Precise positioning to form local laser pattern process

A precise positioning and patterning technology, applied in the printing process, printing, printing of special varieties of printed matter, etc., can solve the problems of dazzling, unclear layers, and abruptness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

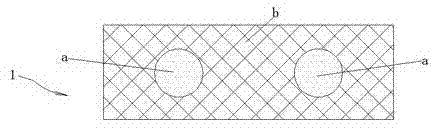

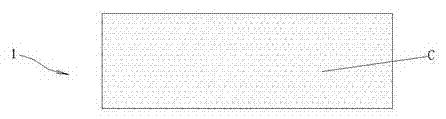

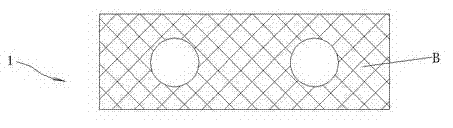

[0031]The process of precisely positioning and forming a local laser pattern includes the following steps in sequence: (1), designing the ideal position and shape of the laser pattern area and the ink printing area, and making the designed ink printing area b cover the periphery of the designed laser pattern area a , there is no gap between the design laser pattern area a and the design ink printing area b, and the two are seamlessly connected, such as figure 1 (2) Print the laser pattern on the entire printing film 1 to form a semi-finished laser pattern area C. The semi-finished laser pattern area C not only covers the designed laser pattern area a, but also exceeds the designed laser pattern area from all directions around it. a, such as figure 2 (3) Precisely print light golden yellow ink on the design ink printing area b by ink printing, thereby forming a light golden yellow ink printing area B on the printing film 1, and the golden yellow ink printing area B is as follo...

Embodiment 2

[0033] The process of precisely positioning and forming a local laser pattern includes the following steps in sequence: (1), designing the ideal position and ideal shape of the laser pattern area, and simultaneously designing the ideal position and ideal shape of the ink printing area, and making the designed ink printing area b set On the periphery of the designed laser pattern area a, there is no gap between the designed laser pattern area a and the designed ink printing area b, and the two are seamlessly connected, such as Figure 6 (2), print the laser pattern on the printing film 1 to form a "semi-finished laser pattern area C", such as Figure 7 As shown, the semi-finished laser pattern area C not only covers the design laser pattern area a, but also exceeds the design laser pattern area a from all directions around, as Figure 8 shown in Figure 8 Among them, the line 11 in the outer circle represents the edge line of the semi-finished laser pattern area C, and the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com