechanical protection for the LED; the thickening primer coating has high bonding strength, can enable the pouring sealant body condensate to be adhered to a bracket of the LED reliably, and makes no space between the pouring sealant body condensate and the bracket of the LED, and the adverse influence on the LED because water vapor, oxygen and the like penetrate into the LED in the using process is prevented, so that the packaging material can protect the LED adequately.

Owner:NICHE TECH KAISER SHANTOU

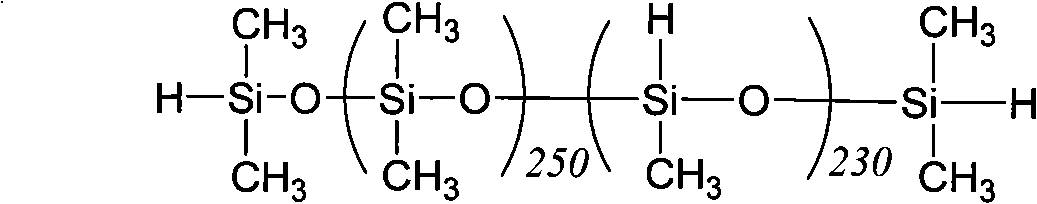

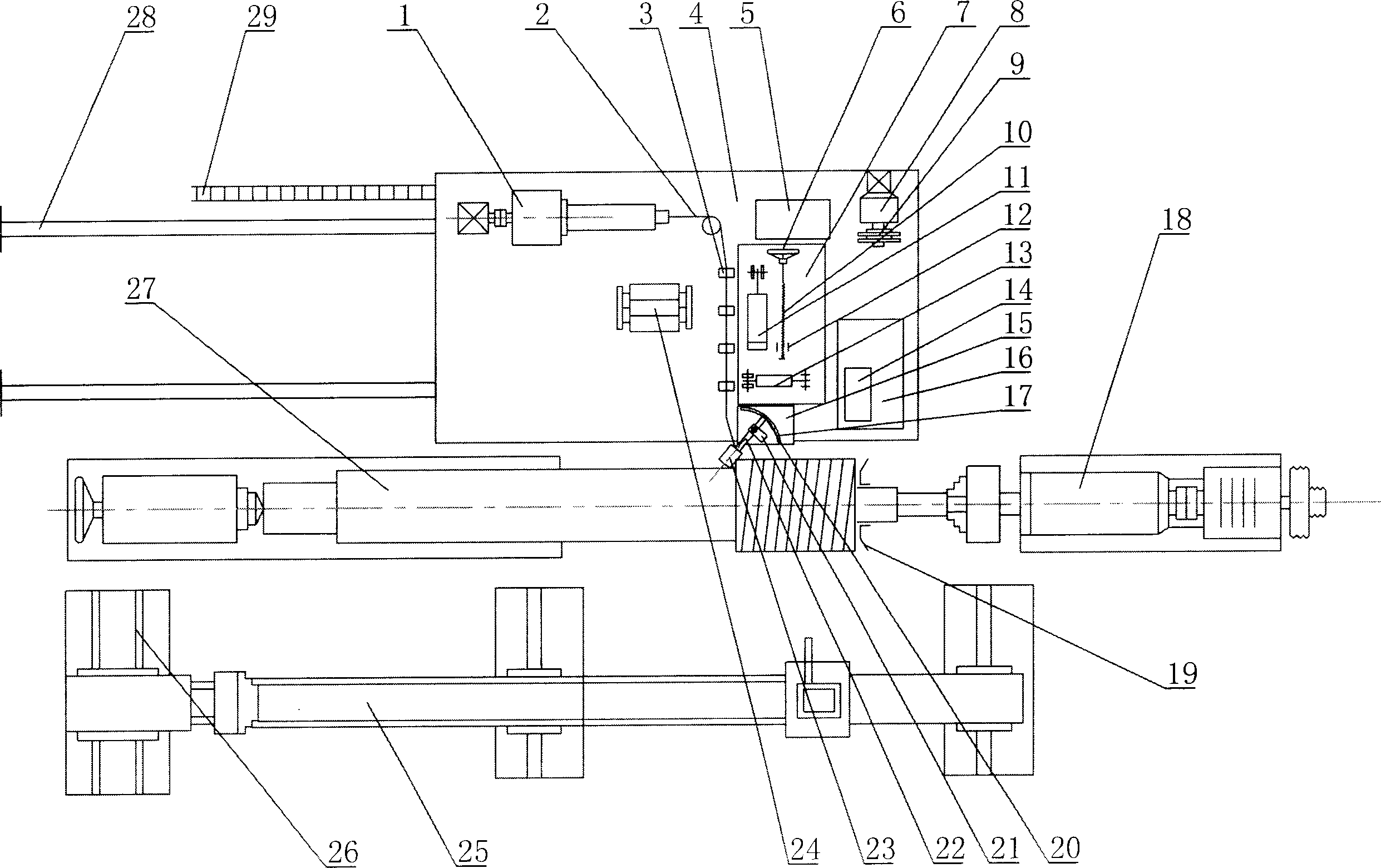

Combined vertical wiring rubber-lined roller device and rubber-lining method

The invention is about the combination vertical wiring rubber-lined roller device and the lining rubber method. It includes the main console, the glue band extruder, the glue band idler roller, the lining roller slewing device, the grinding bed, the glue roller core, the core barrier and the liquid cloth band bind-strike device. It put the glue band extruder, the glue band idler roller, the compacting device, the driving redactor, the driving chain, the change valve group, the oil box, the main console and the liquid cloth band bind-strike device into the moving plate car, the height of the compression roller axis is same as the glue roller core axis. The method is: the glue band is bite between the compression roller and the glue roller core. So it can be fit for all kinds of diameter glue roller cloth.

Owner:ANSHAN HONGTU ANTICORRSIVE ENG

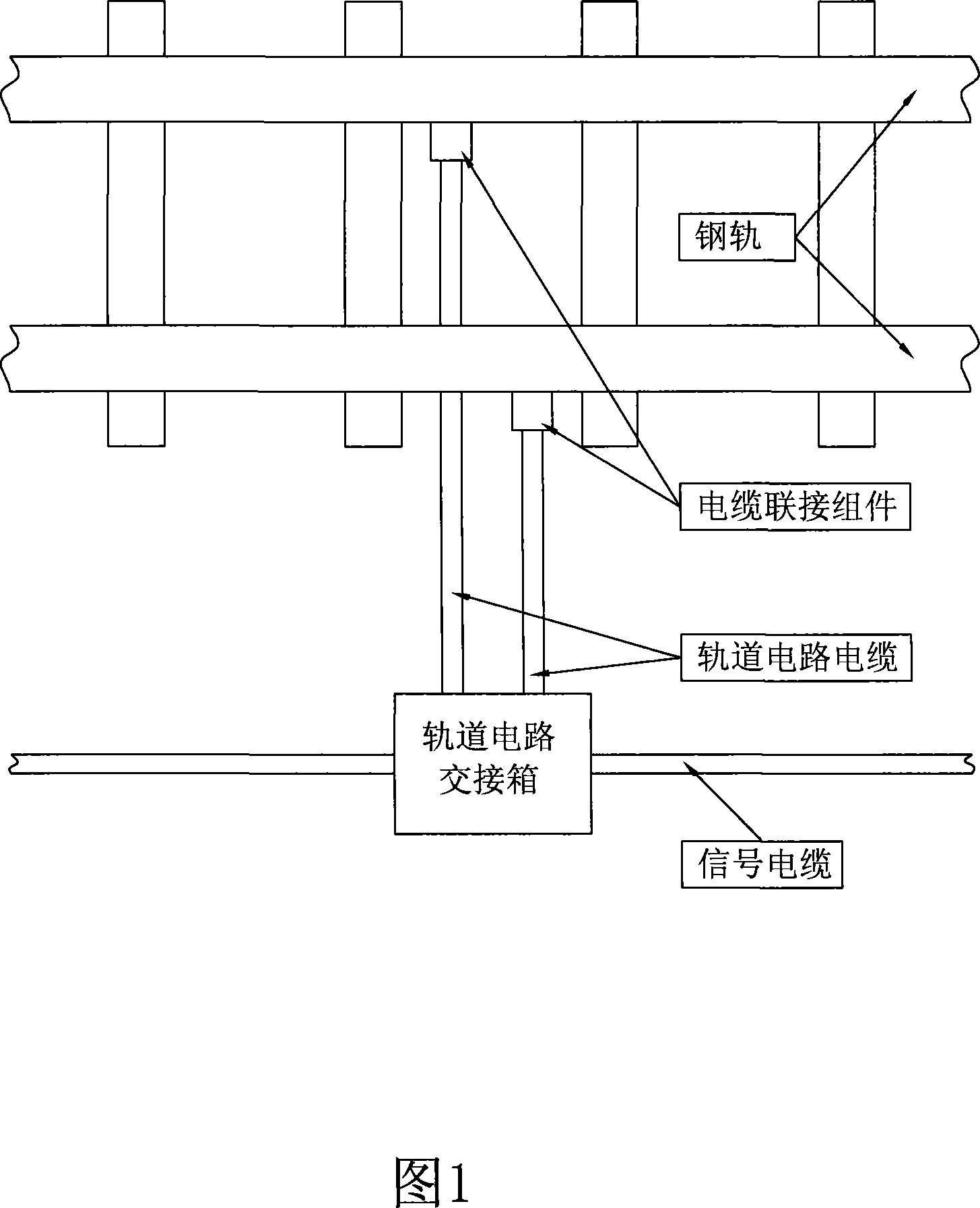

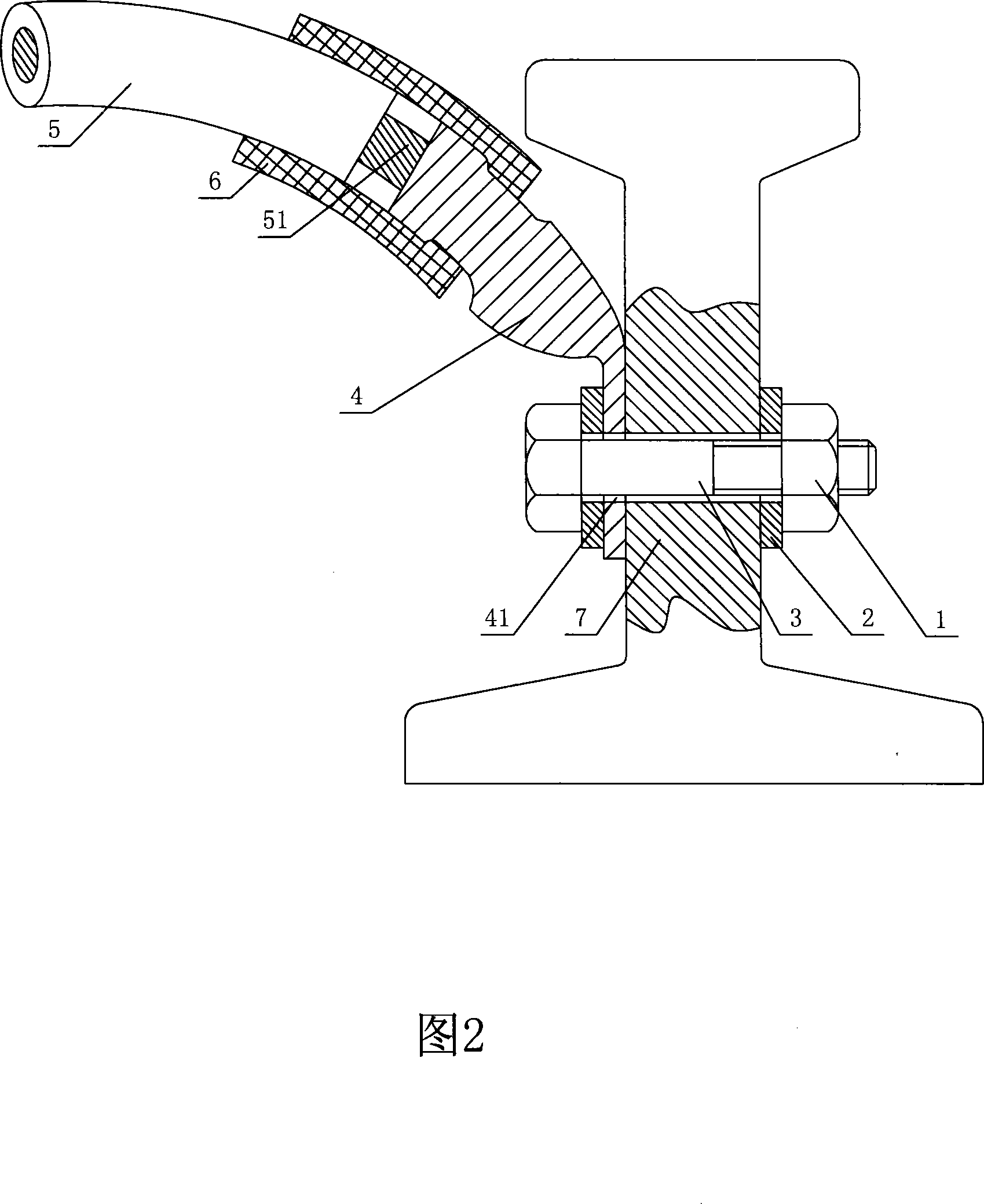

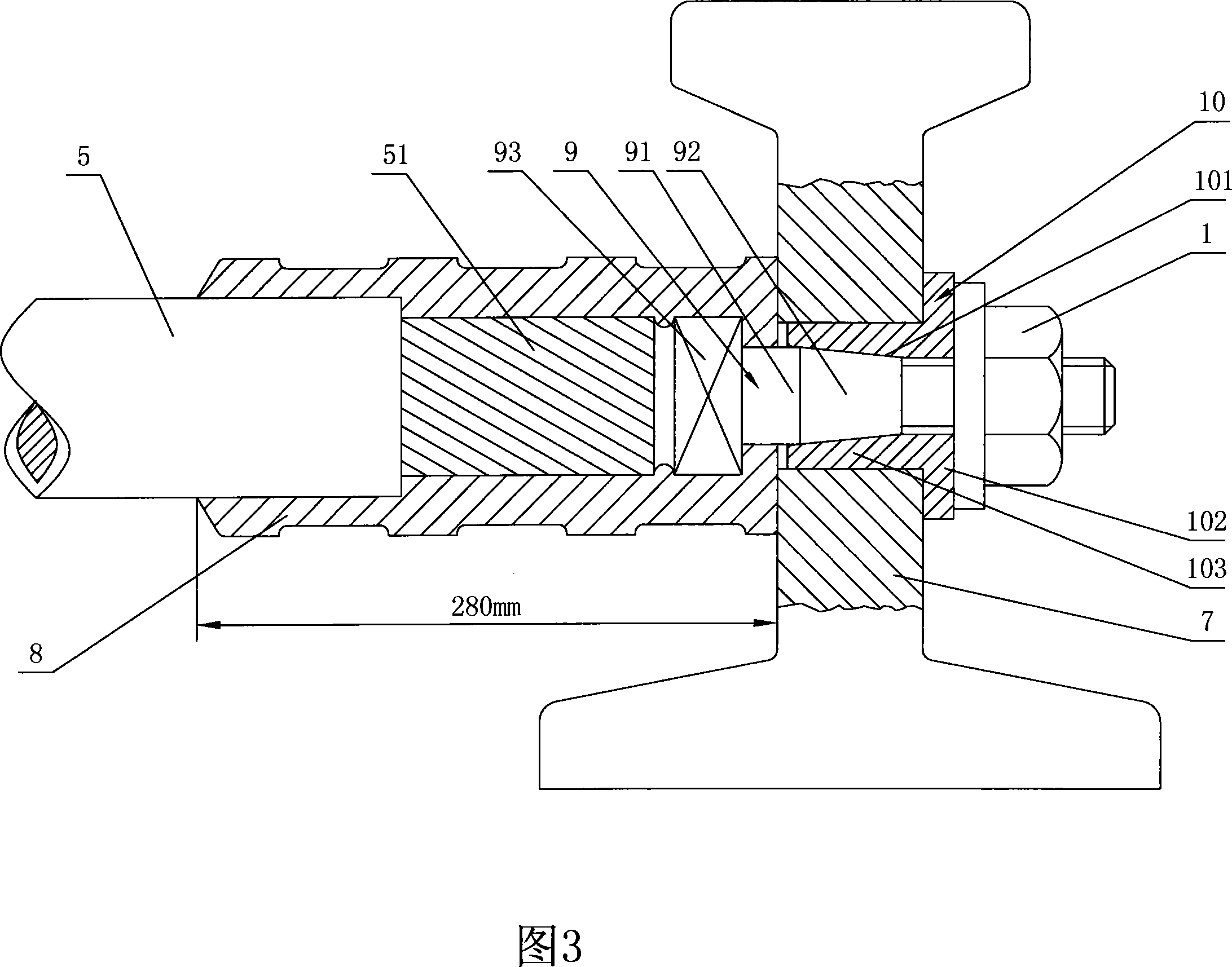

Cable coupling component and method for jointing steel rail with cable using the cable coupling component

ActiveCN101252230ANot easy to rustSoft textureVehicle route interaction devicesElectric connection basesCouplingEngineering

The invention discloses a cable connecting component and a method of connecting cables with rails by using the same. The cable connecting component comprises a tapered bolt of which the head is connected with a track circuit cable and of which a shaft is provided with a cone part with a gradually reduced diameter from the head to the shaft; the cable connecting component also comprises a flexible sheath inserted on a rail web and a taper hole which can accommodate the cone part is arranged on the inner wall of the flexible sheath; one end t of the shaft of the tapered bolt far away from the head is through an inner hole of the flexible sheath, the outer wall of the cone part is held against the inner wall of the taper hole tightly, and the end of the shaft of the tapered bolt far away from the head is also locked with a nut. The cable connecting component and the method enable the tapered bolt, the flexible sheath and the end face of the rail web to stick tightly without gaps, which ensure that the cable connecting component can keep stable metallic performance and be not easy to rust during the long-term application.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

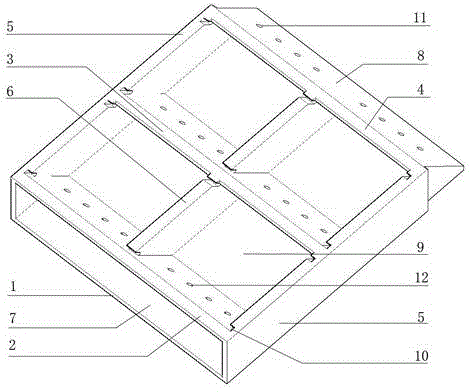

Three-dimensional greening heat-preserving module

InactiveCN104620963ALee growthPromote growthHeat proofingAgriculture gas emission reductionLower borderGreening

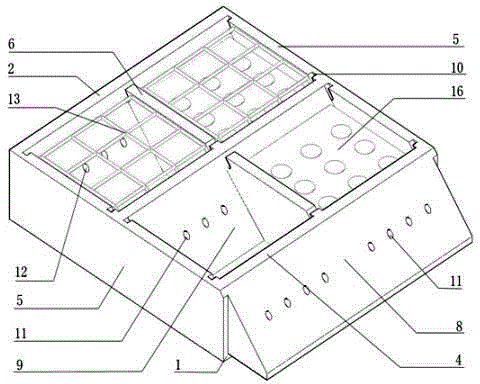

Provided is a three-dimensional greening heat-preserving module. A module body is formed by integrally connecting a bottom plate, an upper border, a lower border, side borders, a transverse partition plate and a longitudinal partition plate, wherein the side borders are vertically arranged on the two sides of the upper surface of the bottom plate, the upper border and the bottom plate are upwards arranged at the upper end of the upper surface of the bottom plate obliquely with an included angle between the upper border and the bottom plate, and the upper border, the side borders and the bottom plate form a wedged bearing and inserting groove; the lower border and the bottom plate are upwards arranged at the lower end of the upper surface of the bottom plate obliquely with an included angle between the lower border and the bottom plate, and the lower border, the side borders and the bottom plate form a wedged bearing and inserting groove; the transverse partition plate and the longitudinal partition plate are arranged in the space defined by the upper border, the lower border, the side borders and the bottom plate in an intersection mode and divide the space into planting grooves arranged in the shape of grids; a plurality of small through holes are formed in the inclined face of the upper border and form drip irrigation holes; a plurality of small through holes are formed in the inclined face of the transverse partition plate and the inclined face of the inclined frame and form overflow holes. The three-dimensional greening heat-preserving module takes the heat-preserving performance and the greening performance of wall both into consideration, construction and watering are convenient, and the purposes of the energy conservation function, the heat preservation function, the fireproof function, the waterproof function, the greening function, the decoration function and other various functions of a building are achieved.

Owner:JINING BLANC STEREO GREENING

Electro-optic compound port machine pony roll high-voltage cable and production method thereof

InactiveCN101546629ASolving Electrical Induction ProblemsRealize optical/electrical functionRubber insulatorsInsulated cablesWaddingEngineering

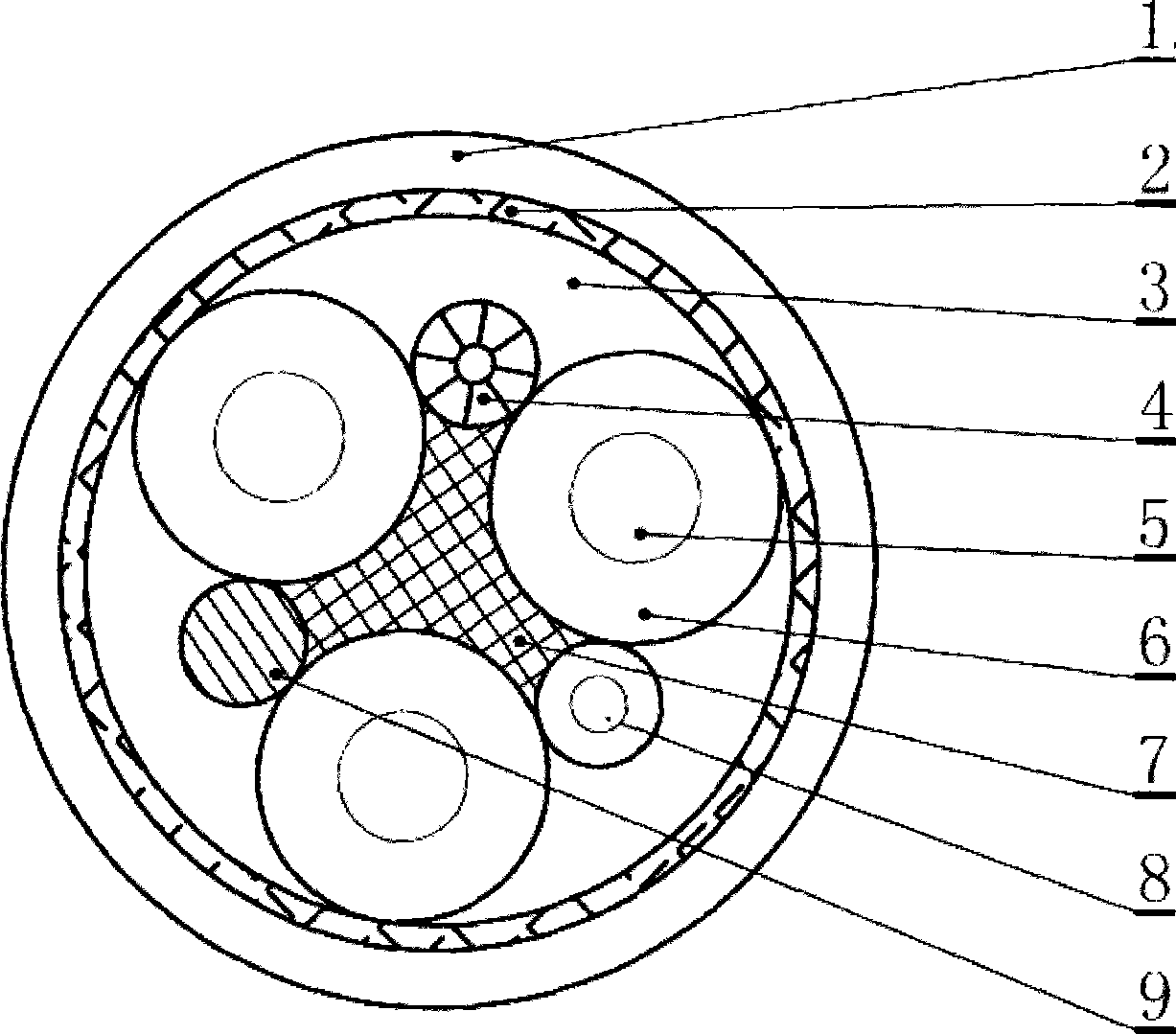

The invention relates to an electro-optic compound port machine pony roll high-voltage cable, which consists of three main high-voltage wire cores, an optical cable, an earthing core, a wadding core, a saddle-shaped skeleton strip, reinforcing layers and an outer sheath. The main high-voltage wire cores, the optical cable, the earthing core and the wadding core are positioned on the saddle-shaped skeleton strip; the optical cable, the earthing core and the wadding core are respectively positioned between two adjacent main high-voltage wire cores of three main high-voltage wire cores; and the reinforcing layer are covered outside the main high-voltage wire cores, the optical cable, the earthing core and the wadding core. A liner layer is filled in the interstice in the reinforcement layer, the outer sheath is arranged outside the reinforcing layer; in addition, the invention also relates to a method for producing the cable. The cable of the invention has the characteristics of no electric induction, less space occupation and long service life.

Owner:SHANGHAI NANYANG ELECTRICAL APPLIANCE

Porcelain cross arm insulation baffle

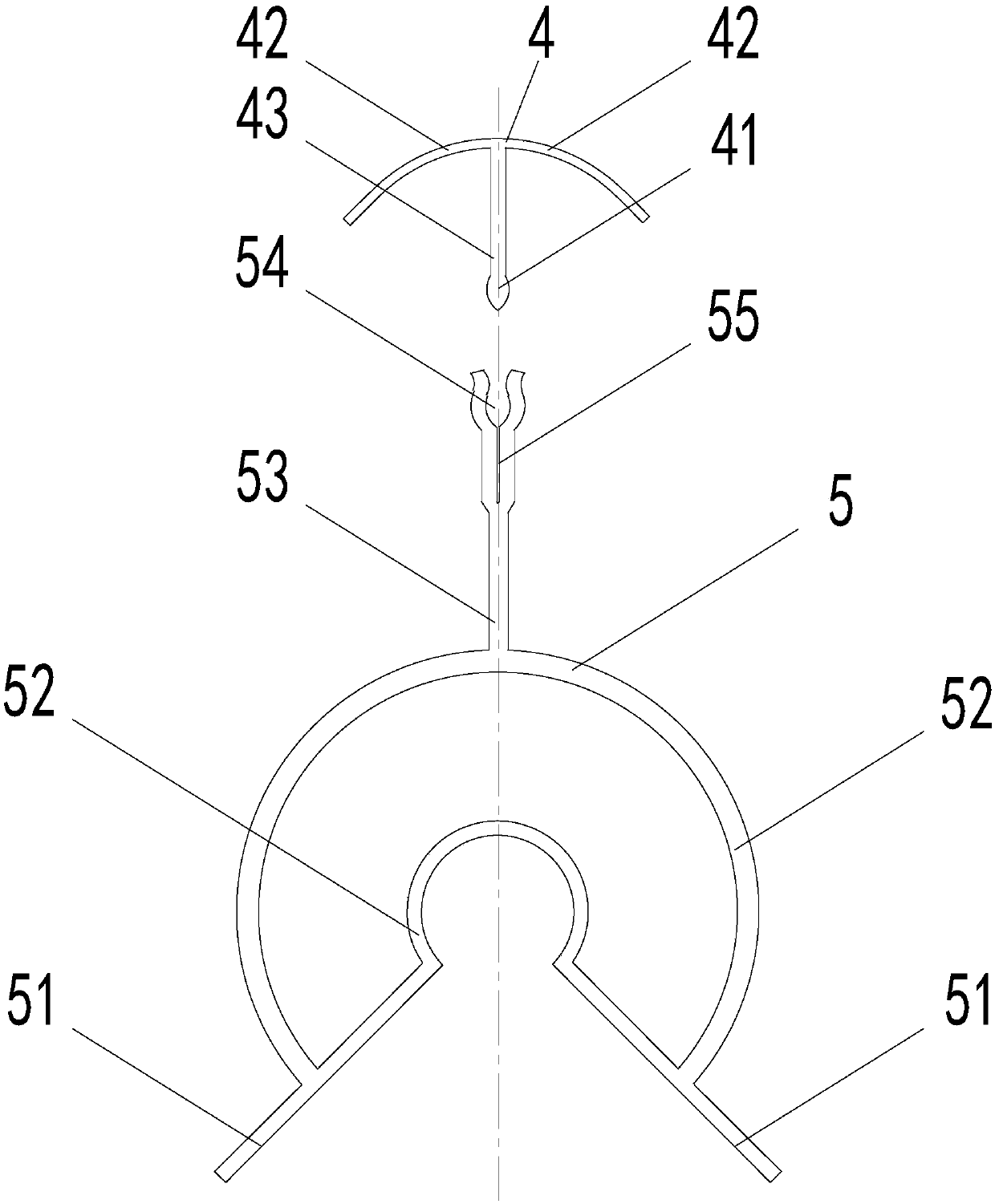

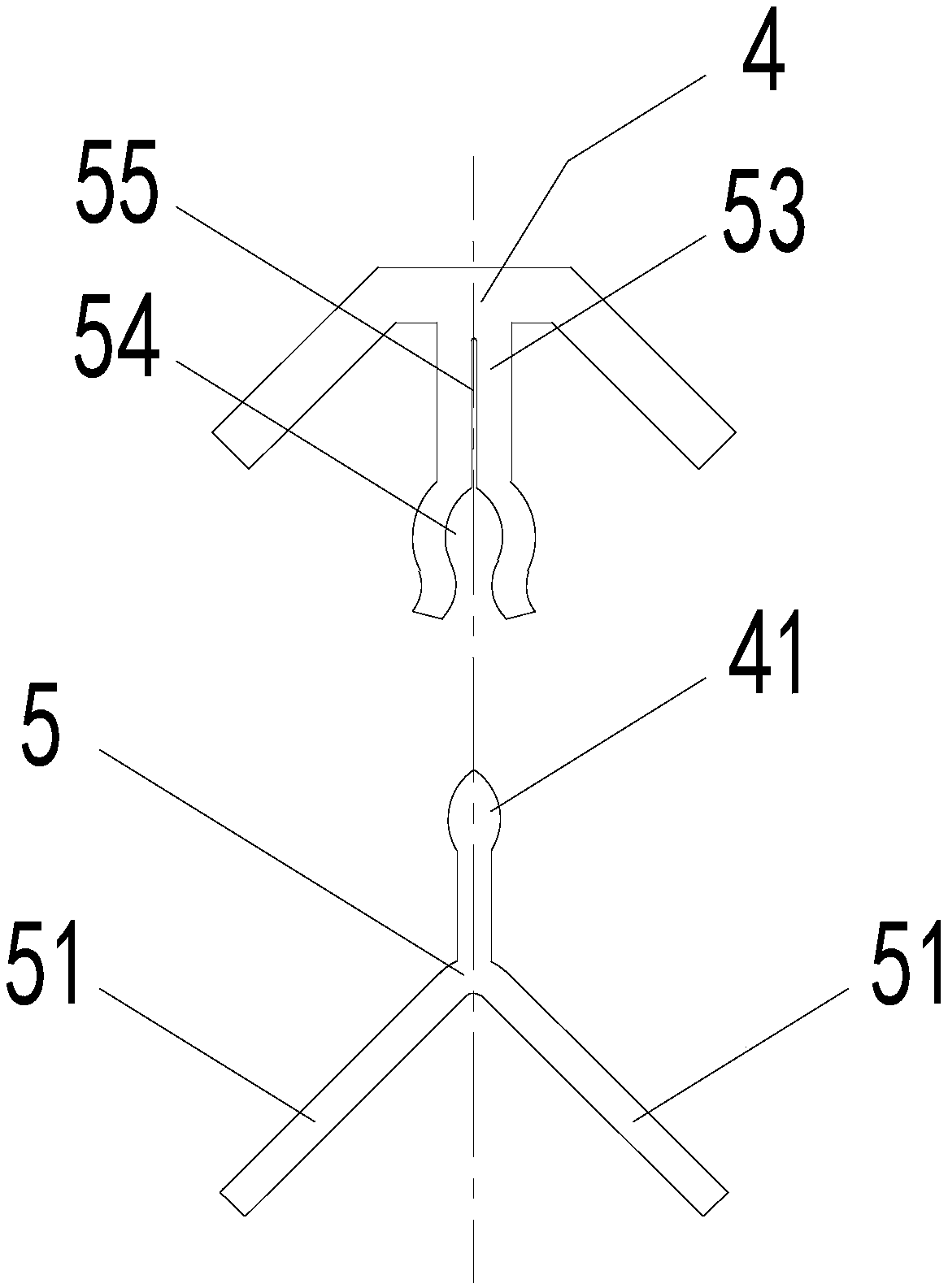

ActiveCN103490340AExpand the range of insulation shieldingGuaranteed not to be in placeApparatus for overhead lines/cablesArchitectural engineering

The invention discloses a porcelain cross arm insulation baffle. A first insulation baffle and a second insulation baffle are connected to form the insulation baffle with a hole in the middle portion, a first insulation seam shielding plate and a first semi-circular notch are arranged on the connecting edge of the first insulation baffle, and a second insulation seam shielding plate and a second semi-circular notch are arranged on the connecting edge of the second insulation baffle. A first semi-ring soft cushion is mounted on the first semi-circular notch, and a second semi-ring soft cushion is mounted on the second semi-circular notch. The porcelain cross arm insulation baffle enlarges the insulation shielding range of wire position operation. The seam between the first insulation baffle and the second insulation baffle is covered effectively, and insulation safety is improved. Further, the insulation baffle cannot loose and be off the position on the mounting part of a porcelain cross arm.

Owner:STATE GRID CORP OF CHINA +1

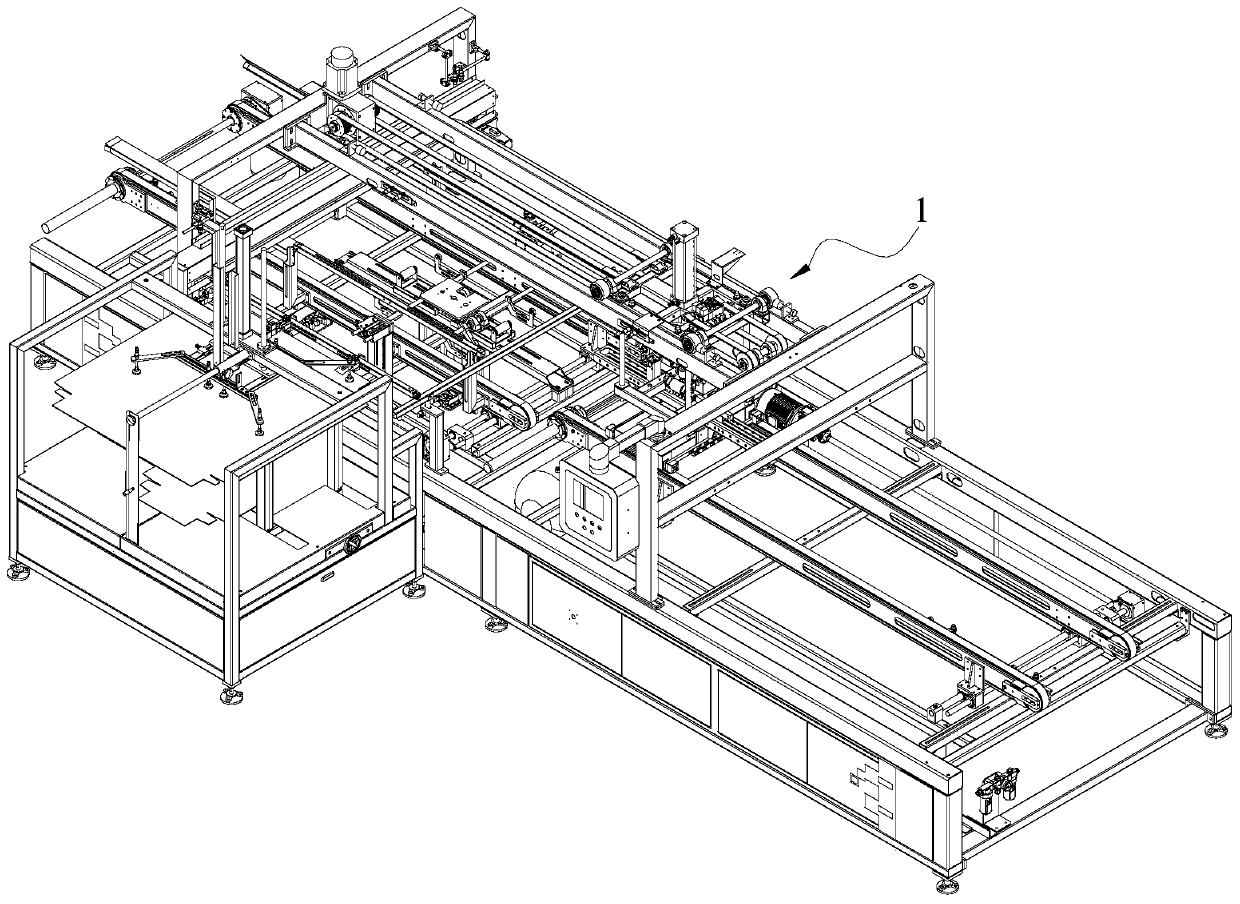

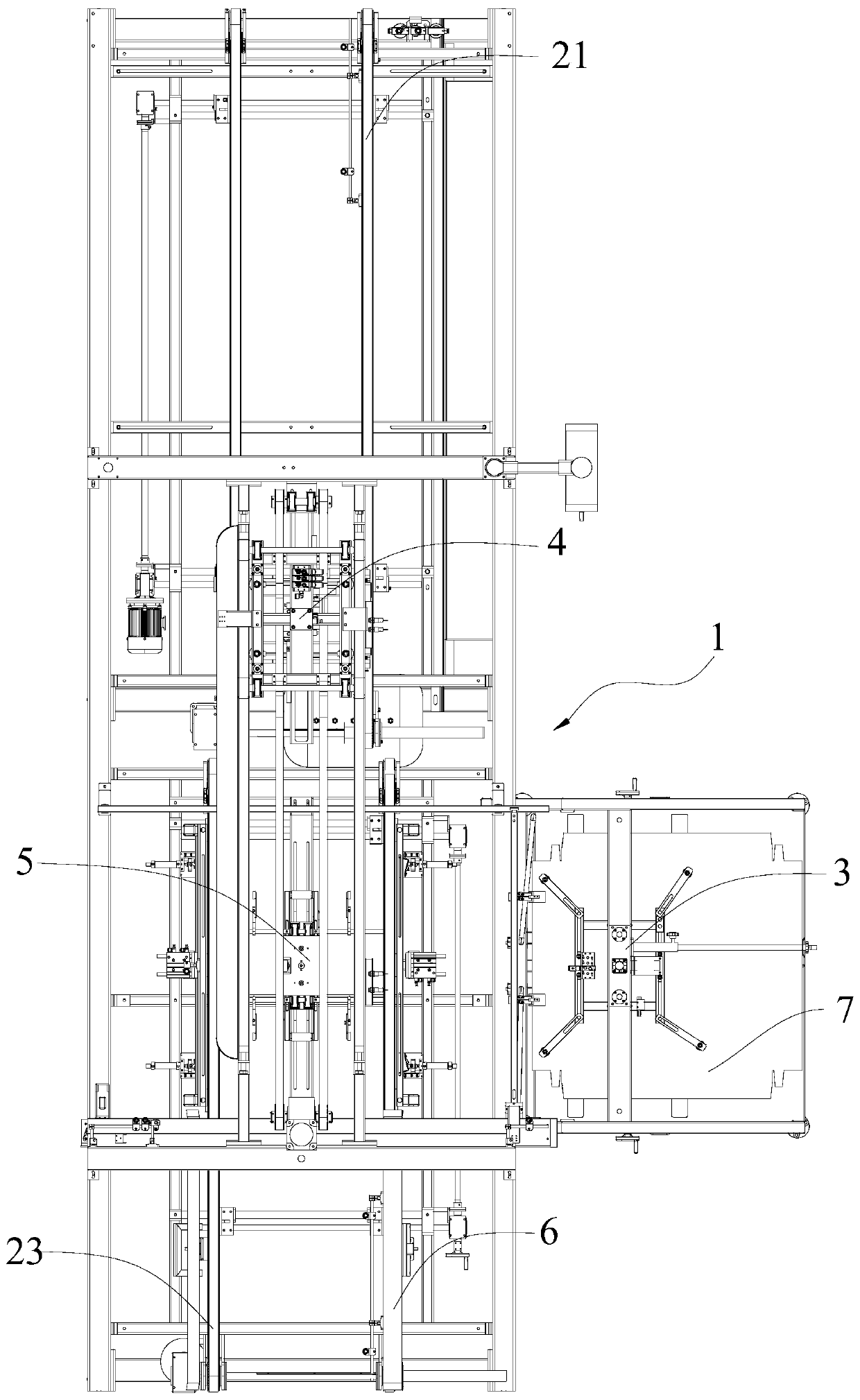

Ceramic tiles packaging machine

PendingCN110481849AFit tightlyWon't moveWrapping material feeding apparatusWrapper folding/bending apparatusPaperboardEngineering

The invention belongs to the field of intelligent packaging device, and particularly relates to a ceramic tiles packaging machine. The ceramic tiles packaging machine comprises a conveying device forconveying the ceramic tiles, a paperboard conveying device for conveying a paperboard to a packaging station, a grabbing device for grabbing ceramic tiles from the conveying device to the packaging station and a packaging device for packing ceramic tiles with the paperboard. The packaging device comprises a bearing seat, two rotating folding devices, two straight-line folding devices and a plurality of ear folding devices. The bearing seat is used for bearing the paperboard and the ceramic tiles, the two rotating folding devices are arranged on two sides of the bearing seat, the two straight-line folding devices are arranged on the other two sides of the bearing seat, and the plurality of ear folding devices are arranged under the two straight-line folding devices and are used for bendingthe paperboard rim angle inward. The ceramic tiles packaging machine can make the packaging paperboard closely fit the ceramic tiles, so that a gap between the ceramic tiles and the packaging paperboard does not exit, the ceramic tiles cannot move during the transportation process, and the risk of collision is reduced.

Owner:GUANGDONG EDING IND

Spreading plain bumper for concrete pouring

ActiveCN109025304ASolve the cumbersome processSolve efficiency problemsBuilding material handlingEngineeringProcess requirements

Owner:珠海德姿建材有限公司

Anti-radiation carbon fiber heating cable

InactiveCN104981037AGuaranteed safety grounding functionEnsure that the cable has a safety grounding functionHeating element shapesHeating element materialsFiberCarbon fibers

The present invention discloses an anti-radiation carbon fiber heating cable. The anti-radiation carbon fiber heating cable comprises a heating wire harnesses consisting of carbon fibers, wherein an insulation protection layer is wrapped outside the heating wire harnesses; a conductive plastic layer is wrapped outside the insulation protection layer; conductive wires are laid outside the conductive plastic layer in parallel and are clung to the conductive plastic layer in parallel; and a protective sheath is wrapped outside the conductive wires and the conductive plastic layer. A novel shielding layer is arranged in the cable, so that the cable not only can be adaptive to softness and bend-ability of the carbon fibers, is good in shield effect, convenient to package and construct, but also is easy to manufacture, relatively low in cost and long in service life.

Owner:HEBEI SHENGJIA ELECTRONICS TECH

Uniformly distributing and discharging type automatic boxing machine and method for melons and fruits

InactiveCN106081218AUniform without leaving gapsImprove packaging efficiencyIndividual articlesPackaging fruits/vegetablesEngineeringMechanical engineering

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

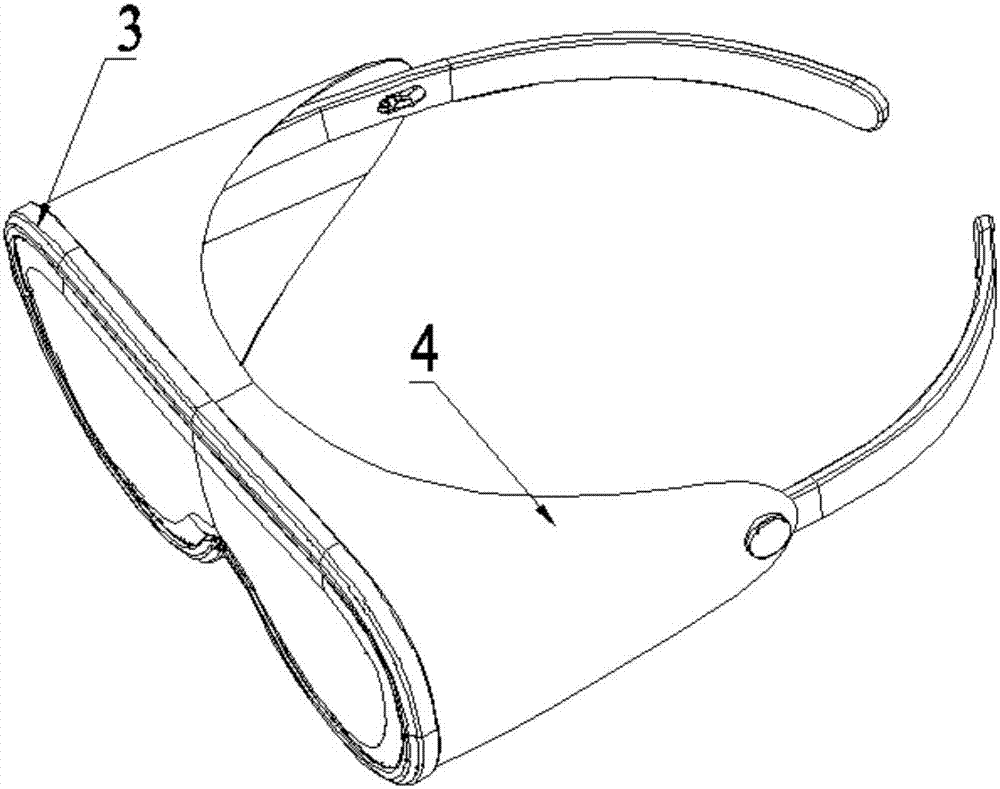

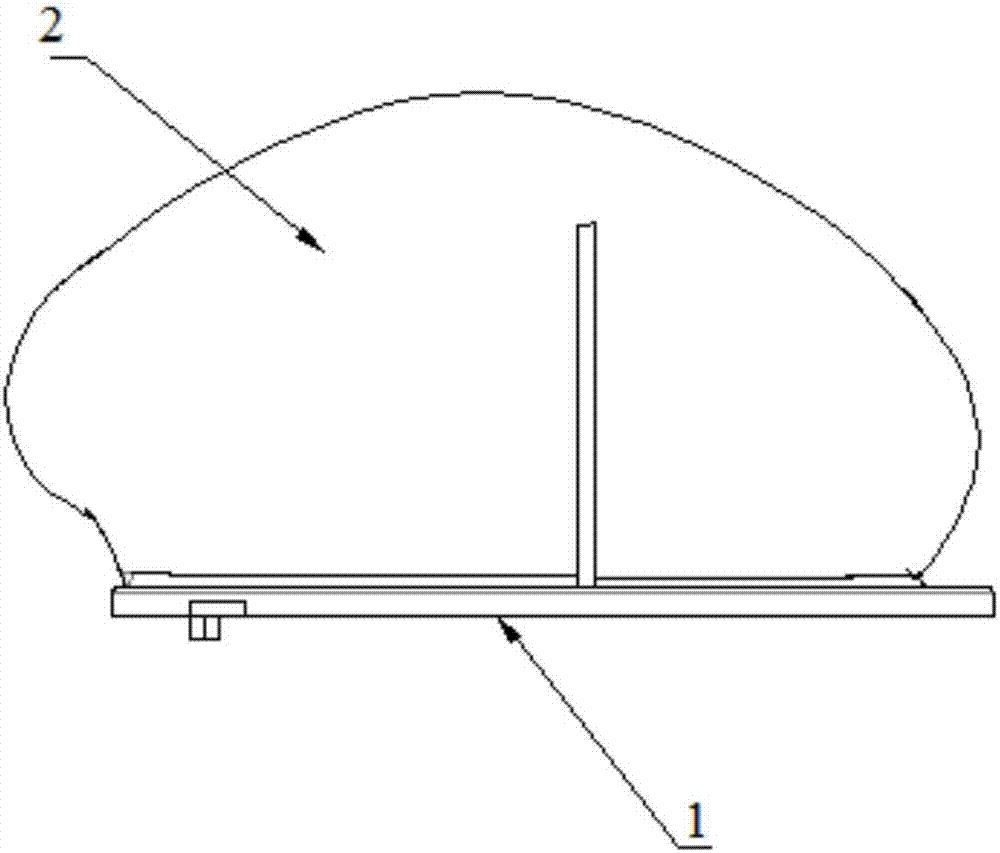

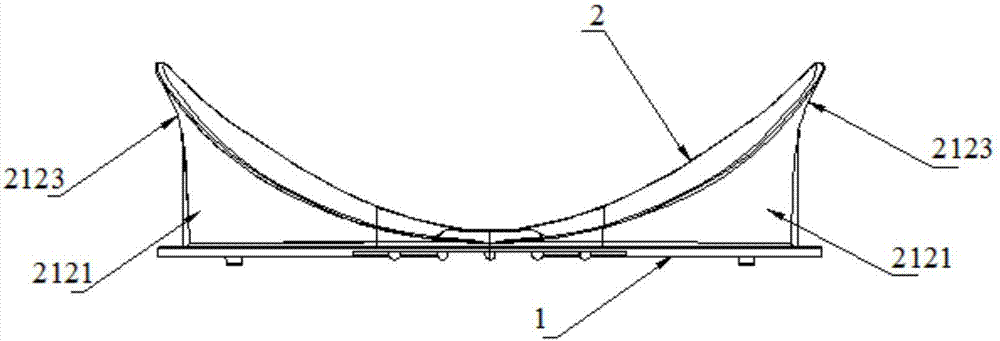

Head-mounted equipment light shield

ActiveCN107422483AInfluential impactAffect the sense of experienceOptical elementsEngineeringSupport curve

The application discloses a head-mounted equipment light shield; in usage, a light shield shadow shield is fixed in the head-mounted equipment; eyeshade shading portions are respectively fixed around user eyes; a transition curved surface, a support curved surface, a stretching curved surface and a nose support member make contacts with the user face; when a random part of the transition curved surface, the support curved surface, the stretching curved surface and the nose support member deforms, other parts will be driven to deform, so the shading portions can make fully contacts with the user face in fixations; no slit is formed, thus preventing lights from entering the light shield through the slit, improving user experience feelings, and improving the head-mounted equipment effect.

Owner:SHENZHEN DLODLO NEW TECHNOLOGY CO LTD

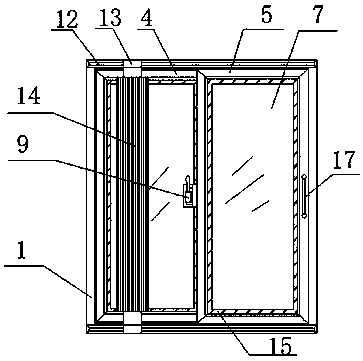

High sealing energy-saving aluminum alloy door and window

InactiveCN107939224ASimple structureLow priceClimate change adaptationWing fastenersPush pullEngineering

The invention provides a high sealing energy-saving aluminum alloy door and window. The door and window comprises a window frame, first slide rails, second slide rails and a first glass frame; a top end and a bottom end at one side inside the window frame are provided with the first slide rails; the other sides of a top end and a bottom end inside the window frame are provided with the second slide rails; the first glass frame is installed at one side, away from the window frame, of the first slide rail; the second glass frame is installed at one side, away from the window frame, of the secondslide rail; a top end and a bottom end of the first glass frame and the second glass frame are provided with pulleys which are matched with the first slide rails and the second slide rails; the firstglass frame and the second glass frame are provided with vacuum glass at the inner side; a middle position at one end inside the first glass frame is provided with a clamp groove. The invention usesaluminum alloy as a material, push-pull design, simple structure, low price, and is not easy to rust, durable and energy-saving and environmental protection. The invention adopts vacuum glass, has good heat insulation and sound insulation effect.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

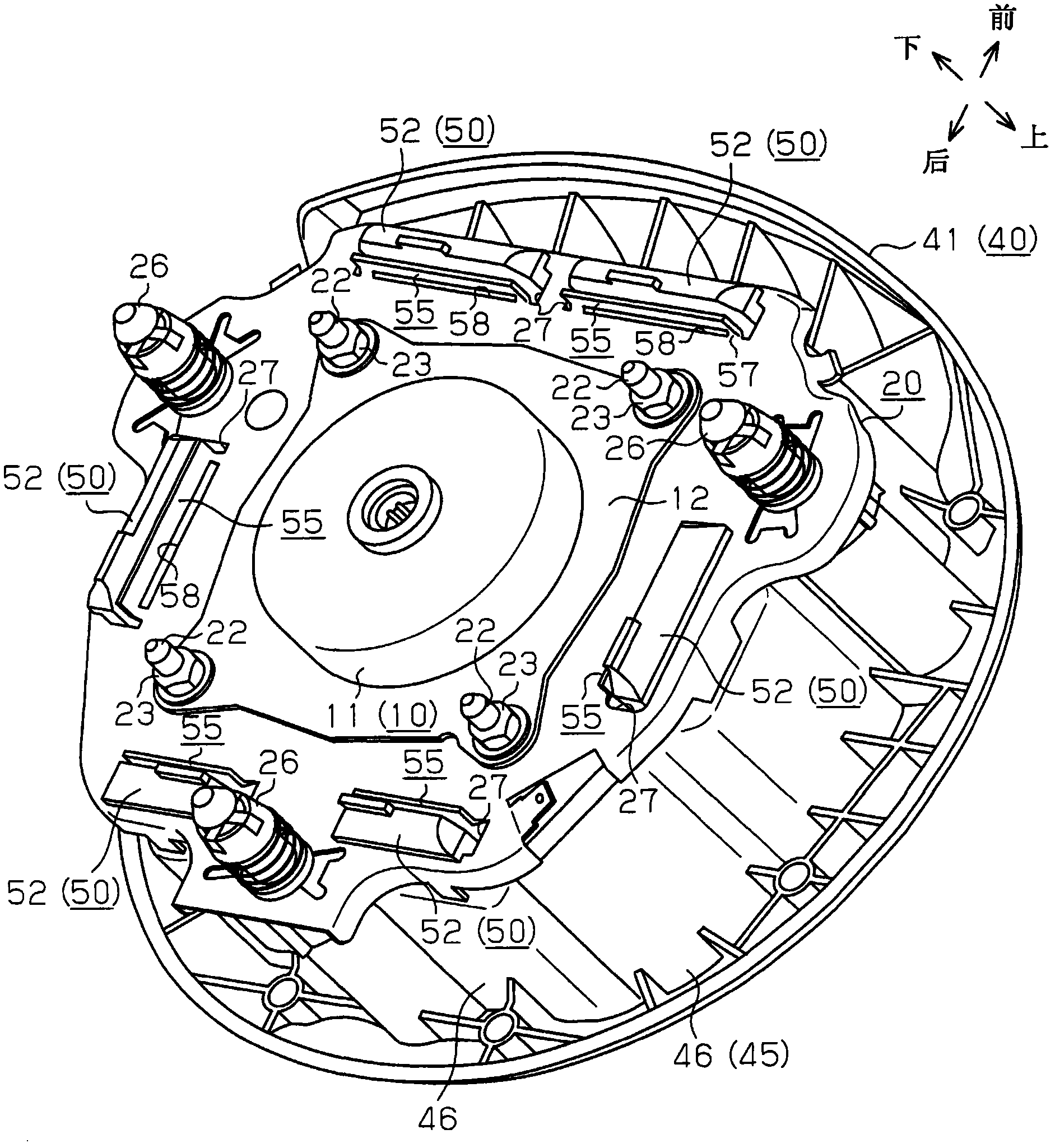

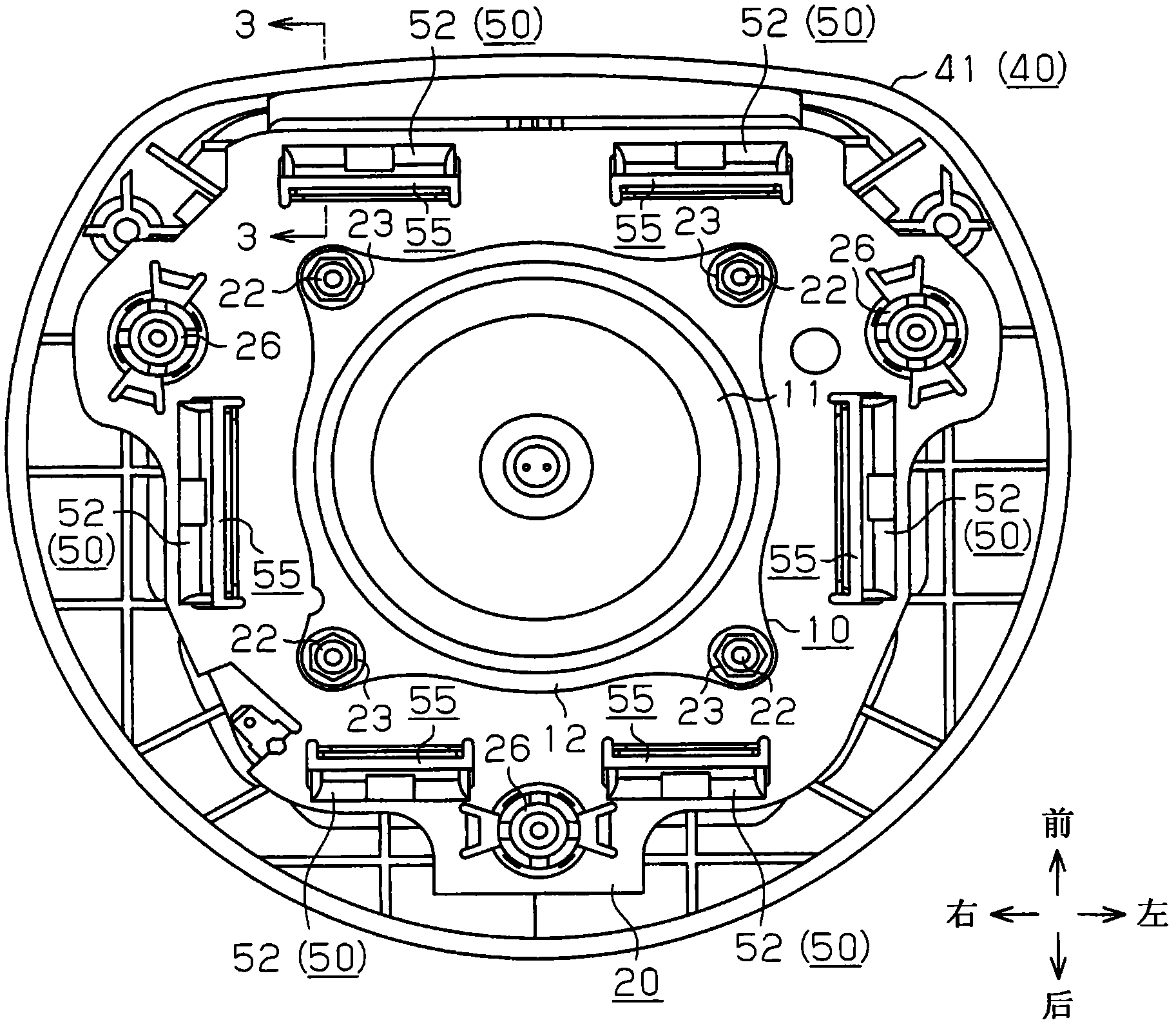

Pad cover fastening structure

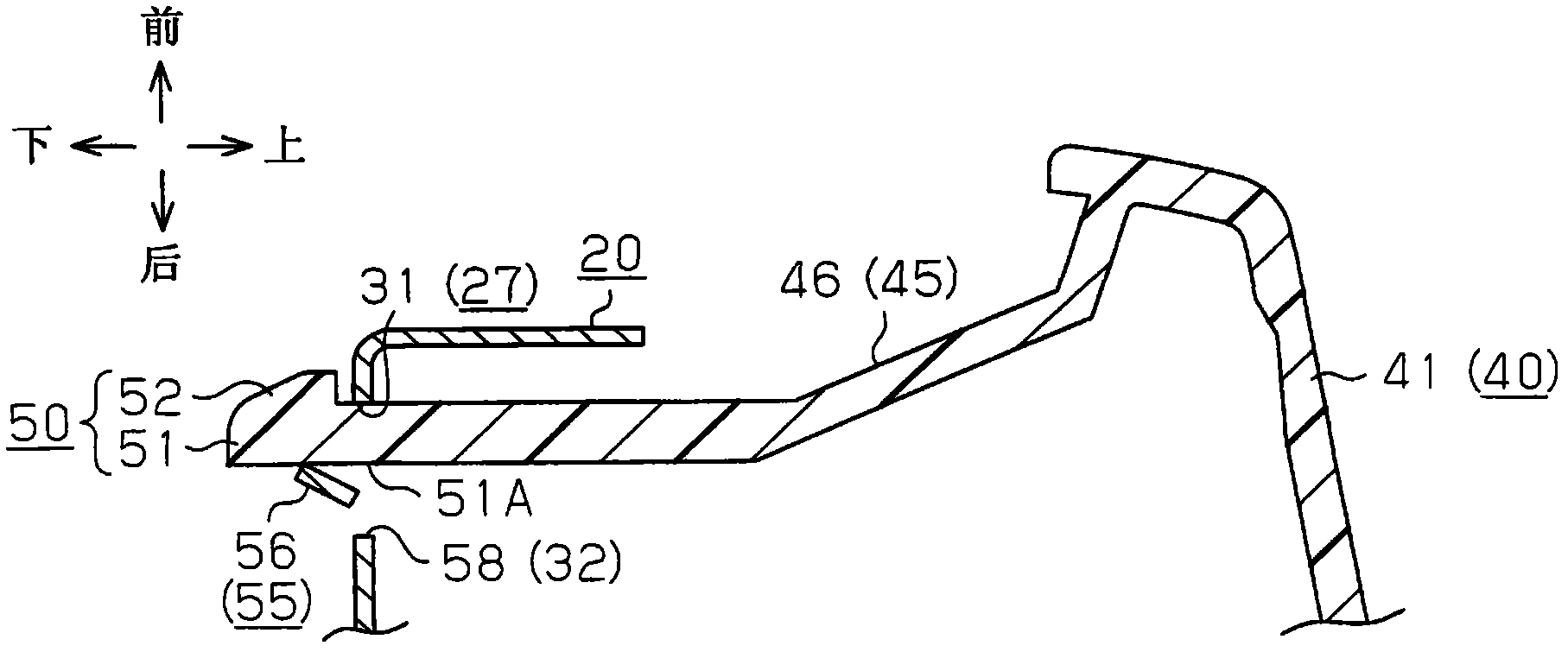

ActiveCN102107642AReduce in quantityLeave no gapsPedestrian/occupant safety arrangementEngineeringAirbag deployment

The present invention discloses a pad cover fastening structure. A bag holder has a plurality of engagement holes about parts to which an airbag device is attached. Each engagement hole has a first long inner wall surface and a second long inner wall surface that extend along a substantially tangential direction of the center a circle of which coincides with the central axis of the bag holder, orof an opening. Engagement claws of a pad cover each include an insertion portion inserted into one of the engagement holes and a claw portion protruding from the lower end of the insertion portion toward the first long inner wall surface. The bag holder has integrally formed fastening pieces, each of which includes a support portion and a pair of coupling portions. The support portion is located in the vicinity of one of the engagement holes, and the coupling portions connect the support portion to the corresponding second long inner wall surface at several positions. Each fastening piece is bent at the coupling portions so as to contact a side surface of the insertion portion on which no claw portion is provided.

Owner:TOYODA GOSEI CO LTD

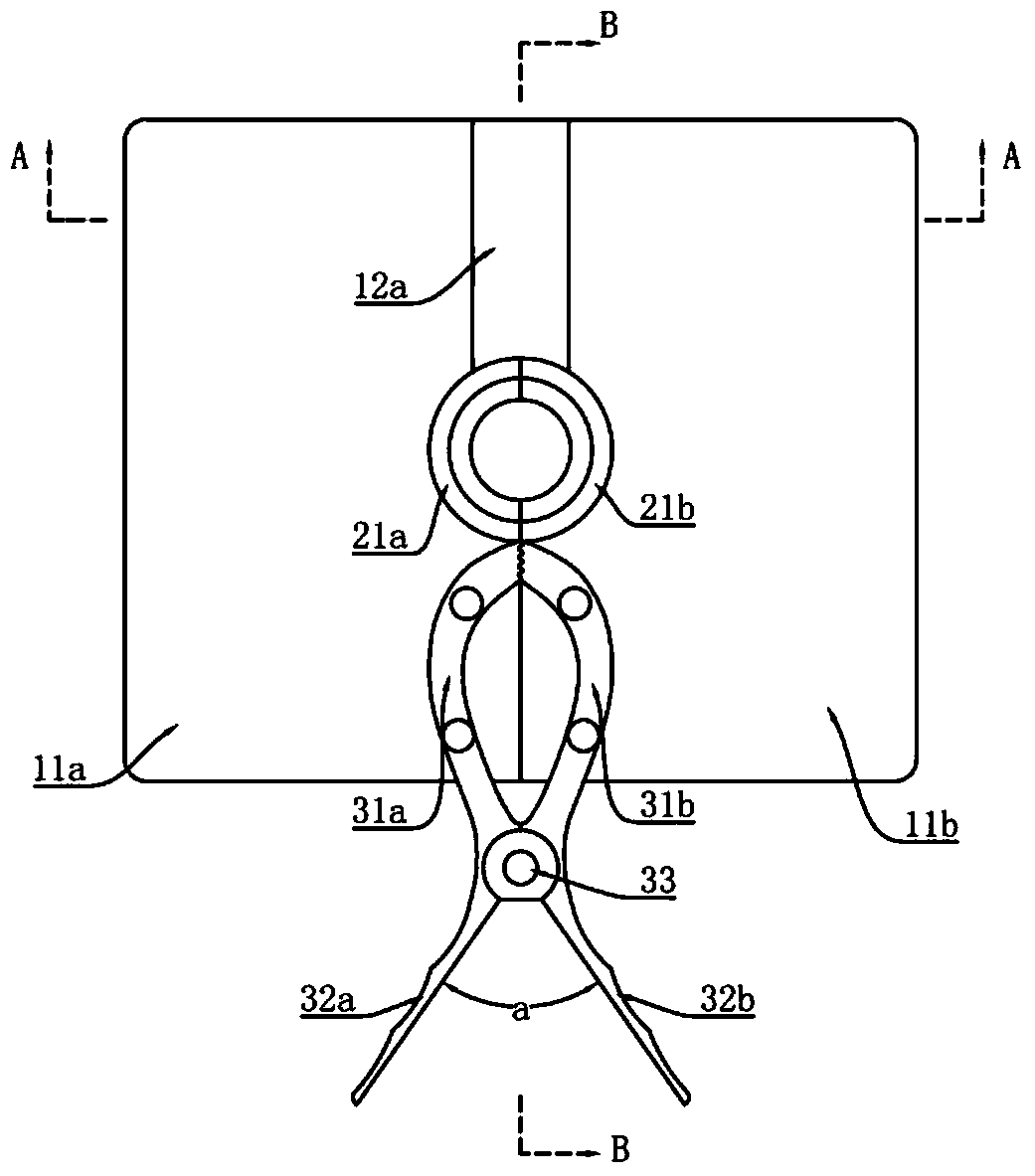

Elastic structure formed by insertion-type connection and used for external corner bead as well as protective structure for external corner of parapet wall

The invention discloses an elastic structure formed by insertion-type connection and used for an external corner bead. The elastic structure comprises an external-corner-bead fastener and an external-corner fastener which can be connected together in a face-to-face manner by insertion, wherein the external-corner fastener is provided with two wall fixing plates which are fixed to the two side walls of the external corner of a wall respectively; a connecting part of the two wall fixing plates extends out in the direction opposite to the direction of the diagonal line of the included angle between the two wall fixing plates to form a clamping plate; a clamping structure is arranged at one end of the clamping plate; correspondingly, the inner side of the external-corner-bead fastener extendsout in the direction of the diagonal line of the included angle between the two wall fixing plates to form a clamped structure; and the clamped structure on the external-corner-bead fastener and the clamping structure on the external-corner fastener can be connected together in a clamped manner and separated from each other in the direction of the diagonal line of the included angle between the two wall fixing plates. On the basis of the elastic structure, the invention also discloses a protective structure for the external corner of a parapet wall. The elastic structure has the beneficial effects of being capable of well adapting to the uneven state of the external corner of the face of the wall and ensuring that two wings of the external corner bead cover a parapet wall board neatly without leaving gaps.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

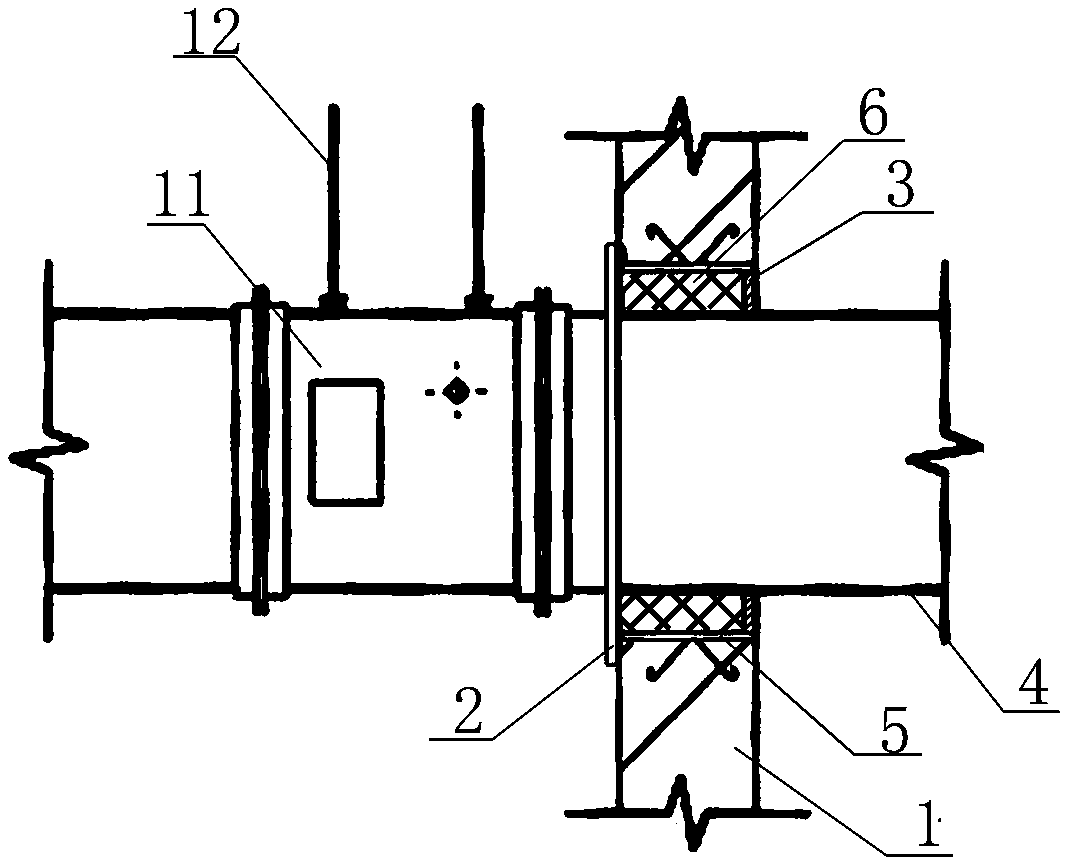

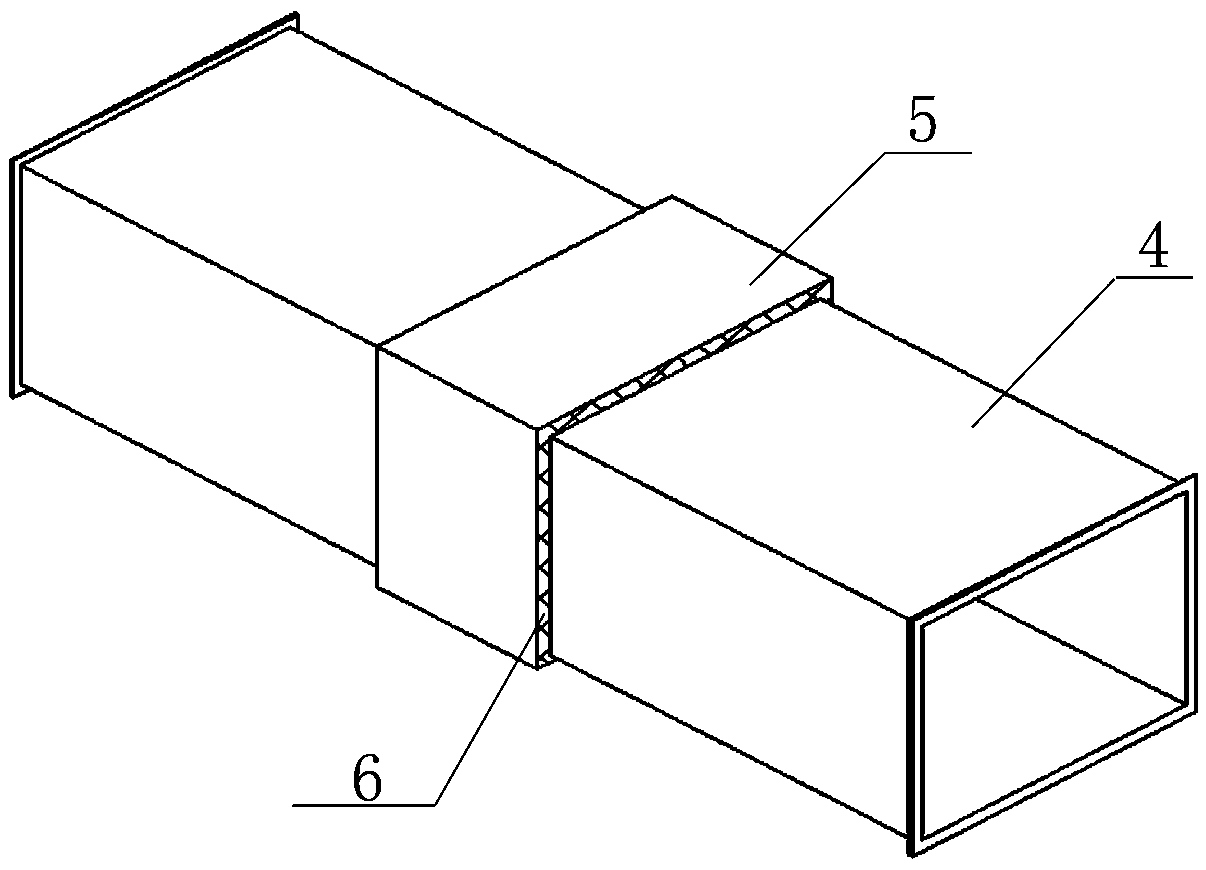

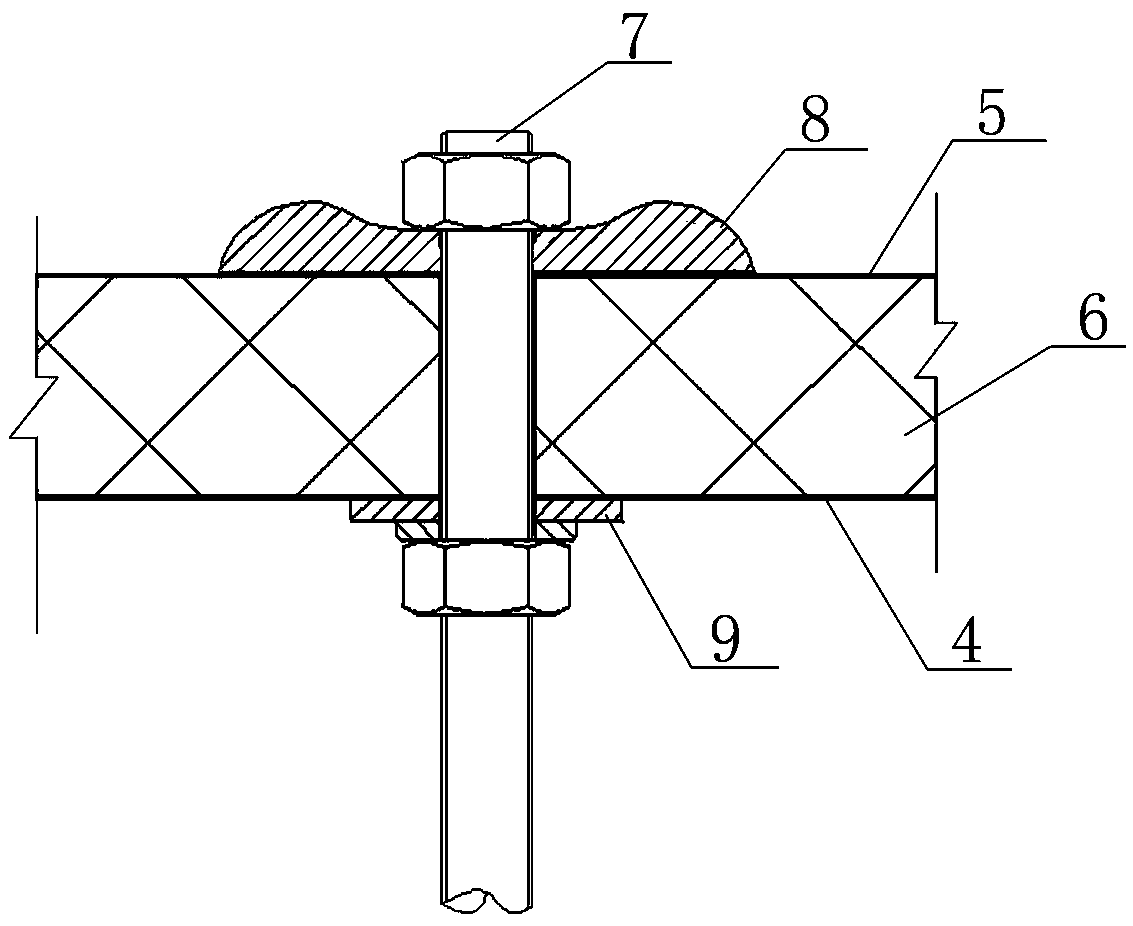

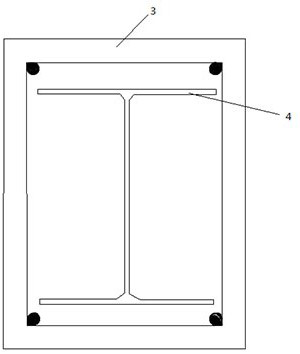

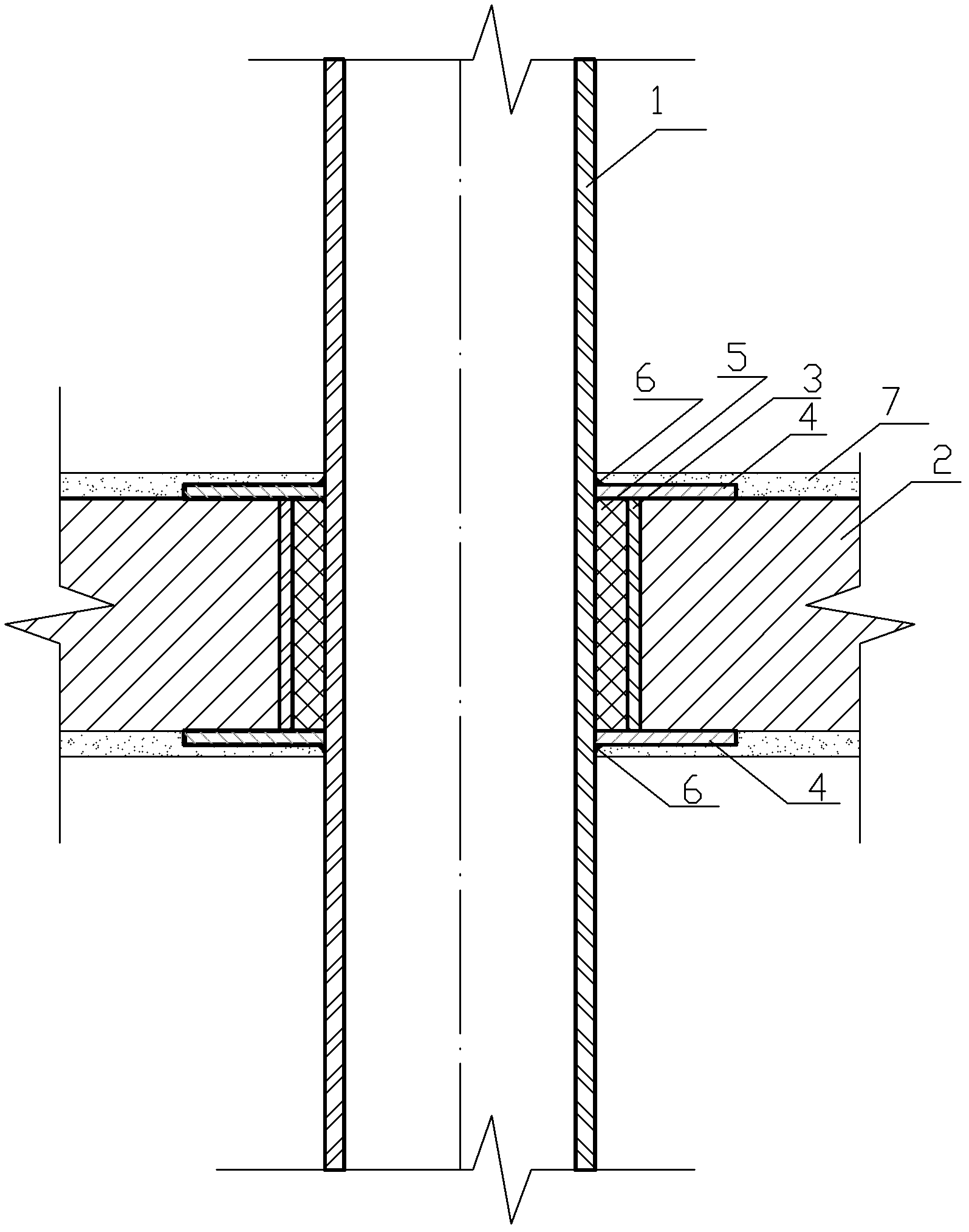

Horizontal duct wall penetrating system and construction method thereof

The invention discloses a horizontal duct wall penetrating system and a construction method thereof. The horizontal duct wall penetrating system comprises a duct assembly, a fixing ring and a sealinglayer; the duct assembly horizontally penetrating through the wall and includes a duct, a casing arranged on the outer side of the duct in a sleeving mode, and a connecting assembly that connects theduct to the casing fixedly; the length of the casing is adapted to the thickness of the wall, and a gap is reserved between the casing and the duct; a fireproofing plugging material is filled in the gap; the connecting assembly include a bolt, an outer washer and an inner washer; the bolt is arranged in the casing, the fireproofing plugging material and the duct in sequence in a penetrating mode;the outer washer is arranged between the outer wall of the casing and the bolt in a laid mode, and the inner washer is arranged between the inner wall of the duct and the bolt in a laid mode; and thefixed ring is arranged on the duct in a sleeving mode, the duct is fixed to the inner side face of the wall, and the sealing layer is sealed on the outer side of the fireproofing plugging material. Bymeans of the horizontal duct wall penetrating system, the technical problems that when a traditional duct is installed, the danger is high, the labor consumption is high, the casing is easily pressedto be broken, and the plugging effect is not good.

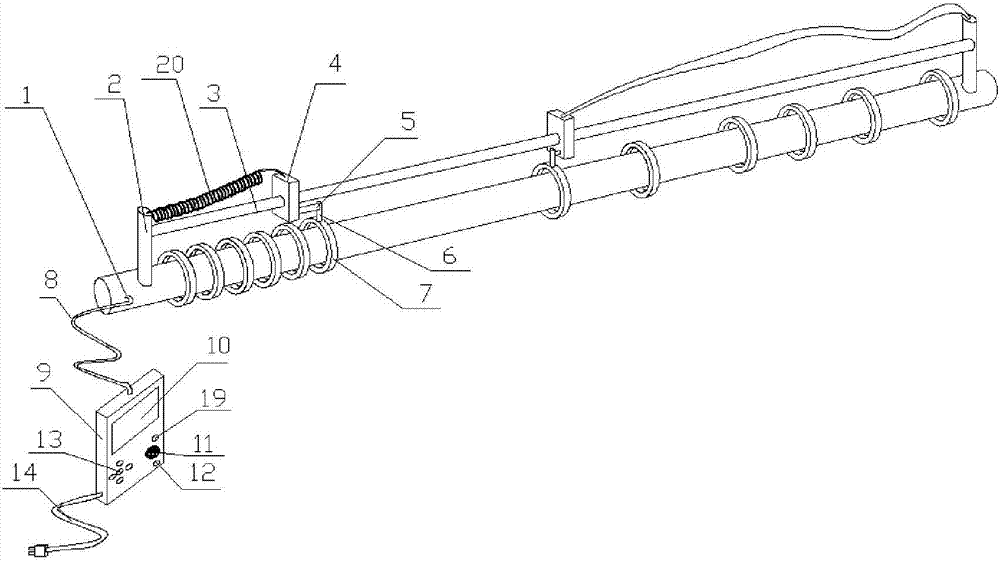

Automatic window curtain

The invention discloses an automatic curtain, which relates to the field of household products, and comprises a support rod, the support rod is cylindrical, and a collar is slidably connected to the support rod. A support rod is connected, and two sliding boxes are slidably connected to the support rod, and a connecting column is arranged on the sliding box, and the connecting column and the collar are fixedly connected by a column, and one end of the supporting rod is connected by a wire A controller is connected, and the controller is provided with a display screen and operation buttons. The inside of the controller is provided with a microprocessor and a temperature and humidity sensor, and the microprocessor is connected with the temperature and humidity sensor, the motor and the sound receiving device respectively. Connection, this kind of automatic curtain can control the opening and closing of the curtain through remote control, voice control and key control, and can also control the opening and closing of the curtain at regular intervals.

Owner:古宏亮

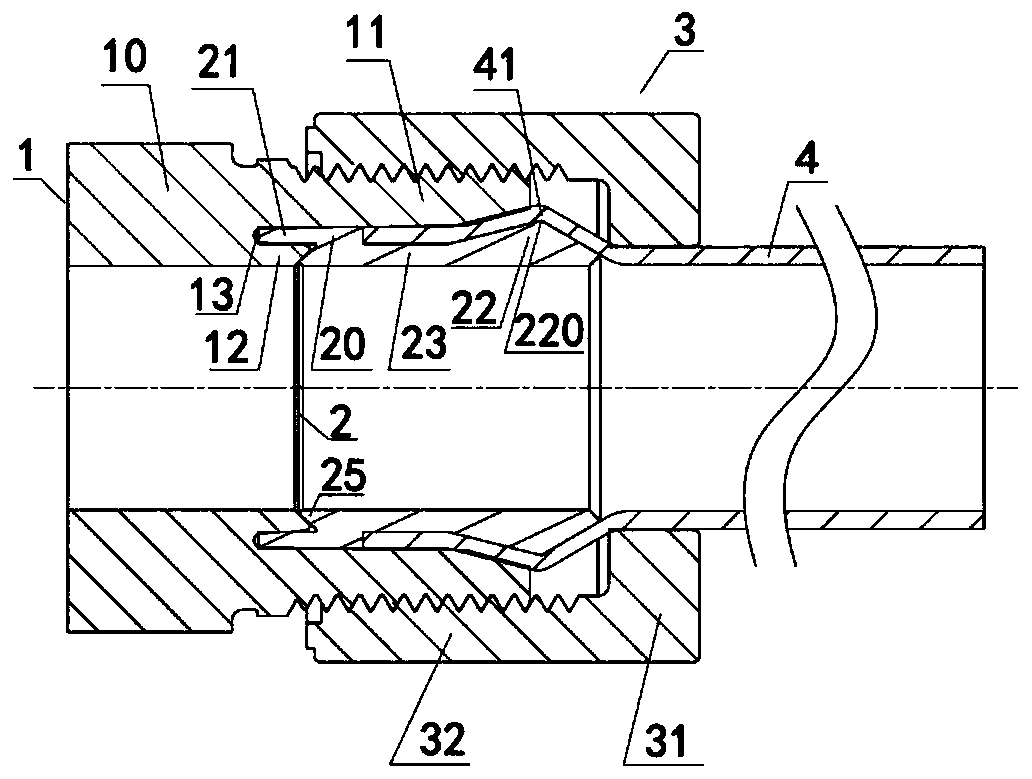

Pipe joint connected with pipe

PendingCN110043722AReduce bending curvatureAvoid damageJoints with sealing surfacesEngineeringAxial length

The invention provides a pipe joint connected with a pipe. The pipe joint connected with the pipe comprises a joint body, an inner ring and a screw cap, wherein a transition section is arranged between an expanding conical surface of a projection part of the inner ring and a reducing conical surface of the projection part of the inner ring; the axial length of the transition section is 15 percentto 30 percent of the axial length of the projection part; an included angle between a tangent line at any point on the outer surface of the transition section and the axial direction of the inner ringis 0 degree to 35 degrees; and an included angle between the axial direction of the inner ring and the expanding conical surface is larger than an included angle between the axial direction of the inner ring and the reducing conical surface. The outer surface of the transition section of the projection part and the inner wall of the pipe form surface contact, so that the action area is increased;an extrusion action force between the outer surface of the transition section of the projection part and the inner wall of the pipe is dispersed, and the bending curvature of the pipe is further reduced through the transition section, so that the damage on the pipe is reduced, and the expanding conical surface and the inner wall of the pipe tightly contact and are fastened; and the included anglebetween the axial direction of the inner ring and the expanding conical surface is larger than the included angle between the axial direction of the inner ring and the reducing conical surface, so that the pipe is prevented from outwards slipping off along the reducing conical surface under the high-temperature environment.

Owner:张春燕

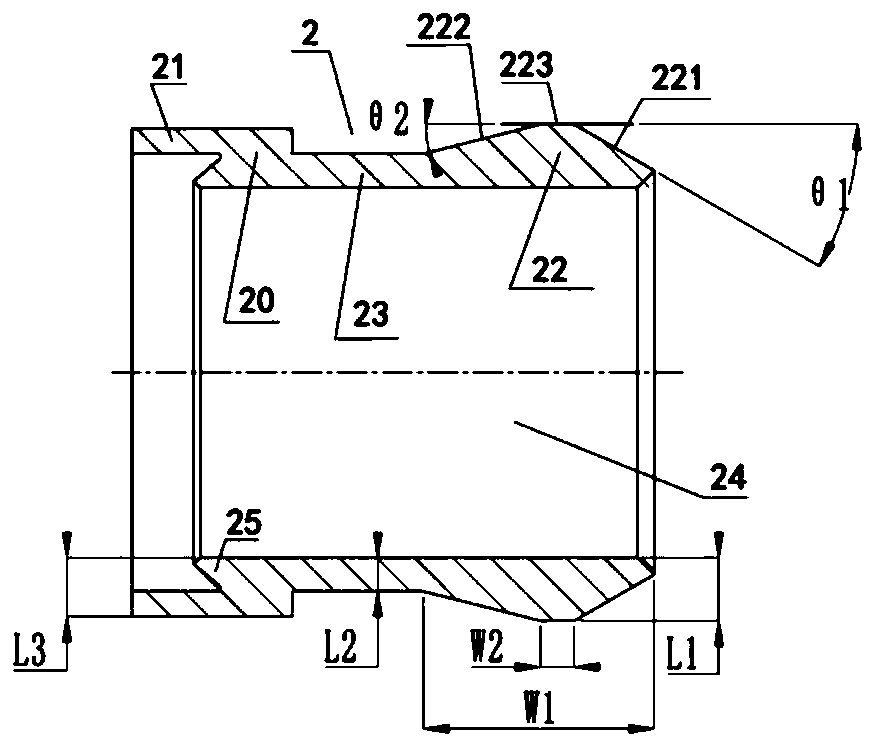

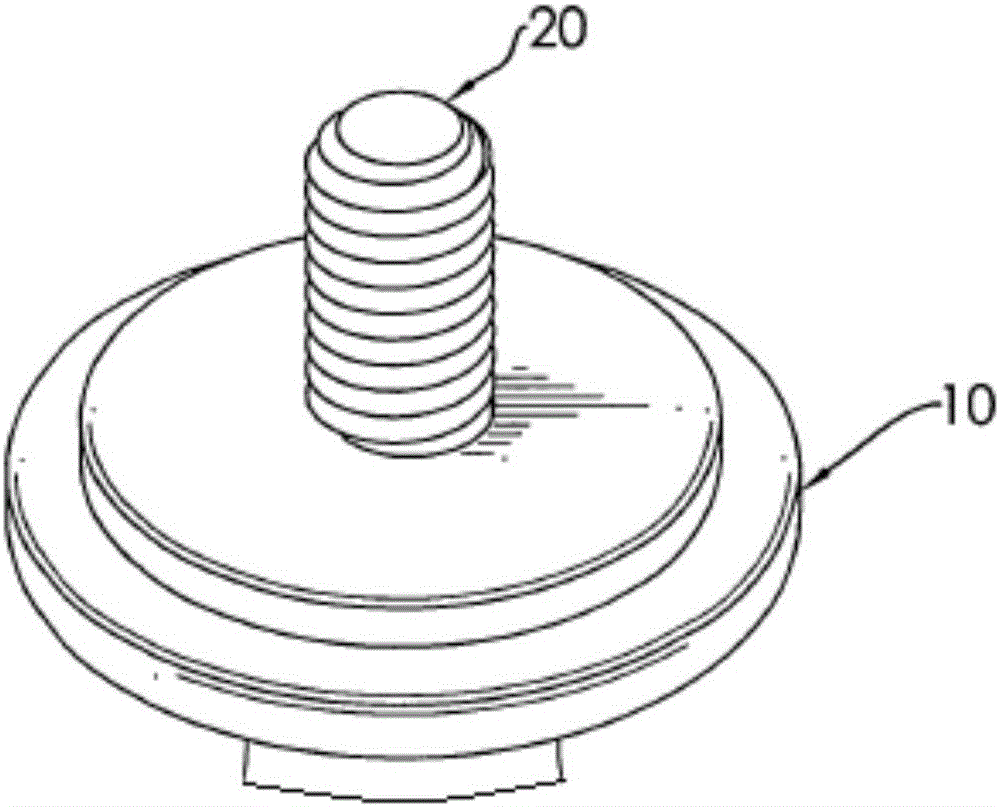

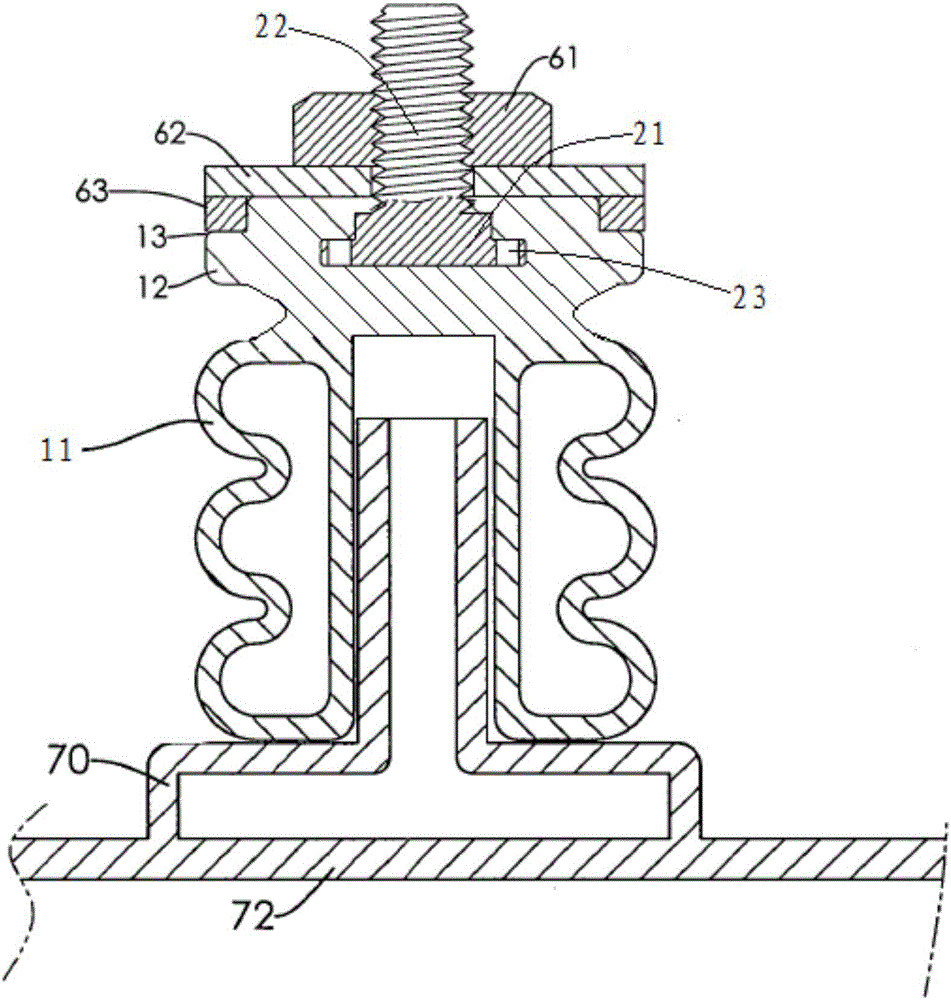

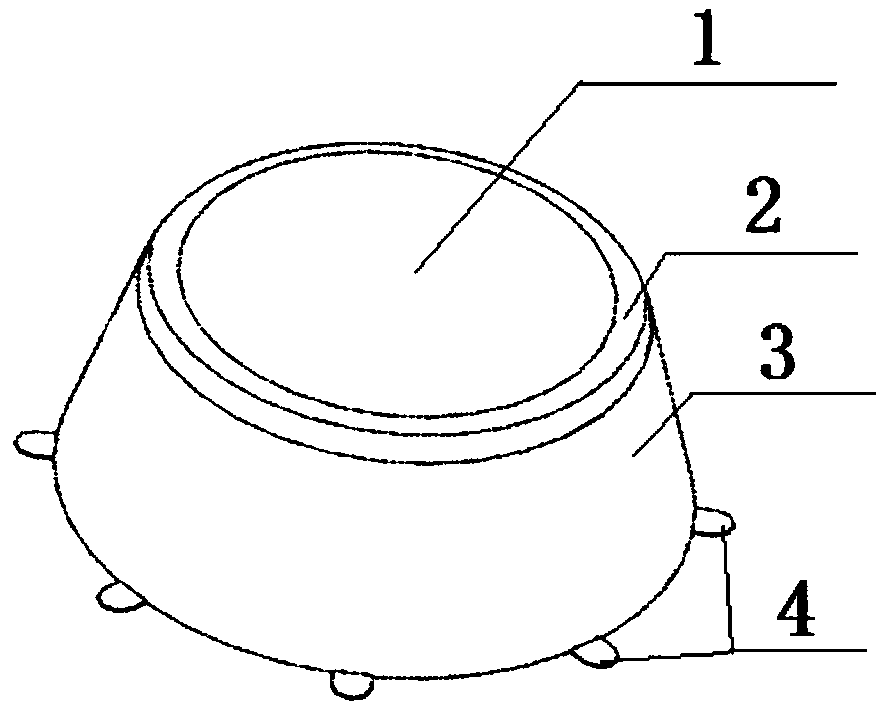

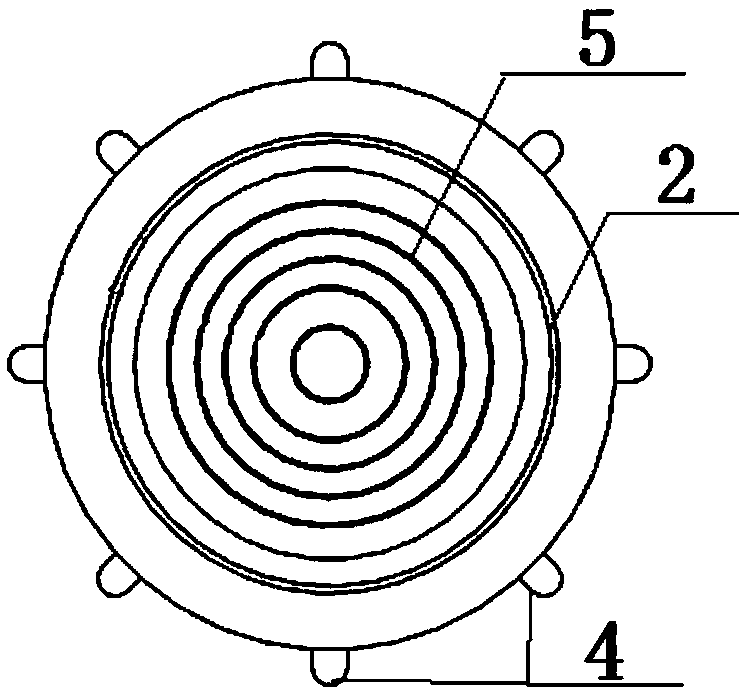

Anti-vibration external member for compressor

InactiveCN105840463AStrong shock absorptionTightly boundPositive displacement pump componentsPositive-displacement liquid enginesInverted tFixed position

A compressor anti-vibration kit according to the present invention includes a connecting part, a fixing column and a bolt; the fixing column is a raised cylinder on the surface of the fixing part; the connecting part is a plastic connecting part, including a buffer pad, a buffer disc; the buffer pad is sleeved outside the fixed column, the buffer disc is connected to the upper end of the buffer pad, and the top surface of the buffer disc protrudes to form a stepped surface; the raised surface of the buffer disc is provided with a "convex" Type blind hole; the bolt includes a bolt head and a threaded portion, the bolt head is arranged in the blind hole, closely fits with the blind hole, and the threaded portion protrudes from the top surface of the buffer plate. The buffer pad and the buffer plate of the anti-shock kit are made of plastic and have a certain degree of elasticity, and the buffer plate is arranged on the top of the buffer pad so that the shock-absorbing device has good shock-absorbing ability.

Owner:FUZHOU YIHUI ELECTRIC POWER EQUIP CO LTD

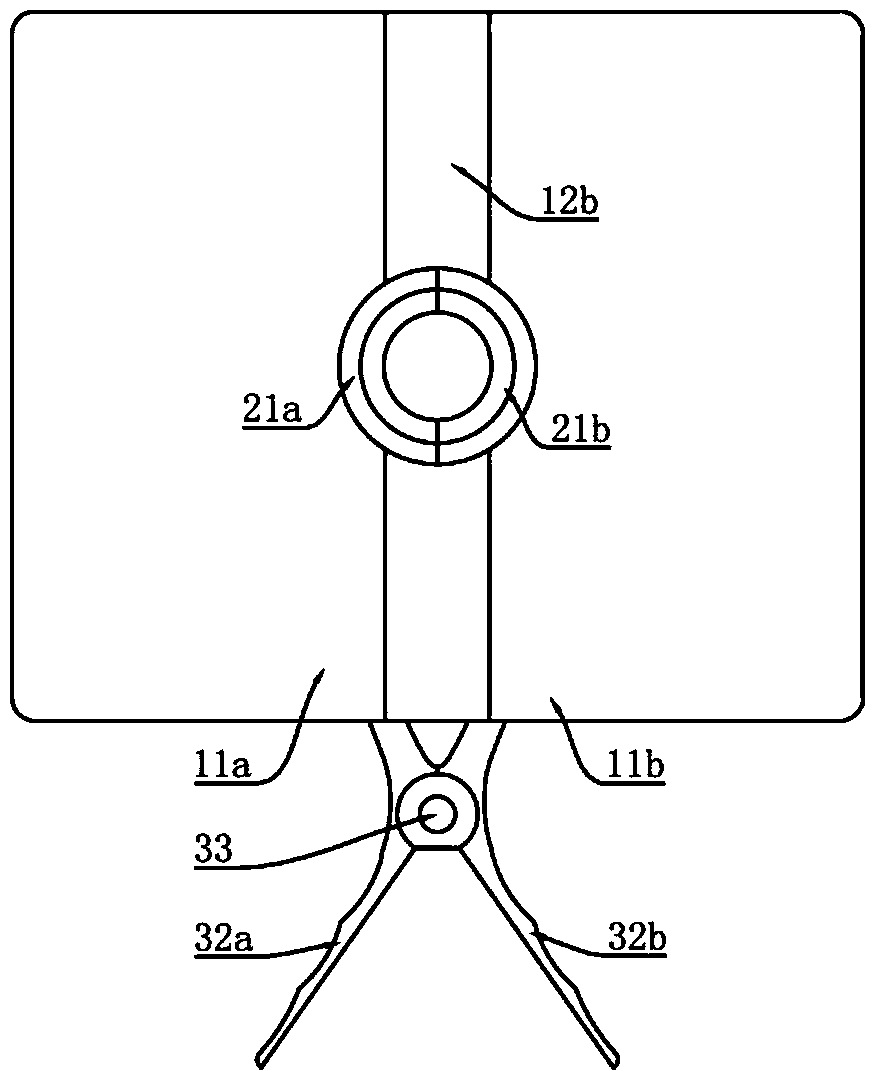

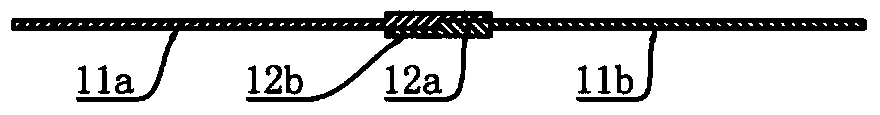

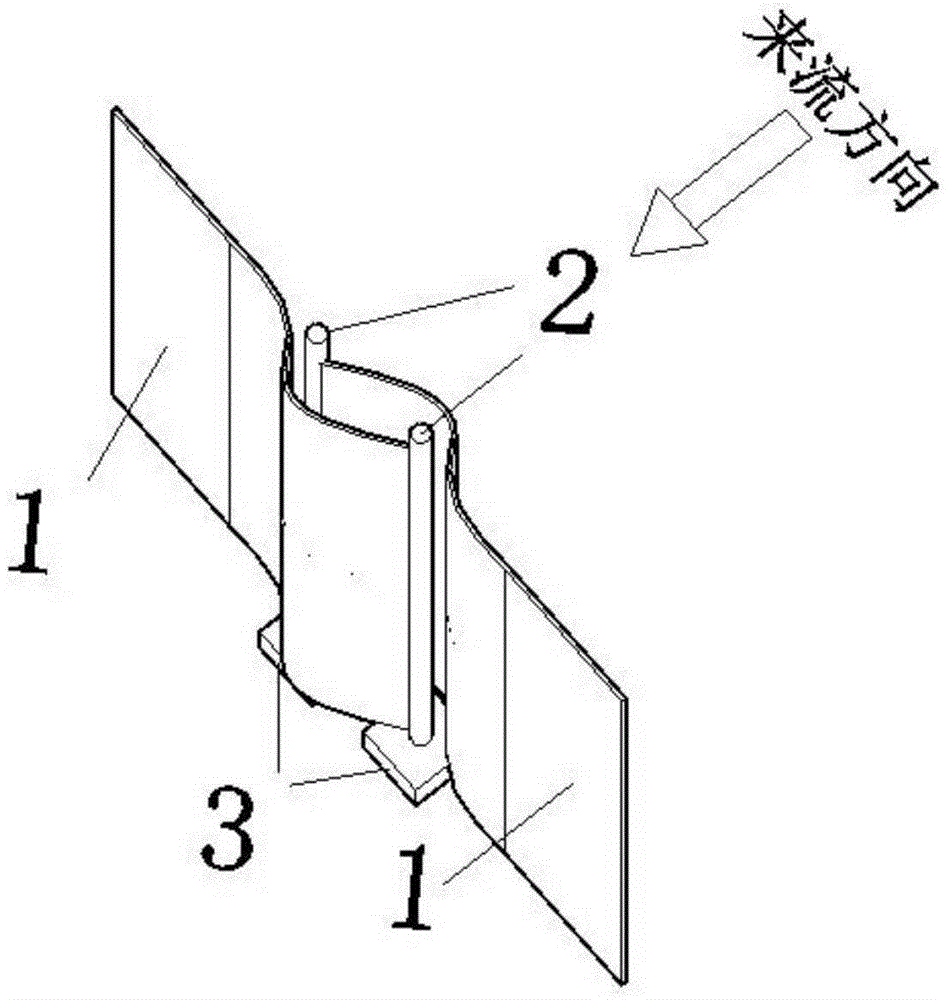

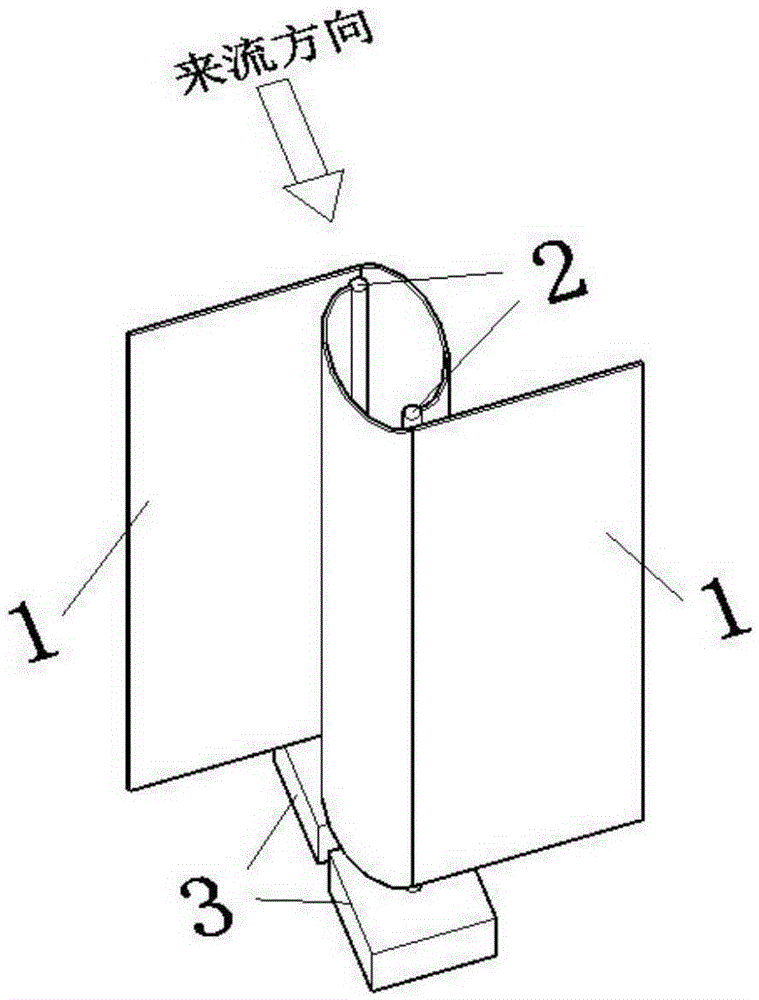

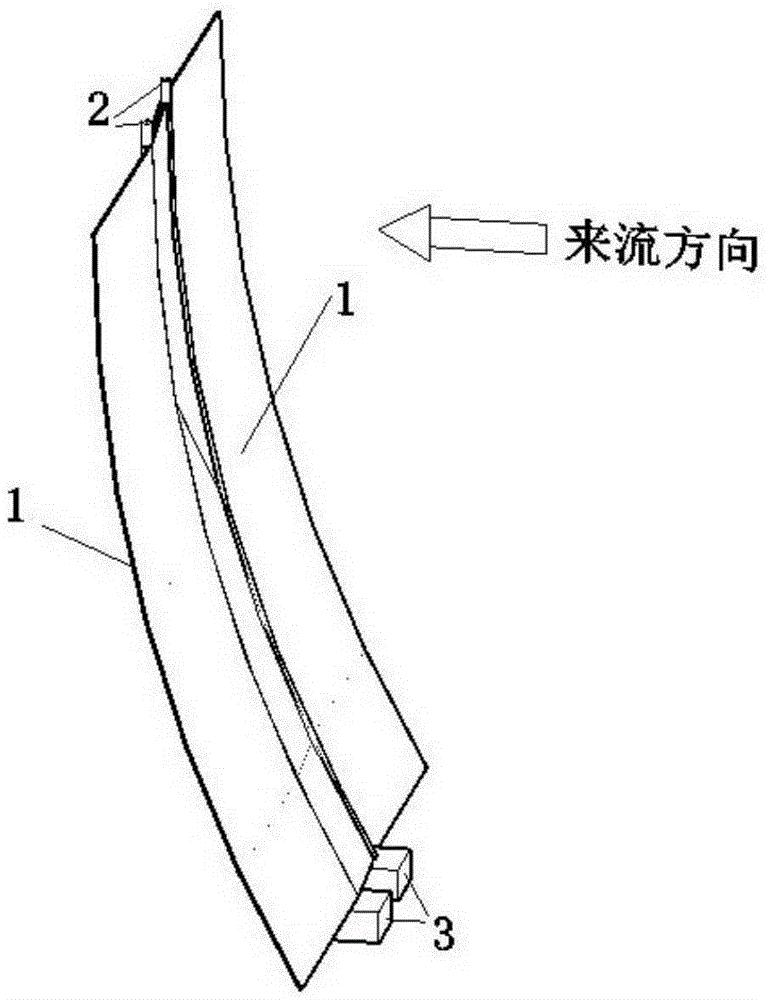

Overlap joint device between water retaining curtains

InactiveCN105421309ABlock the passageReduce the impactBarrages/weirsWater-power plantsWater leakagePower station

The invention discloses an overlap joint device between water retaining curtains, and relates to a curtain overlapping process for solving the problems in overlapping and fixing between adjacent water retaining curtains and the problem of water leakage, and the process refers to that curtains and anchor blocks are distributed in the edge positions of adjacent curtains in a staggered manner. The overlap joint device provided by the invention is used for water retaining below large scale water surfaces. The overlap joint device is composed of two curtains and two anchor blocks, the curtains are connected with the anchor blocks through two cables respectively, the curtains adopt water-stopping structures, the cables are connected with the curtains, and one ends of the cables are fixed on the anchor blocks. Adjacent curtains are overlapped in a crossing manner in edge positions, and the overlap joint between the curtains is achieved through the fixing of the anchor blocks and the cables. After the mounting, under the effect of water flow, the two curtains cling to each other mutually, no clearance is left, water flow passing is stopped, and the purpose of treating low temperature water is achieved. According to the process, no component is required to be added on the curtains, the construction is convenient and quick, the operation is simple, impacts on a power station putting into running are small, and construction and maintenance costs are low.

Owner:THE FRONTIER TECH RES INST OF TIANJIN UNIV

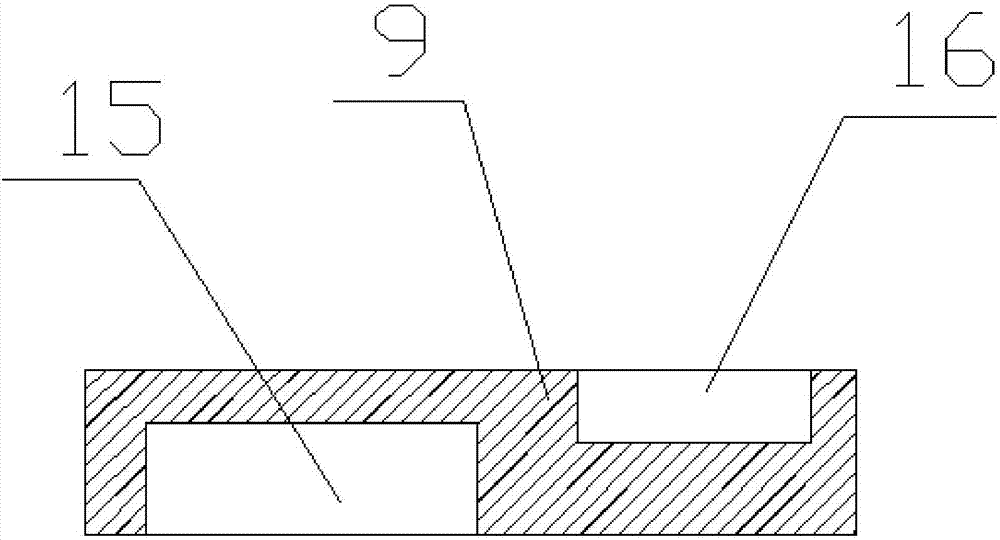

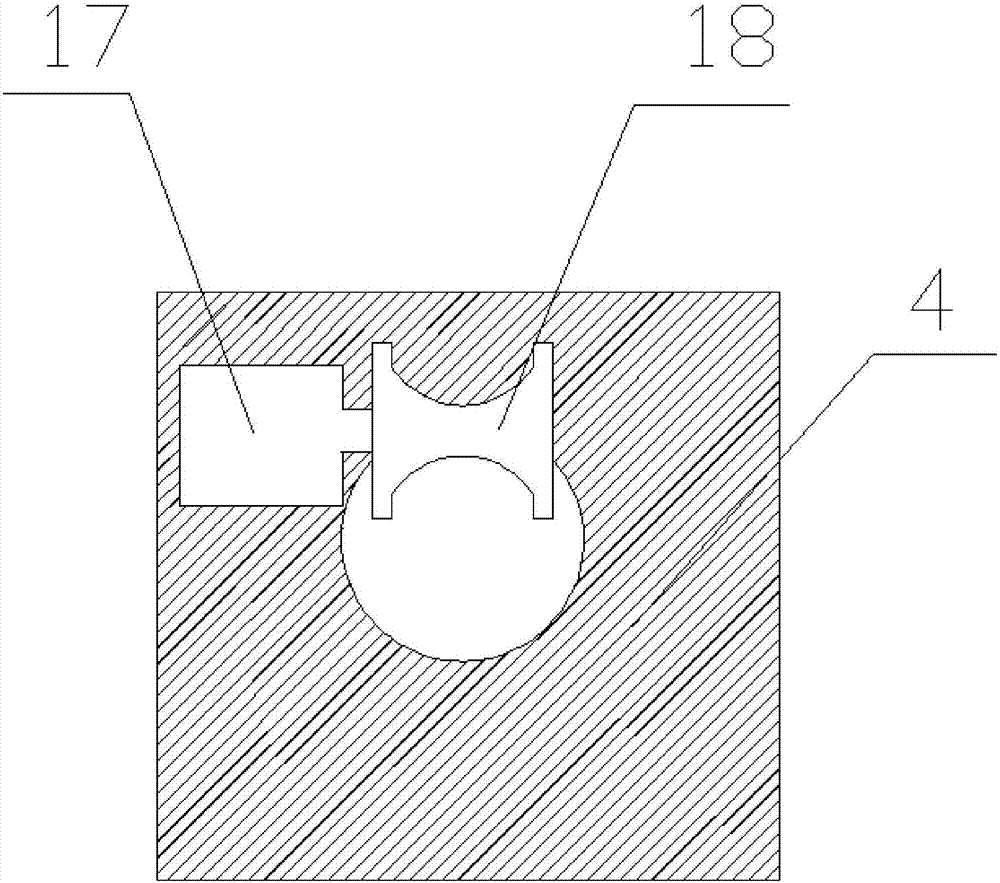

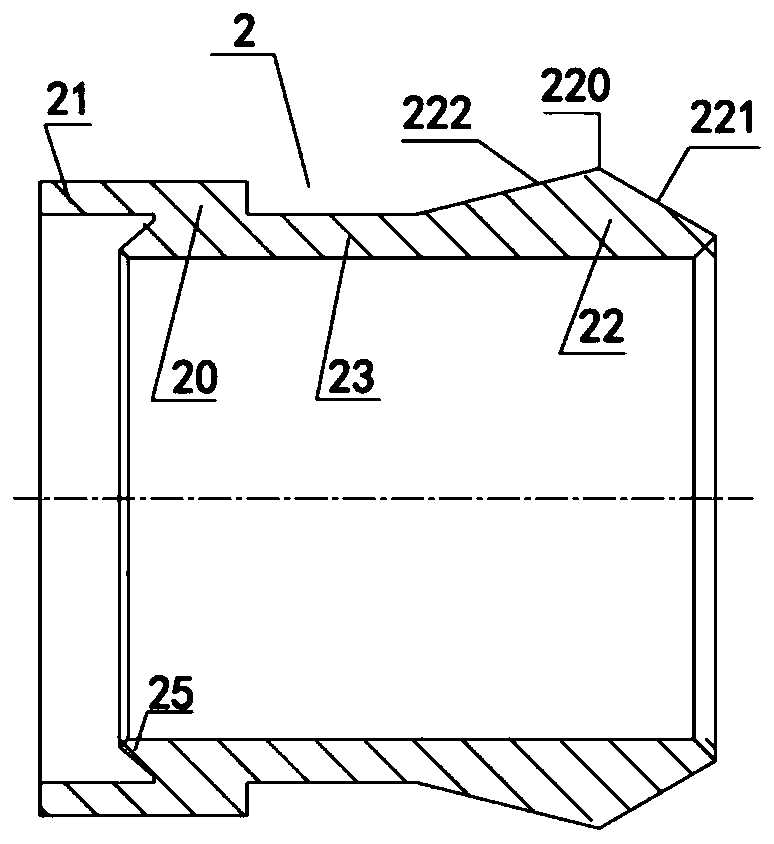

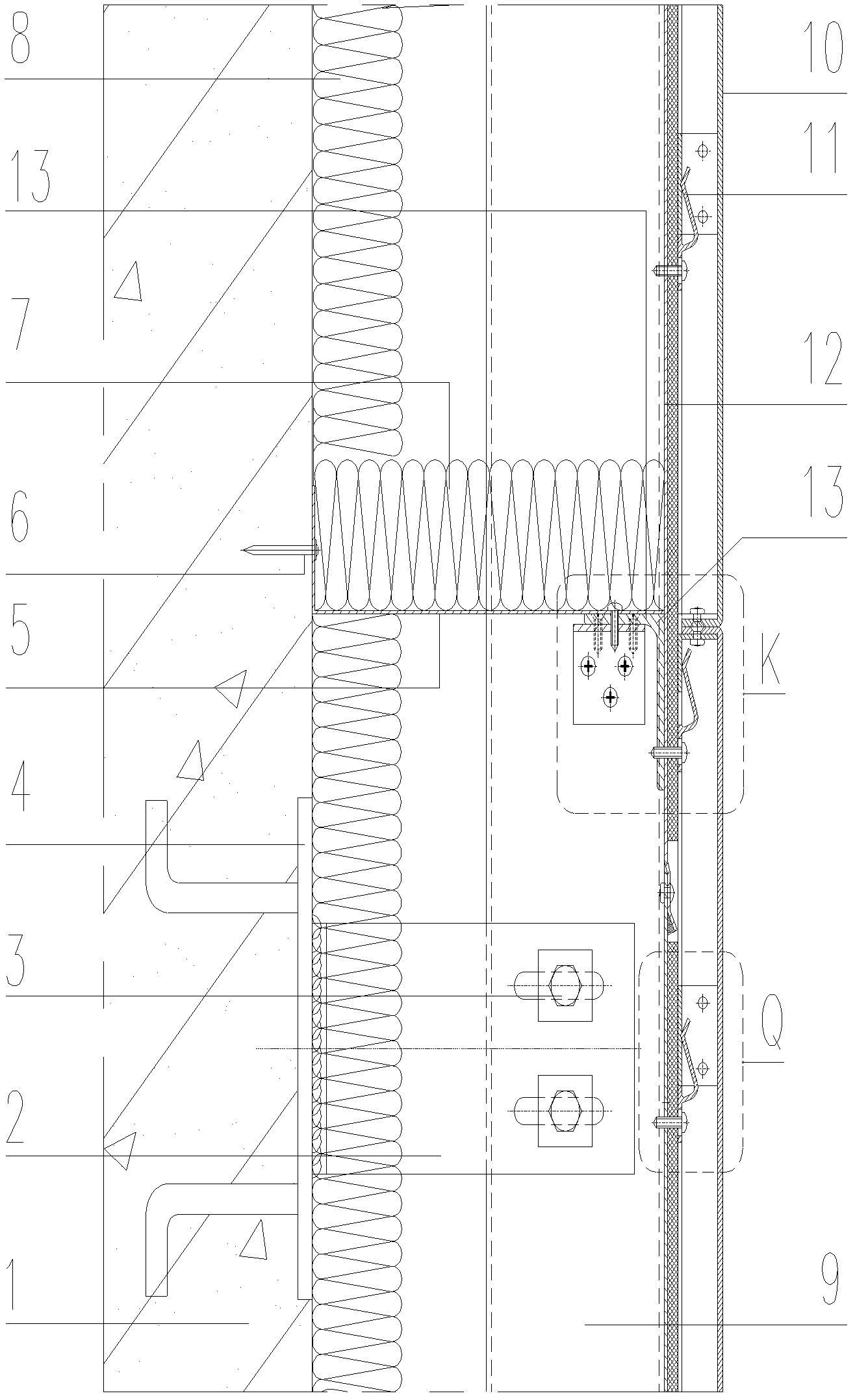

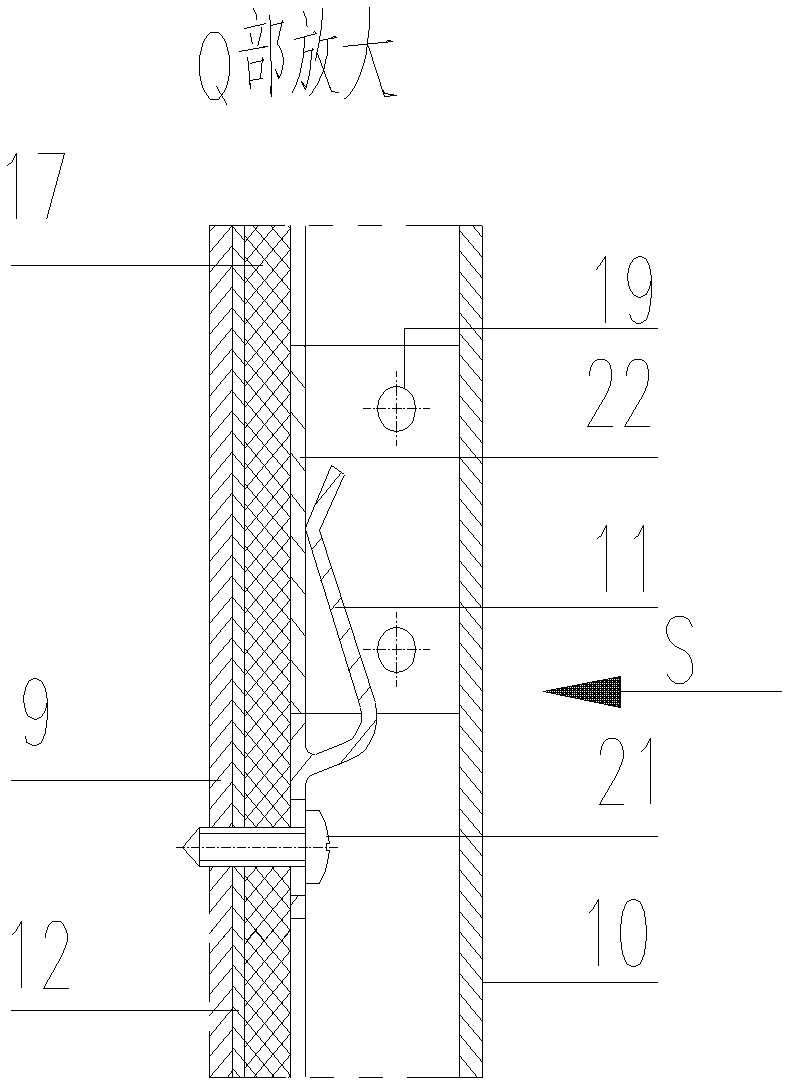

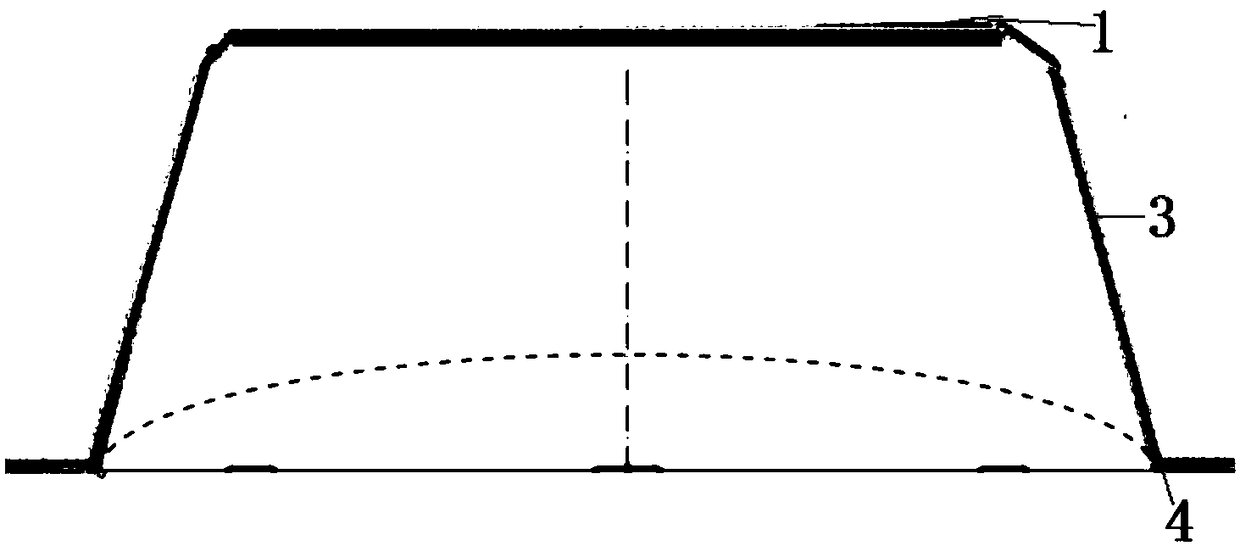

Metal-plate curtain wall structure

A metal-plate curtain wall structure comprises a vertical keel (9), a beam (13) and metal plates (10), wherein the vertical keel is fixed on a building main body (1) via an adapter (2), and the beam is fixed on the vertical keel, wherein spring clamps (11) are mounted on the vertical keel and the beam respectively; the metal plates are in shape of box covers, the peripheries comprise metal cornual plates (18, 20, 22) which are corresponded to the spring clamps, and the metal cornual plates are clamped in the spring clamps. The metal-plate curtain wall structure has advantage of convenient andfast installation; after the metal plates are positioned, the adjacent metal plates are abutted, and no gaps are retained; the curtain wall is good in sealing effect and beautiful and clean in appearance.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

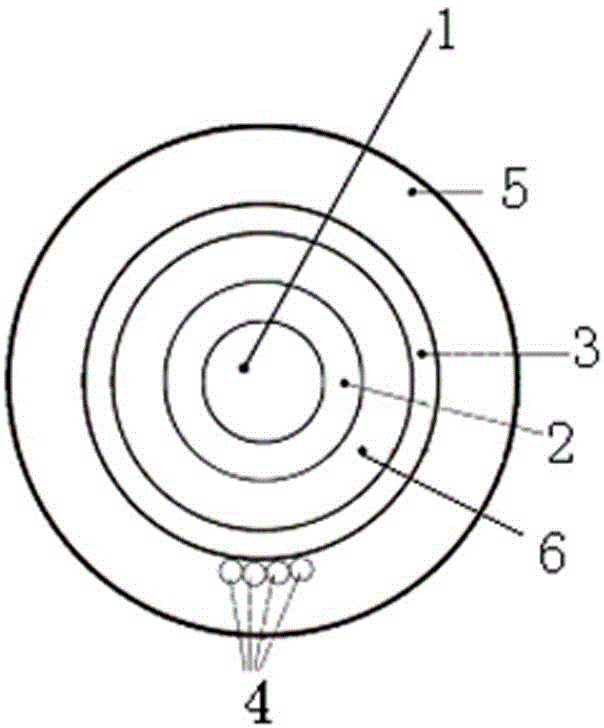

Pine wood nematode disease infected wood stump treatment device and control method thereof

PendingCN108990642AImprove the effect of prevention and controlThe pile is tightly sealedBiocideNematocidesDiseaseNematode

The invention discloses a pine wood nematode disease infected wood stump treatment device and a control method thereof. The pine wood nematode disease infected wood stump treatment device comprises achemical device located at the top of a stump, a wrapping surface covering a side surface of the stump, and a plurality of fixing foot pads disposed at the bottom end of the wrapping surface; the chemical device comprises a chemical pressing surface and a control chemical layer, wherein the chemical pressing surface is disposed on an upper surface of the control chemical layer, and the chemical pressing surface is integrally laminated with the control chemical layer; the chemical device is integrally fixed with the wrapping surface through a sealing strip; and the fixing foot pads are evenly disposed along an edge of a bottom end of the wrapping surface. The Pine wood nematode disease infected wood stump treatment device further kills and blocks the pathogens of the pine wood nematode andmedia insects, and ensures that insects cannot fly out.

Owner:南京林衡农业科技有限公司

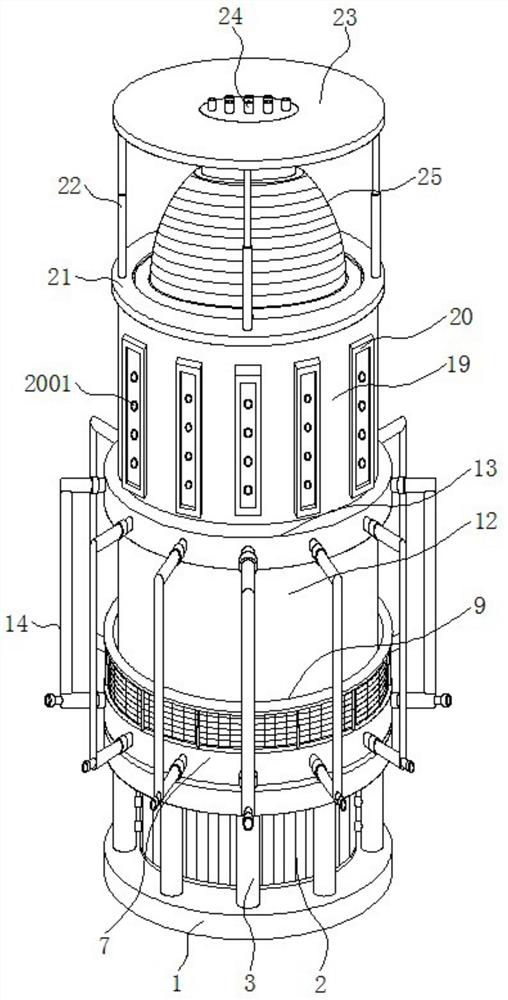

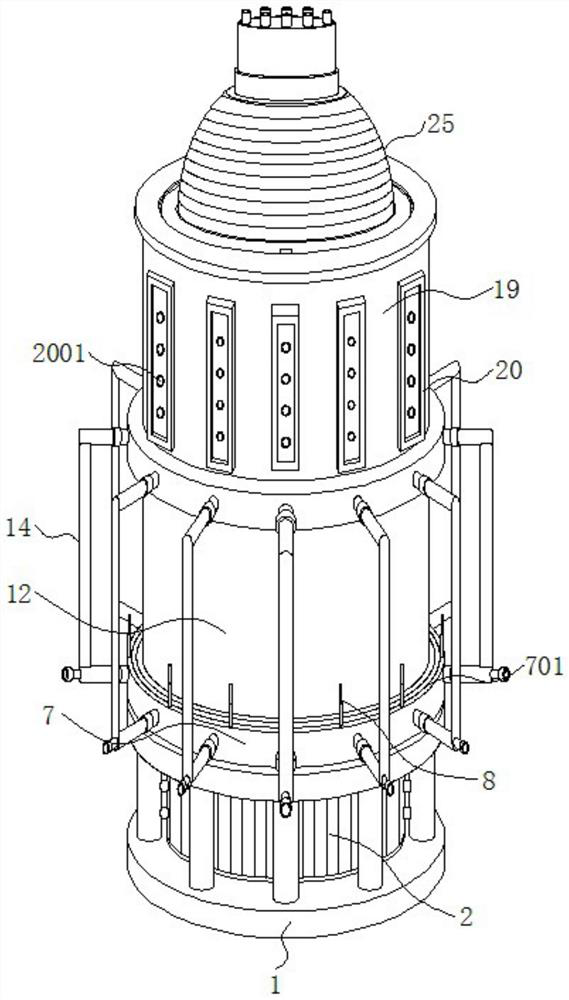

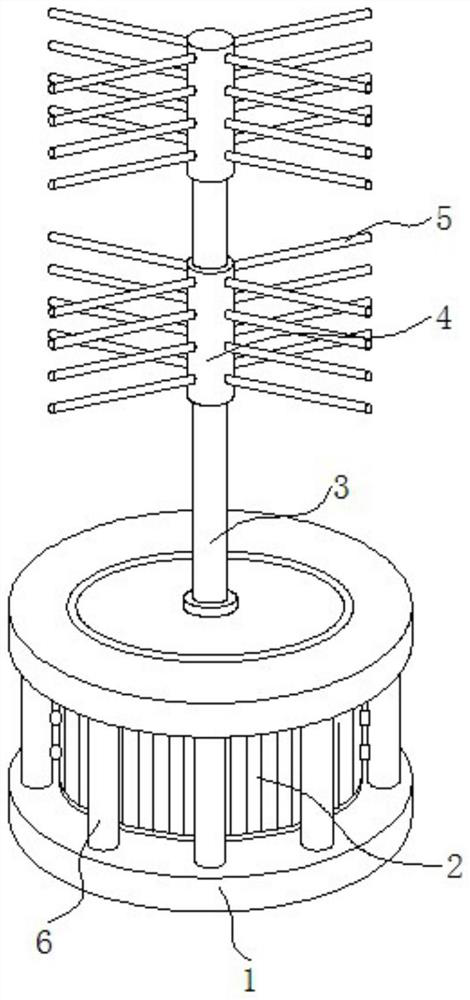

Blowing type multi-cavity alternative powder mixing machine

ActiveCN111644106AAchieving the purpose of mixingTo achieve the purpose of coolingTransportation and packagingMixer accessoriesElectric machineRotation - action

The invention discloses a blowing type multi-cavity alternative powder mixing machine and relates to the technical field of powder mixers. The machine specifically comprises a base, a mixing cylinder,air blowing mechanisms, a feeding cylinder and a pressing mechanism, wherein a motor is mounted in the middle of the interior of the base; the mixing cylinder is fixed above a supporting disc; the air blowing mechanisms are arranged on the outer side of the mixing cylinder at equal intervals in a surrounding mode; each air blowing mechanism is composed of an annular air pipe, a hollow cylinder, aconnecting pipe and a string pipe; the feeding cylinder is fixed above a connecting disc; and the pressing mechanism is arranged in the middle of the upper surface of the top plate. The invention discloses a blowing type multi-cavity alternative powder mixing machine. With a stirring sleeve driven by a rotating shaft, a stirring rod on the stirring sleeve performs mechanical rotation action, so that the purpose that the stirring rod stirs powder is achieved; refrigerant pipes are evenly arranged on the outer side of the motor and used for taking away heat generated by work of the motor, so that the purpose that the motor is cooled is achieved, the motor can obtain good heat dissipation protection, and work is more stable.

Owner:无锡诚智炼钢辅助材料有限公司

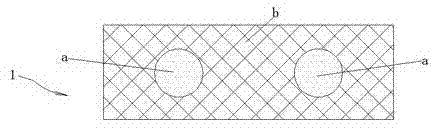

Precise positioning to form local laser pattern process

InactiveCN102285264AIngeniously solve the problem that the printing cannot be directly and accurately positionedPrecise positioningPattern printingLaser patterningPrinting ink

The invention relates to a process for forming local laser patterns by accurately positioning, which sequentially comprises the following steps of: (1) designing ideal positions and shapes for a laser patterned area and an ink printed area, and sleeving a designed ink printed area b at the periphery of a designed laser patterned area a; (2) forming a semi-finished laser patterned area C on a printing-bearing film, and enabling the laser patterned area C to cover the designed laser patterned area a and exceed the designed laser patterned area a from each direction all around; and (3) accurately printing ink on the designed ink printed area b by using an ink-printing manner to form an ink printed area B, wherein the ink fills up concave and convex grains of laser patterns on an overlapped part of the ink printed area B and the semi-finished laser patterned area C, the laser effect of the overlapped part vanishes, the semi-finished laser patterned area is shortened to a laser patterned area A and then the printing-bearing film capable of being accurately sleeved with the laser patterned area A and the ink printed area B is obtained. The process for forming the local laser patterns byaccurately positioning can enable the ink printed area to be accurately sleeved with the laser patterned area.

Owner:SHANTOU KINGSPACK TECH

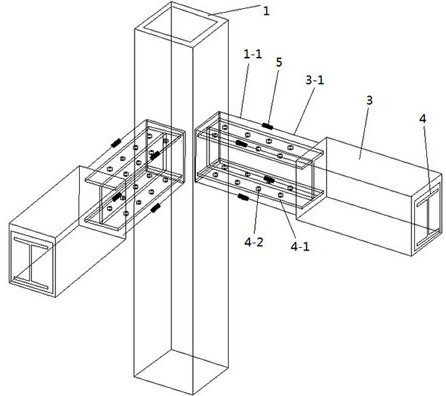

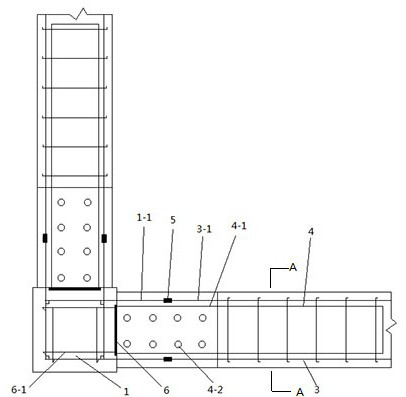

L shaped prefabricated beam column joint

InactiveCN111794377AEasy to weldFirmly connectedBuilding constructionsEarthquake resistanceArchitectural engineering

The invention belongs to the technical field of construction engineering and particularly relates to an L shaped prefabricated beam column joint which is mainly used for improving the anti-seismic property of a structure and comprises a prefabricated column and a prefabricated beam; the prefabricated column comprises a column body and a prefabricated column pouring connecting part; the prefabricated beam comprises a beam body and a prefabricated beam pouring connecting part; and the prefabricated column pouring connecting part and the prefabricated beam pouring connecting part are connected ina welding manner and are poured with concrete. Compared with the prior art, the L shaped prefabricated beam column joint is high in structural bearing capacity, large in rigidity and small in cross section, excellent in structural ductility and are more excellent in anti-seismic property. A combined structure is high in construction speed and short in construction period; before concrete pouring,profile steel forms a steel structure and has higher bearing capacity, so that a support does not need to be arranged, the construction speed is accelerated, and the construction period is shortened.

Owner:FUZHOU UNIV

Pipeline penetrating floor fireproof structure

The invention discloses a pipeline penetrating floor structure and particularly relates to a pipeline penetrating floor fireproof structure. The pipeline penetrating floor fireproof structure is composed of a sleeve pipe, foam glass, fireproof gypsum boards and sealant. A hole is reserved in a floor in advance. The sleeve pipe is embedded in the hole. The upper side and the lower side of the floor are respectively provided with the fireproof gypsum board in a laid mode. The foam glass is used for tightly sealing space among the inner diameter of the sleeve pipe, the outer diameter of a pipeline and the fireproof gypsum boards. The sealant is coated on joint portions of the fireproof gypsum boards and the pipeline. Due to adoption of the structure, a seam does not exist on the portion, where the pipeline penetrates, of the floor and fire endurance of the pipeline the same as that of the floor is achieved.

Owner:陆茹

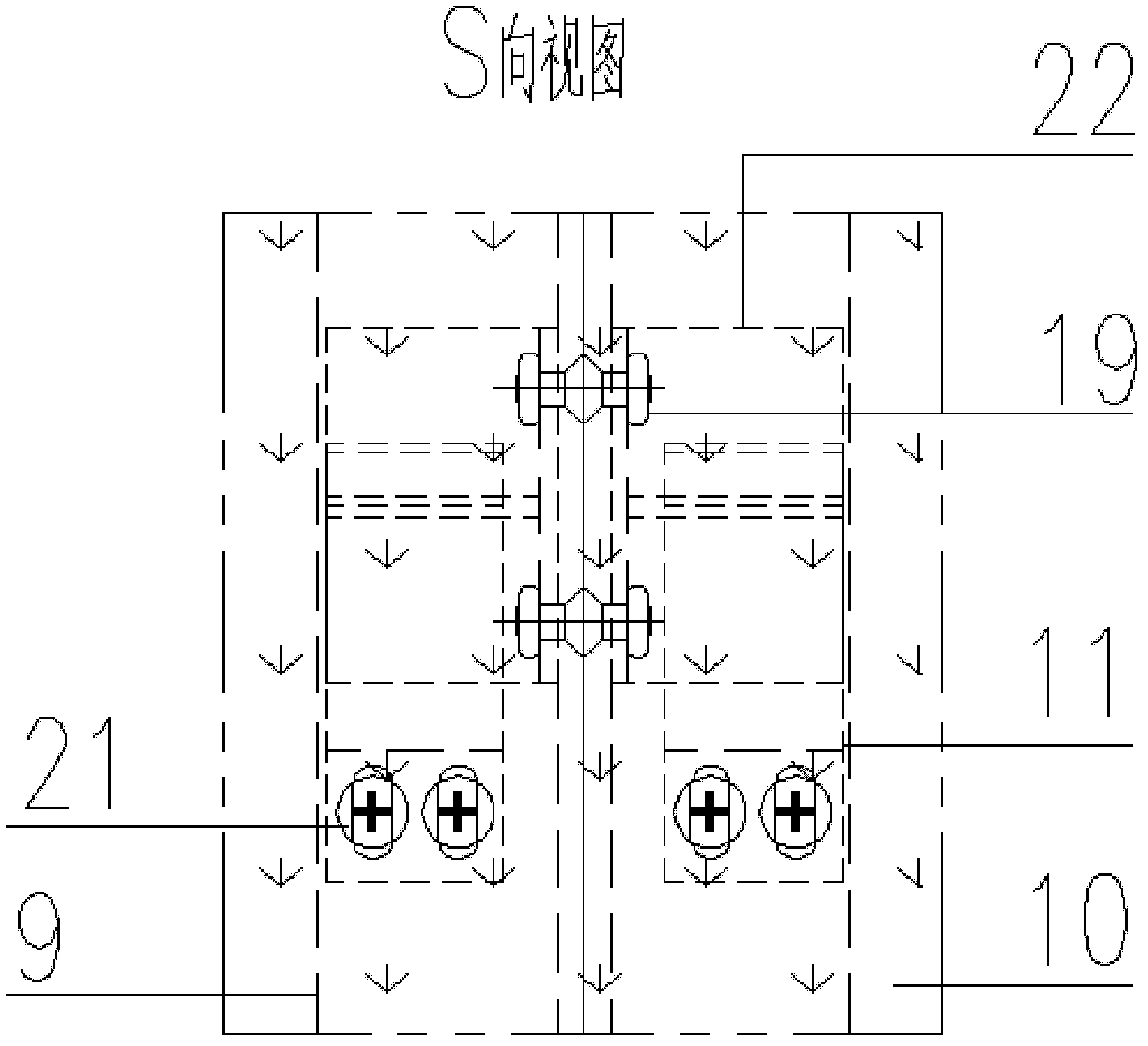

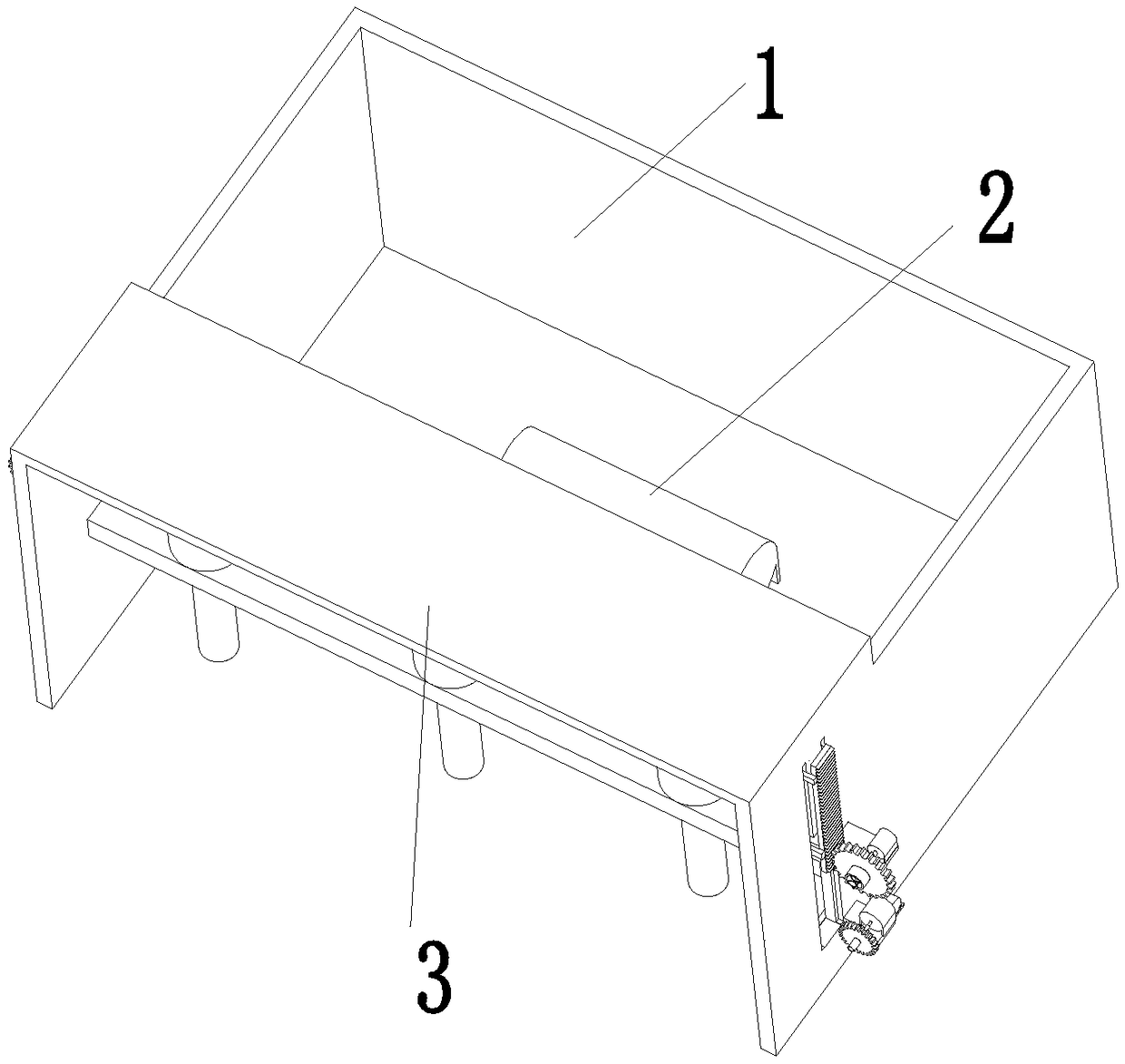

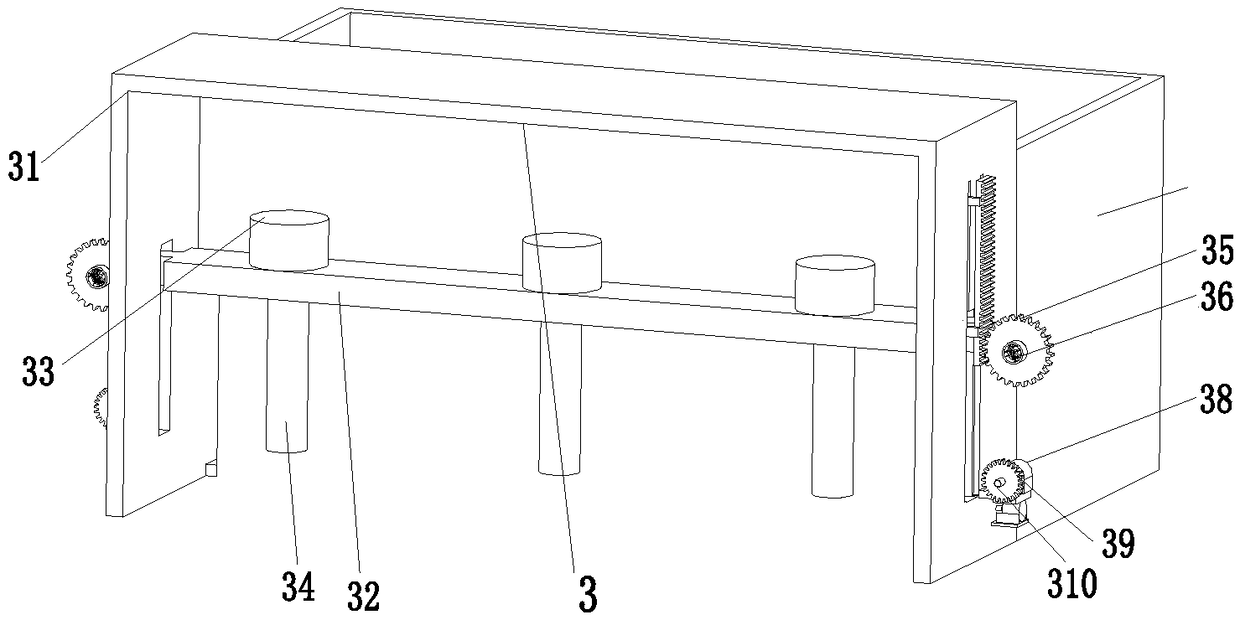

Jolt-ramming system for concrete pouring and concrete pouring jolt-ramming technology

ActiveCN108930410ARealize the function of automatic vibrationSolve efficiency problemsBuilding material handlingEngineeringStructural engineering

The invention relates to a jolt-ramming system for concrete pouring and a concrete pouring jolt-ramming technology. The jolt-ramming system comprises a jolt-ramming box, a jolt-ramming motor and a jolt-ramming device; the jolt-ramming motor is mounted inside the jolt-ramming box, the jolt-ramming device is mounted on the front end face of the jolt-ramming box, the jolt-ramming device comprises a jolt-ramming mounting frame, and through holes are formed in the left and right side faces of the jolt-ramming mounting frame; a jolt-ramming connecting plate is mounted in the through holes in a sliding fit mode, circular holes are formed in the jolt-ramming connecting plate, vibration motors are evenly mounted on the upper end face of the jolt-ramming connecting plate, vibration rods are mountedat the lower ends of the vibration motors, and the vibration rods penetrate through the circular holes; and jolt-ramming mechanisms are mounted on the right side face of the jolt-ramming connecting plate. According to the jolt-ramming system for concrete pouring and the concrete pouring jolt-ramming technology, the problems that in the concrete pouring process, the vibration rods are not vertically inserted into concrete, are inserted into the concrete excessively slowly and are pulled out of the concrete excessively quickly, the jolt-ramming effect is poor, and the working efficiency is low can be solved; and an automatic jolt-ramming function on the concrete can be achieved, and the jolt-ramming system for concrete pouring and the concrete pouring jolt-ramming technology have the advantages that the technology is simple, the jolt-ramming process conforms to the technological requirements, the jolt-ramming effect is good, and the working efficiency is high.

Owner:中国电建集团湖北工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com